Fatigue And Fracture Mechanics Of CMCs Under Aero Engine Conditions

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Fatigue Mechanics Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that have emerged as critical enablers for next-generation aero engines. The evolution of these materials spans several decades, beginning with early research in the 1970s and accelerating significantly in the 1990s when their potential for high-temperature applications became evident. The fundamental advantage of CMCs lies in their exceptional thermal resistance combined with lower density compared to traditional superalloys, offering the possibility of higher operating temperatures and improved engine efficiency.

The technological trajectory of CMCs has been marked by progressive improvements in material composition, manufacturing techniques, and performance characteristics. Early CMCs suffered from reliability issues and limited mechanical properties, but continuous innovation has led to the development of more sophisticated systems incorporating advanced fibers, complex interphases, and optimized matrices. This evolution has been driven by the aerospace industry's persistent demand for materials capable of withstanding increasingly extreme operating conditions.

Current research focuses on understanding the complex fatigue and fracture mechanics of CMCs under the harsh conditions typical of aero engines, including high temperatures (exceeding 1200°C), oxidizing environments, cyclic loading, and vibration. These conditions create unique challenges for material performance and durability that are not adequately addressed by conventional mechanical theories developed for metallic materials.

The primary technical objectives in this field include developing comprehensive models that accurately predict CMC behavior under complex loading conditions, establishing standardized testing methodologies specific to CMCs, and creating design guidelines that enable engineers to fully leverage CMC capabilities in engine components. These objectives are critical for transitioning from the current limited application of CMCs to their widespread implementation in core engine components.

Another key goal is to understand the relationship between microstructural features and macroscopic mechanical behavior, particularly how fiber architecture, matrix composition, and interface characteristics influence fatigue resistance and fracture toughness. This understanding is essential for designing CMCs with optimized performance for specific engine applications.

The long-term technological vision extends beyond current silicon carbide-based CMCs to explore new material systems capable of operating at even higher temperatures, potentially enabling transformative improvements in engine efficiency and performance. This includes investigation of novel compositions, hybrid systems, and advanced manufacturing techniques that could overcome current limitations in CMC technology.

The technological trajectory of CMCs has been marked by progressive improvements in material composition, manufacturing techniques, and performance characteristics. Early CMCs suffered from reliability issues and limited mechanical properties, but continuous innovation has led to the development of more sophisticated systems incorporating advanced fibers, complex interphases, and optimized matrices. This evolution has been driven by the aerospace industry's persistent demand for materials capable of withstanding increasingly extreme operating conditions.

Current research focuses on understanding the complex fatigue and fracture mechanics of CMCs under the harsh conditions typical of aero engines, including high temperatures (exceeding 1200°C), oxidizing environments, cyclic loading, and vibration. These conditions create unique challenges for material performance and durability that are not adequately addressed by conventional mechanical theories developed for metallic materials.

The primary technical objectives in this field include developing comprehensive models that accurately predict CMC behavior under complex loading conditions, establishing standardized testing methodologies specific to CMCs, and creating design guidelines that enable engineers to fully leverage CMC capabilities in engine components. These objectives are critical for transitioning from the current limited application of CMCs to their widespread implementation in core engine components.

Another key goal is to understand the relationship between microstructural features and macroscopic mechanical behavior, particularly how fiber architecture, matrix composition, and interface characteristics influence fatigue resistance and fracture toughness. This understanding is essential for designing CMCs with optimized performance for specific engine applications.

The long-term technological vision extends beyond current silicon carbide-based CMCs to explore new material systems capable of operating at even higher temperatures, potentially enabling transformative improvements in engine efficiency and performance. This includes investigation of novel compositions, hybrid systems, and advanced manufacturing techniques that could overcome current limitations in CMC technology.

Aero Engine Market Requirements Analysis

The global aero engine market is experiencing significant growth, driven by increasing air travel demand and fleet expansion. According to industry forecasts, the commercial aircraft engine market is projected to reach $92.9 billion by 2028, with a compound annual growth rate of approximately 5.8% from 2023. This growth trajectory creates substantial demand for advanced materials capable of withstanding extreme operating conditions.

