Exploring Thermal Stability in Conductive Polymer Composites

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stability Challenges in Conductive Polymers

Conductive polymer composites (CPCs) face significant thermal stability challenges that limit their widespread application in high-temperature environments. The primary issue stems from the inherent thermal degradation mechanisms of polymeric materials, which typically begin at temperatures between 150-300°C depending on the polymer matrix. This degradation manifests as chain scission, cross-linking, or oxidation processes that fundamentally alter the material's electrical conductivity properties.

The conductive fillers incorporated into these composites, such as carbon nanotubes, graphene, or metallic nanoparticles, often exhibit different thermal expansion coefficients compared to the polymer matrix. During thermal cycling, this mismatch creates internal stresses that can disrupt the conductive network, leading to performance deterioration even before chemical degradation occurs. Research indicates that after repeated thermal cycling between -40°C and 125°C, some CPCs can lose up to 40% of their initial conductivity.

Interface stability between the conductive fillers and polymer matrix represents another critical challenge. At elevated temperatures, the weakening of interfacial bonds can cause filler agglomeration or migration, disrupting the carefully engineered percolation networks essential for conductivity. Studies have shown that even minor changes in filler distribution can exponentially impact electrical performance, with a 5% shift in distribution potentially causing a 50-70% reduction in conductivity.

Oxidative environments further exacerbate thermal stability issues. When exposed to oxygen at elevated temperatures, many conductive polymers undergo accelerated degradation through free radical mechanisms. This is particularly problematic for applications in automotive, aerospace, and industrial settings where components may be simultaneously exposed to high temperatures and oxidizing conditions.

The processing history of CPCs significantly influences their thermal stability profile. Manufacturing techniques involving high shear forces or extended exposure to elevated temperatures can introduce initial degradation that compromises long-term thermal stability. Research has demonstrated that seemingly identical composites produced through different processing routes can exhibit up to 30% variation in thermal degradation onset temperatures.

Recent investigations have revealed complex synergistic effects between different degradation mechanisms. For instance, moisture absorption at elevated temperatures can catalyze hydrolysis reactions while simultaneously affecting the electrical percolation network through dimensional changes. These multi-factor degradation pathways make prediction and mitigation strategies particularly challenging for material scientists and engineers working with CPCs.

The conductive fillers incorporated into these composites, such as carbon nanotubes, graphene, or metallic nanoparticles, often exhibit different thermal expansion coefficients compared to the polymer matrix. During thermal cycling, this mismatch creates internal stresses that can disrupt the conductive network, leading to performance deterioration even before chemical degradation occurs. Research indicates that after repeated thermal cycling between -40°C and 125°C, some CPCs can lose up to 40% of their initial conductivity.

Interface stability between the conductive fillers and polymer matrix represents another critical challenge. At elevated temperatures, the weakening of interfacial bonds can cause filler agglomeration or migration, disrupting the carefully engineered percolation networks essential for conductivity. Studies have shown that even minor changes in filler distribution can exponentially impact electrical performance, with a 5% shift in distribution potentially causing a 50-70% reduction in conductivity.

Oxidative environments further exacerbate thermal stability issues. When exposed to oxygen at elevated temperatures, many conductive polymers undergo accelerated degradation through free radical mechanisms. This is particularly problematic for applications in automotive, aerospace, and industrial settings where components may be simultaneously exposed to high temperatures and oxidizing conditions.

The processing history of CPCs significantly influences their thermal stability profile. Manufacturing techniques involving high shear forces or extended exposure to elevated temperatures can introduce initial degradation that compromises long-term thermal stability. Research has demonstrated that seemingly identical composites produced through different processing routes can exhibit up to 30% variation in thermal degradation onset temperatures.

Recent investigations have revealed complex synergistic effects between different degradation mechanisms. For instance, moisture absorption at elevated temperatures can catalyze hydrolysis reactions while simultaneously affecting the electrical percolation network through dimensional changes. These multi-factor degradation pathways make prediction and mitigation strategies particularly challenging for material scientists and engineers working with CPCs.

