Ferrofluid Innovations Driving New Directions in Environmental Science

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution and Environmental Goals

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in their composition, properties, and applications. Initially created for rocket fuel manipulation in zero gravity, these magnetic liquids have since found diverse uses across various industries. The journey of ferrofluid technology has been marked by continuous improvements in stability, magnetic responsiveness, and environmental compatibility.

In recent years, the focus of ferrofluid research has shifted towards environmental applications, aligning with global sustainability goals. This transition reflects a growing awareness of environmental challenges and the potential for innovative solutions. The unique properties of ferrofluids, particularly their ability to be precisely controlled by magnetic fields, have opened new avenues for addressing environmental issues.

One of the primary environmental goals driving ferrofluid innovation is water purification. Researchers are developing ferrofluid-based systems capable of removing contaminants from water bodies with unprecedented efficiency. These systems exploit the magnetic properties of ferrofluids to attract and separate pollutants, offering a promising alternative to traditional water treatment methods.

Another significant area of focus is oil spill remediation. Ferrofluids are being engineered to effectively contain and recover oil from water surfaces, potentially revolutionizing the approach to marine pollution incidents. The ability to manipulate ferrofluids remotely using magnetic fields allows for more precise and controlled clean-up operations, minimizing environmental impact.

In the realm of renewable energy, ferrofluids are being explored for enhancing the efficiency of solar thermal systems. By improving heat transfer and energy storage capabilities, ferrofluid-based technologies aim to contribute to the broader goal of sustainable energy production and consumption.

The evolution of ferrofluids is also closely tied to advancements in nanotechnology. As synthesis techniques improve, researchers are able to create ferrofluids with increasingly sophisticated properties, tailored for specific environmental applications. This includes the development of biocompatible ferrofluids for environmental monitoring and remediation in sensitive ecosystems.

Looking ahead, the trajectory of ferrofluid technology is closely aligned with key environmental objectives such as reducing pollution, conserving resources, and mitigating climate change impacts. The ongoing research and development in this field aim to harness the full potential of ferrofluids in addressing these critical environmental challenges, paving the way for innovative and sustainable solutions.

In recent years, the focus of ferrofluid research has shifted towards environmental applications, aligning with global sustainability goals. This transition reflects a growing awareness of environmental challenges and the potential for innovative solutions. The unique properties of ferrofluids, particularly their ability to be precisely controlled by magnetic fields, have opened new avenues for addressing environmental issues.

One of the primary environmental goals driving ferrofluid innovation is water purification. Researchers are developing ferrofluid-based systems capable of removing contaminants from water bodies with unprecedented efficiency. These systems exploit the magnetic properties of ferrofluids to attract and separate pollutants, offering a promising alternative to traditional water treatment methods.

Another significant area of focus is oil spill remediation. Ferrofluids are being engineered to effectively contain and recover oil from water surfaces, potentially revolutionizing the approach to marine pollution incidents. The ability to manipulate ferrofluids remotely using magnetic fields allows for more precise and controlled clean-up operations, minimizing environmental impact.

In the realm of renewable energy, ferrofluids are being explored for enhancing the efficiency of solar thermal systems. By improving heat transfer and energy storage capabilities, ferrofluid-based technologies aim to contribute to the broader goal of sustainable energy production and consumption.

The evolution of ferrofluids is also closely tied to advancements in nanotechnology. As synthesis techniques improve, researchers are able to create ferrofluids with increasingly sophisticated properties, tailored for specific environmental applications. This includes the development of biocompatible ferrofluids for environmental monitoring and remediation in sensitive ecosystems.

Looking ahead, the trajectory of ferrofluid technology is closely aligned with key environmental objectives such as reducing pollution, conserving resources, and mitigating climate change impacts. The ongoing research and development in this field aim to harness the full potential of ferrofluids in addressing these critical environmental challenges, paving the way for innovative and sustainable solutions.

Market Demand for Eco-Friendly Ferrofluid Applications

The market demand for eco-friendly ferrofluid applications has been steadily growing in recent years, driven by increasing environmental concerns and the push for sustainable technologies. Ferrofluids, with their unique magnetic properties and potential for environmentally friendly applications, are attracting significant attention from various industries and research institutions.

In the environmental science sector, ferrofluids are showing promise in water treatment and pollution control. The ability of ferrofluids to selectively remove contaminants from water bodies has led to increased interest from municipal water treatment facilities and industrial wastewater management companies. This application addresses the growing global need for efficient and cost-effective water purification solutions.

