How Dimethyl Ether Supports Life Cycle Energy Assessments?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, gaining attention in the context of life cycle energy assessments. The development of DME technology can be traced back to the early 20th century, but its potential as a sustainable energy source has only recently been recognized. As global efforts to reduce carbon emissions intensify, DME has become a focal point for researchers and industry professionals seeking cleaner alternatives to conventional fossil fuels.

The evolution of DME technology has been driven by the need for more environmentally friendly energy solutions. Initially used primarily as an aerosol propellant, DME's potential as a fuel was realized in the 1990s. Since then, significant advancements have been made in production methods, storage, and utilization technologies. The growing interest in DME is largely due to its favorable properties, including high cetane number, low emissions, and the ability to be produced from various feedstocks, including renewable sources.

In the context of life cycle energy assessments, DME offers several advantages that align with sustainability goals. Its production process can be designed to have a lower carbon footprint compared to conventional fuels, especially when derived from biomass or waste materials. The versatility of DME as both a fuel and a chemical intermediate further enhances its potential to contribute to a more circular economy.

The primary objective of exploring DME in life cycle energy assessments is to quantify its environmental impact across its entire life cycle, from production to end-use. This comprehensive evaluation aims to determine the net energy balance, greenhouse gas emissions, and overall sustainability of DME compared to other energy carriers. By conducting thorough life cycle assessments, researchers and policymakers can make informed decisions about the role of DME in future energy systems.

Another key goal is to identify opportunities for optimizing DME production and utilization processes to maximize energy efficiency and minimize environmental impact. This includes exploring innovative production pathways, such as the integration of renewable energy sources in DME synthesis, and developing more efficient end-use technologies, particularly in the transportation and industrial sectors.

Furthermore, the assessment of DME within the life cycle energy framework seeks to address potential challenges and limitations associated with its widespread adoption. This involves evaluating infrastructure requirements, economic feasibility, and potential competition with other alternative fuels. By anticipating and addressing these challenges, stakeholders can develop strategies to overcome barriers to DME implementation and realize its full potential as a sustainable energy solution.

The evolution of DME technology has been driven by the need for more environmentally friendly energy solutions. Initially used primarily as an aerosol propellant, DME's potential as a fuel was realized in the 1990s. Since then, significant advancements have been made in production methods, storage, and utilization technologies. The growing interest in DME is largely due to its favorable properties, including high cetane number, low emissions, and the ability to be produced from various feedstocks, including renewable sources.

In the context of life cycle energy assessments, DME offers several advantages that align with sustainability goals. Its production process can be designed to have a lower carbon footprint compared to conventional fuels, especially when derived from biomass or waste materials. The versatility of DME as both a fuel and a chemical intermediate further enhances its potential to contribute to a more circular economy.

The primary objective of exploring DME in life cycle energy assessments is to quantify its environmental impact across its entire life cycle, from production to end-use. This comprehensive evaluation aims to determine the net energy balance, greenhouse gas emissions, and overall sustainability of DME compared to other energy carriers. By conducting thorough life cycle assessments, researchers and policymakers can make informed decisions about the role of DME in future energy systems.

Another key goal is to identify opportunities for optimizing DME production and utilization processes to maximize energy efficiency and minimize environmental impact. This includes exploring innovative production pathways, such as the integration of renewable energy sources in DME synthesis, and developing more efficient end-use technologies, particularly in the transportation and industrial sectors.

Furthermore, the assessment of DME within the life cycle energy framework seeks to address potential challenges and limitations associated with its widespread adoption. This involves evaluating infrastructure requirements, economic feasibility, and potential competition with other alternative fuels. By anticipating and addressing these challenges, stakeholders can develop strategies to overcome barriers to DME implementation and realize its full potential as a sustainable energy solution.

Market Analysis for DME

The market for dimethyl ether (DME) has been experiencing significant growth and transformation, driven by its potential as a clean-burning, renewable fuel alternative. DME's versatility and environmental benefits have positioned it as a promising solution in various sectors, particularly in energy and transportation.

In the energy sector, DME has gained traction as a substitute for liquefied petroleum gas (LPG) and diesel fuel. Its properties make it an excellent candidate for use in domestic cooking and heating applications, especially in regions where access to traditional energy sources is limited. The industrial sector has also shown interest in DME as a potential replacement for propane in aerosol propellants and as a refrigerant.