Market Applications and Demand Analysis

The market for conductive polymer composites with enhanced thermal stability is experiencing significant growth across multiple industries. The global conductive polymer market was valued at approximately 3.9 billion USD in 2022 and is projected to reach 7.2 billion USD by 2030, with a compound annual growth rate of 8.2%. Within this broader market, thermally stable conductive polymers represent a rapidly expanding segment due to their unique combination of electrical conductivity and heat resistance properties.

Electronics manufacturing constitutes the largest application sector, accounting for roughly 35% of the market share. The miniaturization trend in consumer electronics has intensified thermal management challenges, creating strong demand for materials that can maintain conductivity under elevated operating temperatures. Smartphone manufacturers particularly seek composites that can withstand temperatures up to 150°C without performance degradation.

Automotive electrification represents another major growth driver, with electric vehicle production increasing by 40% year-over-year in 2022. Battery thermal management systems require conductive polymers that maintain stability across wide temperature ranges (-40°C to 125°C). The transition to 800V architecture in premium electric vehicles further amplifies the need for thermally robust conductive materials for power electronics and charging infrastructure.

Aerospace and defense applications demand the highest performance specifications, with requirements for materials that can withstand extreme temperature cycling while maintaining consistent electrical properties. Though smaller in volume, this sector offers premium pricing opportunities, with specialized thermally stable composites commanding 3-5 times the price of standard variants.

Renewable energy systems, particularly solar panel manufacturing and energy storage solutions, represent an emerging application area with projected annual growth exceeding 12%. These applications require conductive polymers that can withstand outdoor exposure and temperature fluctuations while maintaining long-term performance stability.

Regional analysis reveals Asia-Pacific as the dominant market (42% share), driven by electronics manufacturing hubs in China, South Korea, and Taiwan. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in automotive and aerospace applications.

Customer requirements are increasingly focused on sustainability alongside performance metrics. End-users are willing to pay premium prices (15-20% higher) for thermally stable conductive polymers that also offer reduced environmental impact through recyclability or bio-based content. This trend is particularly pronounced in European markets where regulatory pressures regarding end-of-life product management are most stringent.

Electronics manufacturing constitutes the largest application sector, accounting for roughly 35% of the market share. The miniaturization trend in consumer electronics has intensified thermal management challenges, creating strong demand for materials that can maintain conductivity under elevated operating temperatures. Smartphone manufacturers particularly seek composites that can withstand temperatures up to 150°C without performance degradation.

Automotive electrification represents another major growth driver, with electric vehicle production increasing by 40% year-over-year in 2022. Battery thermal management systems require conductive polymers that maintain stability across wide temperature ranges (-40°C to 125°C). The transition to 800V architecture in premium electric vehicles further amplifies the need for thermally robust conductive materials for power electronics and charging infrastructure.

Aerospace and defense applications demand the highest performance specifications, with requirements for materials that can withstand extreme temperature cycling while maintaining consistent electrical properties. Though smaller in volume, this sector offers premium pricing opportunities, with specialized thermally stable composites commanding 3-5 times the price of standard variants.

Renewable energy systems, particularly solar panel manufacturing and energy storage solutions, represent an emerging application area with projected annual growth exceeding 12%. These applications require conductive polymers that can withstand outdoor exposure and temperature fluctuations while maintaining long-term performance stability.

Regional analysis reveals Asia-Pacific as the dominant market (42% share), driven by electronics manufacturing hubs in China, South Korea, and Taiwan. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in automotive and aerospace applications.

Customer requirements are increasingly focused on sustainability alongside performance metrics. End-users are willing to pay premium prices (15-20% higher) for thermally stable conductive polymers that also offer reduced environmental impact through recyclability or bio-based content. This trend is particularly pronounced in European markets where regulatory pressures regarding end-of-life product management are most stringent.

Current Technical Limitations and Global Research Status

Despite significant advancements in conductive polymer composites (CPCs), thermal stability remains a critical challenge limiting their widespread industrial application. Current CPCs typically experience performance degradation at temperatures above 150°C, with conductivity often decreasing dramatically or irreversibly changing after thermal cycling. This limitation severely restricts their use in automotive, aerospace, and electronics applications where operating temperatures frequently exceed this threshold.

