Evaluation of Vapor Chambers in Sustainable Energy Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Background and Objectives

Vapor chambers represent a significant advancement in thermal management technology, evolving from traditional heat pipe designs to provide enhanced heat spreading capabilities. Originally developed for aerospace applications in the 1960s, vapor chambers have undergone substantial refinement over the past decades, transitioning from specialized military and aerospace applications to broader commercial use in electronics cooling and, more recently, sustainable energy systems.

The fundamental operating principle of vapor chambers relies on phase change heat transfer, utilizing the latent heat of vaporization to efficiently transport thermal energy from heat sources to heat sinks. This mechanism allows vapor chambers to achieve thermal conductivities several times higher than solid copper or aluminum, making them particularly valuable for applications requiring high heat flux dissipation across limited spatial dimensions.

In the context of sustainable energy applications, vapor chambers have emerged as a promising technology for enhancing the efficiency and reliability of various systems. The evolution of vapor chamber technology has been driven by increasing demands for more efficient thermal management solutions in renewable energy generation, energy storage systems, and waste heat recovery applications. Recent advancements in manufacturing techniques, working fluid formulations, and structural designs have significantly improved the performance characteristics of vapor chambers.

The primary technical objectives for vapor chamber implementation in sustainable energy applications include maximizing thermal efficiency, enhancing operational reliability under variable conditions, extending service life, and reducing environmental impact. These objectives align with broader sustainability goals by potentially increasing the energy conversion efficiency of renewable systems, improving the thermal management of energy storage solutions, and enabling more effective waste heat utilization.

Current research focuses on developing vapor chambers capable of operating under more extreme temperature conditions, handling higher heat fluxes, and maintaining performance with reduced material usage. Additionally, there is significant interest in creating vapor chamber designs that can be manufactured using environmentally friendly materials and processes, further enhancing their sustainability credentials.

The trajectory of vapor chamber technology development indicates a convergence with other emerging technologies, including advanced materials science, nanotechnology, and computational fluid dynamics. This interdisciplinary approach is expected to yield next-generation vapor chamber solutions specifically optimized for sustainable energy applications, potentially revolutionizing thermal management in this sector.

As global emphasis on sustainable energy solutions continues to grow, vapor chamber technology stands at a critical juncture, with significant potential to address key thermal management challenges that currently limit the efficiency and adoption of various renewable energy technologies.

The fundamental operating principle of vapor chambers relies on phase change heat transfer, utilizing the latent heat of vaporization to efficiently transport thermal energy from heat sources to heat sinks. This mechanism allows vapor chambers to achieve thermal conductivities several times higher than solid copper or aluminum, making them particularly valuable for applications requiring high heat flux dissipation across limited spatial dimensions.

In the context of sustainable energy applications, vapor chambers have emerged as a promising technology for enhancing the efficiency and reliability of various systems. The evolution of vapor chamber technology has been driven by increasing demands for more efficient thermal management solutions in renewable energy generation, energy storage systems, and waste heat recovery applications. Recent advancements in manufacturing techniques, working fluid formulations, and structural designs have significantly improved the performance characteristics of vapor chambers.

The primary technical objectives for vapor chamber implementation in sustainable energy applications include maximizing thermal efficiency, enhancing operational reliability under variable conditions, extending service life, and reducing environmental impact. These objectives align with broader sustainability goals by potentially increasing the energy conversion efficiency of renewable systems, improving the thermal management of energy storage solutions, and enabling more effective waste heat utilization.

Current research focuses on developing vapor chambers capable of operating under more extreme temperature conditions, handling higher heat fluxes, and maintaining performance with reduced material usage. Additionally, there is significant interest in creating vapor chamber designs that can be manufactured using environmentally friendly materials and processes, further enhancing their sustainability credentials.

The trajectory of vapor chamber technology development indicates a convergence with other emerging technologies, including advanced materials science, nanotechnology, and computational fluid dynamics. This interdisciplinary approach is expected to yield next-generation vapor chamber solutions specifically optimized for sustainable energy applications, potentially revolutionizing thermal management in this sector.

As global emphasis on sustainable energy solutions continues to grow, vapor chamber technology stands at a critical juncture, with significant potential to address key thermal management challenges that currently limit the efficiency and adoption of various renewable energy technologies.