The renewable energy sector is another area where eco-friendly ferrofluid applications are gaining traction. Solar thermal power plants are exploring the use of ferrofluids as heat transfer mediums, potentially increasing energy efficiency and reducing the environmental impact of power generation. This aligns with the global push towards cleaner energy sources and improved energy efficiency.

In the field of environmental remediation, ferrofluids are being investigated for their potential in soil decontamination and oil spill cleanup. The magnetic properties of ferrofluids allow for targeted removal of pollutants, offering a more precise and less invasive approach compared to traditional methods. This has sparked interest from environmental agencies and cleanup specialists seeking innovative solutions for complex contamination scenarios.

The automotive industry is also showing interest in eco-friendly ferrofluid applications, particularly in the development of more efficient and environmentally friendly cooling systems for electric vehicles. As the electric vehicle market continues to grow, the demand for advanced thermal management solutions using ferrofluids is expected to increase.

In the realm of green building technologies, ferrofluids are being explored for their potential in smart windows and energy-efficient building materials. The ability to control light transmission and heat flow using ferrofluids could lead to significant energy savings in commercial and residential buildings, aligning with the growing demand for sustainable construction practices.

The agricultural sector is another area where eco-friendly ferrofluid applications are gaining attention. Precision agriculture techniques are exploring the use of ferrofluids in targeted nutrient delivery and soil remediation, potentially reducing the use of harmful chemicals and improving crop yields.

As environmental regulations become more stringent worldwide, industries are increasingly seeking innovative solutions to meet compliance requirements. This regulatory pressure is expected to further drive the demand for eco-friendly ferrofluid applications across various sectors, from manufacturing to waste management.

In the environmental science sector, ferrofluids are showing promise in water treatment and pollution control. The ability of ferrofluids to selectively remove contaminants from water bodies has led to increased interest from municipal water treatment facilities and industrial wastewater management companies. This application addresses the growing global need for efficient and cost-effective water purification solutions.

The renewable energy sector is another area where eco-friendly ferrofluid applications are gaining traction. Solar thermal power plants are exploring the use of ferrofluids as heat transfer mediums, potentially increasing energy efficiency and reducing the environmental impact of power generation. This aligns with the global push towards cleaner energy sources and improved energy efficiency.

In the field of environmental remediation, ferrofluids are being investigated for their potential in soil decontamination and oil spill cleanup. The magnetic properties of ferrofluids allow for targeted removal of pollutants, offering a more precise and less invasive approach compared to traditional methods. This has sparked interest from environmental agencies and cleanup specialists seeking innovative solutions for complex contamination scenarios.

The automotive industry is also showing interest in eco-friendly ferrofluid applications, particularly in the development of more efficient and environmentally friendly cooling systems for electric vehicles. As the electric vehicle market continues to grow, the demand for advanced thermal management solutions using ferrofluids is expected to increase.

In the realm of green building technologies, ferrofluids are being explored for their potential in smart windows and energy-efficient building materials. The ability to control light transmission and heat flow using ferrofluids could lead to significant energy savings in commercial and residential buildings, aligning with the growing demand for sustainable construction practices.

The agricultural sector is another area where eco-friendly ferrofluid applications are gaining attention. Precision agriculture techniques are exploring the use of ferrofluids in targeted nutrient delivery and soil remediation, potentially reducing the use of harmful chemicals and improving crop yields.

As environmental regulations become more stringent worldwide, industries are increasingly seeking innovative solutions to meet compliance requirements. This regulatory pressure is expected to further drive the demand for eco-friendly ferrofluid applications across various sectors, from manufacturing to waste management.

Current Ferrofluid Technology and Environmental Challenges

Ferrofluids, a unique class of magnetic nanomaterials, have gained significant attention in environmental science due to their remarkable properties and potential applications. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit both magnetic and fluid characteristics, making them versatile for various environmental challenges.

Currently, ferrofluid technology is being explored for water treatment and purification. The magnetic properties of ferrofluids allow for efficient separation of contaminants from water sources. Researchers have developed ferrofluid-based systems that can remove heavy metals, organic pollutants, and microplastics from water with high efficiency. These systems utilize magnetic fields to manipulate the ferrofluid, creating a dynamic and controllable filtration process.

Another promising application of ferrofluids in environmental science is oil spill remediation. Ferrofluids can be designed to selectively absorb oil while repelling water, making them ideal for cleaning up oil spills in marine environments. When applied to an oil slick, the ferrofluid forms a thin film that encapsulates the oil, allowing for easy collection using magnetic fields.

