Green Zeolite Synthesis from Agricultural Residues

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zeolite Synthesis Background and Objectives

Zeolites have been a subject of intense research and development for several decades due to their unique structural properties and wide-ranging applications. These crystalline aluminosilicates possess a three-dimensional framework structure with uniform molecular-sized pores, making them invaluable in various industrial processes. The journey of zeolite synthesis began in the mid-20th century, with initial efforts focused on mimicking natural zeolite formation conditions. As understanding of their structure and properties grew, so did the methods for their synthetic production.

The evolution of zeolite synthesis techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly processes. Traditional methods often involved high-temperature hydrothermal synthesis using chemical precursors, which, while effective, posed environmental concerns and high energy costs. This has led to a growing interest in developing greener synthesis routes, particularly those utilizing renewable resources.

In recent years, the concept of green zeolite synthesis has gained significant traction, with a particular focus on using agricultural residues as precursors. This approach aligns with the principles of circular economy and waste valorization, offering a sustainable alternative to conventional synthesis methods. Agricultural residues, such as rice husks, corn cobs, and sugarcane bagasse, are rich in silica and other minerals, making them potential candidates for zeolite synthesis.

The primary objective of green zeolite synthesis from agricultural residues is to develop a sustainable and economically viable process that can produce high-quality zeolites while minimizing environmental impact. This involves optimizing extraction methods to efficiently obtain silica and other necessary components from agricultural waste, developing low-energy synthesis protocols, and ensuring the final products meet the stringent quality standards required for industrial applications.

Another crucial goal is to expand the range of zeolite types that can be synthesized using these green methods. While certain zeolite structures have been successfully produced from agricultural residues, there is ongoing research to broaden this spectrum, potentially leading to novel zeolite structures with unique properties and applications. Additionally, researchers aim to improve the scalability of these green synthesis methods, bridging the gap between laboratory-scale production and industrial-scale manufacturing.

The pursuit of green zeolite synthesis also encompasses the broader objective of contributing to sustainable development goals. By transforming agricultural waste into high-value materials, this technology has the potential to create new economic opportunities in agricultural regions, reduce waste, and decrease the carbon footprint associated with zeolite production. As such, the development of this technology is not just a scientific endeavor but also a step towards more sustainable industrial practices and circular economy models.

The evolution of zeolite synthesis techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly processes. Traditional methods often involved high-temperature hydrothermal synthesis using chemical precursors, which, while effective, posed environmental concerns and high energy costs. This has led to a growing interest in developing greener synthesis routes, particularly those utilizing renewable resources.

In recent years, the concept of green zeolite synthesis has gained significant traction, with a particular focus on using agricultural residues as precursors. This approach aligns with the principles of circular economy and waste valorization, offering a sustainable alternative to conventional synthesis methods. Agricultural residues, such as rice husks, corn cobs, and sugarcane bagasse, are rich in silica and other minerals, making them potential candidates for zeolite synthesis.

The primary objective of green zeolite synthesis from agricultural residues is to develop a sustainable and economically viable process that can produce high-quality zeolites while minimizing environmental impact. This involves optimizing extraction methods to efficiently obtain silica and other necessary components from agricultural waste, developing low-energy synthesis protocols, and ensuring the final products meet the stringent quality standards required for industrial applications.

Another crucial goal is to expand the range of zeolite types that can be synthesized using these green methods. While certain zeolite structures have been successfully produced from agricultural residues, there is ongoing research to broaden this spectrum, potentially leading to novel zeolite structures with unique properties and applications. Additionally, researchers aim to improve the scalability of these green synthesis methods, bridging the gap between laboratory-scale production and industrial-scale manufacturing.

The pursuit of green zeolite synthesis also encompasses the broader objective of contributing to sustainable development goals. By transforming agricultural waste into high-value materials, this technology has the potential to create new economic opportunities in agricultural regions, reduce waste, and decrease the carbon footprint associated with zeolite production. As such, the development of this technology is not just a scientific endeavor but also a step towards more sustainable industrial practices and circular economy models.

Market Analysis for Green Zeolites

The market for green zeolites synthesized from agricultural residues is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable materials. This eco-friendly approach to zeolite production aligns with circular economy principles, offering a solution to agricultural waste management while creating valuable products for various industries.