The primary technical limitation stems from the inherent thermal expansion mismatch between polymer matrices and conductive fillers. When exposed to elevated temperatures, polymers expand at rates significantly higher than metallic or carbon-based fillers, disrupting the conductive network and increasing electrical resistivity. Additionally, prolonged exposure to high temperatures accelerates polymer degradation through oxidation, chain scission, and cross-linking reactions, further compromising the composite's electrical properties.

Research efforts addressing thermal stability are distributed globally, with distinct regional focuses. North American institutions primarily concentrate on carbon nanotube and graphene-based composites with specialized polymer matrices, while European research centers emphasize environmentally sustainable solutions and standardization of testing protocols. Asian research, particularly in China, Japan, and South Korea, leads in high-volume manufacturing techniques and novel hybrid filler systems.

Recent innovations from MIT and the University of Tokyo have demonstrated promising approaches using covalently bonded networks between fillers and matrices, achieving stability up to 220°C. However, these solutions typically involve complex synthesis procedures that present scalability challenges for mass production.

Another significant limitation is the trade-off between thermal stability and other desirable properties. Enhancing thermal resistance often requires additives or processing techniques that negatively impact flexibility, transparency, or processability. For instance, flame retardants commonly used to improve thermal properties frequently reduce electrical conductivity by interfering with conductive pathways.

The reproducibility of thermally stable CPCs presents another major challenge. Current manufacturing processes show significant batch-to-batch variations in thermal performance, with reported standard deviations in thermal degradation temperatures ranging from 15-30°C across different studies. This inconsistency hampers industrial adoption where precise performance specifications are required.

Global research status indicates a growing trend toward multifunctional CPCs that maintain conductivity while offering self-healing capabilities after thermal damage. Research groups at Stanford University and Tsinghua University have independently developed reversible bond systems that can restore up to 85% of original conductivity after thermal cycling, though these systems currently work only within limited temperature ranges.

The primary technical limitation stems from the inherent thermal expansion mismatch between polymer matrices and conductive fillers. When exposed to elevated temperatures, polymers expand at rates significantly higher than metallic or carbon-based fillers, disrupting the conductive network and increasing electrical resistivity. Additionally, prolonged exposure to high temperatures accelerates polymer degradation through oxidation, chain scission, and cross-linking reactions, further compromising the composite's electrical properties.

Research efforts addressing thermal stability are distributed globally, with distinct regional focuses. North American institutions primarily concentrate on carbon nanotube and graphene-based composites with specialized polymer matrices, while European research centers emphasize environmentally sustainable solutions and standardization of testing protocols. Asian research, particularly in China, Japan, and South Korea, leads in high-volume manufacturing techniques and novel hybrid filler systems.

Recent innovations from MIT and the University of Tokyo have demonstrated promising approaches using covalently bonded networks between fillers and matrices, achieving stability up to 220°C. However, these solutions typically involve complex synthesis procedures that present scalability challenges for mass production.

Another significant limitation is the trade-off between thermal stability and other desirable properties. Enhancing thermal resistance often requires additives or processing techniques that negatively impact flexibility, transparency, or processability. For instance, flame retardants commonly used to improve thermal properties frequently reduce electrical conductivity by interfering with conductive pathways.

The reproducibility of thermally stable CPCs presents another major challenge. Current manufacturing processes show significant batch-to-batch variations in thermal performance, with reported standard deviations in thermal degradation temperatures ranging from 15-30°C across different studies. This inconsistency hampers industrial adoption where precise performance specifications are required.

Global research status indicates a growing trend toward multifunctional CPCs that maintain conductivity while offering self-healing capabilities after thermal damage. Research groups at Stanford University and Tsinghua University have independently developed reversible bond systems that can restore up to 85% of original conductivity after thermal cycling, though these systems currently work only within limited temperature ranges.