In the field of air pollution control, ferrofluids are being investigated for their potential in capturing and removing airborne particulates. Magnetic nanoparticles in ferrofluids can attract and trap fine particles, including PM2.5 and other harmful pollutants, improving air quality in urban areas and industrial settings.

Despite these advancements, several challenges remain in the widespread adoption of ferrofluid technology for environmental applications. One major concern is the long-term stability of ferrofluids in diverse environmental conditions. Exposure to varying pH levels, temperatures, and chemical compositions can affect the performance and durability of ferrofluids, potentially limiting their effectiveness in real-world scenarios.

Additionally, the potential environmental impact of ferrofluids themselves needs careful consideration. While these materials show promise in addressing various environmental issues, their own ecological footprint and potential toxicity must be thoroughly evaluated to ensure they do not introduce new environmental risks.

Scaling up ferrofluid-based technologies for large-scale environmental applications also presents significant engineering challenges. Developing cost-effective production methods and designing systems that can handle large volumes of pollutants efficiently are crucial steps in transitioning from laboratory success to practical implementation.

As research in this field progresses, addressing these challenges will be key to unlocking the full potential of ferrofluids in environmental science. Continued innovation in ferrofluid synthesis, functionalization, and application methodologies will drive new directions in tackling pressing environmental issues, from water and air pollution to ecosystem restoration and climate change mitigation.

Currently, ferrofluid technology is being explored for water treatment and purification. The magnetic properties of ferrofluids allow for efficient separation of contaminants from water sources. Researchers have developed ferrofluid-based systems that can remove heavy metals, organic pollutants, and microplastics from water with high efficiency. These systems utilize magnetic fields to manipulate the ferrofluid, creating a dynamic and controllable filtration process.

Another promising application of ferrofluids in environmental science is oil spill remediation. Ferrofluids can be designed to selectively absorb oil while repelling water, making them ideal for cleaning up oil spills in marine environments. When applied to an oil slick, the ferrofluid forms a thin film that encapsulates the oil, allowing for easy collection using magnetic fields.

In the field of air pollution control, ferrofluids are being investigated for their potential in capturing and removing airborne particulates. Magnetic nanoparticles in ferrofluids can attract and trap fine particles, including PM2.5 and other harmful pollutants, improving air quality in urban areas and industrial settings.

Despite these advancements, several challenges remain in the widespread adoption of ferrofluid technology for environmental applications. One major concern is the long-term stability of ferrofluids in diverse environmental conditions. Exposure to varying pH levels, temperatures, and chemical compositions can affect the performance and durability of ferrofluids, potentially limiting their effectiveness in real-world scenarios.

Additionally, the potential environmental impact of ferrofluids themselves needs careful consideration. While these materials show promise in addressing various environmental issues, their own ecological footprint and potential toxicity must be thoroughly evaluated to ensure they do not introduce new environmental risks.

Scaling up ferrofluid-based technologies for large-scale environmental applications also presents significant engineering challenges. Developing cost-effective production methods and designing systems that can handle large volumes of pollutants efficiently are crucial steps in transitioning from laboratory success to practical implementation.

As research in this field progresses, addressing these challenges will be key to unlocking the full potential of ferrofluids in environmental science. Continued innovation in ferrofluid synthesis, functionalization, and application methodologies will drive new directions in tackling pressing environmental issues, from water and air pollution to ecosystem restoration and climate change mitigation.

Existing Ferrofluid Solutions for Environmental Issues

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are used in various sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, contamination-resistant seals that can operate in vacuum or high-pressure environments. The magnetic properties of ferrofluids allow them to be retained in place while providing effective sealing and lubrication.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly for electronic devices and power systems. They can be used in heat sinks, cooling systems, and thermal interfaces to enhance heat transfer and dissipation. The magnetic properties of ferrofluids allow for controlled movement and positioning within cooling systems.

- Damping and vibration control: Ferrofluids are utilized in damping systems and vibration control applications. Their unique properties allow for adaptive damping in response to magnetic fields, making them suitable for use in shock absorbers, vibration isolators, and acoustic devices. The controllable viscosity of ferrofluids enables tunable damping characteristics.