The global zeolite market, valued at approximately $33 billion in 2021, is projected to reach $46 billion by 2028, with a compound annual growth rate (CAGR) of 5.2%. Green zeolites are poised to capture a growing share of this market due to their sustainability credentials and cost-effectiveness. The agricultural residue-based zeolite segment is expected to grow at a higher rate than the overall market, potentially reaching a CAGR of 7-8% in the coming years.

Key industries driving the demand for green zeolites include water treatment, agriculture, construction, and petrochemicals. In the water treatment sector, green zeolites are increasingly used for their excellent ion-exchange properties, contributing to the removal of heavy metals and other contaminants. The agriculture industry is adopting these materials for soil amendment and slow-release fertilizers, leveraging their ability to retain nutrients and improve soil quality.

The construction sector is incorporating green zeolites into cement and concrete formulations to enhance strength and durability while reducing the carbon footprint of building materials. In petrochemicals, these sustainable zeolites are finding applications in catalysis and gas separation processes, offering environmentally friendly alternatives to traditional synthetic zeolites.

Geographically, Asia-Pacific is expected to be the fastest-growing market for green zeolites, driven by rapid industrialization, increasing environmental regulations, and abundant agricultural residues in countries like China and India. North America and Europe are also significant markets, with strong demand in water treatment and sustainable construction applications.

The market for green zeolites faces some challenges, including the need for standardization of production processes and quality control measures. However, ongoing research and development efforts are addressing these issues, focusing on optimizing synthesis methods and expanding the range of agricultural residues that can be used as raw materials.

As sustainability becomes a key focus across industries, the market for green zeolites is expected to benefit from favorable government policies, increasing corporate sustainability initiatives, and growing consumer awareness of eco-friendly products. This trend is likely to drive further investment in research and commercialization of agricultural residue-based zeolites, expanding their market potential in the coming years.

The global zeolite market, valued at approximately $33 billion in 2021, is projected to reach $46 billion by 2028, with a compound annual growth rate (CAGR) of 5.2%. Green zeolites are poised to capture a growing share of this market due to their sustainability credentials and cost-effectiveness. The agricultural residue-based zeolite segment is expected to grow at a higher rate than the overall market, potentially reaching a CAGR of 7-8% in the coming years.

Key industries driving the demand for green zeolites include water treatment, agriculture, construction, and petrochemicals. In the water treatment sector, green zeolites are increasingly used for their excellent ion-exchange properties, contributing to the removal of heavy metals and other contaminants. The agriculture industry is adopting these materials for soil amendment and slow-release fertilizers, leveraging their ability to retain nutrients and improve soil quality.

The construction sector is incorporating green zeolites into cement and concrete formulations to enhance strength and durability while reducing the carbon footprint of building materials. In petrochemicals, these sustainable zeolites are finding applications in catalysis and gas separation processes, offering environmentally friendly alternatives to traditional synthetic zeolites.

Geographically, Asia-Pacific is expected to be the fastest-growing market for green zeolites, driven by rapid industrialization, increasing environmental regulations, and abundant agricultural residues in countries like China and India. North America and Europe are also significant markets, with strong demand in water treatment and sustainable construction applications.

The market for green zeolites faces some challenges, including the need for standardization of production processes and quality control measures. However, ongoing research and development efforts are addressing these issues, focusing on optimizing synthesis methods and expanding the range of agricultural residues that can be used as raw materials.

As sustainability becomes a key focus across industries, the market for green zeolites is expected to benefit from favorable government policies, increasing corporate sustainability initiatives, and growing consumer awareness of eco-friendly products. This trend is likely to drive further investment in research and commercialization of agricultural residue-based zeolites, expanding their market potential in the coming years.

Current Challenges in Agricultural Residue Utilization

The utilization of agricultural residues for green zeolite synthesis faces several significant challenges. One of the primary obstacles is the heterogeneous nature of agricultural waste materials. These residues vary widely in composition, moisture content, and physical properties, making it difficult to establish standardized processing methods. The inconsistency in feedstock quality can lead to variations in the final zeolite product, affecting its performance and applicability.

