Exploring Cellophane's Impact on Global Sustainability Goals

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

Cellophane, a transparent sheet made from regenerated cellulose, has undergone significant evolution since its invention in 1908 by Jacques E. Brandenberger. Initially developed as a protective coating for tablecloths, cellophane's potential as a versatile packaging material was quickly recognized, leading to its widespread adoption in various industries.

The early stages of cellophane production focused on improving its moisture resistance and clarity. In the 1920s, DuPont acquired the rights to produce cellophane in the United States, marking a pivotal moment in its commercialization. The company invested heavily in research and development, resulting in moisture-proof cellophane in 1927, which greatly expanded its applications in food packaging.

The 1930s and 1940s saw cellophane's popularity soar, becoming synonymous with modern packaging. Its ability to preserve food freshness while allowing visibility of the product revolutionized the retail industry. During World War II, cellophane's importance grew as it was used for military packaging and as a substitute for other materials in short supply.

Post-war, cellophane continued to evolve with advancements in production techniques and the introduction of new additives to enhance its properties. The 1950s and 1960s witnessed the development of heat-sealable cellophane, further expanding its use in the packaging industry. However, the rise of petroleum-based plastics in the 1970s began to challenge cellophane's market dominance.

In response to growing environmental concerns, the late 20th and early 21st centuries saw a renewed interest in cellophane due to its biodegradable nature. Research efforts shifted towards improving its sustainability profile, focusing on renewable sourcing of cellulose and eco-friendly production methods. Recent innovations have led to the development of bio-based cellophane alternatives, aligning with global sustainability goals.

Today, cellophane's evolution continues with a focus on enhancing its environmental credentials while maintaining its unique properties. Researchers are exploring ways to reduce the energy intensity of production processes and investigating novel applications beyond traditional packaging. The material's potential in fields such as electronics, medical devices, and advanced filtration systems is being actively explored, showcasing its ongoing relevance in the pursuit of sustainable technologies.

As global sustainability goals gain prominence, cellophane's journey exemplifies the adaptation of traditional materials to meet modern environmental challenges. Its evolution from a simple protective film to a potential contributor to circular economy initiatives highlights the importance of continuous innovation in materials science.

The early stages of cellophane production focused on improving its moisture resistance and clarity. In the 1920s, DuPont acquired the rights to produce cellophane in the United States, marking a pivotal moment in its commercialization. The company invested heavily in research and development, resulting in moisture-proof cellophane in 1927, which greatly expanded its applications in food packaging.

The 1930s and 1940s saw cellophane's popularity soar, becoming synonymous with modern packaging. Its ability to preserve food freshness while allowing visibility of the product revolutionized the retail industry. During World War II, cellophane's importance grew as it was used for military packaging and as a substitute for other materials in short supply.

Post-war, cellophane continued to evolve with advancements in production techniques and the introduction of new additives to enhance its properties. The 1950s and 1960s witnessed the development of heat-sealable cellophane, further expanding its use in the packaging industry. However, the rise of petroleum-based plastics in the 1970s began to challenge cellophane's market dominance.

In response to growing environmental concerns, the late 20th and early 21st centuries saw a renewed interest in cellophane due to its biodegradable nature. Research efforts shifted towards improving its sustainability profile, focusing on renewable sourcing of cellulose and eco-friendly production methods. Recent innovations have led to the development of bio-based cellophane alternatives, aligning with global sustainability goals.

Today, cellophane's evolution continues with a focus on enhancing its environmental credentials while maintaining its unique properties. Researchers are exploring ways to reduce the energy intensity of production processes and investigating novel applications beyond traditional packaging. The material's potential in fields such as electronics, medical devices, and advanced filtration systems is being actively explored, showcasing its ongoing relevance in the pursuit of sustainable technologies.

As global sustainability goals gain prominence, cellophane's journey exemplifies the adaptation of traditional materials to meet modern environmental challenges. Its evolution from a simple protective film to a potential contributor to circular economy initiatives highlights the importance of continuous innovation in materials science.

Sustainability Market

The sustainability market has witnessed significant growth in recent years, driven by increasing global awareness of environmental issues and the urgent need for sustainable solutions. As consumers, businesses, and governments alike prioritize eco-friendly products and practices, the demand for sustainable alternatives has surged across various industries. Cellophane, a biodegradable and compostable material, has emerged as a potential solution to address sustainability challenges in packaging and other applications.