Existing Thermal Stabilization Methods

01 Incorporation of inorganic fillers for thermal stability

Inorganic fillers such as metal oxides, ceramics, and carbon-based materials can be incorporated into conductive polymer composites to enhance their thermal stability. These fillers act as heat dissipators and structural reinforcements, allowing the composite to maintain its electrical conductivity at elevated temperatures. The addition of these materials can increase the decomposition temperature and reduce thermal expansion, resulting in more stable conductive polymer composites for high-temperature applications.- Incorporation of thermally stable additives: Various additives can be incorporated into conductive polymer composites to enhance their thermal stability. These additives include flame retardants, heat stabilizers, and antioxidants that prevent degradation at high temperatures. The addition of these compounds helps maintain the electrical conductivity and mechanical properties of the polymer composites even when exposed to elevated temperatures for extended periods, making them suitable for high-temperature applications.

- Nanoparticle reinforcement for thermal stability: Incorporating nanoparticles such as carbon nanotubes, graphene, metal oxides, and ceramic nanoparticles into polymer matrices significantly improves the thermal stability of conductive polymer composites. These nanofillers create a network structure that not only enhances electrical conductivity but also provides thermal resistance. The high surface area and strong interfacial interactions between nanoparticles and polymer matrices lead to improved heat dissipation and reduced thermal degradation.

- Cross-linking and copolymerization techniques: Cross-linking and copolymerization techniques are effective methods to enhance the thermal stability of conductive polymer composites. By forming chemical bonds between polymer chains or introducing thermally stable comonomers, these techniques create a more rigid molecular structure that resists thermal degradation. The resulting three-dimensional network structure maintains its integrity and electrical properties at elevated temperatures, extending the operating temperature range of the composite materials.

- Surface modification of conductive fillers: Surface modification of conductive fillers improves their compatibility with polymer matrices and enhances the thermal stability of the resulting composites. Functionalization techniques such as oxidation, silanization, or polymer grafting create stronger interfacial bonding between fillers and matrices. This improved interaction prevents agglomeration of conductive particles and creates a more homogeneous composite structure with enhanced thermal resistance and consistent electrical conductivity across a wide temperature range.

- Multi-component composite systems: Multi-component composite systems combine different types of conductive materials and polymers to achieve superior thermal stability. These hybrid systems often incorporate a combination of organic and inorganic components, each contributing specific properties to the final composite. By carefully selecting compatible components with complementary thermal properties, these systems can maintain electrical conductivity while withstanding thermal cycling, thermal shock, and prolonged exposure to high temperatures without significant degradation.

02 Cross-linking and copolymerization techniques

Cross-linking and copolymerization techniques can significantly improve the thermal stability of conductive polymer composites. By forming covalent bonds between polymer chains or introducing thermally stable comonomers, these methods create more rigid structures that resist deformation and degradation at high temperatures. These techniques can be applied during synthesis or post-processing to enhance the temperature resistance while maintaining the desired electrical conductivity properties.Expand Specific Solutions03 Nanostructured conductive additives

Incorporating nanostructured conductive additives such as carbon nanotubes, graphene, and metal nanowires can enhance both the electrical conductivity and thermal stability of polymer composites. These nanomaterials create efficient conductive networks within the polymer matrix while also improving heat dissipation. Their high aspect ratio and surface area allow for better interfacial interactions with the polymer, resulting in composites that maintain conductivity even after exposure to thermal stress.Expand Specific Solutions04 Thermal stabilizers and antioxidants

The addition of thermal stabilizers and antioxidants can prevent degradation of conductive polymer composites at elevated temperatures. These additives work by neutralizing free radicals, inhibiting oxidation processes, and preventing chain scission reactions that typically occur during thermal aging. By incorporating these specialized compounds, the service life of conductive polymer composites can be significantly extended, particularly in applications involving continuous exposure to high temperatures.Expand Specific Solutions05 Processing techniques for enhanced thermal properties