Another major challenge lies in the pretreatment of agricultural residues. Many of these materials contain complex organic compounds, such as lignin and cellulose, which can interfere with zeolite formation. Effective pretreatment methods are necessary to remove or convert these compounds, but current techniques often involve energy-intensive processes or the use of harsh chemicals, which can compromise the environmental benefits of using agricultural waste.

The extraction of silica, a crucial component for zeolite synthesis, from agricultural residues presents its own set of challenges. While many agricultural wastes are rich in silica, the extraction process can be inefficient and often requires high temperatures or strong alkaline conditions. This not only increases energy consumption but also generates additional waste streams that need to be managed.

Scale-up and commercialization of green zeolite synthesis from agricultural residues face economic hurdles. The collection, transportation, and storage of agricultural waste can be costly, especially when considering the seasonal availability of many crop residues. Additionally, the processing equipment and infrastructure required for large-scale production may necessitate significant capital investment, which can deter industrial adoption.

The purification and quality control of zeolites produced from agricultural residues remain challenging. Impurities inherent in the biomass feedstock can affect the crystallization process and the final product properties. Developing efficient purification methods that do not compromise the sustainability of the overall process is crucial for producing high-quality zeolites suitable for various applications.

Lastly, there is a need for more comprehensive life cycle assessments to fully understand the environmental impact of using agricultural residues for zeolite synthesis. While the approach promises to be more sustainable than traditional methods, factors such as transportation emissions, water usage, and waste generation throughout the production chain must be carefully evaluated to ensure a net positive environmental outcome.

Another major challenge lies in the pretreatment of agricultural residues. Many of these materials contain complex organic compounds, such as lignin and cellulose, which can interfere with zeolite formation. Effective pretreatment methods are necessary to remove or convert these compounds, but current techniques often involve energy-intensive processes or the use of harsh chemicals, which can compromise the environmental benefits of using agricultural waste.

The extraction of silica, a crucial component for zeolite synthesis, from agricultural residues presents its own set of challenges. While many agricultural wastes are rich in silica, the extraction process can be inefficient and often requires high temperatures or strong alkaline conditions. This not only increases energy consumption but also generates additional waste streams that need to be managed.

Scale-up and commercialization of green zeolite synthesis from agricultural residues face economic hurdles. The collection, transportation, and storage of agricultural waste can be costly, especially when considering the seasonal availability of many crop residues. Additionally, the processing equipment and infrastructure required for large-scale production may necessitate significant capital investment, which can deter industrial adoption.

The purification and quality control of zeolites produced from agricultural residues remain challenging. Impurities inherent in the biomass feedstock can affect the crystallization process and the final product properties. Developing efficient purification methods that do not compromise the sustainability of the overall process is crucial for producing high-quality zeolites suitable for various applications.

Lastly, there is a need for more comprehensive life cycle assessments to fully understand the environmental impact of using agricultural residues for zeolite synthesis. While the approach promises to be more sustainable than traditional methods, factors such as transportation emissions, water usage, and waste generation throughout the production chain must be carefully evaluated to ensure a net positive environmental outcome.

Existing Green Zeolite Synthesis Techniques

01 Zeolite synthesis and modification

Various methods for synthesizing and modifying zeolites to enhance their properties and performance. This includes techniques for controlling crystal size, morphology, and composition, as well as post-synthesis treatments to improve stability and functionality.- Synthesis and modification of zeolites: Various methods for synthesizing and modifying zeolites to enhance their properties and performance. This includes techniques for controlling pore size, improving stability, and tailoring the zeolite structure for specific applications.

- Zeolites in gas separation and purification: Application of zeolites in gas separation and purification processes, utilizing their molecular sieving properties. This includes the use of zeolites in air separation, natural gas purification, and removal of contaminants from various gas streams.

- Zeolites in catalysis and petrochemical processes: Utilization of zeolites as catalysts in various chemical reactions and petrochemical processes. This includes their application in fluid catalytic cracking, hydrocracking, and isomerization reactions to produce valuable products from crude oil and other feedstocks.

- Zeolites in water treatment and purification: Application of zeolites in water treatment and purification processes, leveraging their ion exchange and adsorption properties. This includes the removal of heavy metals, ammonia, and other contaminants from wastewater and drinking water.

- Zeolites in environmental applications: Use of zeolites in various environmental applications, including air pollution control, soil remediation, and radioactive waste treatment. This involves the adsorption and immobilization of pollutants and hazardous materials using zeolite-based materials.