The transportation industry represents a key market for DME, with its potential to replace conventional diesel fuel in heavy-duty vehicles. Several major automotive manufacturers have conducted trials and demonstrations of DME-powered trucks, showcasing the fuel's ability to reduce emissions and improve engine efficiency. This has led to increased interest from fleet operators and logistics companies seeking to reduce their carbon footprint.

Geographically, the DME market has seen notable developments in Asia, particularly in China and Japan. China has been at the forefront of DME production and utilization, with government support driving large-scale adoption in both the energy and transportation sectors. In Europe and North America, the market is still in its early stages but showing promising growth potential, supported by increasing environmental regulations and sustainability initiatives.

The global DME market size has been steadily expanding, with projections indicating continued growth in the coming years. Factors contributing to this growth include increasing awareness of environmental issues, stringent emission regulations, and the push for energy security and diversification. However, challenges such as infrastructure development and competition from other alternative fuels continue to impact market dynamics.

In terms of production, the DME market has seen advancements in both fossil-based and bio-based production methods. While traditional production from natural gas or coal remains dominant, there is growing interest in bio-based DME production using renewable feedstocks. This shift aligns with the increasing focus on life cycle energy assessments and the push for more sustainable fuel options.

The market analysis for DME in the context of life cycle energy assessments reveals a complex landscape with significant potential for growth and innovation. As industries and governments worldwide seek to reduce their environmental impact and transition to cleaner energy sources, DME's role in supporting comprehensive life cycle energy assessments is likely to become increasingly important, shaping market trends and driving further research and development in this field.

In the energy sector, DME has gained traction as a substitute for liquefied petroleum gas (LPG) and diesel fuel. Its properties make it an excellent candidate for use in domestic cooking and heating applications, especially in regions where access to traditional energy sources is limited. The industrial sector has also shown interest in DME as a potential replacement for propane in aerosol propellants and as a refrigerant.

The transportation industry represents a key market for DME, with its potential to replace conventional diesel fuel in heavy-duty vehicles. Several major automotive manufacturers have conducted trials and demonstrations of DME-powered trucks, showcasing the fuel's ability to reduce emissions and improve engine efficiency. This has led to increased interest from fleet operators and logistics companies seeking to reduce their carbon footprint.

Geographically, the DME market has seen notable developments in Asia, particularly in China and Japan. China has been at the forefront of DME production and utilization, with government support driving large-scale adoption in both the energy and transportation sectors. In Europe and North America, the market is still in its early stages but showing promising growth potential, supported by increasing environmental regulations and sustainability initiatives.

The global DME market size has been steadily expanding, with projections indicating continued growth in the coming years. Factors contributing to this growth include increasing awareness of environmental issues, stringent emission regulations, and the push for energy security and diversification. However, challenges such as infrastructure development and competition from other alternative fuels continue to impact market dynamics.

In terms of production, the DME market has seen advancements in both fossil-based and bio-based production methods. While traditional production from natural gas or coal remains dominant, there is growing interest in bio-based DME production using renewable feedstocks. This shift aligns with the increasing focus on life cycle energy assessments and the push for more sustainable fuel options.

The market analysis for DME in the context of life cycle energy assessments reveals a complex landscape with significant potential for growth and innovation. As industries and governments worldwide seek to reduce their environmental impact and transition to cleaner energy sources, DME's role in supporting comprehensive life cycle energy assessments is likely to become increasingly important, shaping market trends and driving further research and development in this field.

DME Technology Status

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, gaining significant attention in recent years due to its potential to support sustainable energy transitions. The current technology status of DME production and utilization is characterized by a mix of established processes and ongoing innovations.

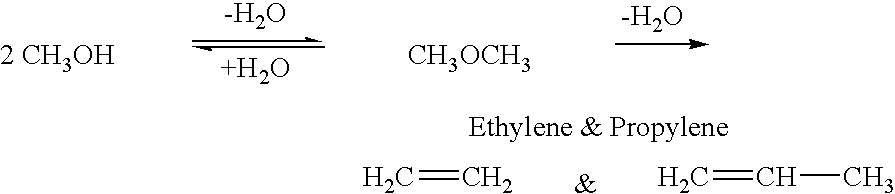

The primary production method for DME involves a two-step process: first, syngas is converted to methanol, and then methanol is dehydrated to form DME. This process has been well-established and commercially implemented in various scales. However, recent advancements have led to the development of single-step processes, where DME is produced directly from syngas, offering improved efficiency and reduced capital costs.