Ceramic Matrix Composites (CMCs) have emerged as critical materials for next-generation aero engines, primarily due to their exceptional high-temperature capabilities. Modern turbofan engines operate at temperatures exceeding 1400°C in the hottest sections, where traditional nickel-based superalloys reach their operational limits. The aviation industry demands materials that can function reliably at these extreme temperatures while maintaining structural integrity through thousands of flight cycles.

Weight reduction represents another crucial market requirement. Airlines consistently seek to reduce fuel consumption, with each pound of weight saved translating to approximately $1,000 in fuel cost savings over an aircraft's lifetime. CMCs offer up to 30% weight reduction compared to conventional metal components, directly addressing this economic imperative while contributing to reduced emissions.

Durability under cyclic loading conditions constitutes a fundamental requirement for aero engine materials. Components must withstand the stress of frequent takeoffs and landings, with each cycle subjecting materials to rapid temperature fluctuations and varying mechanical loads. The industry standard now demands component lifespans of 20,000+ flight cycles, placing extraordinary demands on material fatigue resistance.

Environmental considerations have become increasingly prominent in market requirements. Regulatory frameworks like ICAO's CORSIA and the European Union's emissions trading system impose stringent emissions targets on airlines. Materials enabling higher operating temperatures directly contribute to improved thermodynamic efficiency and reduced emissions, aligning with these regulatory pressures.

Maintenance costs represent approximately 15% of airline operating expenses, with engine maintenance forming a substantial portion of this figure. The market increasingly demands materials with predictable degradation patterns and extended service intervals. Understanding fatigue and fracture mechanics of CMCs becomes essential for developing reliable prognostic health monitoring systems that can predict component failure before it occurs.

Manufacturing scalability and cost-effectiveness remain significant market considerations. While CMCs offer superior performance, their complex manufacturing processes currently result in components costing 5-10 times more than conventional alternatives. The market requires continued innovation in manufacturing technologies to reduce this cost differential while maintaining performance advantages.

Ceramic Matrix Composites (CMCs) have emerged as critical materials for next-generation aero engines, primarily due to their exceptional high-temperature capabilities. Modern turbofan engines operate at temperatures exceeding 1400°C in the hottest sections, where traditional nickel-based superalloys reach their operational limits. The aviation industry demands materials that can function reliably at these extreme temperatures while maintaining structural integrity through thousands of flight cycles.

Weight reduction represents another crucial market requirement. Airlines consistently seek to reduce fuel consumption, with each pound of weight saved translating to approximately $1,000 in fuel cost savings over an aircraft's lifetime. CMCs offer up to 30% weight reduction compared to conventional metal components, directly addressing this economic imperative while contributing to reduced emissions.

Durability under cyclic loading conditions constitutes a fundamental requirement for aero engine materials. Components must withstand the stress of frequent takeoffs and landings, with each cycle subjecting materials to rapid temperature fluctuations and varying mechanical loads. The industry standard now demands component lifespans of 20,000+ flight cycles, placing extraordinary demands on material fatigue resistance.

Environmental considerations have become increasingly prominent in market requirements. Regulatory frameworks like ICAO's CORSIA and the European Union's emissions trading system impose stringent emissions targets on airlines. Materials enabling higher operating temperatures directly contribute to improved thermodynamic efficiency and reduced emissions, aligning with these regulatory pressures.

Maintenance costs represent approximately 15% of airline operating expenses, with engine maintenance forming a substantial portion of this figure. The market increasingly demands materials with predictable degradation patterns and extended service intervals. Understanding fatigue and fracture mechanics of CMCs becomes essential for developing reliable prognostic health monitoring systems that can predict component failure before it occurs.

Manufacturing scalability and cost-effectiveness remain significant market considerations. While CMCs offer superior performance, their complex manufacturing processes currently result in components costing 5-10 times more than conventional alternatives. The market requires continued innovation in manufacturing technologies to reduce this cost differential while maintaining performance advantages.