Advanced processing techniques such as melt blending, solution casting, and in-situ polymerization can be optimized to enhance the thermal stability of conductive polymer composites. These methods focus on achieving better dispersion of conductive fillers, reducing thermal interface resistance, and creating more homogeneous structures. Controlled cooling rates and post-processing treatments like annealing can further improve crystallinity and reduce defects, resulting in composites with superior thermal resistance while maintaining electrical conductivity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal stability of conductive polymer composites market is in a growth phase, with increasing demand driven by electronics, automotive, and aerospace applications. The market is projected to expand significantly due to advancements in material science and growing need for lightweight, durable components. Leading players like DuPont, SABIC, and Covestro are investing heavily in R&D to overcome thermal degradation challenges. Academic institutions such as Sichuan University and Arizona State University collaborate with industry leaders including Texas Instruments and Boeing to enhance thermal stability while maintaining conductivity. The technology is approaching maturity with recent innovations focusing on nano-additives and hybrid composites to achieve optimal thermal-electrical performance balance.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced conductive polymer composites with enhanced thermal stability through their proprietary Zytel® and Rynite® thermoplastic resins. Their technology incorporates specialized heat-resistant polymer matrices combined with uniformly dispersed conductive fillers such as carbon nanotubes and metallic particles. The company employs a multi-phase approach where the primary polymer provides mechanical integrity while secondary phases contribute to thermal management. Their patented processing techniques include reactive extrusion and in-situ polymerization that creates covalent bonds between the polymer matrix and conductive fillers, significantly improving the thermal stability up to 280°C without conductivity loss. DuPont's materials maintain electrical conductivity at elevated temperatures through controlled thermal expansion coefficients and engineered interfaces that prevent conductive network disruption during thermal cycling[1][3].

Strengths: Superior thermal stability retention (up to 280°C) while maintaining electrical properties; excellent mechanical integrity at high temperatures; proprietary processing techniques for enhanced filler-matrix interfaces. Weaknesses: Higher production costs compared to conventional composites; requires specialized processing equipment; some formulations have limited recyclability due to cross-linking agents.

SABIC Global Technologies BV

Technical Solution: SABIC has developed advanced thermally stable conductive polymer composites through their NORYL™ and ULTEM™ resin platforms. Their approach combines high-temperature resistant polymer matrices (PPE/PS alloys and polyetherimide) with carefully engineered conductive networks. SABIC employs a proprietary compatibilization technology that creates strong interfaces between the polymer matrix and conductive fillers, preventing network disruption during thermal expansion. Their materials incorporate specialized heat stabilizers and metal deactivators that prevent oxidative degradation at elevated temperatures. SABIC's innovation includes a controlled morphology approach where the conductive network is partially embedded within a more thermally stable polymer phase, creating mechanical anchors that maintain conductivity during thermal cycling. Their composites demonstrate stable electrical properties at continuous operating temperatures up to 180°C, with some specialized grades maintaining performance up to 230°C for short periods. SABIC's materials show less than 15% conductivity change after 1500 hours at elevated temperatures[6][8].

Strengths: Excellent balance of thermal stability and processability; good mechanical properties retention at elevated temperatures; wide processing window for various manufacturing methods. Weaknesses: Moderate moisture sensitivity in some formulations; higher cost compared to standard engineering plastics; limited flexibility in high-temperature grades.

Key Patents and Scientific Breakthroughs

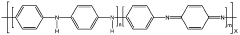

Thermally stable and solvent-resistant conductive polymer composites

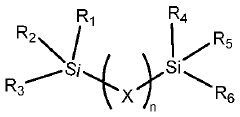

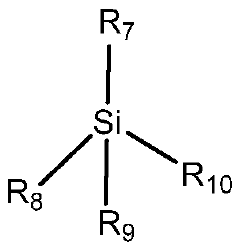

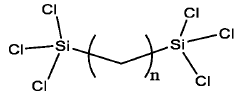

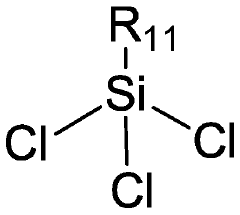

PatentWO2022015284A1

Innovation

- A thermally stable and solvent-resistant conductive polymer composite is developed by incorporating a doped host conjugated polymer with a crosslinked siloxane network, formed from crosslinkable silane precursors, which enhances electrical conductivity and stability through simultaneous doping and crosslinking reactions.