In terms of feedstock, DME can be produced from a wide range of sources, including natural gas, coal, and biomass. This versatility has positioned DME as a potential bridge between fossil fuels and renewable energy sources. The production of bio-DME from renewable feedstocks has gained particular interest in the context of life cycle energy assessments, as it offers a pathway to reduce greenhouse gas emissions.

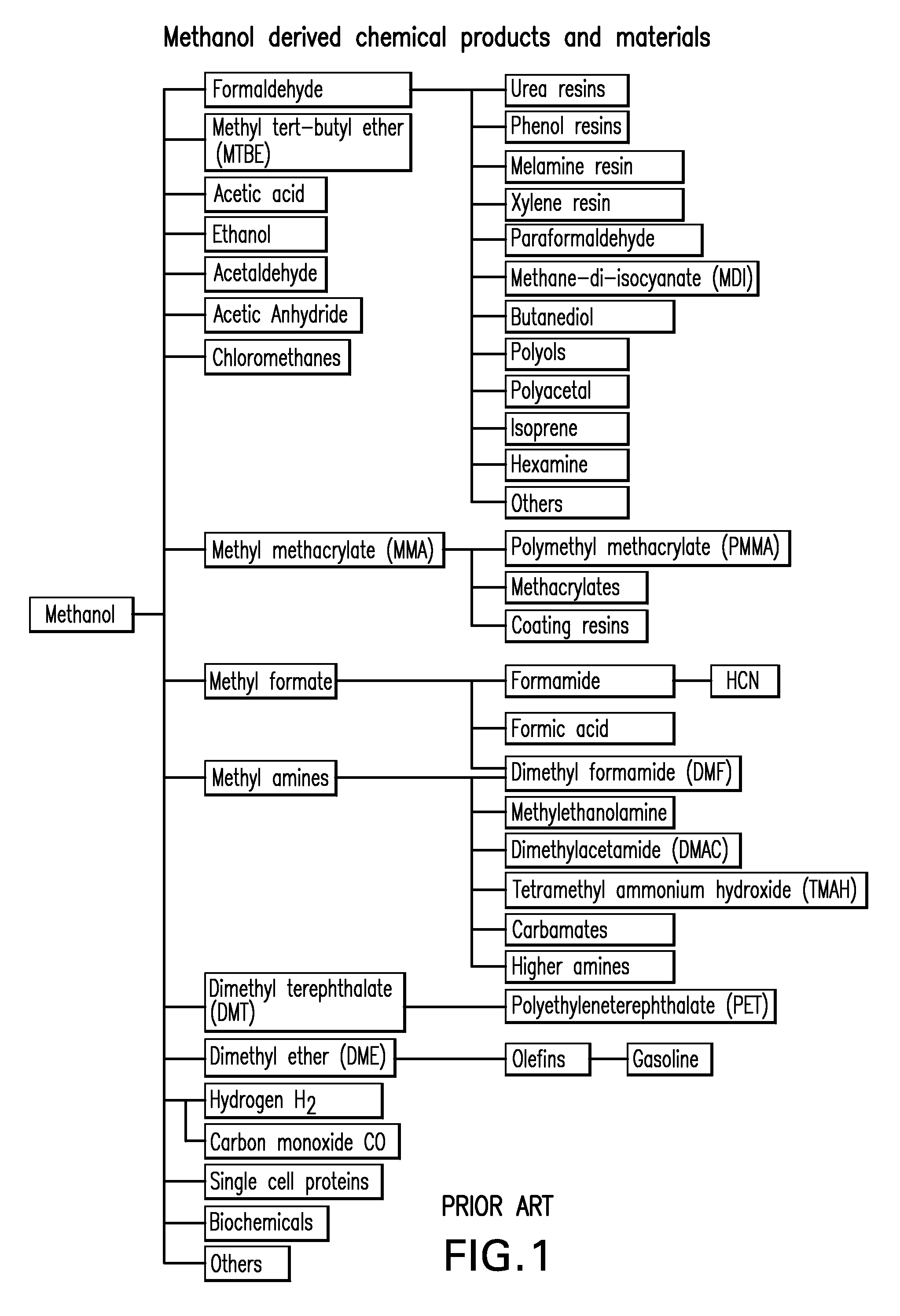

The utilization of DME spans multiple sectors. In the energy sector, DME is being explored as a clean-burning fuel for diesel engines, power generation, and domestic cooking and heating. Its properties make it an attractive alternative to liquefied petroleum gas (LPG) and diesel fuel. In the chemical industry, DME serves as a versatile intermediate for the production of various chemicals, including olefins and aromatics.