The global sustainability market is projected to continue its upward trajectory, with estimates suggesting a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is fueled by factors such as stringent environmental regulations, consumer preferences for green products, and corporate sustainability initiatives. The packaging sector, in particular, has seen a notable shift towards sustainable materials, with biodegradable and compostable options gaining traction.

Cellophane's potential impact on the sustainability market is multifaceted. As a renewable and biodegradable material derived from plant-based sources, it aligns well with the growing demand for eco-friendly packaging solutions. The food and beverage industry, which accounts for a significant portion of packaging waste, has shown increasing interest in cellophane as an alternative to traditional plastic packaging. This shift is driven by consumer preferences for plastic-free options and regulatory pressures to reduce single-use plastics.

The personal care and cosmetics industry has also recognized the potential of cellophane in meeting sustainability goals. With consumers becoming more conscious of the environmental impact of their purchasing decisions, brands are exploring cellophane-based packaging for products such as soaps, shampoos, and cosmetics. This trend is expected to contribute to the growth of the sustainability market and create new opportunities for cellophane manufacturers.

However, challenges remain in fully realizing cellophane's potential in the sustainability market. While the material offers advantages in terms of biodegradability and renewability, concerns about its production costs and scalability persist. Additionally, the performance characteristics of cellophane compared to conventional plastics in certain applications may require further improvement to meet industry standards.

Despite these challenges, the sustainability market presents significant opportunities for cellophane. As research and development efforts continue to enhance the material's properties and production efficiency, its adoption is likely to increase across various sectors. The growing emphasis on circular economy principles and the need for sustainable packaging solutions in e-commerce and retail sectors further underscore the potential for cellophane to contribute to global sustainability goals.

In conclusion, the sustainability market's growth trajectory and the increasing demand for eco-friendly materials position cellophane as a promising solution. Its alignment with sustainability objectives and potential applications across multiple industries suggest that cellophane could play a significant role in shaping the future of sustainable packaging and contribute to broader environmental goals.

The global sustainability market is projected to continue its upward trajectory, with estimates suggesting a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is fueled by factors such as stringent environmental regulations, consumer preferences for green products, and corporate sustainability initiatives. The packaging sector, in particular, has seen a notable shift towards sustainable materials, with biodegradable and compostable options gaining traction.

Cellophane's potential impact on the sustainability market is multifaceted. As a renewable and biodegradable material derived from plant-based sources, it aligns well with the growing demand for eco-friendly packaging solutions. The food and beverage industry, which accounts for a significant portion of packaging waste, has shown increasing interest in cellophane as an alternative to traditional plastic packaging. This shift is driven by consumer preferences for plastic-free options and regulatory pressures to reduce single-use plastics.

The personal care and cosmetics industry has also recognized the potential of cellophane in meeting sustainability goals. With consumers becoming more conscious of the environmental impact of their purchasing decisions, brands are exploring cellophane-based packaging for products such as soaps, shampoos, and cosmetics. This trend is expected to contribute to the growth of the sustainability market and create new opportunities for cellophane manufacturers.

However, challenges remain in fully realizing cellophane's potential in the sustainability market. While the material offers advantages in terms of biodegradability and renewability, concerns about its production costs and scalability persist. Additionally, the performance characteristics of cellophane compared to conventional plastics in certain applications may require further improvement to meet industry standards.

Despite these challenges, the sustainability market presents significant opportunities for cellophane. As research and development efforts continue to enhance the material's properties and production efficiency, its adoption is likely to increase across various sectors. The growing emphasis on circular economy principles and the need for sustainable packaging solutions in e-commerce and retail sectors further underscore the potential for cellophane to contribute to global sustainability goals.

In conclusion, the sustainability market's growth trajectory and the increasing demand for eco-friendly materials position cellophane as a promising solution. Its alignment with sustainability objectives and potential applications across multiple industries suggest that cellophane could play a significant role in shaping the future of sustainable packaging and contribute to broader environmental goals.

Technical Challenges

Cellophane, a transparent film made from regenerated cellulose, faces several technical challenges in its journey towards contributing to global sustainability goals. One of the primary issues is the environmental impact of its production process. Traditional cellophane manufacturing involves the use of carbon disulfide, a toxic and flammable chemical that poses significant health and environmental risks. The emission of this substance during production contributes to air pollution and potential worker safety hazards.

