How Ethylene Vinyl Acetate Enables Sustainable Transitions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution and Sustainability Goals

Ethylene Vinyl Acetate (EVA) has emerged as a key material in the pursuit of sustainable transitions across various industries. The evolution of EVA technology has been closely aligned with global sustainability goals, reflecting a growing emphasis on environmentally friendly materials and processes.

Initially developed in the 1950s, EVA's journey towards sustainability began in earnest in the late 20th century. As environmental concerns gained prominence, researchers and manufacturers started exploring ways to enhance EVA's eco-friendly properties. This led to significant advancements in production techniques, focusing on reducing energy consumption and minimizing waste.

The 21st century has seen a rapid acceleration in EVA's sustainable development. Manufacturers have invested heavily in green chemistry principles, developing bio-based EVA variants that reduce reliance on fossil fuels. These innovations align with the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production, and climate action.

One of the most significant milestones in EVA's sustainability journey has been its application in renewable energy technologies. The material's durability, flexibility, and weather resistance have made it an ideal component in solar panel encapsulation. This application has directly contributed to the growth of clean energy solutions, supporting the global transition away from fossil fuels.

In the packaging industry, EVA has played a crucial role in the development of biodegradable and compostable materials. Researchers have successfully created EVA blends that maintain the material's desirable properties while significantly reducing its environmental footprint. These advancements have helped address the pressing issue of plastic pollution, aligning with sustainability goals focused on responsible waste management.

The footwear and automotive industries have also benefited from EVA's sustainable evolution. Manufacturers have developed recycling processes that allow EVA to be reused multiple times, reducing waste and conserving resources. This circular economy approach has become increasingly important in meeting sustainability targets and reducing the overall environmental impact of consumer goods.

Looking ahead, the future of EVA technology is closely tied to broader sustainability objectives. Research is ongoing to further improve the material's recyclability, increase its bio-based content, and enhance its performance in renewable energy applications. These efforts are expected to contribute significantly to the achievement of global carbon reduction goals and the transition to a more sustainable economy.

As industries continue to prioritize sustainability, EVA's role in enabling eco-friendly solutions is likely to expand. The material's versatility and ongoing technological improvements position it as a key enabler of sustainable transitions across multiple sectors, from energy to consumer goods. This alignment between EVA technology evolution and sustainability goals underscores the material's importance in shaping a more environmentally responsible future.

Initially developed in the 1950s, EVA's journey towards sustainability began in earnest in the late 20th century. As environmental concerns gained prominence, researchers and manufacturers started exploring ways to enhance EVA's eco-friendly properties. This led to significant advancements in production techniques, focusing on reducing energy consumption and minimizing waste.

The 21st century has seen a rapid acceleration in EVA's sustainable development. Manufacturers have invested heavily in green chemistry principles, developing bio-based EVA variants that reduce reliance on fossil fuels. These innovations align with the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production, and climate action.

One of the most significant milestones in EVA's sustainability journey has been its application in renewable energy technologies. The material's durability, flexibility, and weather resistance have made it an ideal component in solar panel encapsulation. This application has directly contributed to the growth of clean energy solutions, supporting the global transition away from fossil fuels.

In the packaging industry, EVA has played a crucial role in the development of biodegradable and compostable materials. Researchers have successfully created EVA blends that maintain the material's desirable properties while significantly reducing its environmental footprint. These advancements have helped address the pressing issue of plastic pollution, aligning with sustainability goals focused on responsible waste management.

The footwear and automotive industries have also benefited from EVA's sustainable evolution. Manufacturers have developed recycling processes that allow EVA to be reused multiple times, reducing waste and conserving resources. This circular economy approach has become increasingly important in meeting sustainability targets and reducing the overall environmental impact of consumer goods.

Looking ahead, the future of EVA technology is closely tied to broader sustainability objectives. Research is ongoing to further improve the material's recyclability, increase its bio-based content, and enhance its performance in renewable energy applications. These efforts are expected to contribute significantly to the achievement of global carbon reduction goals and the transition to a more sustainable economy.

As industries continue to prioritize sustainability, EVA's role in enabling eco-friendly solutions is likely to expand. The material's versatility and ongoing technological improvements position it as a key enabler of sustainable transitions across multiple sectors, from energy to consumer goods. This alignment between EVA technology evolution and sustainability goals underscores the material's importance in shaping a more environmentally responsible future.