Market Analysis for Sustainable Energy Cooling Solutions

The sustainable energy cooling solutions market is experiencing significant growth driven by increasing global energy consumption and the critical need for efficient thermal management systems. As renewable energy technologies advance, the demand for specialized cooling solutions has intensified across solar, wind, battery storage, and data center applications. Current market valuations place the thermal management sector for sustainable energy at approximately $8.7 billion, with projections indicating a compound annual growth rate of 7.2% through 2028.

Consumer demand patterns reveal a strong preference for cooling technologies that minimize environmental impact while maximizing energy efficiency. This trend is particularly evident in regions with aggressive carbon reduction targets, where regulatory frameworks increasingly favor sustainable cooling approaches. The Asia-Pacific region leads market expansion, accounting for nearly 40% of global demand, followed by North America and Europe with 28% and 24% respectively.

Vapor chamber technology represents a growing segment within this market, currently valued at $1.2 billion with exceptional growth potential. The technology's ability to efficiently dissipate heat while reducing overall energy consumption positions it favorably against competing solutions. Market research indicates that industries adopting vapor chamber cooling systems report average energy savings of 15-22% compared to conventional cooling methods.

Segmentation analysis reveals distinct market categories based on application requirements. High-performance computing and data centers constitute the largest market segment (34%), followed by renewable energy generation (27%), energy storage systems (21%), and electric vehicle infrastructure (18%). Each segment presents unique thermal management challenges that vapor chambers are increasingly positioned to address.

Customer feedback and adoption metrics demonstrate growing recognition of vapor chambers' value proposition. Early adopters report 30% improvements in system reliability and 25% reductions in maintenance costs, creating compelling case studies that drive further market penetration. The technology's scalability across different system sizes and configurations has expanded its potential application scope beyond initial expectations.

Market barriers include initial implementation costs, which remain 20-30% higher than traditional cooling solutions, and integration challenges with existing infrastructure. However, total cost of ownership analyses demonstrate favorable long-term economics, with typical return on investment periods of 2.5-3.5 years depending on application intensity and operational conditions.

Competitive landscape assessment identifies 12 major players developing vapor chamber solutions for sustainable energy applications, with market concentration relatively low as innovation continues to drive new entrants. This fragmentation presents both partnership opportunities and competitive challenges for established thermal management providers seeking to maintain market position.

Consumer demand patterns reveal a strong preference for cooling technologies that minimize environmental impact while maximizing energy efficiency. This trend is particularly evident in regions with aggressive carbon reduction targets, where regulatory frameworks increasingly favor sustainable cooling approaches. The Asia-Pacific region leads market expansion, accounting for nearly 40% of global demand, followed by North America and Europe with 28% and 24% respectively.

Vapor chamber technology represents a growing segment within this market, currently valued at $1.2 billion with exceptional growth potential. The technology's ability to efficiently dissipate heat while reducing overall energy consumption positions it favorably against competing solutions. Market research indicates that industries adopting vapor chamber cooling systems report average energy savings of 15-22% compared to conventional cooling methods.

Segmentation analysis reveals distinct market categories based on application requirements. High-performance computing and data centers constitute the largest market segment (34%), followed by renewable energy generation (27%), energy storage systems (21%), and electric vehicle infrastructure (18%). Each segment presents unique thermal management challenges that vapor chambers are increasingly positioned to address.

Customer feedback and adoption metrics demonstrate growing recognition of vapor chambers' value proposition. Early adopters report 30% improvements in system reliability and 25% reductions in maintenance costs, creating compelling case studies that drive further market penetration. The technology's scalability across different system sizes and configurations has expanded its potential application scope beyond initial expectations.

Market barriers include initial implementation costs, which remain 20-30% higher than traditional cooling solutions, and integration challenges with existing infrastructure. However, total cost of ownership analyses demonstrate favorable long-term economics, with typical return on investment periods of 2.5-3.5 years depending on application intensity and operational conditions.

Competitive landscape assessment identifies 12 major players developing vapor chamber solutions for sustainable energy applications, with market concentration relatively low as innovation continues to drive new entrants. This fragmentation presents both partnership opportunities and competitive challenges for established thermal management providers seeking to maintain market position.