Current CMC Technology Status and Challenges

Ceramic Matrix Composites (CMCs) represent a significant advancement in high-temperature materials for aerospace applications, particularly in aero engine environments. Currently, the global development of CMC technology demonstrates considerable regional variation, with the United States, Europe, and Japan leading research efforts. These materials have progressed from laboratory curiosities to commercial implementation in select engine components, marking a significant technological milestone.

The primary technical challenges facing CMC implementation in aero engine conditions center on their complex fatigue and fracture behavior. Unlike traditional metallic materials, CMCs exhibit non-linear damage accumulation and unique failure mechanisms that complicate prediction models. The interaction between matrix cracking, fiber-matrix debonding, and environmental degradation creates a multifaceted problem that current analytical frameworks struggle to fully capture.

Environmental factors present particularly formidable challenges for CMCs in engine applications. Oxidation at high temperatures significantly degrades fiber strength and interface properties, while moisture ingress can accelerate chemical degradation processes. The combination of thermal cycling, mechanical loading, and environmental attack creates synergistic damage mechanisms that are difficult to characterize through conventional testing methodologies.

Current testing protocols for CMC fatigue and fracture mechanics remain inadequate for fully predicting in-service behavior. Standard test methods developed for metallic materials often fail to capture the unique damage progression in CMCs, while specialized testing approaches lack standardization across the industry. This creates significant uncertainty in component life prediction and safety margin determination.

Manufacturing consistency represents another substantial challenge. Variations in fiber architecture, matrix infiltration, and interface coating thickness can dramatically influence fatigue performance. The statistical nature of ceramic strength further complicates reliability assessments, requiring probabilistic approaches rather than deterministic design methodologies common with metals.

Computational modeling capabilities, while advancing rapidly, still face limitations in accurately predicting CMC behavior under complex loading conditions. Current models struggle to integrate microstructural features, environmental effects, and loading history in a unified framework that can reliably predict component lifetimes under realistic engine conditions.

The economic barriers to widespread CMC adoption remain significant. High material and processing costs, coupled with complex certification requirements, limit application to high-value components where performance benefits clearly outweigh cost premiums. Manufacturing scale-up challenges further constrain broader implementation across engine platforms.

The primary technical challenges facing CMC implementation in aero engine conditions center on their complex fatigue and fracture behavior. Unlike traditional metallic materials, CMCs exhibit non-linear damage accumulation and unique failure mechanisms that complicate prediction models. The interaction between matrix cracking, fiber-matrix debonding, and environmental degradation creates a multifaceted problem that current analytical frameworks struggle to fully capture.

Environmental factors present particularly formidable challenges for CMCs in engine applications. Oxidation at high temperatures significantly degrades fiber strength and interface properties, while moisture ingress can accelerate chemical degradation processes. The combination of thermal cycling, mechanical loading, and environmental attack creates synergistic damage mechanisms that are difficult to characterize through conventional testing methodologies.

Current testing protocols for CMC fatigue and fracture mechanics remain inadequate for fully predicting in-service behavior. Standard test methods developed for metallic materials often fail to capture the unique damage progression in CMCs, while specialized testing approaches lack standardization across the industry. This creates significant uncertainty in component life prediction and safety margin determination.

Manufacturing consistency represents another substantial challenge. Variations in fiber architecture, matrix infiltration, and interface coating thickness can dramatically influence fatigue performance. The statistical nature of ceramic strength further complicates reliability assessments, requiring probabilistic approaches rather than deterministic design methodologies common with metals.

Computational modeling capabilities, while advancing rapidly, still face limitations in accurately predicting CMC behavior under complex loading conditions. Current models struggle to integrate microstructural features, environmental effects, and loading history in a unified framework that can reliably predict component lifetimes under realistic engine conditions.

The economic barriers to widespread CMC adoption remain significant. High material and processing costs, coupled with complex certification requirements, limit application to high-value components where performance benefits clearly outweigh cost premiums. Manufacturing scale-up challenges further constrain broader implementation across engine platforms.