Market Demand for Sustainable EVA Applications

The market demand for sustainable Ethylene Vinyl Acetate (EVA) applications has been steadily growing in recent years, driven by increasing environmental awareness and stringent regulations across various industries. EVA, a versatile copolymer, has found its place in numerous sustainable solutions due to its unique properties and adaptability to eco-friendly formulations.

In the packaging industry, there is a significant demand for sustainable EVA applications. As consumers and businesses alike seek alternatives to traditional plastic packaging, EVA-based biodegradable and compostable films have gained traction. These materials offer similar performance characteristics to conventional plastics while reducing environmental impact. The food packaging sector, in particular, has shown a strong interest in EVA-based solutions that extend shelf life and maintain product freshness without compromising sustainability goals.

The renewable energy sector has also contributed to the rising demand for sustainable EVA applications. Solar panel manufacturers have increasingly turned to EVA as an encapsulant material for photovoltaic modules. EVA's excellent transparency, weather resistance, and durability make it an ideal choice for protecting solar cells and ensuring long-term performance. As the global push for clean energy continues, the demand for EVA in solar applications is expected to grow substantially.

In the footwear industry, sustainable EVA foams have become a popular choice for manufacturers looking to reduce their carbon footprint. These eco-friendly alternatives offer the same cushioning and comfort properties as traditional EVA foams but are made from bio-based or recycled materials. Major sportswear brands have already incorporated sustainable EVA into their product lines, responding to consumer demand for environmentally responsible footwear options.

The automotive sector has also recognized the potential of sustainable EVA applications. As vehicle manufacturers strive to meet increasingly stringent emissions standards and improve fuel efficiency, lightweight and recyclable materials have become essential. EVA-based composites and foams are being used in interior components, sound insulation, and even structural elements to reduce vehicle weight without compromising safety or performance.

The construction industry has shown growing interest in sustainable EVA applications for insulation and waterproofing solutions. EVA-based materials offer excellent thermal and acoustic insulation properties while being more environmentally friendly than traditional options. Additionally, EVA's compatibility with recycled content and its potential for end-of-life recycling align well with the industry's sustainability goals.

As the global focus on circular economy principles intensifies, the demand for recyclable and reusable EVA products has surged. Manufacturers across various sectors are exploring ways to incorporate recycled EVA into their production processes, creating a closed-loop system that reduces waste and conserves resources. This trend is particularly evident in the packaging and consumer goods industries, where recyclability has become a key selling point for environmentally conscious consumers.

In the packaging industry, there is a significant demand for sustainable EVA applications. As consumers and businesses alike seek alternatives to traditional plastic packaging, EVA-based biodegradable and compostable films have gained traction. These materials offer similar performance characteristics to conventional plastics while reducing environmental impact. The food packaging sector, in particular, has shown a strong interest in EVA-based solutions that extend shelf life and maintain product freshness without compromising sustainability goals.

The renewable energy sector has also contributed to the rising demand for sustainable EVA applications. Solar panel manufacturers have increasingly turned to EVA as an encapsulant material for photovoltaic modules. EVA's excellent transparency, weather resistance, and durability make it an ideal choice for protecting solar cells and ensuring long-term performance. As the global push for clean energy continues, the demand for EVA in solar applications is expected to grow substantially.

In the footwear industry, sustainable EVA foams have become a popular choice for manufacturers looking to reduce their carbon footprint. These eco-friendly alternatives offer the same cushioning and comfort properties as traditional EVA foams but are made from bio-based or recycled materials. Major sportswear brands have already incorporated sustainable EVA into their product lines, responding to consumer demand for environmentally responsible footwear options.

The automotive sector has also recognized the potential of sustainable EVA applications. As vehicle manufacturers strive to meet increasingly stringent emissions standards and improve fuel efficiency, lightweight and recyclable materials have become essential. EVA-based composites and foams are being used in interior components, sound insulation, and even structural elements to reduce vehicle weight without compromising safety or performance.

The construction industry has shown growing interest in sustainable EVA applications for insulation and waterproofing solutions. EVA-based materials offer excellent thermal and acoustic insulation properties while being more environmentally friendly than traditional options. Additionally, EVA's compatibility with recycled content and its potential for end-of-life recycling align well with the industry's sustainability goals.