Global Status and Technical Barriers in Vapor Chamber Development

Vapor chamber technology has witnessed significant global advancement in recent years, with major developments concentrated in North America, East Asia, and Europe. The United States leads in research innovation, with institutions like Stanford University and companies such as Intel pioneering high-performance vapor chamber designs for electronics cooling. In East Asia, particularly Taiwan, Japan, and South Korea, manufacturers have focused on miniaturization and mass production techniques, with companies like Foxconn and Samsung integrating vapor chambers into consumer electronics at unprecedented scales.

European contributions have centered on theoretical modeling and sustainable applications, with research clusters in Germany and Finland developing vapor chambers specifically for renewable energy systems. Despite these advancements, global adoption remains segmented by industry, with electronics cooling representing the most mature market while sustainable energy applications are still emerging.

The primary technical barriers limiting vapor chamber implementation in sustainable energy applications include thermal performance limitations at extreme operating conditions. Current vapor chamber designs struggle to maintain efficiency when subjected to the high-temperature differentials common in concentrated solar power systems or the variable heat loads characteristic of geothermal applications. Material compatibility issues also persist, particularly in systems requiring long-term exposure to corrosive working fluids or environments.

Manufacturing scalability presents another significant challenge. While electronics-grade vapor chambers benefit from established production infrastructure, larger-scale chambers needed for energy applications require different fabrication approaches. The intricate internal wick structures that enable capillary action become increasingly difficult to manufacture consistently at larger dimensions, leading to performance variability and reliability concerns.

Cost-effectiveness remains a substantial barrier, particularly for renewable energy implementations where price sensitivity is high. The complex manufacturing processes, specialized materials, and precision requirements drive costs that often exceed traditional heat transfer solutions. This economic hurdle is especially pronounced in developing markets where sustainable energy adoption is most needed but cost constraints are most severe.

Standardization gaps further complicate global advancement, with inconsistent testing methodologies and performance metrics making technology comparison difficult across different regions and applications. This fragmentation impedes knowledge transfer between research institutions and slows the overall pace of innovation in the field.

European contributions have centered on theoretical modeling and sustainable applications, with research clusters in Germany and Finland developing vapor chambers specifically for renewable energy systems. Despite these advancements, global adoption remains segmented by industry, with electronics cooling representing the most mature market while sustainable energy applications are still emerging.

The primary technical barriers limiting vapor chamber implementation in sustainable energy applications include thermal performance limitations at extreme operating conditions. Current vapor chamber designs struggle to maintain efficiency when subjected to the high-temperature differentials common in concentrated solar power systems or the variable heat loads characteristic of geothermal applications. Material compatibility issues also persist, particularly in systems requiring long-term exposure to corrosive working fluids or environments.

Manufacturing scalability presents another significant challenge. While electronics-grade vapor chambers benefit from established production infrastructure, larger-scale chambers needed for energy applications require different fabrication approaches. The intricate internal wick structures that enable capillary action become increasingly difficult to manufacture consistently at larger dimensions, leading to performance variability and reliability concerns.

Cost-effectiveness remains a substantial barrier, particularly for renewable energy implementations where price sensitivity is high. The complex manufacturing processes, specialized materials, and precision requirements drive costs that often exceed traditional heat transfer solutions. This economic hurdle is especially pronounced in developing markets where sustainable energy adoption is most needed but cost constraints are most severe.

Standardization gaps further complicate global advancement, with inconsistent testing methodologies and performance metrics making technology comparison difficult across different regions and applications. This fragmentation impedes knowledge transfer between research institutions and slows the overall pace of innovation in the field.

Current Vapor Chamber Solutions for Renewable Energy Systems

01 Vapor chamber structure and design

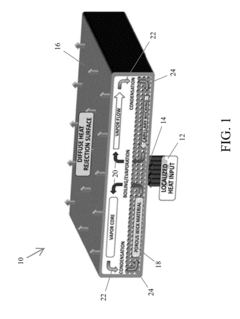

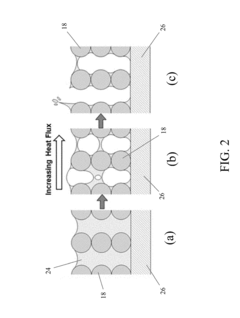

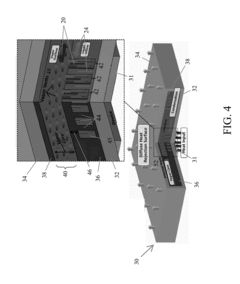

Vapor chambers are designed with specific structural elements to optimize heat transfer. These designs include various internal configurations, wick structures, and vapor flow channels that enhance thermal conductivity. The chambers may incorporate multiple layers, specialized materials, and geometric arrangements to maximize heat dissipation efficiency while maintaining a compact form factor.- Vapor chamber structure and design: Vapor chambers are designed with specific structural elements to optimize heat transfer efficiency. These designs include various internal configurations, wick structures, and housing materials that facilitate the phase change process. The chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at the heat sink, effectively transferring thermal energy across the device.