Existing CMC Fatigue Testing Methodologies

01 Fatigue resistance mechanisms in CMCs

Ceramic Matrix Composites can be engineered with specific microstructural features to enhance fatigue resistance. These include fiber-matrix interface optimization, crack deflection mechanisms, and self-healing capabilities that prevent crack propagation during cyclic loading. The incorporation of specific reinforcement architectures and interface coatings allows for energy dissipation during loading cycles, significantly improving the fatigue life of CMC components under high-temperature and high-stress applications.- Fatigue resistance mechanisms in CMCs: Ceramic Matrix Composites (CMCs) can be engineered to resist fatigue through various mechanisms including fiber reinforcement, interface design, and microstructural optimization. These mechanisms help to distribute stress, prevent crack propagation, and enhance the overall durability of the composite under cyclic loading conditions. The fatigue resistance of CMCs is critical for applications in high-temperature environments where components are subjected to repeated thermal and mechanical stresses.

- Fracture toughness enhancement techniques: Various techniques can be employed to enhance the fracture toughness of Ceramic Matrix Composites, including the incorporation of secondary phases, control of fiber-matrix interfaces, and optimization of fiber architecture. These approaches create energy dissipation mechanisms such as crack deflection, fiber bridging, and fiber pull-out that significantly improve the material's resistance to crack propagation. Enhanced fracture toughness allows CMCs to withstand higher stress intensities before catastrophic failure occurs.

- High-temperature mechanical behavior: The mechanical behavior of Ceramic Matrix Composites at elevated temperatures is characterized by complex interactions between creep, oxidation, and microstructural evolution. Understanding these interactions is essential for predicting fatigue life and fracture behavior in high-temperature applications. CMCs designed for high-temperature environments incorporate specific matrix compositions and fiber coatings that maintain their mechanical integrity and fracture resistance even under extreme thermal conditions.

- Non-destructive evaluation methods: Non-destructive evaluation techniques are crucial for assessing damage progression and predicting failure in Ceramic Matrix Composites. Methods such as acoustic emission, thermography, X-ray computed tomography, and ultrasonic testing can be used to detect and monitor crack initiation, propagation, and other damage mechanisms in CMCs. These techniques enable the development of reliable life prediction models and help establish safe operating parameters for CMC components under fatigue loading conditions.

- Novel CMC compositions and processing techniques: Innovative compositions and processing techniques are being developed to create Ceramic Matrix Composites with superior fatigue and fracture properties. These include novel matrix materials, advanced fiber coatings, and specialized manufacturing processes such as chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration. These advancements result in CMCs with improved microstructural uniformity, reduced defect populations, and enhanced mechanical properties that directly contribute to better fatigue resistance and fracture toughness.

02 Fracture toughness enhancement techniques

Various methods can be employed to enhance the fracture toughness of Ceramic Matrix Composites, including the incorporation of secondary phases, fiber treatments, and engineered interfaces. These techniques promote crack bridging, deflection, and branching mechanisms that increase energy absorption during fracture. Advanced processing methods can create controlled heterogeneities within the matrix that serve as crack arresters, significantly improving the material's resistance to catastrophic failure under mechanical and thermal stresses.Expand Specific Solutions03 High-temperature testing methodologies

Specialized testing methodologies have been developed to evaluate the fatigue and fracture behavior of Ceramic Matrix Composites under extreme temperature conditions. These include modified creep-fatigue testing, thermomechanical fatigue assessment, and in-situ monitoring techniques that provide real-time data on crack initiation and propagation. Advanced non-destructive evaluation methods allow for accurate characterization of damage evolution in CMCs during high-temperature cyclic loading, enabling better prediction of component lifetimes in aerospace and energy applications.Expand Specific Solutions04 Environmental effects on CMC degradation

The performance of Ceramic Matrix Composites under fatigue loading is significantly affected by environmental factors such as oxidation, moisture, and chemical exposure. Protective coatings and matrix modifications can be implemented to mitigate environmental degradation mechanisms that accelerate crack growth and reduce mechanical properties. Understanding the synergistic effects of mechanical loading and environmental exposure is crucial for developing CMCs with improved durability in aggressive service environments like combustion chambers and turbine components.Expand Specific Solutions05 Computational modeling of CMC failure