02 Zeolite applications in gas separation and purification

Utilization of zeolites in gas separation and purification processes, including the removal of contaminants from air and industrial gases. This involves the development of specialized zeolite adsorbents and membranes for selective gas adsorption and separation.Expand Specific Solutions03 Zeolite-based catalysts for chemical processes

Development and application of zeolite-based catalysts for various chemical processes, including petrochemical refining, fine chemical synthesis, and environmental remediation. This involves tailoring zeolite properties to enhance catalytic activity, selectivity, and stability.Expand Specific Solutions04 Zeolite composites and hybrid materials

Creation of zeolite composites and hybrid materials by combining zeolites with other materials such as polymers, metals, or carbon-based materials. These composites often exhibit enhanced properties and find applications in areas like water treatment, energy storage, and sensing.Expand Specific Solutions05 Zeolite applications in environmental remediation

Use of zeolites for environmental remediation, including water treatment, soil decontamination, and air pollution control. This involves developing specialized zeolite formulations and treatment processes to remove pollutants and improve environmental quality.Expand Specific Solutions

Key Players in Green Zeolite Industry

The green zeolite synthesis from agricultural residues market is in its early growth stage, characterized by increasing research and development activities. The market size is expanding due to growing interest in sustainable materials and waste valorization. Technologically, it is still evolving, with varying levels of maturity among key players. Universities like Beijing Forestry University, University of Tokyo, and King Fahd University of Petroleum & Minerals are at the forefront of research, while companies such as BASF Corp. and LG Electronics, Inc. are exploring commercial applications. Research institutions like IFP Energies Nouvelles and Korea Institute of Geoscience & Mineral Resources are bridging the gap between academia and industry, driving innovation in this emerging field.

University of Tokyo

Technical Solution: The University of Tokyo has made significant advancements in green zeolite synthesis from agricultural residues, focusing on rice husk ash and bamboo leaf ash. Their approach utilizes a novel, low-energy hydrothermal synthesis method combined with microwave-assisted heating[10]. This technique allows for rapid crystallization of zeolites under mild conditions, significantly reducing the overall energy consumption. The research team has developed a unique pretreatment process that enhances the reactivity of the agricultural ash, enabling the formation of high-quality zeolites with controlled Si/Al ratios[11]. Additionally, they have successfully incorporated transition metal ions into the zeolite framework during synthesis, creating multifunctional materials with enhanced catalytic properties[12]. The university has also explored the use of deep eutectic solvents as green reaction media, further improving the sustainability of the synthesis process.

Strengths: Rapid synthesis, precise control over zeolite properties, and potential for multifunctional materials. Weaknesses: May require specialized microwave equipment, potentially increasing initial setup costs.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has pioneered a green zeolite synthesis method using agricultural residues, focusing on lignocellulosic biomass. Their approach involves a two-step process: first, the biomass undergoes a hydrothermal pretreatment to extract silica and other inorganic components[4]. The extracted silica is then used as a precursor for zeolite synthesis under mild conditions. IFP has developed a proprietary catalyst system that enhances the crystallization process, resulting in zeolites with tailored properties for specific applications[5]. The company has successfully scaled up this technology, demonstrating its feasibility for industrial production. Additionally, IFP has integrated a circular economy approach by utilizing the remaining organic fraction of the biomass for biofuel production[6].

Strengths: Holistic approach combining zeolite synthesis with biofuel production, scalable technology. Weaknesses: May require specialized equipment for biomass pretreatment, potentially limiting widespread adoption.

Innovative Agricultural Residue Conversion Processes

Zeolite production method

PatentWO2012002367A1

Innovation

- A method involving the use of zeolite seed crystals and a gel composition containing a silica source, an alumina source, an alkali source, and water to synthesize zeolites without organic SDAs, allowing for a wide range of SiO2/Al2O3 ratios and eliminating the need for calcination, thereby reducing costs and environmental impact.

Method for the synthesis of zeolites from raw materials and sources of energy alternatives to the conventional use.