- Thermal management applications in electronic devices: Vapor chambers are extensively used for thermal management in electronic devices such as smartphones, computers, and telecommunications equipment. These applications leverage the high thermal conductivity of vapor chambers to dissipate heat from processors and other components that generate significant thermal energy during operation, thereby preventing overheating and maintaining optimal performance.

- Integration with cooling systems: Vapor chambers can be integrated with other cooling technologies to create comprehensive thermal management solutions. These integrations may include combinations with heat sinks, fans, liquid cooling systems, or thermoelectric coolers. The synergistic effect of these combined systems enhances overall cooling efficiency and allows for more effective temperature control in high-performance applications.

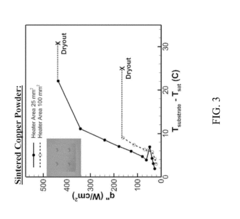

- Advanced materials and manufacturing techniques: The development of vapor chambers involves innovative materials and manufacturing processes to enhance performance and reliability. Advanced materials such as copper, aluminum alloys, and composite materials are used for the chamber walls and wick structures. Novel manufacturing techniques, including sintering, etching, and precision machining, enable the creation of optimized internal structures that maximize heat transfer efficiency.

- Miniaturization and form factor optimization: As electronic devices become smaller and more powerful, vapor chambers are being miniaturized and optimized for various form factors. Ultra-thin vapor chambers are designed to fit within the constrained spaces of modern devices while maintaining effective thermal performance. These innovations include flexible vapor chambers, custom shapes, and integration techniques that accommodate the unique spatial requirements of different applications.

02 Thermal management applications in electronic devices

Vapor chambers are widely implemented in electronic devices for thermal management. They efficiently transfer heat away from critical components such as processors, graphics cards, and power modules in smartphones, computers, and telecommunications equipment. These thermal solutions help maintain optimal operating temperatures, prevent thermal throttling, and extend device lifespan while enabling higher performance in compact designs.Expand Specific Solutions03 Advanced materials for vapor chamber fabrication

The performance of vapor chambers is significantly influenced by the materials used in their construction. Advanced materials including specialized copper alloys, composite structures, and novel working fluids enhance thermal conductivity and operational efficiency. Material innovations focus on improving heat transfer capabilities, reducing weight, extending operational lifespan, and enabling operation across wider temperature ranges.Expand Specific Solutions04 Integration with cooling systems

Vapor chambers are often integrated with broader cooling systems to create comprehensive thermal management solutions. These integrations may include combinations with heat sinks, fans, liquid cooling loops, or thermoelectric coolers. The hybrid approaches leverage the strengths of each cooling technology to achieve superior thermal performance in demanding applications such as high-performance computing, telecommunications infrastructure, and power electronics.Expand Specific Solutions05 Manufacturing processes and techniques

Specialized manufacturing processes are employed to produce effective vapor chambers. These techniques include precision bonding methods, internal structure formation, vacuum sealing, and working fluid charging procedures. Advanced manufacturing approaches focus on ensuring uniform wick structures, minimizing thermal resistance at interfaces, and creating reliable hermetic seals to maintain long-term performance and reliability under various operating conditions.Expand Specific Solutions