Advanced computational models have been developed to predict the fatigue and fracture behavior of Ceramic Matrix Composites across multiple scales. These models incorporate microstructural details, damage evolution mechanisms, and material property degradation to simulate progressive failure under complex loading conditions. Machine learning approaches combined with physics-based modeling enable more accurate lifetime predictions and can be used to optimize CMC compositions and architectures for specific applications requiring exceptional mechanical performance under extreme conditions.Expand Specific Solutions

Leading CMC Manufacturers and Research Institutions

The fatigue and fracture mechanics of Ceramic Matrix Composites (CMCs) under aero engine conditions represents a critical technological frontier in the aerospace industry, currently in a growth phase with increasing market adoption. The global market for CMCs in aero engines is expanding rapidly as manufacturers seek materials capable of withstanding extreme temperatures and stresses while reducing weight. Leading aerospace companies including GE, RTX Corp., Rolls-Royce, and Airbus are investing heavily in CMC research and implementation, while academic institutions such as Beihang University, Nanjing University of Aeronautics & Astronautics, and Beijing Institute of Aeronautical Materials are advancing fundamental understanding of failure mechanisms. The technology is approaching maturity for certain applications but continues to evolve as manufacturers seek to optimize durability, predictability, and cost-effectiveness for next-generation engine designs.

General Electric Company

Technical Solution: GE has pioneered advanced CMC technology for aero engine applications, particularly focusing on SiC/SiC composites for high-temperature turbine components. Their technical approach involves a proprietary melt infiltration process that creates dense, high-strength CMCs with superior temperature capabilities up to 2400°F (1316°C). GE's fatigue and fracture mechanics solution incorporates a multi-scale modeling approach that predicts crack initiation and propagation under cyclic loading conditions typical in aero engines. Their CMCs feature engineered fiber-matrix interfaces with boron nitride coatings that create controlled debonding paths, enhancing fracture toughness. GE has implemented these materials in the LEAP engine's combustor liners and high-pressure turbine shrouds, demonstrating 20% weight reduction and 2% fuel efficiency improvement compared to traditional nickel superalloys. Their testing methodology includes specialized high-temperature mechanical testing under simulated engine conditions with acoustic emission monitoring to detect microcracking phenomena.

Strengths: Industry-leading experience with CMCs in actual flight engines; proprietary manufacturing processes; comprehensive testing facilities. Weaknesses: High manufacturing costs; complex processing requirements; limited repairability of components once damaged; challenges in non-destructive evaluation of internal defects.

RTX Corp.

Technical Solution: RTX Corporation (formerly United Technologies) has developed an advanced technical approach to CMC fatigue and fracture mechanics through its Pratt & Whitney division. Their solution focuses on hybrid CMC systems that combine the benefits of both oxide and non-oxide ceramics for optimal performance across different engine zones. RTX's methodology incorporates physics-based modeling that predicts microcrack formation and coalescence under thermomechanical fatigue conditions, validated through specialized rig testing that replicates engine thermal transients. They have pioneered environmental barrier coatings specifically designed to protect CMCs in water vapor-rich combustion environments, addressing a key degradation mechanism. RTX has implemented a digital thread approach that tracks material variability from raw material to finished component, enabling precise correlation between manufacturing parameters and in-service performance. Their testing protocols include simulated foreign object damage scenarios to assess impact resistance and subsequent fatigue life degradation, a critical consideration for engine certification.

Strengths: Extensive engine integration experience; sophisticated coating technologies; comprehensive digital material tracking systems. Weaknesses: Relatively later entry into CMC implementation compared to some competitors; challenges in balancing performance with manufacturing cost at production scale.

Critical Patents in CMC Fracture Resistance

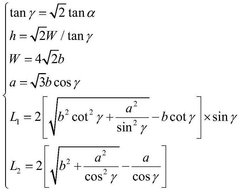

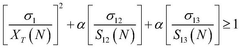

A method for predicting the dispersion of CMC fatigue life considering the thermo-solid coupling effect

PatentActiveCN116933603B

Innovation

- By establishing a representative volume element (RVE) geometric model, combined with thermo-solid coupling mechanical analysis, the progressive damage process of CMC is simulated, the structure and performance dispersion of CMC are taken into account, and its stress-fatigue life relationship is predicted, using the Miner cumulative damage failure criterion and Weibull Distribution method to determine the dispersion distribution law of fatigue life of CMC.