Another challenge lies in the disposal and biodegradability of cellophane. While it is derived from natural sources, the chemical modifications during production can affect its ability to decompose naturally. This has led to concerns about cellophane's long-term environmental impact, particularly when it ends up in landfills or marine environments. The slow degradation rate can contribute to the accumulation of waste, contradicting sustainability objectives.

The energy-intensive nature of cellophane production presents an additional hurdle. The manufacturing process requires substantial amounts of energy, often derived from non-renewable sources. This high energy consumption not only increases production costs but also contributes to greenhouse gas emissions, potentially offsetting some of the material's environmental benefits.

Water usage in cellophane production is another area of concern. The process demands significant quantities of water, which can strain local water resources, especially in water-scarce regions. Moreover, the wastewater generated during production may contain chemical residues, necessitating extensive treatment before release into the environment.

The scalability of sustainable cellophane production poses a technical challenge. While there have been advancements in developing more environmentally friendly production methods, scaling these up to meet global demand without compromising on quality or increasing costs remains difficult. This includes finding sustainable alternatives to carbon disulfide and optimizing the regeneration process of cellulose.

Recycling cellophane presents its own set of technical challenges. The material's properties can change during use, making it difficult to recycle effectively. Additionally, the lack of widespread recycling infrastructure specifically designed for cellophane contributes to its disposal in general waste streams, hindering efforts to create a circular economy for this material.

Lastly, the development of bio-based alternatives that can match cellophane's performance characteristics while offering improved sustainability profiles is an ongoing challenge. While progress has been made in creating bio-plastics and other sustainable films, achieving the same level of transparency, strength, and barrier properties as cellophane while ensuring complete biodegradability remains a complex task for material scientists and engineers.

Another challenge lies in the disposal and biodegradability of cellophane. While it is derived from natural sources, the chemical modifications during production can affect its ability to decompose naturally. This has led to concerns about cellophane's long-term environmental impact, particularly when it ends up in landfills or marine environments. The slow degradation rate can contribute to the accumulation of waste, contradicting sustainability objectives.

The energy-intensive nature of cellophane production presents an additional hurdle. The manufacturing process requires substantial amounts of energy, often derived from non-renewable sources. This high energy consumption not only increases production costs but also contributes to greenhouse gas emissions, potentially offsetting some of the material's environmental benefits.

Water usage in cellophane production is another area of concern. The process demands significant quantities of water, which can strain local water resources, especially in water-scarce regions. Moreover, the wastewater generated during production may contain chemical residues, necessitating extensive treatment before release into the environment.

The scalability of sustainable cellophane production poses a technical challenge. While there have been advancements in developing more environmentally friendly production methods, scaling these up to meet global demand without compromising on quality or increasing costs remains difficult. This includes finding sustainable alternatives to carbon disulfide and optimizing the regeneration process of cellulose.

Recycling cellophane presents its own set of technical challenges. The material's properties can change during use, making it difficult to recycle effectively. Additionally, the lack of widespread recycling infrastructure specifically designed for cellophane contributes to its disposal in general waste streams, hindering efforts to create a circular economy for this material.

Lastly, the development of bio-based alternatives that can match cellophane's performance characteristics while offering improved sustainability profiles is an ongoing challenge. While progress has been made in creating bio-plastics and other sustainable films, achieving the same level of transparency, strength, and barrier properties as cellophane while ensuring complete biodegradability remains a complex task for material scientists and engineers.

Current Solutions

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly effective in food packaging, where it can help preserve freshness and extend shelf life. The material's impact on packaging includes improved product visibility, protection against moisture and gases, and potential for biodegradability.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly effective in food packaging, where it helps to preserve freshness and extend shelf life. The material's impact on packaging includes improved product visibility, protection against moisture and gases, and ease of sealing.

- Environmental impact of cellophane: The environmental impact of cellophane is a significant consideration. While traditional cellophane is derived from renewable resources, its disposal can be problematic. Research focuses on developing biodegradable alternatives and improving recycling processes to minimize the material's environmental footprint. Some innovations aim to create cellophane-like materials with enhanced eco-friendly properties.

- Cellophane in biotechnology and medical applications: Cellophane has found applications in biotechnology and medical fields. Its semi-permeable nature makes it useful for dialysis membranes and cell culture studies. The material's impact in these areas includes facilitating controlled substance exchange, supporting cell growth, and enabling certain diagnostic procedures.