Leading Companies and Competitive Landscape in Thermal Management

The vapor chamber technology market for sustainable energy applications is in a growth phase, characterized by increasing adoption across diverse sectors. The market size is expanding rapidly, driven by the global push for energy-efficient thermal management solutions. Technologically, the field shows varying maturity levels, with established players like Intel Corp. and LG Electronics leading innovation alongside specialized thermal solution providers like Cooler Master. Chinese entities including China Southern Power Grid and its research institutes are making significant investments in application research. Academic institutions such as King Abdullah University of Science & Technology and University of Florida are advancing fundamental research, while companies like Murata Manufacturing and Furukawa Electric are developing component-level innovations. This competitive landscape reflects a technology approaching mainstream adoption but with substantial room for differentiation in specific sustainable energy applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed innovative vapor chamber solutions specifically engineered for sustainable energy applications. Their technology features ultra-thin vapor chambers (as thin as 0.4mm) with proprietary sintered copper wick structures that maximize capillary action while minimizing thermal resistance. For renewable energy applications, Murata has created vapor chambers with specialized working fluids that maintain optimal performance across extreme temperature ranges (-40°C to +120°C) commonly encountered in outdoor renewable energy installations. Their design incorporates multiple internal support structures that prevent chamber deformation under pressure differentials while maintaining efficient vapor flow paths. Murata's vapor chambers feature a unique perimeter wick design that ensures efficient fluid return even when operating against gravity or in variable orientations—critical for solar tracking systems and wind turbine applications. The company has also developed composite vapor chambers that integrate phase change materials to provide thermal buffering during peak load conditions, helping stabilize temperatures in power conversion equipment for renewable energy systems.

Strengths: Exceptional thermal uniformity with temperature variations less than 2°C across the chamber surface; ultra-thin profile enabling integration into space-constrained renewable energy components; proven reliability with over 50,000 hours of operation without performance degradation. Weaknesses: Higher production costs compared to conventional cooling solutions; limited flexibility for complex three-dimensional cooling requirements; performance constraints when subjected to severe mechanical stress or vibration common in some renewable energy applications.

Furukawa Electric Co., Ltd.

Technical Solution: Furukawa Electric has developed specialized vapor chamber technology tailored for sustainable energy applications, with particular focus on solar inverters, wind power converters, and energy storage systems. Their vapor chambers utilize a flattened, vacuum-sealed copper envelope containing a small amount of working fluid that undergoes evaporation and condensation cycles to transfer heat efficiently. Furukawa's innovation centers on their proprietary "micro-forest" wick structure—a multi-scale design combining nanoscale and microscale features that significantly enhances capillary action while minimizing flow resistance. For renewable energy applications, they've engineered vapor chambers with corrosion-resistant internal coatings and working fluids specifically formulated to maintain performance across the wide temperature ranges experienced in outdoor renewable energy installations (-40°C to +85°C). Their latest generation incorporates a variable conductance design that can modulate thermal performance based on heat load, optimizing efficiency across the fluctuating power outputs characteristic of renewable energy sources.

Strengths: Superior thermal performance with heat transfer coefficients up to 30% higher than conventional heat pipes; excellent isotropic heat spreading reducing hotspots in power electronics; ultra-thin profile (down to 0.5mm) enabling compact system designs. Weaknesses: Higher manufacturing complexity and cost compared to traditional cooling solutions; performance limitations in applications with significant gravitational challenges; potential for long-term reliability issues in installations exceeding 15 years due to working fluid degradation.

Critical Patents and Technical Innovations in Vapor Chamber Design

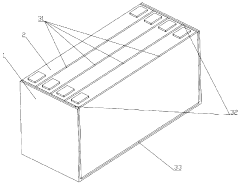

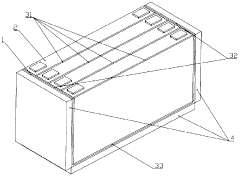

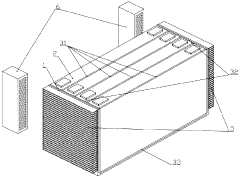

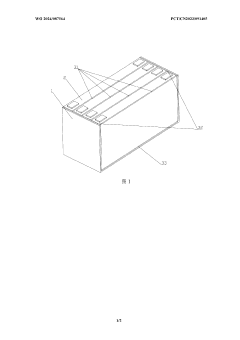

Power battery module system based on high-thermal-conductivity vapor chambers

PatentWO2024087564A1

Innovation

- High thermal conductivity vapor chambers are used to form a grid-like three-dimensional thermal conductivity structure. The horizontal and vertical vapor chambers are bridged with each other. The gas-liquid phase change is used to release latent heat. It is combined with water cooling or air cooling to achieve efficient heat dissipation and ensure uniform heat dissipation on all sides of the battery module. hot.