- Sensing and measurement applications: Ferrofluids find applications in various sensing and measurement devices. They are used in accelerometers, inclinometers, and position sensors, leveraging their response to magnetic fields and gravity. Ferrofluid-based sensors can provide accurate measurements of tilt, acceleration, and fluid levels in different industrial and scientific applications.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials while minimizing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices and in thermal management applications. The ability to control the fluid's movement using magnetic fields allows for targeted cooling and improved heat dissipation.Expand Specific Solutions04 Damping and vibration control

The unique properties of ferrofluids make them suitable for damping applications and vibration control. They can be used in shock absorbers, inertial dampers, and other systems where controlled energy dissipation is required. The magnetic nature of the fluid allows for adaptive damping characteristics.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are employed in various sensing and measurement devices. They can be used in accelerometers, inclinometers, and other instruments that rely on fluid movement or displacement. The magnetic properties of the fluid allow for precise control and measurement of its behavior under different conditions.Expand Specific Solutions

Key Players in Ferrofluid Environmental Research

The ferrofluid innovations market is in a growth phase, driven by increasing applications in environmental science. The global market size for ferrofluids is projected to expand significantly in the coming years, fueled by advancements in nanotechnology and growing environmental concerns. While the technology is maturing, it still offers substantial room for innovation. Companies like Ferrotec (USA) Corp. and LORD Corp. are leading players, leveraging their expertise in ferrofluid technology to develop novel environmental applications. Academic institutions such as Northeastern University and Shandong University are also contributing to research and development in this field, indicating a collaborative ecosystem between industry and academia. The involvement of major corporations like 3M Innovative Properties Co. and Honeywell International Technologies Ltd. suggests growing interest in commercializing ferrofluid-based environmental solutions.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid technologies for environmental applications. Their innovative approach involves using nanoparticle-based ferrofluids for water purification and oil spill cleanup. The company's ferrofluids are engineered to selectively attract and capture pollutants in water bodies. For oil spill remediation, Ferrotec has created magnetic ferrofluid barriers that can contain and collect oil on water surfaces [1]. Additionally, they have developed ferrofluid-based filtration systems that can remove heavy metals and organic contaminants from industrial wastewater with high efficiency [3]. Ferrotec's research also extends to using ferrofluids for enhancing heat transfer in environmental control systems, potentially reducing energy consumption in HVAC applications [5].

Strengths: Specialized expertise in ferrofluid technology, diverse environmental applications, proven effectiveness in pollutant removal. Weaknesses: Potential high costs for large-scale implementation, limited data on long-term environmental impacts of nanoparticles.

LORD Corp.

Technical Solution: LORD Corporation has pioneered the use of magnetorheological (MR) fluids, a type of smart ferrofluid, in environmental science applications. Their technology focuses on creating adaptive damping systems for vibration control in wind turbines and other renewable energy infrastructure. LORD's MR fluids can change viscosity in milliseconds when exposed to a magnetic field, allowing for real-time adjustment of damping properties [2]. This innovation has led to increased efficiency and longevity of wind turbines by reducing structural stress. Furthermore, LORD has developed ferrofluid-based sealing solutions for industrial equipment, minimizing leakage of harmful chemicals into the environment [4]. The company is also exploring the use of their MR technology in water treatment processes, particularly for the removal of suspended solids in wastewater [6].

Strengths: Advanced MR fluid technology, applications in renewable energy sector, potential for improving industrial environmental safety. Weaknesses: Limited focus on direct environmental remediation, technology may be complex to implement in some settings.

Core Innovations in Eco-Friendly Ferrofluid Technology

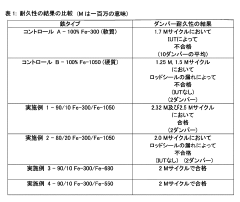

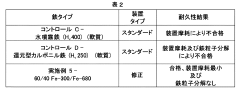

High durability ferrofluid

PatentInactiveJP2012529160A

Innovation

- A ferrofluid composition comprising a mixture of relatively soft and hard magnetically responsive particles, with specific size ranges and hardness characteristics, is used to enhance durability and reduce particle decomposition.