- Modifications to enhance cellophane properties: Ongoing research focuses on modifying cellophane to enhance its properties. This includes improving its mechanical strength, barrier properties, and heat resistance. Techniques such as coating, lamination, and chemical modifications are employed to tailor cellophane's characteristics for specific applications, expanding its potential uses and impact across various industries.

- Cellophane in textile and fiber applications: Cellophane has made an impact in the textile and fiber industry. It can be processed into fibers or used as a component in composite materials. Applications include decorative fabrics, protective clothing, and reinforcement in composite structures. The material's transparency and strength contribute to unique aesthetic and functional properties in these applications.

02 Cellophane in biotechnology and medical applications

Cellophane membranes are utilized in various biotechnology and medical applications. They can serve as a substrate for cell culture, act as a dialysis membrane, or be used in wound dressings. The impact of cellophane in these fields includes improved cell growth, efficient separation of molecules, and enhanced wound healing processes.Expand Specific Solutions03 Cellophane in textile and fiber industry

Cellophane has a significant impact on the textile and fiber industry. It can be used to create unique fabric textures, enhance the appearance of textiles, or serve as a component in composite materials. The material's properties contribute to improved durability, water resistance, and aesthetic appeal in various textile applications.Expand Specific Solutions04 Environmental impact and biodegradability of cellophane

The environmental impact of cellophane is a subject of interest due to its potential biodegradability. As a cellulose-based material, cellophane can be more environmentally friendly compared to synthetic plastics. Research focuses on improving its biodegradation properties and assessing its overall environmental impact throughout its lifecycle.Expand Specific Solutions05 Cellophane in electronic and energy applications

Cellophane finds applications in electronic and energy-related fields. It can be used as a dielectric material in capacitors, as a separator in batteries, or as a component in flexible electronics. The impact of cellophane in these areas includes improved device performance, enhanced flexibility, and potential for sustainable energy storage solutions.Expand Specific Solutions

Industry Leaders

The global cellophane market is in a mature stage, with steady growth driven by increasing demand for sustainable packaging solutions. The market size is estimated to be in the billions of dollars, with moderate annual growth rates. Technologically, cellophane production has evolved to address environmental concerns, with companies like Futamura Chemical Co., Ltd. and Rengo Co., Ltd. leading innovations in biodegradable and compostable variants. Major players such as Braskem SA and Suzano SA are investing in bio-based alternatives, while established firms like Shell Oil Co. and ExxonMobil Technology & Engineering Co. are exploring ways to improve the material's properties and production efficiency. Research institutions like the University of Southern California and California Institute of Technology are contributing to advancements in cellophane technology, focusing on enhancing its sustainability profile and expanding its applications in various industries.

Suzano SA

Technical Solution: Suzano SA, a leading pulp and paper company, has developed Eucafluff, a fluff pulp made from eucalyptus that can be used as a raw material for cellophane production. This innovation offers a more sustainable alternative to traditional softwood fluff pulp, with a lower environmental footprint due to faster tree growth and higher yield per hectare[10]. Suzano's cellophane-related products benefit from the company's vertically integrated supply chain, ensuring traceability and sustainable forest management practices. The company has also invested in water management and energy efficiency in its production processes, further contributing to sustainability goals[11].

Strengths: Sustainable raw material sourcing, vertically integrated supply chain, lower environmental footprint. Weaknesses: Limited direct experience in cellophane film production, potential need for technology partnerships.

Braskem SA

Technical Solution: Braskem SA has developed a bio-based cellophane alternative as part of its I'm green™ portfolio. The company utilizes sugarcane ethanol to produce bio-based polyethylene, which is then processed into a thin, transparent film with properties similar to traditional cellophane[7]. Braskem's solution offers a renewable content of up to 100%, reducing carbon footprint compared to fossil-based alternatives. The material maintains high transparency, good barrier properties, and is suitable for food packaging applications[8]. Braskem has also invested in mechanical and chemical recycling technologies to support a circular economy for its products[9].

Strengths: High renewable content, reduced carbon footprint, recyclable. Weaknesses: Not biodegradable like traditional cellophane, limited compostability.