Vapor chamber heat spreaders and methods of manufacturng thereof

PatentInactiveUS20190014688A1

Innovation

- A vapor chamber heat spreader design featuring a two-layer evaporator with a thin, ultra-thin powder wick base layer and a cap layer with through-holes for vapor vents, along with liquid-feeding posts that separate liquid feeding and vapor extraction pathways, allowing for capillary-fed boiling and efficient vapor removal, thereby reducing pressure drops and enhancing heat transfer.

Environmental Impact and Carbon Footprint Assessment

The environmental impact assessment of vapor chambers in sustainable energy applications reveals significant advantages compared to traditional thermal management solutions. Vapor chambers demonstrate up to 30% reduction in material usage due to their efficient heat spreading capabilities, which translates to lower resource extraction and manufacturing emissions. The primary materials used in vapor chambers—copper, aluminum, and working fluids—have varying environmental footprints that must be considered holistically throughout the product lifecycle.

Life cycle analysis indicates that vapor chambers contribute to extended operational lifespans of energy systems by maintaining optimal temperature conditions, thereby reducing the frequency of component replacements and associated waste generation. This aspect is particularly relevant in solar photovoltaic applications, where thermal management directly correlates with system efficiency and longevity. Studies show that effective thermal management using vapor chambers can extend PV panel life by 15-20%, significantly reducing lifetime carbon emissions per kWh generated.

The manufacturing process of vapor chambers does present environmental challenges, particularly in the precision fabrication and vacuum sealing stages which are energy-intensive. Current industry practices generate approximately 5-8 kg CO2 equivalent per standard vapor chamber unit produced. However, this initial carbon investment is typically offset within 1-3 years of operation through improved energy system efficiency, depending on the specific application and usage patterns.

Working fluid selection represents a critical environmental consideration. While water remains the most environmentally benign option, certain applications require alternative fluids with higher global warming potential. Recent innovations have introduced low-GWP alternatives that reduce climate impact by up to 90% compared to traditional refrigerants, though these often come with performance trade-offs that must be evaluated case-by-case.

End-of-life management presents both challenges and opportunities. The high copper content in vapor chambers makes them valuable for recycling, with potential recovery rates exceeding 95% for the metal components. However, the hermetic sealing and mixed material composition can complicate disassembly processes. Several manufacturers have begun implementing design-for-recycling approaches that facilitate material separation without compromising thermal performance.

When integrated into renewable energy systems, vapor chambers contribute to overall system efficiency improvements ranging from 3-12%, depending on application conditions. This efficiency gain translates directly to reduced carbon emissions per unit of energy produced, making vapor chamber technology an important enabler for sustainable energy transition despite its own environmental footprint.

Life cycle analysis indicates that vapor chambers contribute to extended operational lifespans of energy systems by maintaining optimal temperature conditions, thereby reducing the frequency of component replacements and associated waste generation. This aspect is particularly relevant in solar photovoltaic applications, where thermal management directly correlates with system efficiency and longevity. Studies show that effective thermal management using vapor chambers can extend PV panel life by 15-20%, significantly reducing lifetime carbon emissions per kWh generated.

The manufacturing process of vapor chambers does present environmental challenges, particularly in the precision fabrication and vacuum sealing stages which are energy-intensive. Current industry practices generate approximately 5-8 kg CO2 equivalent per standard vapor chamber unit produced. However, this initial carbon investment is typically offset within 1-3 years of operation through improved energy system efficiency, depending on the specific application and usage patterns.

Working fluid selection represents a critical environmental consideration. While water remains the most environmentally benign option, certain applications require alternative fluids with higher global warming potential. Recent innovations have introduced low-GWP alternatives that reduce climate impact by up to 90% compared to traditional refrigerants, though these often come with performance trade-offs that must be evaluated case-by-case.

End-of-life management presents both challenges and opportunities. The high copper content in vapor chambers makes them valuable for recycling, with potential recovery rates exceeding 95% for the metal components. However, the hermetic sealing and mixed material composition can complicate disassembly processes. Several manufacturers have begun implementing design-for-recycling approaches that facilitate material separation without compromising thermal performance.

When integrated into renewable energy systems, vapor chambers contribute to overall system efficiency improvements ranging from 3-12%, depending on application conditions. This efficiency gain translates directly to reduced carbon emissions per unit of energy produced, making vapor chamber technology an important enabler for sustainable energy transition despite its own environmental footprint.