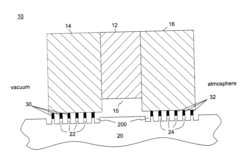

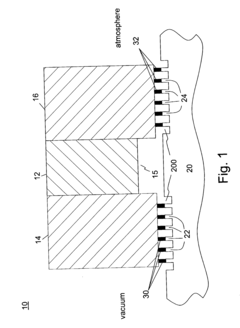

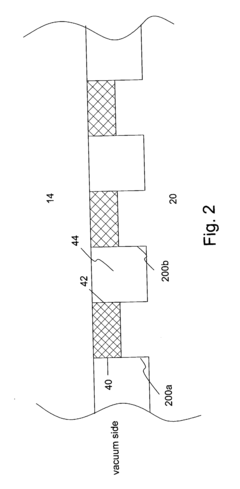

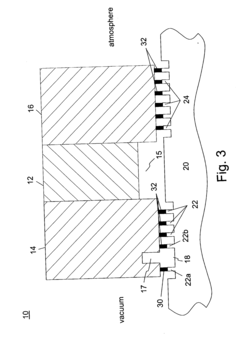

Ferrofluid seal incorporating multiple types of ferrofluid

PatentInactiveUS20040173972A1

Innovation

- A multi-stage ferrofluid seal apparatus utilizing multiple types of ferrofluids, where each type is optimized for specific stages based on environmental conditions, such as low evaporation rate and high viscosity for vacuum stages and lower viscosity and higher oxidation resistance for atmospheric stages, to balance performance requirements and reduce torque and heat generation.

Environmental Regulations Impacting Ferrofluid Use

The use of ferrofluids in environmental science applications is subject to a complex web of regulations that vary across jurisdictions and are continually evolving. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the use of ferrofluids, particularly in relation to their potential impact on water resources and ecosystems. The Clean Water Act and the Safe Drinking Water Act provide the primary regulatory framework for controlling the release of ferrofluids into aquatic environments.

European regulations, governed by the European Chemicals Agency (ECHA), tend to be more stringent. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation requires thorough safety assessments and registration of ferrofluids before they can be used in environmental applications. Additionally, the Water Framework Directive sets standards for water quality that must be considered when deploying ferrofluid-based technologies in aquatic environments.

In Asia, regulations vary significantly between countries. Japan, for instance, has implemented the Chemical Substances Control Law, which requires manufacturers to assess the environmental and health risks of ferrofluids before their use. China's Environmental Protection Law has been strengthened in recent years, imposing stricter controls on the use of novel materials like ferrofluids in environmental applications.

Globally, the Stockholm Convention on Persistent Organic Pollutants influences the regulation of ferrofluids, particularly those containing organic solvents or coatings. This international treaty aims to eliminate or restrict the production and use of persistent organic pollutants, which may include certain components used in ferrofluid formulations.

Regulatory bodies are increasingly focusing on the potential long-term environmental impacts of nanoparticles, including those found in ferrofluids. The Organization for Economic Co-operation and Development (OECD) has developed guidelines for testing the safety of manufactured nanomaterials, which are being adopted by many countries and influencing ferrofluid regulations.

As environmental applications of ferrofluids expand, regulators are grappling with the need to balance innovation with precaution. Many jurisdictions are adopting a "precautionary principle" approach, requiring extensive safety data before approving new ferrofluid applications. This has led to the development of more rigorous testing protocols and risk assessment methodologies specific to ferrofluid technologies.

The disposal of ferrofluids used in environmental applications is another area of regulatory focus. Many countries now classify used ferrofluids as hazardous waste, subject to special handling and disposal requirements. This has implications for the entire lifecycle of ferrofluid-based environmental technologies, from development to decommissioning.

European regulations, governed by the European Chemicals Agency (ECHA), tend to be more stringent. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation requires thorough safety assessments and registration of ferrofluids before they can be used in environmental applications. Additionally, the Water Framework Directive sets standards for water quality that must be considered when deploying ferrofluid-based technologies in aquatic environments.

In Asia, regulations vary significantly between countries. Japan, for instance, has implemented the Chemical Substances Control Law, which requires manufacturers to assess the environmental and health risks of ferrofluids before their use. China's Environmental Protection Law has been strengthened in recent years, imposing stricter controls on the use of novel materials like ferrofluids in environmental applications.

Globally, the Stockholm Convention on Persistent Organic Pollutants influences the regulation of ferrofluids, particularly those containing organic solvents or coatings. This international treaty aims to eliminate or restrict the production and use of persistent organic pollutants, which may include certain components used in ferrofluid formulations.

Regulatory bodies are increasingly focusing on the potential long-term environmental impacts of nanoparticles, including those found in ferrofluids. The Organization for Economic Co-operation and Development (OECD) has developed guidelines for testing the safety of manufactured nanomaterials, which are being adopted by many countries and influencing ferrofluid regulations.