Current technological challenges in DME production and utilization include optimizing catalyst performance for direct DME synthesis, improving the energy efficiency of production processes, and adapting existing infrastructure for DME distribution and use. Research efforts are focused on developing more active and selective catalysts, enhancing process integration, and addressing the technical barriers to widespread DME adoption in various applications.

From a life cycle perspective, the technology status of DME is particularly relevant. The ability to produce DME from diverse feedstocks allows for comprehensive life cycle energy assessments that consider different production pathways. These assessments are crucial for evaluating the overall environmental impact and energy efficiency of DME as an alternative fuel or chemical feedstock.

In conclusion, the current technology status of DME reflects a mature production process with ongoing innovations aimed at improving efficiency and sustainability. The versatility of DME in terms of both production feedstocks and end-use applications positions it as a significant player in future energy systems, particularly when considering life cycle energy assessments and the transition to more sustainable energy solutions.

The primary production method for DME involves a two-step process: first, syngas is converted to methanol, and then methanol is dehydrated to form DME. This process has been well-established and commercially implemented in various scales. However, recent advancements have led to the development of single-step processes, where DME is produced directly from syngas, offering improved efficiency and reduced capital costs.

In terms of feedstock, DME can be produced from a wide range of sources, including natural gas, coal, and biomass. This versatility has positioned DME as a potential bridge between fossil fuels and renewable energy sources. The production of bio-DME from renewable feedstocks has gained particular interest in the context of life cycle energy assessments, as it offers a pathway to reduce greenhouse gas emissions.

The utilization of DME spans multiple sectors. In the energy sector, DME is being explored as a clean-burning fuel for diesel engines, power generation, and domestic cooking and heating. Its properties make it an attractive alternative to liquefied petroleum gas (LPG) and diesel fuel. In the chemical industry, DME serves as a versatile intermediate for the production of various chemicals, including olefins and aromatics.

Current technological challenges in DME production and utilization include optimizing catalyst performance for direct DME synthesis, improving the energy efficiency of production processes, and adapting existing infrastructure for DME distribution and use. Research efforts are focused on developing more active and selective catalysts, enhancing process integration, and addressing the technical barriers to widespread DME adoption in various applications.

From a life cycle perspective, the technology status of DME is particularly relevant. The ability to produce DME from diverse feedstocks allows for comprehensive life cycle energy assessments that consider different production pathways. These assessments are crucial for evaluating the overall environmental impact and energy efficiency of DME as an alternative fuel or chemical feedstock.

In conclusion, the current technology status of DME reflects a mature production process with ongoing innovations aimed at improving efficiency and sustainability. The versatility of DME in terms of both production feedstocks and end-use applications positions it as a significant player in future energy systems, particularly when considering life cycle energy assessments and the transition to more sustainable energy solutions.

Current DME LCA Methods

01 Production of dimethyl ether from synthesis gas

Dimethyl ether can be produced from synthesis gas (syngas) through a two-step process involving methanol synthesis and subsequent dehydration. This method is energy-efficient and allows for the utilization of various feedstocks, including natural gas, coal, and biomass. The life cycle energy of dimethyl ether produced through this route depends on the source of syngas and the efficiency of the conversion process.- Production methods for dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes aim to improve energy efficiency and reduce environmental impact throughout the life cycle of dimethyl ether production.

- Energy-efficient catalysts for dimethyl ether synthesis: Development of novel catalysts to enhance the energy efficiency of dimethyl ether production. These catalysts aim to lower reaction temperatures, improve selectivity, and increase conversion rates, thereby reducing overall energy consumption in the life cycle of dimethyl ether.

- Utilization of renewable resources for dimethyl ether production: Exploration of renewable resources such as biomass and waste materials for dimethyl ether production. This approach aims to reduce the carbon footprint and improve the overall life cycle energy balance of dimethyl ether by utilizing sustainable feedstocks.