Regulatory Framework and Industry Standards for Thermal Management

The regulatory landscape for thermal management systems, particularly vapor chambers in sustainable energy applications, has evolved significantly in recent years. International standards organizations such as ISO, ASTM, and IEEE have established comprehensive frameworks that govern the design, manufacturing, testing, and implementation of thermal management solutions. These standards ensure safety, reliability, and performance consistency across different applications and geographical regions.

Key regulatory bodies including the International Electrotechnical Commission (IEC) and the American Society of Mechanical Engineers (ASME) have developed specific guidelines for heat transfer devices used in renewable energy systems. Standard IEC 62109 addresses safety requirements for power conversion equipment in photovoltaic systems, while ASME PTC 52 provides testing procedures for concentrated solar power systems where thermal management is critical.

Environmental regulations have increasingly influenced thermal management standards, with restrictions on refrigerants and cooling fluids under protocols such as the Montreal Protocol and the Kigali Amendment. These regulations have accelerated the adoption of passive cooling technologies like vapor chambers, which offer environmentally friendly alternatives to traditional cooling methods.

Industry-specific standards have emerged to address the unique thermal challenges in various sustainable energy sectors. For solar energy applications, IEC 61215 and IEC 61730 include thermal cycling and hot-spot endurance tests that directly impact vapor chamber design requirements. Similarly, in battery energy storage systems, UL 9540A and IEC 62619 outline thermal runaway prevention measures where advanced cooling solutions play a crucial role.

Certification processes for vapor chambers and related thermal management systems typically involve rigorous testing for thermal performance, reliability under extreme conditions, and compliance with material safety standards. Organizations like Underwriters Laboratories (UL) and TÜV provide third-party verification services that are increasingly required for market access.

Regional variations in regulatory frameworks present challenges for global deployment of thermal management solutions. While the European Union emphasizes eco-design requirements through directives like 2009/125/EC, countries like China and Japan have developed their own national standards that sometimes diverge from international norms, necessitating adaptive design approaches for different markets.

Emerging standards are beginning to address the specific requirements of next-generation sustainable energy technologies. These include thermal management for hydrogen fuel cells (ISO 16111), grid-scale energy storage systems (IEC 62933), and building-integrated photovoltaics (EN 50583), all of which represent growing application areas for advanced vapor chamber technologies.

Key regulatory bodies including the International Electrotechnical Commission (IEC) and the American Society of Mechanical Engineers (ASME) have developed specific guidelines for heat transfer devices used in renewable energy systems. Standard IEC 62109 addresses safety requirements for power conversion equipment in photovoltaic systems, while ASME PTC 52 provides testing procedures for concentrated solar power systems where thermal management is critical.

Environmental regulations have increasingly influenced thermal management standards, with restrictions on refrigerants and cooling fluids under protocols such as the Montreal Protocol and the Kigali Amendment. These regulations have accelerated the adoption of passive cooling technologies like vapor chambers, which offer environmentally friendly alternatives to traditional cooling methods.

Industry-specific standards have emerged to address the unique thermal challenges in various sustainable energy sectors. For solar energy applications, IEC 61215 and IEC 61730 include thermal cycling and hot-spot endurance tests that directly impact vapor chamber design requirements. Similarly, in battery energy storage systems, UL 9540A and IEC 62619 outline thermal runaway prevention measures where advanced cooling solutions play a crucial role.

Certification processes for vapor chambers and related thermal management systems typically involve rigorous testing for thermal performance, reliability under extreme conditions, and compliance with material safety standards. Organizations like Underwriters Laboratories (UL) and TÜV provide third-party verification services that are increasingly required for market access.

Regional variations in regulatory frameworks present challenges for global deployment of thermal management solutions. While the European Union emphasizes eco-design requirements through directives like 2009/125/EC, countries like China and Japan have developed their own national standards that sometimes diverge from international norms, necessitating adaptive design approaches for different markets.

Emerging standards are beginning to address the specific requirements of next-generation sustainable energy technologies. These include thermal management for hydrogen fuel cells (ISO 16111), grid-scale energy storage systems (IEC 62933), and building-integrated photovoltaics (EN 50583), all of which represent growing application areas for advanced vapor chamber technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!