Key Innovations

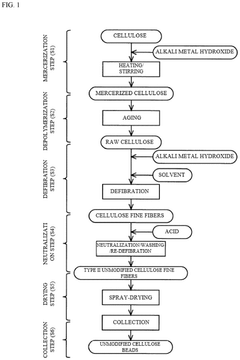

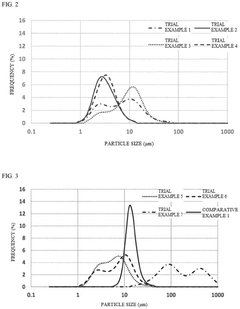

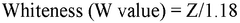

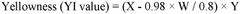

Unmodified cellulose beads and method for manufacturing same

PatentPendingEP4549471A1

Innovation

- The development of unmodified cellulose beads with specific particle size distributions and production methods that exclude chemical defibration, utilizing a mercerization, depolymerization, defibration, neutralization, and drying process to create beads suitable for cosmetics.

Cellophane laminate

PatentPendingJP2024001514A

Innovation

- A cellophane laminate with moisture-resistant layers of specific thickness and composition, made from olefin, aliphatic, or alicyclic hydrocarbon resins, applied directly to both surfaces without an anchor coat or adhesive, providing heat-sealability and moisture resistance.

Environmental Impact

Cellophane, a transparent sheet made from regenerated cellulose, has been widely used in packaging and various industrial applications for decades. However, its environmental impact has become a growing concern in the context of global sustainability goals. The production, use, and disposal of cellophane have significant implications for the environment, both positive and negative.

The manufacturing process of cellophane involves the use of chemicals and energy-intensive procedures, which can contribute to air and water pollution. The primary raw material, wood pulp, raises concerns about deforestation and habitat loss if not sourced responsibly. Additionally, the chemical treatments required to produce cellophane can result in the release of harmful substances into the environment if not properly managed.

Despite these challenges, cellophane offers some environmental advantages over certain synthetic plastics. Being derived from renewable resources, cellophane is biodegradable under specific conditions, potentially reducing long-term environmental pollution compared to petroleum-based plastics. However, the rate of biodegradation can vary significantly depending on environmental conditions, and improper disposal can still lead to accumulation in landfills or marine environments.

The use of cellophane in packaging has both positive and negative environmental impacts. On one hand, its barrier properties can help extend the shelf life of food products, potentially reducing food waste. On the other hand, the widespread use of cellophane in single-use applications contributes to the global packaging waste problem.

In terms of energy consumption and greenhouse gas emissions, the production of cellophane generally has a lower carbon footprint compared to some synthetic plastics. However, the overall lifecycle assessment of cellophane products must consider factors such as transportation, end-of-life disposal, and potential for recycling or composting.

Water usage is another critical environmental factor in cellophane production. The manufacturing process requires significant amounts of water, which can strain local water resources if not managed sustainably. Efforts to improve water recycling and treatment in cellophane production facilities are crucial for minimizing this impact.

As global sustainability goals increasingly focus on circular economy principles, the role of cellophane in achieving these objectives is under scrutiny. While its biodegradability offers potential advantages, the current lack of widespread industrial composting facilities limits the realization of these benefits. Furthermore, the mixing of cellophane with other materials in consumer products can complicate recycling efforts.

The manufacturing process of cellophane involves the use of chemicals and energy-intensive procedures, which can contribute to air and water pollution. The primary raw material, wood pulp, raises concerns about deforestation and habitat loss if not sourced responsibly. Additionally, the chemical treatments required to produce cellophane can result in the release of harmful substances into the environment if not properly managed.

Despite these challenges, cellophane offers some environmental advantages over certain synthetic plastics. Being derived from renewable resources, cellophane is biodegradable under specific conditions, potentially reducing long-term environmental pollution compared to petroleum-based plastics. However, the rate of biodegradation can vary significantly depending on environmental conditions, and improper disposal can still lead to accumulation in landfills or marine environments.

The use of cellophane in packaging has both positive and negative environmental impacts. On one hand, its barrier properties can help extend the shelf life of food products, potentially reducing food waste. On the other hand, the widespread use of cellophane in single-use applications contributes to the global packaging waste problem.

In terms of energy consumption and greenhouse gas emissions, the production of cellophane generally has a lower carbon footprint compared to some synthetic plastics. However, the overall lifecycle assessment of cellophane products must consider factors such as transportation, end-of-life disposal, and potential for recycling or composting.

Water usage is another critical environmental factor in cellophane production. The manufacturing process requires significant amounts of water, which can strain local water resources if not managed sustainably. Efforts to improve water recycling and treatment in cellophane production facilities are crucial for minimizing this impact.