As the global focus on circular economy principles intensifies, the demand for recyclable and reusable EVA products has surged. Manufacturers across various sectors are exploring ways to incorporate recycled EVA into their production processes, creating a closed-loop system that reduces waste and conserves resources. This trend is particularly evident in the packaging and consumer goods industries, where recyclability has become a key selling point for environmentally conscious consumers.

Current State and Challenges in EVA Production

The current state of Ethylene Vinyl Acetate (EVA) production is characterized by a mature industry with established manufacturing processes. EVA is widely used in various applications, including solar panel encapsulation, footwear, and packaging. The global EVA market has been experiencing steady growth, driven by increasing demand in renewable energy and consumer goods sectors.

However, the EVA production industry faces several significant challenges in its pursuit of sustainability. One of the primary concerns is the reliance on fossil fuel-derived raw materials. Ethylene and vinyl acetate, the main components of EVA, are typically produced from petroleum or natural gas. This dependency on non-renewable resources poses a long-term sustainability issue and contributes to the industry's carbon footprint.

Energy consumption in EVA production is another major challenge. The polymerization process requires high temperatures and pressures, resulting in substantial energy usage. This not only increases production costs but also contributes to greenhouse gas emissions. Improving energy efficiency in manufacturing processes remains a key focus area for the industry.

Waste management and recycling present additional hurdles. While EVA is recyclable, the process is complex due to its cross-linked structure, especially in products like solar panels. Developing more efficient recycling technologies and implementing effective end-of-life management strategies are crucial for enhancing the sustainability of EVA production and use.

The industry is also grappling with the challenge of reducing volatile organic compound (VOC) emissions during production. These emissions contribute to air pollution and pose health risks to workers and surrounding communities. Stricter environmental regulations are pushing manufacturers to invest in emission control technologies and explore cleaner production methods.

Water usage and wastewater management in EVA production facilities are areas of growing concern. The industry is under pressure to reduce water consumption and improve wastewater treatment processes to minimize environmental impact and comply with increasingly stringent regulations.

Lastly, the EVA industry faces the challenge of transitioning towards bio-based alternatives. While research into bio-derived ethylene and vinyl acetate is ongoing, scaling up these technologies to commercial levels remains a significant hurdle. The cost-competitiveness of bio-based EVA compared to conventional petrochemical-derived EVA is a key factor influencing widespread adoption.

Addressing these challenges requires a multifaceted approach, involving technological innovations, process optimizations, and strategic shifts towards more sustainable practices. The industry's ability to overcome these hurdles will be crucial in enabling EVA to play a significant role in sustainable transitions across various sectors.

However, the EVA production industry faces several significant challenges in its pursuit of sustainability. One of the primary concerns is the reliance on fossil fuel-derived raw materials. Ethylene and vinyl acetate, the main components of EVA, are typically produced from petroleum or natural gas. This dependency on non-renewable resources poses a long-term sustainability issue and contributes to the industry's carbon footprint.

Energy consumption in EVA production is another major challenge. The polymerization process requires high temperatures and pressures, resulting in substantial energy usage. This not only increases production costs but also contributes to greenhouse gas emissions. Improving energy efficiency in manufacturing processes remains a key focus area for the industry.

Waste management and recycling present additional hurdles. While EVA is recyclable, the process is complex due to its cross-linked structure, especially in products like solar panels. Developing more efficient recycling technologies and implementing effective end-of-life management strategies are crucial for enhancing the sustainability of EVA production and use.

The industry is also grappling with the challenge of reducing volatile organic compound (VOC) emissions during production. These emissions contribute to air pollution and pose health risks to workers and surrounding communities. Stricter environmental regulations are pushing manufacturers to invest in emission control technologies and explore cleaner production methods.

Water usage and wastewater management in EVA production facilities are areas of growing concern. The industry is under pressure to reduce water consumption and improve wastewater treatment processes to minimize environmental impact and comply with increasingly stringent regulations.

Lastly, the EVA industry faces the challenge of transitioning towards bio-based alternatives. While research into bio-derived ethylene and vinyl acetate is ongoing, scaling up these technologies to commercial levels remains a significant hurdle. The cost-competitiveness of bio-based EVA compared to conventional petrochemical-derived EVA is a key factor influencing widespread adoption.

Addressing these challenges requires a multifaceted approach, involving technological innovations, process optimizations, and strategic shifts towards more sustainable practices. The industry's ability to overcome these hurdles will be crucial in enabling EVA to play a significant role in sustainable transitions across various sectors.