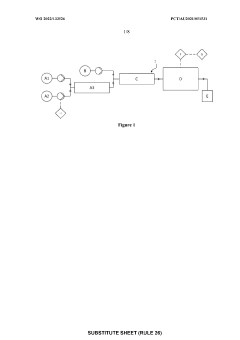

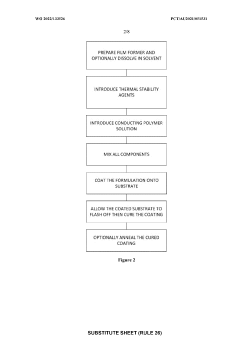

Thermally stabilised conductive polymer coatings

PatentWO2022133526A1

Innovation

- Incorporating thermal stability agents like alkali metal salts, amphoteric metal oxides, and antioxidants into polyaniline conducting polymer coatings to enhance thermal stability while maintaining conductivity, specifically by forming stable compositions that remain processable and soluble in organic solvents.

Environmental Impact and Sustainability Considerations

The environmental implications of conductive polymer composites (CPCs) are increasingly significant as these materials gain wider industrial adoption. Traditional electronic materials often contain toxic heavy metals and halogenated compounds that pose serious environmental hazards during production, use, and disposal. In contrast, many polymer-based composites offer reduced environmental impact through lower processing temperatures, decreased toxic material content, and potential biodegradability pathways.

When examining thermal stability improvements in CPCs, sustainability considerations must be integrated from the design phase. The selection of polymer matrices and conductive fillers significantly influences the ecological footprint of these materials. Bio-based polymers derived from renewable resources present promising alternatives to petroleum-based polymers, potentially reducing carbon emissions while maintaining thermal performance requirements.

Life cycle assessment (LCA) studies reveal that the environmental benefits of thermally stable CPCs extend beyond production. Their enhanced durability under thermal stress translates to longer product lifespans, reducing electronic waste generation. Additionally, the lower processing temperatures of many polymer composites compared to traditional metal-based conductors result in reduced energy consumption during manufacturing, contributing to decreased greenhouse gas emissions.

Recycling and end-of-life management present both challenges and opportunities for CPC materials. Current recycling infrastructure is often inadequate for handling composite materials, as separating the polymer matrix from conductive fillers remains technically difficult. Research into designing thermally stable CPCs with reversible crosslinking or stimuli-responsive properties could facilitate future disassembly and component recovery, advancing circular economy principles.

Regulatory frameworks worldwide are increasingly emphasizing reduced environmental impact of electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the transition toward more environmentally benign materials. Thermally stable CPCs that eliminate restricted substances while maintaining performance specifications align with these global sustainability initiatives.

Water consumption and pollution associated with CPC production represent additional environmental considerations. Solvent-free processing methods and water-based synthesis approaches are emerging as sustainable alternatives to traditional solvent-intensive manufacturing. These approaches not only reduce environmental contamination but often contribute to improved thermal stability through better interfacial interactions between polymer matrices and conductive fillers.

When examining thermal stability improvements in CPCs, sustainability considerations must be integrated from the design phase. The selection of polymer matrices and conductive fillers significantly influences the ecological footprint of these materials. Bio-based polymers derived from renewable resources present promising alternatives to petroleum-based polymers, potentially reducing carbon emissions while maintaining thermal performance requirements.

Life cycle assessment (LCA) studies reveal that the environmental benefits of thermally stable CPCs extend beyond production. Their enhanced durability under thermal stress translates to longer product lifespans, reducing electronic waste generation. Additionally, the lower processing temperatures of many polymer composites compared to traditional metal-based conductors result in reduced energy consumption during manufacturing, contributing to decreased greenhouse gas emissions.

Recycling and end-of-life management present both challenges and opportunities for CPC materials. Current recycling infrastructure is often inadequate for handling composite materials, as separating the polymer matrix from conductive fillers remains technically difficult. Research into designing thermally stable CPCs with reversible crosslinking or stimuli-responsive properties could facilitate future disassembly and component recovery, advancing circular economy principles.

Regulatory frameworks worldwide are increasingly emphasizing reduced environmental impact of electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the transition toward more environmentally benign materials. Thermally stable CPCs that eliminate restricted substances while maintaining performance specifications align with these global sustainability initiatives.

Water consumption and pollution associated with CPC production represent additional environmental considerations. Solvent-free processing methods and water-based synthesis approaches are emerging as sustainable alternatives to traditional solvent-intensive manufacturing. These approaches not only reduce environmental contamination but often contribute to improved thermal stability through better interfacial interactions between polymer matrices and conductive fillers.