PatentPendingMX2023013103A

Innovation

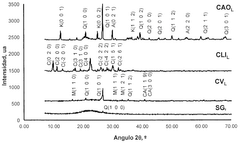

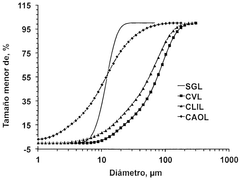

- The method involves using microwaves, ultrasound, or a combination of both with conventional heating to transform thermodynamically stable phases in fly ash, geothermal silica, and natural zeolites into more reactive silicates and aluminates, which are then used to synthesize zeolites with varying S1O2/AI2O3 ratios, reducing energy consumption and production costs.

Environmental Impact Assessment

The environmental impact assessment of green zeolite synthesis from agricultural residues reveals significant potential for sustainable materials production. This innovative approach addresses two critical environmental challenges: the management of agricultural waste and the reduction of carbon emissions associated with traditional zeolite synthesis methods.

Agricultural residues, such as rice husks, corn stalks, and sugarcane bagasse, are abundant and often underutilized resources. By repurposing these materials for zeolite synthesis, the process effectively diverts waste from landfills or open burning, which can contribute to air pollution and greenhouse gas emissions. The utilization of these residues also reduces the demand for virgin raw materials, thereby conserving natural resources and minimizing the environmental footprint of zeolite production.

The green synthesis process typically employs lower temperatures and milder reaction conditions compared to conventional methods. This results in reduced energy consumption and, consequently, lower carbon dioxide emissions. Studies have shown that the carbon footprint of green zeolite synthesis can be up to 50% lower than that of traditional synthesis routes, depending on the specific agricultural residue and process parameters used.

Water usage is another critical environmental factor to consider. Green zeolite synthesis often requires less water compared to conventional methods, as the agricultural residues themselves contain moisture and organic compounds that can facilitate the reaction. This reduction in water consumption is particularly beneficial in water-stressed regions where zeolite production facilities may be located.

The process also generates fewer harmful by-products and waste streams. Traditional zeolite synthesis often involves the use of toxic organic templates and strong alkaline solutions, which can pose environmental risks if not properly managed. In contrast, green synthesis methods typically utilize more benign reagents and produce less hazardous waste, reducing the potential for soil and water contamination.

Furthermore, the life cycle assessment of green zeolite synthesis indicates potential benefits in terms of resource efficiency and circular economy principles. The process not only valorizes agricultural waste but also produces a high-value material with numerous applications in catalysis, adsorption, and ion exchange. This closed-loop approach aligns well with sustainability goals and promotes the development of eco-friendly industrial processes.

However, it is important to note that the environmental impact can vary depending on the specific agricultural residue used and the process conditions employed. Factors such as transportation distances, pre-treatment requirements, and the efficiency of the synthesis process must be carefully evaluated to ensure that the overall environmental benefits are realized. Additionally, the scalability of green zeolite synthesis and its ability to meet industrial demand without compromising quality or performance are crucial considerations for widespread adoption and long-term environmental impact.

Agricultural residues, such as rice husks, corn stalks, and sugarcane bagasse, are abundant and often underutilized resources. By repurposing these materials for zeolite synthesis, the process effectively diverts waste from landfills or open burning, which can contribute to air pollution and greenhouse gas emissions. The utilization of these residues also reduces the demand for virgin raw materials, thereby conserving natural resources and minimizing the environmental footprint of zeolite production.

The green synthesis process typically employs lower temperatures and milder reaction conditions compared to conventional methods. This results in reduced energy consumption and, consequently, lower carbon dioxide emissions. Studies have shown that the carbon footprint of green zeolite synthesis can be up to 50% lower than that of traditional synthesis routes, depending on the specific agricultural residue and process parameters used.

Water usage is another critical environmental factor to consider. Green zeolite synthesis often requires less water compared to conventional methods, as the agricultural residues themselves contain moisture and organic compounds that can facilitate the reaction. This reduction in water consumption is particularly beneficial in water-stressed regions where zeolite production facilities may be located.

The process also generates fewer harmful by-products and waste streams. Traditional zeolite synthesis often involves the use of toxic organic templates and strong alkaline solutions, which can pose environmental risks if not properly managed. In contrast, green synthesis methods typically utilize more benign reagents and produce less hazardous waste, reducing the potential for soil and water contamination.