Calculation method for fatigue prediction model of three-dimensional woven ceramic matrix composite

PatentPendingCN119889534A

Innovation

- A fatigue prediction model calculation method for three-dimensional braided ceramic matrix composite materials is proposed. By carrying out tensile tests and tensile fatigue tests under different temperature environments, the residual stiffness degradation model of fiber bundle composite materials is established, and the RVE finite element model of three-dimensional braided CMCs is constructed. The fatigue failure criterion is applied for iterative calculation until the structure fails.

Environmental Impact of CMC Implementation

The implementation of Ceramic Matrix Composites (CMCs) in aero engines represents a significant technological advancement with substantial environmental implications. The reduced weight of CMC components directly translates to improved fuel efficiency in aircraft operations. Studies indicate that for every 100 pounds of weight reduction in an aircraft, fuel consumption decreases by approximately 0.75-1.5%, resulting in proportional reductions in greenhouse gas emissions. When applied to critical hot section components, CMCs enable engines to operate at higher temperatures with improved thermal efficiency, further reducing the carbon footprint of aviation operations.

Manufacturing processes for CMCs, however, present environmental challenges that must be considered in a comprehensive assessment. The production of ceramic fibers and matrices typically requires high-temperature processing, consuming significant energy and potentially generating hazardous byproducts. Life cycle assessments reveal that the environmental impact of CMC manufacturing can be 30-40% higher than traditional nickel-based superalloys in the production phase, though this is generally offset by operational benefits over the component lifetime.

The extended service life of CMC components contributes positively to environmental sustainability by reducing the frequency of replacement and associated resource consumption. CMC parts in aero engines typically demonstrate 2-3 times longer operational lifespans compared to conventional materials under similar conditions, decreasing the demand for raw materials and energy-intensive manufacturing processes over the engine's operational lifetime.

End-of-life considerations for CMC components present both challenges and opportunities. The complex nature of these composites makes traditional recycling difficult, with current technologies achieving only partial material recovery rates of 40-60%. Research into advanced recycling methods, including chemical separation techniques and thermal decomposition processes, shows promise for improving these rates to over 80% in the next decade.

Regulatory frameworks are evolving to address the environmental aspects of advanced materials like CMCs. The European Union's REACH regulations and similar initiatives worldwide are increasingly focusing on the entire lifecycle environmental impact of aerospace materials, potentially influencing future CMC development and implementation strategies. Manufacturers are responding by developing cleaner production methods and exploring bio-derived precursors for certain CMC components.

Manufacturing processes for CMCs, however, present environmental challenges that must be considered in a comprehensive assessment. The production of ceramic fibers and matrices typically requires high-temperature processing, consuming significant energy and potentially generating hazardous byproducts. Life cycle assessments reveal that the environmental impact of CMC manufacturing can be 30-40% higher than traditional nickel-based superalloys in the production phase, though this is generally offset by operational benefits over the component lifetime.

The extended service life of CMC components contributes positively to environmental sustainability by reducing the frequency of replacement and associated resource consumption. CMC parts in aero engines typically demonstrate 2-3 times longer operational lifespans compared to conventional materials under similar conditions, decreasing the demand for raw materials and energy-intensive manufacturing processes over the engine's operational lifetime.

End-of-life considerations for CMC components present both challenges and opportunities. The complex nature of these composites makes traditional recycling difficult, with current technologies achieving only partial material recovery rates of 40-60%. Research into advanced recycling methods, including chemical separation techniques and thermal decomposition processes, shows promise for improving these rates to over 80% in the next decade.