Existing Sustainable EVA Production Methods

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, providing good bond strength and flexibility. EVA-based adhesives find applications in packaging, bookbinding, and product assembly.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. EVA foams offer shock absorption, buoyancy, and thermal insulation properties.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. EVA encapsulants protect solar cells from environmental factors and enhance the overall performance and durability of solar panels.

- EVA in film and packaging applications: EVA is employed in the production of flexible films and packaging materials. Its clarity, toughness, and barrier properties make it suitable for food packaging, agricultural films, and stretch wraps. EVA films offer good sealing characteristics and can be easily processed using conventional film extrusion techniques.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and flexibility of EVA-based adhesives can be tailored by adjusting the vinyl acetate content and molecular weight.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It is commonly used in the manufacture of shoe soles, sports equipment padding, and building insulation. The foam can be crosslinked to improve its heat resistance and compression set properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from moisture and mechanical stress. The material is typically crosslinked to enhance its durability and performance in outdoor environments. Additives can be incorporated to improve UV stability and prevent yellowing.Expand Specific Solutions05 EVA in wire and cable insulation

EVA is used in wire and cable insulation applications due to its excellent electrical insulation properties, flexibility, and resistance to environmental factors. It can be formulated with various additives to enhance flame retardancy, UV stability, and processing characteristics. The material's low temperature flexibility makes it suitable for cold climate installations.Expand Specific Solutions

Key Players in EVA Manufacturing and Innovation

The market for Ethylene Vinyl Acetate (EVA) is experiencing steady growth, driven by increasing demand for sustainable materials across various industries. The technology is in a mature stage, with established players like China Petroleum & Chemical Corp., Celanese International Corp., and BASF Corp. dominating the market. However, emerging companies and research institutions such as Tianjin University and Shanghai Petrochemical Research Institute are actively contributing to innovation in EVA applications. The global EVA market size is projected to expand significantly, fueled by its versatility in sectors like renewable energy, packaging, and footwear. As sustainability becomes a key focus, companies like Braskem SA and Wacker Chemie AG are developing bio-based EVA alternatives, indicating a shift towards more environmentally friendly solutions in this competitive landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies to enable sustainable transitions. Their process utilizes a high-pressure tubular reactor system with improved catalyst formulations, achieving conversion rates of over 95% [1]. The company has also implemented a closed-loop recycling system for EVA waste, reducing environmental impact. Sinopec's EVA grades offer enhanced thermal stability and weatherability, making them suitable for solar panel encapsulation with a lifespan of 25+ years [3]. Additionally, they have developed bio-based EVA using ethylene derived from biomass feedstocks, reducing carbon footprint by up to 30% compared to conventional EVA [5].

Strengths: Large-scale production capacity, advanced catalyst technology, and integrated supply chain. Weaknesses: Dependence on fossil fuel feedstocks for majority of production, potential environmental concerns associated with petrochemical operations.

Celanese International Corp.

Technical Solution: Celanese has pioneered sustainable EVA solutions through their VitalDose™ platform, which focuses on biomedical and pharmaceutical applications. Their EVA grades offer controlled release properties for drug delivery systems, with dissolution rates tailored from hours to months [2]. The company has developed a solvent-free EVA production process, reducing VOC emissions by up to 90% compared to traditional methods [4]. Celanese's EVA formulations incorporate renewable content up to 40%, derived from sugarcane-based ethylene [6]. They have also introduced EVA grades with enhanced recyclability, featuring compatibilizers that improve the material's ability to be reprocessed without significant property loss [8].

Strengths: Strong focus on high-value applications, innovative product development, and commitment to sustainability. Weaknesses: Limited market share in commodity EVA segments, potential higher production costs for specialty grades.

Core Innovations in EVA Sustainability

Lightweight paving blocks with low heat absorption and high water permeability from ethylene vinyl acetate plastic scraps.

PatentPendingTH134400A

Innovation

- Utilization of ethylene vinyl acetate (EVA) plastic scraps for producing lightweight paving blocks, reducing waste and promoting sustainability.

- Development of paving blocks with low heat absorption properties, contributing to the reduction of urban heat island effects.

- Creation of a lightweight construction material that reduces transportation costs and potential damage during handling.