- Process integration and heat recovery in dimethyl ether production: Implementation of process integration techniques and heat recovery systems in dimethyl ether production plants. These strategies aim to optimize energy use, reduce waste heat, and improve overall energy efficiency throughout the life cycle of dimethyl ether.

- Life cycle assessment and optimization of dimethyl ether production: Conducting comprehensive life cycle assessments of dimethyl ether production processes to identify areas for improvement. This includes analyzing energy consumption, greenhouse gas emissions, and environmental impacts at each stage of the life cycle, leading to optimized production methods and reduced overall energy footprint.

02 Direct synthesis of dimethyl ether

Direct synthesis of dimethyl ether from syngas in a single-step process has been developed to improve energy efficiency. This method combines methanol synthesis and dehydration in a single reactor, reducing the overall energy consumption and simplifying the production process. The life cycle energy of dimethyl ether produced through direct synthesis is generally lower compared to the two-step process.Expand Specific Solutions03 Dimethyl ether as a renewable fuel

Dimethyl ether can be produced from renewable sources such as biomass, making it a potential alternative to fossil fuels. The life cycle energy of renewable dimethyl ether depends on the biomass feedstock and conversion process. When produced from waste biomass or agricultural residues, dimethyl ether can have a lower carbon footprint compared to fossil-derived fuels.Expand Specific Solutions04 Energy-efficient catalysts for dimethyl ether production

Development of advanced catalysts for dimethyl ether production has led to improved energy efficiency in the conversion process. These catalysts enhance the selectivity and yield of dimethyl ether, reducing energy consumption and improving the overall life cycle energy balance. Bifunctional catalysts that combine methanol synthesis and dehydration functions have shown promising results in direct dimethyl ether synthesis.Expand Specific Solutions05 Life cycle assessment of dimethyl ether production

Life cycle assessment studies have been conducted to evaluate the energy consumption and environmental impact of dimethyl ether production from various feedstocks and through different processes. These assessments consider factors such as raw material extraction, transportation, production, and end-use to provide a comprehensive understanding of the life cycle energy of dimethyl ether. The results help in comparing dimethyl ether with other fuels and identifying areas for improvement in the production process.Expand Specific Solutions

Key DME Industry Players

The development of dimethyl ether (DME) as a clean fuel alternative is in an emerging phase, with growing market potential driven by environmental concerns and energy security. The global DME market size is projected to expand significantly in the coming years. Technologically, DME production is advancing, but still requires further optimization for widespread commercial adoption. Key players like China Petroleum & Chemical Corp., SK Energy, and Linde GmbH are investing in DME research and production capabilities. Academic institutions such as the University of Southern California and Changzhou University are contributing to fundamental research, while companies like Mitsubishi Gas Chemical and Air Liquide are developing innovative DME applications and production processes. The collaboration between industry and academia is accelerating the maturation of DME technology for life cycle energy assessments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to life cycle energy assessments of dimethyl ether (DME). Their method involves analyzing the entire production chain, from feedstock extraction to end-use applications. Sinopec has implemented advanced catalytic processes that improve DME yield and reduce energy consumption during production[1]. They have also conducted extensive studies on the use of DME as a clean-burning alternative fuel in transportation and household applications, demonstrating significant reductions in greenhouse gas emissions compared to conventional fuels[3]. Sinopec's research includes detailed energy input-output analyses across the DME life cycle, incorporating factors such as raw material sourcing, production efficiency, and end-use energy conversion rates[5].

Strengths: Extensive experience in large-scale DME production and distribution; comprehensive understanding of the entire DME value chain. Weaknesses: Potential bias towards fossil fuel-based DME production methods; limited focus on renewable DME sources.

Chinese Academy of Science Guanzhou Energy Research Institute

Technical Solution: The Chinese Academy of Science Guanzhou Energy Research Institute has made significant contributions to DME life cycle energy assessments through their innovative research on renewable DME production. They have developed a novel biomass-to-DME conversion process that utilizes agricultural waste as feedstock, significantly reducing the carbon footprint of DME production[2]. Their life cycle assessment methodology incorporates advanced modeling techniques to account for regional variations in biomass availability and energy infrastructure[4]. The institute has also conducted comparative studies of different DME production pathways, including coal-based and natural gas-based methods, providing valuable insights into the energy efficiency and environmental impacts of each approach[6].