Furthermore, the life cycle assessment of green zeolite synthesis indicates potential benefits in terms of resource efficiency and circular economy principles. The process not only valorizes agricultural waste but also produces a high-value material with numerous applications in catalysis, adsorption, and ion exchange. This closed-loop approach aligns well with sustainability goals and promotes the development of eco-friendly industrial processes.

However, it is important to note that the environmental impact can vary depending on the specific agricultural residue used and the process conditions employed. Factors such as transportation distances, pre-treatment requirements, and the efficiency of the synthesis process must be carefully evaluated to ensure that the overall environmental benefits are realized. Additionally, the scalability of green zeolite synthesis and its ability to meet industrial demand without compromising quality or performance are crucial considerations for widespread adoption and long-term environmental impact.

Regulatory Framework for Green Materials

The regulatory framework for green materials plays a crucial role in promoting and governing the development of sustainable technologies like green zeolite synthesis from agricultural residues. This framework encompasses a range of policies, standards, and guidelines designed to encourage the adoption of environmentally friendly practices and materials across various industries.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) have established guidelines for sustainable chemistry and waste management. These guidelines provide a foundation for national and regional regulatory bodies to develop more specific regulations for green materials.

In the context of green zeolite synthesis, regulatory frameworks often focus on several key areas. Waste management regulations play a significant role, as they govern the collection, handling, and processing of agricultural residues used as raw materials. These regulations ensure that the sourcing of agricultural waste for zeolite synthesis does not interfere with existing waste management systems or create unintended environmental impacts.

Environmental protection regulations also form a critical component of the framework. These regulations typically set standards for emissions, water quality, and soil contamination, which green zeolite synthesis processes must adhere to. Additionally, they may mandate the use of life cycle assessments to evaluate the overall environmental impact of the production process and final product.

Product safety and quality standards are another essential aspect of the regulatory framework. As green zeolites may be used in various applications, including water treatment, catalysis, and agriculture, they must meet stringent safety and performance criteria. Regulatory bodies often require extensive testing and certification processes to ensure that green zeolites meet these standards.

Incentive programs and tax policies are frequently incorporated into the regulatory framework to encourage the development and adoption of green materials. These may include research grants, tax credits for companies investing in sustainable technologies, or preferential treatment in government procurement processes for products incorporating green materials.

As the field of green zeolite synthesis from agricultural residues continues to evolve, regulatory frameworks must adapt to keep pace with technological advancements. This often involves regular reviews and updates to existing regulations, as well as the development of new standards specific to emerging green technologies. Collaboration between regulatory bodies, research institutions, and industry stakeholders is crucial in ensuring that the regulatory framework remains effective and supportive of innovation in green materials.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) have established guidelines for sustainable chemistry and waste management. These guidelines provide a foundation for national and regional regulatory bodies to develop more specific regulations for green materials.

In the context of green zeolite synthesis, regulatory frameworks often focus on several key areas. Waste management regulations play a significant role, as they govern the collection, handling, and processing of agricultural residues used as raw materials. These regulations ensure that the sourcing of agricultural waste for zeolite synthesis does not interfere with existing waste management systems or create unintended environmental impacts.

Environmental protection regulations also form a critical component of the framework. These regulations typically set standards for emissions, water quality, and soil contamination, which green zeolite synthesis processes must adhere to. Additionally, they may mandate the use of life cycle assessments to evaluate the overall environmental impact of the production process and final product.

Product safety and quality standards are another essential aspect of the regulatory framework. As green zeolites may be used in various applications, including water treatment, catalysis, and agriculture, they must meet stringent safety and performance criteria. Regulatory bodies often require extensive testing and certification processes to ensure that green zeolites meet these standards.

Incentive programs and tax policies are frequently incorporated into the regulatory framework to encourage the development and adoption of green materials. These may include research grants, tax credits for companies investing in sustainable technologies, or preferential treatment in government procurement processes for products incorporating green materials.

As the field of green zeolite synthesis from agricultural residues continues to evolve, regulatory frameworks must adapt to keep pace with technological advancements. This often involves regular reviews and updates to existing regulations, as well as the development of new standards specific to emerging green technologies. Collaboration between regulatory bodies, research institutions, and industry stakeholders is crucial in ensuring that the regulatory framework remains effective and supportive of innovation in green materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!