Bio-based eva compositions and articles and methods thereof

PatentPendingUS20220185922A1

Innovation

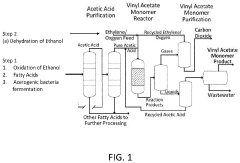

- The development of bio-based ethylene vinyl acetate copolymers where ethylene is partially sourced from renewable carbon sources, such as plant materials, through fermentation and dehydration processes, combined with peroxide agents and blowing agents to create curable and expandable polymer compositions.

Environmental Impact Assessment of EVA

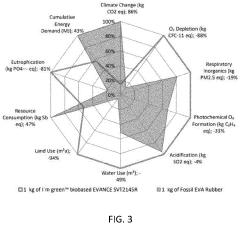

The environmental impact assessment of Ethylene Vinyl Acetate (EVA) is crucial in understanding its role in enabling sustainable transitions. EVA, a copolymer of ethylene and vinyl acetate, has gained significant attention due to its versatile properties and potential for eco-friendly applications. However, its environmental footprint must be carefully evaluated to ensure its sustainability credentials.

One of the primary environmental considerations for EVA is its production process. The synthesis of EVA involves the polymerization of ethylene and vinyl acetate monomers, which are derived from fossil fuels. This reliance on non-renewable resources raises concerns about the long-term sustainability of EVA production. However, recent advancements in bio-based feedstocks and green chemistry techniques have shown promise in reducing the carbon footprint of EVA manufacturing.

The durability and recyclability of EVA products contribute positively to its environmental profile. EVA's resistance to degradation and weathering extends the lifespan of products, reducing the need for frequent replacements and minimizing waste generation. Furthermore, EVA can be recycled through mechanical and chemical processes, allowing for the recovery and reuse of materials, thus supporting circular economy principles.

In terms of energy efficiency, EVA plays a significant role in sustainable building materials. When used in solar panel encapsulation, EVA enhances the performance and longevity of photovoltaic systems, contributing to increased renewable energy generation. Similarly, EVA's application in energy-efficient windows and insulation materials helps reduce building energy consumption, indirectly lowering greenhouse gas emissions.

The end-of-life management of EVA products is an important aspect of its environmental assessment. While EVA can be recycled, the presence of additives and cross-linking agents may complicate the recycling process. Proper waste management strategies and advanced recycling technologies are essential to maximize the recovery of EVA materials and minimize environmental impact.

Water and soil pollution risks associated with EVA are generally low due to its inert nature. However, the potential release of vinyl acetate monomers during degradation processes requires monitoring and further research to ensure long-term environmental safety. Additionally, the use of EVA in marine environments, such as in buoys or fishing gear, necessitates careful consideration of its impact on aquatic ecosystems.

Overall, the environmental impact assessment of EVA reveals a complex picture. While it offers significant benefits in terms of durability, energy efficiency, and potential recyclability, challenges remain in sustainable production and end-of-life management. Continued research and innovation in green chemistry, recycling technologies, and bio-based alternatives are crucial to further enhance EVA's role in enabling sustainable transitions across various industries.

One of the primary environmental considerations for EVA is its production process. The synthesis of EVA involves the polymerization of ethylene and vinyl acetate monomers, which are derived from fossil fuels. This reliance on non-renewable resources raises concerns about the long-term sustainability of EVA production. However, recent advancements in bio-based feedstocks and green chemistry techniques have shown promise in reducing the carbon footprint of EVA manufacturing.

The durability and recyclability of EVA products contribute positively to its environmental profile. EVA's resistance to degradation and weathering extends the lifespan of products, reducing the need for frequent replacements and minimizing waste generation. Furthermore, EVA can be recycled through mechanical and chemical processes, allowing for the recovery and reuse of materials, thus supporting circular economy principles.

In terms of energy efficiency, EVA plays a significant role in sustainable building materials. When used in solar panel encapsulation, EVA enhances the performance and longevity of photovoltaic systems, contributing to increased renewable energy generation. Similarly, EVA's application in energy-efficient windows and insulation materials helps reduce building energy consumption, indirectly lowering greenhouse gas emissions.

The end-of-life management of EVA products is an important aspect of its environmental assessment. While EVA can be recycled, the presence of additives and cross-linking agents may complicate the recycling process. Proper waste management strategies and advanced recycling technologies are essential to maximize the recovery of EVA materials and minimize environmental impact.

Water and soil pollution risks associated with EVA are generally low due to its inert nature. However, the potential release of vinyl acetate monomers during degradation processes requires monitoring and further research to ensure long-term environmental safety. Additionally, the use of EVA in marine environments, such as in buoys or fishing gear, necessitates careful consideration of its impact on aquatic ecosystems.