Strengths: Strong focus on renewable DME production methods; advanced modeling capabilities for regional life cycle assessments. Weaknesses: Limited experience in large-scale industrial implementation; potential challenges in scaling up biomass-based DME production.

DME LCA Innovations

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Efficient and selective chemical recycling of carbon dioxide to methanol, dimethyl ether and derived products

PatentActiveUS7608743B2

Innovation

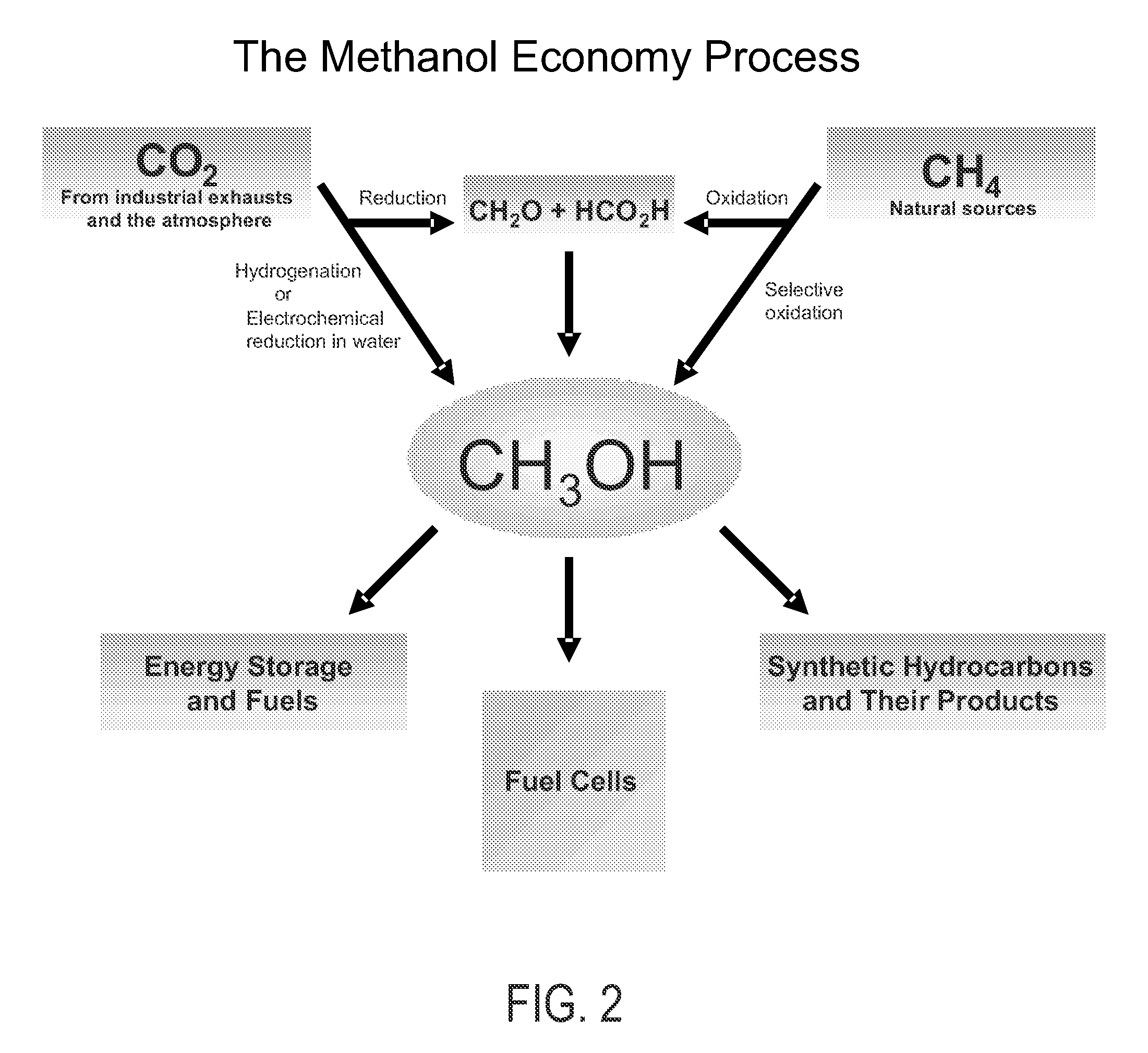

- A process that converts carbon dioxide from industrial or natural sources, including the atmosphere, into methanol and dimethyl ether through catalytic, photochemical, or electrochemical hydrogenation, followed by recycling the carbon dioxide in a carbon-neutral cycle, allowing for the production of methanol without the need for synthesis gas and reducing greenhouse gas emissions.