As global sustainability goals increasingly focus on circular economy principles, the role of cellophane in achieving these objectives is under scrutiny. While its biodegradability offers potential advantages, the current lack of widespread industrial composting facilities limits the realization of these benefits. Furthermore, the mixing of cellophane with other materials in consumer products can complicate recycling efforts.

Regulatory Framework

The regulatory framework surrounding cellophane and its impact on global sustainability goals is complex and multifaceted. As governments and international organizations increasingly prioritize environmental protection and sustainable development, the production, use, and disposal of cellophane have come under scrutiny.

At the international level, the United Nations Sustainable Development Goals (SDGs) provide a broad framework for addressing global challenges, including those related to sustainable consumption and production patterns. Goal 12, in particular, focuses on ensuring sustainable consumption and production patterns, which directly impacts the cellophane industry.

Many countries have implemented regulations to address the environmental impact of plastic products, including cellophane. The European Union, for instance, has introduced the Single-Use Plastics Directive, which aims to reduce the environmental impact of certain plastic products. While cellophane is not explicitly mentioned in the directive, it falls under the broader category of plastic packaging materials.

In the United States, the Food and Drug Administration (FDA) regulates cellophane as a food contact substance. The FDA has established specific guidelines for the use of cellophane in food packaging, ensuring its safety for consumers. Additionally, various state-level regulations address the disposal and recycling of plastic materials, which may include cellophane.

Developing countries are also implementing regulations to address plastic pollution. For example, India has introduced a ban on single-use plastics, which could potentially impact the use of cellophane in certain applications.

The regulatory landscape is continuously evolving, with an increasing focus on circular economy principles. This shift is driving the development of regulations that promote the reuse, recycling, and biodegradability of packaging materials, including cellophane.

Industry self-regulation also plays a role in shaping the regulatory framework. Many companies in the packaging industry have voluntarily adopted sustainability commitments, which often include targets for reducing plastic waste and increasing the use of recyclable or biodegradable materials.

As the global community continues to grapple with sustainability challenges, it is likely that the regulatory framework surrounding cellophane will become more stringent. Future regulations may focus on promoting the development of more sustainable alternatives, improving recycling infrastructure, and implementing extended producer responsibility schemes.

The impact of these regulations on the cellophane industry is significant. Manufacturers are increasingly required to invest in research and development to improve the sustainability profile of their products. This includes exploring bio-based alternatives, enhancing recyclability, and reducing the overall environmental footprint of cellophane production.

At the international level, the United Nations Sustainable Development Goals (SDGs) provide a broad framework for addressing global challenges, including those related to sustainable consumption and production patterns. Goal 12, in particular, focuses on ensuring sustainable consumption and production patterns, which directly impacts the cellophane industry.

Many countries have implemented regulations to address the environmental impact of plastic products, including cellophane. The European Union, for instance, has introduced the Single-Use Plastics Directive, which aims to reduce the environmental impact of certain plastic products. While cellophane is not explicitly mentioned in the directive, it falls under the broader category of plastic packaging materials.

In the United States, the Food and Drug Administration (FDA) regulates cellophane as a food contact substance. The FDA has established specific guidelines for the use of cellophane in food packaging, ensuring its safety for consumers. Additionally, various state-level regulations address the disposal and recycling of plastic materials, which may include cellophane.

Developing countries are also implementing regulations to address plastic pollution. For example, India has introduced a ban on single-use plastics, which could potentially impact the use of cellophane in certain applications.

The regulatory landscape is continuously evolving, with an increasing focus on circular economy principles. This shift is driving the development of regulations that promote the reuse, recycling, and biodegradability of packaging materials, including cellophane.

Industry self-regulation also plays a role in shaping the regulatory framework. Many companies in the packaging industry have voluntarily adopted sustainability commitments, which often include targets for reducing plastic waste and increasing the use of recyclable or biodegradable materials.

As the global community continues to grapple with sustainability challenges, it is likely that the regulatory framework surrounding cellophane will become more stringent. Future regulations may focus on promoting the development of more sustainable alternatives, improving recycling infrastructure, and implementing extended producer responsibility schemes.

The impact of these regulations on the cellophane industry is significant. Manufacturers are increasingly required to invest in research and development to improve the sustainability profile of their products. This includes exploring bio-based alternatives, enhancing recyclability, and reducing the overall environmental footprint of cellophane production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!