Regulatory frameworks are evolving to address the environmental aspects of advanced materials like CMCs. The European Union's REACH regulations and similar initiatives worldwide are increasingly focusing on the entire lifecycle environmental impact of aerospace materials, potentially influencing future CMC development and implementation strategies. Manufacturers are responding by developing cleaner production methods and exploring bio-derived precursors for certain CMC components.

Certification Standards for Aero Engine CMCs

The certification of Ceramic Matrix Composites (CMCs) for aero engine applications represents a complex regulatory landscape that has evolved significantly over the past decade. Currently, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established specific certification frameworks for CMCs, primarily through Advisory Circulars (ACs) such as AC 20-107B and the Certification Memorandum CM-S-004.

These standards address the unique characteristics of CMCs, particularly their distinct failure mechanisms compared to traditional metallic components. The certification process requires extensive material property databases, including data on fatigue behavior, fracture toughness, and environmental degradation under engine operating conditions. Notably, the standards mandate statistical approaches to account for the inherent variability in CMC properties.

For fatigue certification, the standards require demonstration of durability under cyclic loading conditions representative of the engine operational envelope. This includes high-temperature fatigue testing with hold times to capture creep-fatigue interaction effects. The certification standards typically require a minimum of 3-5 times the expected service life in component testing to establish an adequate safety margin.

Fracture mechanics certification follows damage tolerance principles adapted specifically for CMCs. Unlike metals, where linear elastic fracture mechanics (LEFM) is often applicable, CMCs require consideration of non-linear fracture behavior and the influence of the fiber-matrix interface on crack propagation. Standards require manufacturers to establish allowable damage sizes and demonstrate that components can sustain operation with such damage for a specified period.

Environmental factors receive particular attention in certification standards, with requirements for testing in representative engine environments including moisture, combustion products, and thermal cycling. The standards mandate accelerated testing protocols to simulate long-term environmental degradation effects within practical timeframes.

Manufacturing process control forms a critical component of CMC certification. Standards require detailed process specifications and quality control procedures to ensure consistency in production. This includes non-destructive evaluation (NDE) techniques validated specifically for CMCs, as conventional methods developed for metals often prove inadequate for detecting critical flaws in composite structures.

Recent updates to certification standards have begun incorporating probabilistic approaches to account for the statistical nature of CMC properties and failure mechanisms. This represents a shift from the traditional deterministic certification methods used for metallic components, acknowledging the different reliability characteristics of composite materials under aero engine conditions.

These standards address the unique characteristics of CMCs, particularly their distinct failure mechanisms compared to traditional metallic components. The certification process requires extensive material property databases, including data on fatigue behavior, fracture toughness, and environmental degradation under engine operating conditions. Notably, the standards mandate statistical approaches to account for the inherent variability in CMC properties.

For fatigue certification, the standards require demonstration of durability under cyclic loading conditions representative of the engine operational envelope. This includes high-temperature fatigue testing with hold times to capture creep-fatigue interaction effects. The certification standards typically require a minimum of 3-5 times the expected service life in component testing to establish an adequate safety margin.

Fracture mechanics certification follows damage tolerance principles adapted specifically for CMCs. Unlike metals, where linear elastic fracture mechanics (LEFM) is often applicable, CMCs require consideration of non-linear fracture behavior and the influence of the fiber-matrix interface on crack propagation. Standards require manufacturers to establish allowable damage sizes and demonstrate that components can sustain operation with such damage for a specified period.

Environmental factors receive particular attention in certification standards, with requirements for testing in representative engine environments including moisture, combustion products, and thermal cycling. The standards mandate accelerated testing protocols to simulate long-term environmental degradation effects within practical timeframes.

Manufacturing process control forms a critical component of CMC certification. Standards require detailed process specifications and quality control procedures to ensure consistency in production. This includes non-destructive evaluation (NDE) techniques validated specifically for CMCs, as conventional methods developed for metals often prove inadequate for detecting critical flaws in composite structures.

Recent updates to certification standards have begun incorporating probabilistic approaches to account for the statistical nature of CMC properties and failure mechanisms. This represents a shift from the traditional deterministic certification methods used for metallic components, acknowledging the different reliability characteristics of composite materials under aero engine conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!