Environmental Regulations

Environmental regulations play a crucial role in shaping the adoption and implementation of dimethyl ether (DME) in life cycle energy assessments. As governments worldwide strive to reduce greenhouse gas emissions and promote sustainable energy solutions, DME has gained attention as a potential alternative fuel with lower environmental impact.

In the United States, the Environmental Protection Agency (EPA) has established stringent regulations for fuel emissions and energy efficiency. The Clean Air Act and its amendments have set standards for air quality and emissions from various sources, including transportation and industrial processes. These regulations have indirectly supported the development and adoption of cleaner fuels like DME, which can help meet increasingly stringent emission standards.

The European Union has implemented comprehensive environmental regulations through its Climate and Energy Package. This includes targets for reducing greenhouse gas emissions, increasing renewable energy use, and improving energy efficiency. The EU's Renewable Energy Directive specifically promotes the use of renewable fuels in transportation, creating opportunities for DME produced from renewable sources to contribute to meeting these targets.

In Asia, countries like China and Japan have also introduced environmental regulations that impact the use of DME. China's Air Pollution Prevention and Control Action Plan has led to increased interest in cleaner fuels, including DME, as a means to reduce air pollution in urban areas. Japan's Strategic Energy Plan emphasizes the importance of diversifying energy sources and reducing carbon emissions, creating a favorable regulatory environment for DME adoption.

International agreements, such as the Paris Agreement, have further reinforced the need for sustainable energy solutions. These global commitments have prompted many countries to implement or strengthen their environmental regulations, indirectly supporting the development and use of alternative fuels like DME in life cycle energy assessments.

Environmental regulations also influence the methodologies used in life cycle energy assessments. Standards and guidelines for conducting these assessments, such as ISO 14040 and 14044, ensure that the environmental impacts of DME and other fuels are evaluated consistently and comprehensively. These standards help in comparing different energy options and inform decision-making processes in both public and private sectors.

The regulatory landscape continues to evolve, with increasing focus on circular economy principles and sustainable resource management. This trend is likely to further support the integration of DME into life cycle energy assessments, as its potential for production from renewable sources aligns well with circular economy goals.

In the United States, the Environmental Protection Agency (EPA) has established stringent regulations for fuel emissions and energy efficiency. The Clean Air Act and its amendments have set standards for air quality and emissions from various sources, including transportation and industrial processes. These regulations have indirectly supported the development and adoption of cleaner fuels like DME, which can help meet increasingly stringent emission standards.

The European Union has implemented comprehensive environmental regulations through its Climate and Energy Package. This includes targets for reducing greenhouse gas emissions, increasing renewable energy use, and improving energy efficiency. The EU's Renewable Energy Directive specifically promotes the use of renewable fuels in transportation, creating opportunities for DME produced from renewable sources to contribute to meeting these targets.

In Asia, countries like China and Japan have also introduced environmental regulations that impact the use of DME. China's Air Pollution Prevention and Control Action Plan has led to increased interest in cleaner fuels, including DME, as a means to reduce air pollution in urban areas. Japan's Strategic Energy Plan emphasizes the importance of diversifying energy sources and reducing carbon emissions, creating a favorable regulatory environment for DME adoption.

International agreements, such as the Paris Agreement, have further reinforced the need for sustainable energy solutions. These global commitments have prompted many countries to implement or strengthen their environmental regulations, indirectly supporting the development and use of alternative fuels like DME in life cycle energy assessments.

Environmental regulations also influence the methodologies used in life cycle energy assessments. Standards and guidelines for conducting these assessments, such as ISO 14040 and 14044, ensure that the environmental impacts of DME and other fuels are evaluated consistently and comprehensively. These standards help in comparing different energy options and inform decision-making processes in both public and private sectors.

The regulatory landscape continues to evolve, with increasing focus on circular economy principles and sustainable resource management. This trend is likely to further support the integration of DME into life cycle energy assessments, as its potential for production from renewable sources aligns well with circular economy goals.