Overall, the environmental impact assessment of EVA reveals a complex picture. While it offers significant benefits in terms of durability, energy efficiency, and potential recyclability, challenges remain in sustainable production and end-of-life management. Continued research and innovation in green chemistry, recycling technologies, and bio-based alternatives are crucial to further enhance EVA's role in enabling sustainable transitions across various industries.

Regulatory Framework for Sustainable Polymers

The regulatory framework for sustainable polymers, including Ethylene Vinyl Acetate (EVA), is evolving rapidly to address environmental concerns and promote circular economy principles. At the global level, the United Nations Sustainable Development Goals (SDGs) provide a broad framework that influences polymer regulations, particularly SDG 12 (Responsible Consumption and Production) and SDG 13 (Climate Action).

In the European Union, the European Green Deal and the Circular Economy Action Plan have set ambitious targets for plastic recycling and the use of recycled content in new products. The EU's Single-Use Plastics Directive, while not directly targeting EVA, has implications for the broader polymer industry and encourages the development of more sustainable alternatives. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation also plays a crucial role in ensuring the safety of polymers and their additives.

In the United States, regulations vary by state, but there is a growing trend towards Extended Producer Responsibility (EPR) laws for packaging materials, which could impact EVA use in certain applications. The Environmental Protection Agency (EPA) has also been working on updating its Toxic Substances Control Act (TSCA) to better address polymer safety and sustainability.

Asian countries, particularly China and Japan, have been implementing stricter regulations on plastic waste and promoting the use of biodegradable and recyclable materials. China's ban on imported plastic waste has had global repercussions and has accelerated the development of domestic recycling capabilities in many countries.

Specific to EVA, its classification as a thermoplastic elastomer allows it to be potentially recycled, which aligns with many regulatory frameworks promoting circular economy principles. However, the presence of vinyl acetate in EVA can complicate recycling processes, and regulations may need to evolve to address this challenge.

Industry standards and certifications also play a crucial role in the regulatory landscape. Organizations such as ASTM International and ISO are developing standards for sustainable polymers, including test methods for biodegradability and compostability. These standards often inform regulatory decisions and can help manufacturers demonstrate compliance with sustainability requirements.

As the push for sustainable materials intensifies, it is likely that future regulations will focus more on life cycle assessments, carbon footprint reduction, and the promotion of bio-based alternatives. This evolving regulatory landscape presents both challenges and opportunities for EVA manufacturers and users, driving innovation in material design, recycling technologies, and sustainable production processes.

In the European Union, the European Green Deal and the Circular Economy Action Plan have set ambitious targets for plastic recycling and the use of recycled content in new products. The EU's Single-Use Plastics Directive, while not directly targeting EVA, has implications for the broader polymer industry and encourages the development of more sustainable alternatives. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation also plays a crucial role in ensuring the safety of polymers and their additives.

In the United States, regulations vary by state, but there is a growing trend towards Extended Producer Responsibility (EPR) laws for packaging materials, which could impact EVA use in certain applications. The Environmental Protection Agency (EPA) has also been working on updating its Toxic Substances Control Act (TSCA) to better address polymer safety and sustainability.

Asian countries, particularly China and Japan, have been implementing stricter regulations on plastic waste and promoting the use of biodegradable and recyclable materials. China's ban on imported plastic waste has had global repercussions and has accelerated the development of domestic recycling capabilities in many countries.

Specific to EVA, its classification as a thermoplastic elastomer allows it to be potentially recycled, which aligns with many regulatory frameworks promoting circular economy principles. However, the presence of vinyl acetate in EVA can complicate recycling processes, and regulations may need to evolve to address this challenge.

Industry standards and certifications also play a crucial role in the regulatory landscape. Organizations such as ASTM International and ISO are developing standards for sustainable polymers, including test methods for biodegradability and compostability. These standards often inform regulatory decisions and can help manufacturers demonstrate compliance with sustainability requirements.

As the push for sustainable materials intensifies, it is likely that future regulations will focus more on life cycle assessments, carbon footprint reduction, and the promotion of bio-based alternatives. This evolving regulatory landscape presents both challenges and opportunities for EVA manufacturers and users, driving innovation in material design, recycling technologies, and sustainable production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!