As environmental applications of ferrofluids expand, regulators are grappling with the need to balance innovation with precaution. Many jurisdictions are adopting a "precautionary principle" approach, requiring extensive safety data before approving new ferrofluid applications. This has led to the development of more rigorous testing protocols and risk assessment methodologies specific to ferrofluid technologies.

The disposal of ferrofluids used in environmental applications is another area of regulatory focus. Many countries now classify used ferrofluids as hazardous waste, subject to special handling and disposal requirements. This has implications for the entire lifecycle of ferrofluid-based environmental technologies, from development to decommissioning.

Sustainability Assessment of Ferrofluid Technologies

The sustainability assessment of ferrofluid technologies is a critical aspect of evaluating their long-term viability and environmental impact. Ferrofluids, being colloidal suspensions of magnetic nanoparticles, offer unique properties that have sparked interest in various environmental applications. However, their widespread adoption necessitates a comprehensive analysis of their sustainability across multiple dimensions.

One key consideration is the life cycle assessment of ferrofluid production and use. The synthesis of ferrofluids typically involves the use of iron oxide nanoparticles, which may require energy-intensive processes and potentially harmful chemicals. Evaluating the environmental footprint of these production methods is essential to determine the overall sustainability of ferrofluid technologies.

The recyclability and end-of-life management of ferrofluids also play a crucial role in their sustainability profile. As these materials are often used in specialized applications, developing efficient recycling processes and proper disposal methods is vital to minimize environmental impact and resource depletion.

Energy efficiency is another important factor in assessing the sustainability of ferrofluid technologies. While ferrofluids can enhance the performance of certain systems, such as heat transfer applications, it is necessary to quantify the energy savings achieved compared to conventional methods. This analysis should consider both the operational energy requirements and the embodied energy in the production of ferrofluids.

The potential environmental risks associated with the release of ferrofluids into ecosystems must be thoroughly evaluated. This includes assessing their biodegradability, potential for bioaccumulation, and effects on aquatic and terrestrial organisms. Long-term studies on the ecological impact of ferrofluids are essential to ensure their safe use in environmental applications.

Resource efficiency is another critical aspect of sustainability assessment. The use of rare earth elements or other scarce materials in ferrofluid production could raise concerns about resource depletion and geopolitical dependencies. Exploring alternative formulations or developing more sustainable sourcing strategies for raw materials is crucial for the long-term viability of ferrofluid technologies.

Lastly, the economic sustainability of ferrofluid technologies must be considered. This involves analyzing the cost-effectiveness of ferrofluid-based solutions compared to existing alternatives, as well as evaluating the potential for scalability and market adoption. A holistic approach that balances environmental benefits with economic feasibility is essential for the successful implementation of ferrofluid innovations in environmental science.

One key consideration is the life cycle assessment of ferrofluid production and use. The synthesis of ferrofluids typically involves the use of iron oxide nanoparticles, which may require energy-intensive processes and potentially harmful chemicals. Evaluating the environmental footprint of these production methods is essential to determine the overall sustainability of ferrofluid technologies.

The recyclability and end-of-life management of ferrofluids also play a crucial role in their sustainability profile. As these materials are often used in specialized applications, developing efficient recycling processes and proper disposal methods is vital to minimize environmental impact and resource depletion.

Energy efficiency is another important factor in assessing the sustainability of ferrofluid technologies. While ferrofluids can enhance the performance of certain systems, such as heat transfer applications, it is necessary to quantify the energy savings achieved compared to conventional methods. This analysis should consider both the operational energy requirements and the embodied energy in the production of ferrofluids.

The potential environmental risks associated with the release of ferrofluids into ecosystems must be thoroughly evaluated. This includes assessing their biodegradability, potential for bioaccumulation, and effects on aquatic and terrestrial organisms. Long-term studies on the ecological impact of ferrofluids are essential to ensure their safe use in environmental applications.

Resource efficiency is another critical aspect of sustainability assessment. The use of rare earth elements or other scarce materials in ferrofluid production could raise concerns about resource depletion and geopolitical dependencies. Exploring alternative formulations or developing more sustainable sourcing strategies for raw materials is crucial for the long-term viability of ferrofluid technologies.

Lastly, the economic sustainability of ferrofluid technologies must be considered. This involves analyzing the cost-effectiveness of ferrofluid-based solutions compared to existing alternatives, as well as evaluating the potential for scalability and market adoption. A holistic approach that balances environmental benefits with economic feasibility is essential for the successful implementation of ferrofluid innovations in environmental science.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!