Sustainability Implications

Dimethyl ether (DME) plays a significant role in supporting life cycle energy assessments, offering several sustainability implications that merit careful consideration. As a clean-burning, renewable fuel alternative, DME demonstrates potential in reducing greenhouse gas emissions and enhancing energy efficiency across various sectors.

From a production standpoint, DME can be synthesized from a wide range of feedstocks, including biomass, natural gas, and coal. This versatility allows for the utilization of locally available resources, potentially reducing transportation-related emissions and supporting regional energy independence. The production process of DME from biomass, in particular, presents a promising pathway for carbon-neutral fuel generation, as the carbon dioxide released during combustion is offset by the CO2 absorbed during biomass growth.

In the transportation sector, DME serves as a viable substitute for conventional diesel fuel, offering comparable performance with significantly lower particulate matter and NOx emissions. This characteristic makes DME an attractive option for improving air quality in urban areas and reducing the environmental impact of heavy-duty vehicles. Furthermore, the relatively simple molecular structure of DME facilitates more complete combustion, potentially leading to improved engine efficiency and reduced overall fuel consumption.

The use of DME in power generation and industrial processes also contributes to sustainability efforts. As a clean-burning fuel, it can be employed in gas turbines and combined heat and power systems, offering a lower-carbon alternative to traditional fossil fuels. This application is particularly relevant in regions transitioning away from coal-based power generation, as DME can provide a bridge to renewable energy sources while utilizing existing infrastructure.

From a life cycle perspective, the production and use of DME present opportunities for closed-loop systems and circular economy principles. For instance, the CO2 generated during DME production can be captured and utilized in other industrial processes or for enhanced oil recovery, further reducing the overall carbon footprint of the fuel cycle.

However, it is crucial to note that the sustainability benefits of DME are highly dependent on the feedstock and production methods employed. Life cycle assessments must carefully consider factors such as land use changes, water consumption, and energy inputs throughout the entire production and distribution chain to accurately evaluate the net environmental impact of DME utilization.

In conclusion, dimethyl ether offers promising sustainability implications in supporting life cycle energy assessments. Its potential to reduce emissions, improve energy efficiency, and integrate with renewable energy systems positions DME as a valuable component in the transition towards more sustainable energy practices. Nonetheless, ongoing research and comprehensive life cycle analyses are essential to fully understand and optimize the environmental benefits of DME across various applications and production pathways.

From a production standpoint, DME can be synthesized from a wide range of feedstocks, including biomass, natural gas, and coal. This versatility allows for the utilization of locally available resources, potentially reducing transportation-related emissions and supporting regional energy independence. The production process of DME from biomass, in particular, presents a promising pathway for carbon-neutral fuel generation, as the carbon dioxide released during combustion is offset by the CO2 absorbed during biomass growth.

In the transportation sector, DME serves as a viable substitute for conventional diesel fuel, offering comparable performance with significantly lower particulate matter and NOx emissions. This characteristic makes DME an attractive option for improving air quality in urban areas and reducing the environmental impact of heavy-duty vehicles. Furthermore, the relatively simple molecular structure of DME facilitates more complete combustion, potentially leading to improved engine efficiency and reduced overall fuel consumption.

The use of DME in power generation and industrial processes also contributes to sustainability efforts. As a clean-burning fuel, it can be employed in gas turbines and combined heat and power systems, offering a lower-carbon alternative to traditional fossil fuels. This application is particularly relevant in regions transitioning away from coal-based power generation, as DME can provide a bridge to renewable energy sources while utilizing existing infrastructure.

From a life cycle perspective, the production and use of DME present opportunities for closed-loop systems and circular economy principles. For instance, the CO2 generated during DME production can be captured and utilized in other industrial processes or for enhanced oil recovery, further reducing the overall carbon footprint of the fuel cycle.

However, it is crucial to note that the sustainability benefits of DME are highly dependent on the feedstock and production methods employed. Life cycle assessments must carefully consider factors such as land use changes, water consumption, and energy inputs throughout the entire production and distribution chain to accurately evaluate the net environmental impact of DME utilization.

In conclusion, dimethyl ether offers promising sustainability implications in supporting life cycle energy assessments. Its potential to reduce emissions, improve energy efficiency, and integrate with renewable energy systems positions DME as a valuable component in the transition towards more sustainable energy practices. Nonetheless, ongoing research and comprehensive life cycle analyses are essential to fully understand and optimize the environmental benefits of DME across various applications and production pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!