Performance Testing Standards and Certification Requirements

The standardization of performance testing for conductive polymer composites (CPCs) is essential for ensuring product reliability and market acceptance. Currently, several international standards govern thermal stability testing, including ASTM D3850 for thermal stability determination, ISO 11357 for differential scanning calorimetry (DSC) measurements, and UL 746B for long-term thermal aging. These standards provide methodologies for evaluating critical parameters such as thermal degradation onset, glass transition temperature, and retention of electrical conductivity after thermal exposure.

Certification requirements for thermally stable CPCs vary significantly across industries. In automotive applications, materials must meet stringent standards like USCAR-2 for under-hood components, requiring stability at temperatures up to 150°C with minimal property degradation over 3,000 hours. Aerospace applications follow standards such as RTCA DO-160 with even more demanding requirements, including resistance to thermal cycling between -55°C and 200°C.

Testing protocols typically involve multiple thermal characterization techniques. Thermogravimetric analysis (TGA) measures weight loss during controlled heating, with most commercial applications requiring less than 5% mass loss at operating temperatures. Dynamic mechanical analysis (DMA) evaluates viscoelastic properties under thermal stress, while thermal conductivity measurements follow standards like ASTM E1530 or ISO 22007.

Accelerated aging tests represent another critical certification requirement, simulating years of thermal exposure in compressed timeframes. These tests follow protocols such as IEC 60216 for electrical insulation materials, requiring extrapolation of performance data to predict service life. For electronic applications, the JEDEC J-STD-020 standard governs moisture sensitivity and reflow soldering resistance, ensuring CPC materials can withstand manufacturing processes.

Emerging certification trends include the development of specialized standards for novel applications like wearable electronics (IEC 63203) and flexible displays (IEC 62715), which demand unique combinations of thermal stability and mechanical flexibility. Additionally, environmental compliance certifications such as RoHS and REACH increasingly influence material selection, requiring manufacturers to document thermal stability without restricted substances traditionally used as stabilizers.

Certification costs and timelines present significant market barriers, particularly for startups and small manufacturers. The complete certification process for a new thermally stable CPC can require 6-18 months and investments exceeding $100,000, depending on target applications. This has led to industry initiatives for streamlined testing protocols and pre-certification programs to reduce market entry barriers while maintaining rigorous performance standards.

Certification requirements for thermally stable CPCs vary significantly across industries. In automotive applications, materials must meet stringent standards like USCAR-2 for under-hood components, requiring stability at temperatures up to 150°C with minimal property degradation over 3,000 hours. Aerospace applications follow standards such as RTCA DO-160 with even more demanding requirements, including resistance to thermal cycling between -55°C and 200°C.

Testing protocols typically involve multiple thermal characterization techniques. Thermogravimetric analysis (TGA) measures weight loss during controlled heating, with most commercial applications requiring less than 5% mass loss at operating temperatures. Dynamic mechanical analysis (DMA) evaluates viscoelastic properties under thermal stress, while thermal conductivity measurements follow standards like ASTM E1530 or ISO 22007.

Accelerated aging tests represent another critical certification requirement, simulating years of thermal exposure in compressed timeframes. These tests follow protocols such as IEC 60216 for electrical insulation materials, requiring extrapolation of performance data to predict service life. For electronic applications, the JEDEC J-STD-020 standard governs moisture sensitivity and reflow soldering resistance, ensuring CPC materials can withstand manufacturing processes.

Emerging certification trends include the development of specialized standards for novel applications like wearable electronics (IEC 63203) and flexible displays (IEC 62715), which demand unique combinations of thermal stability and mechanical flexibility. Additionally, environmental compliance certifications such as RoHS and REACH increasingly influence material selection, requiring manufacturers to document thermal stability without restricted substances traditionally used as stabilizers.

Certification costs and timelines present significant market barriers, particularly for startups and small manufacturers. The complete certification process for a new thermally stable CPC can require 6-18 months and investments exceeding $100,000, depending on target applications. This has led to industry initiatives for streamlined testing protocols and pre-certification programs to reduce market entry barriers while maintaining rigorous performance standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!