How Kevlar Supports Vast Technological Advancements?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Evolution and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has undergone significant evolution since its inception. Initially created as a replacement for steel in tires, Kevlar's exceptional strength-to-weight ratio and heat-resistant properties quickly led to its adoption in a wide range of applications. The evolution of Kevlar has been driven by continuous research and development efforts aimed at enhancing its properties and expanding its potential uses.

The primary objective behind Kevlar's development was to create a material that could provide superior strength and durability while remaining lightweight. This goal has remained central to Kevlar's evolution, with ongoing efforts to improve its performance characteristics. Over the years, researchers have focused on refining the molecular structure of Kevlar, optimizing its manufacturing processes, and exploring new formulations to enhance its already impressive properties.

One of the key milestones in Kevlar's evolution was the development of different variants tailored for specific applications. For instance, Kevlar 29 was optimized for ballistic protection, while Kevlar 49 was designed for aerospace applications requiring high modulus and low weight. These advancements have allowed Kevlar to support technological progress across diverse industries, from personal protective equipment to advanced composites in aerospace and automotive sectors.

The evolution of Kevlar has also been closely tied to advancements in polymer science and materials engineering. Researchers have explored various techniques to modify Kevlar's structure, such as incorporating nanoparticles or creating hybrid composites, to further enhance its properties. These efforts have led to improvements in areas such as impact resistance, flame retardancy, and environmental stability.

As technology continues to advance, the objectives for Kevlar's development have expanded. Current research aims to create even stronger and lighter variants of Kevlar, improve its resistance to environmental factors, and enhance its compatibility with other materials. There is also a growing focus on developing sustainable manufacturing processes for Kevlar and exploring bio-based alternatives that can offer similar performance characteristics.

The evolution of Kevlar has played a crucial role in supporting technological advancements across multiple sectors. Its unique combination of properties has enabled the development of innovative products and solutions that were previously impossible or impractical. From lightweight body armor that has saved countless lives to advanced aerospace components that have revolutionized aircraft design, Kevlar's impact on technological progress has been profound and far-reaching.

Looking ahead, the objectives for Kevlar's continued evolution are likely to focus on addressing emerging technological challenges and societal needs. This may include developing variants with enhanced electrical or thermal properties, improving its recyclability and environmental footprint, and exploring new applications in emerging fields such as renewable energy and advanced robotics. As Kevlar continues to evolve, it is poised to remain a key enabler of technological advancements for years to come.

The primary objective behind Kevlar's development was to create a material that could provide superior strength and durability while remaining lightweight. This goal has remained central to Kevlar's evolution, with ongoing efforts to improve its performance characteristics. Over the years, researchers have focused on refining the molecular structure of Kevlar, optimizing its manufacturing processes, and exploring new formulations to enhance its already impressive properties.

One of the key milestones in Kevlar's evolution was the development of different variants tailored for specific applications. For instance, Kevlar 29 was optimized for ballistic protection, while Kevlar 49 was designed for aerospace applications requiring high modulus and low weight. These advancements have allowed Kevlar to support technological progress across diverse industries, from personal protective equipment to advanced composites in aerospace and automotive sectors.

The evolution of Kevlar has also been closely tied to advancements in polymer science and materials engineering. Researchers have explored various techniques to modify Kevlar's structure, such as incorporating nanoparticles or creating hybrid composites, to further enhance its properties. These efforts have led to improvements in areas such as impact resistance, flame retardancy, and environmental stability.

As technology continues to advance, the objectives for Kevlar's development have expanded. Current research aims to create even stronger and lighter variants of Kevlar, improve its resistance to environmental factors, and enhance its compatibility with other materials. There is also a growing focus on developing sustainable manufacturing processes for Kevlar and exploring bio-based alternatives that can offer similar performance characteristics.

The evolution of Kevlar has played a crucial role in supporting technological advancements across multiple sectors. Its unique combination of properties has enabled the development of innovative products and solutions that were previously impossible or impractical. From lightweight body armor that has saved countless lives to advanced aerospace components that have revolutionized aircraft design, Kevlar's impact on technological progress has been profound and far-reaching.

Looking ahead, the objectives for Kevlar's continued evolution are likely to focus on addressing emerging technological challenges and societal needs. This may include developing variants with enhanced electrical or thermal properties, improving its recyclability and environmental footprint, and exploring new applications in emerging fields such as renewable energy and advanced robotics. As Kevlar continues to evolve, it is poised to remain a key enabler of technological advancements for years to come.

Market Demand Analysis

The market demand for Kevlar has experienced significant growth across various industries due to its exceptional properties and versatility. In the automotive sector, Kevlar's lightweight and high-strength characteristics have led to increased adoption in manufacturing components such as tires, belts, and hoses. This trend aligns with the industry's push towards fuel efficiency and improved vehicle performance. The aerospace industry has also shown a rising demand for Kevlar, particularly in aircraft and spacecraft construction, where its ability to withstand extreme temperatures and provide superior impact resistance is highly valued.

In the defense and law enforcement sectors, Kevlar remains a crucial material for personal protective equipment, including bulletproof vests and helmets. The ongoing global security concerns and technological advancements in weaponry continue to drive the demand for more effective and lightweight protective gear. Additionally, the construction industry has recognized Kevlar's potential in reinforcing concrete structures and enhancing the durability of building materials, leading to a growing market in infrastructure development.

The sports and recreation industry has embraced Kevlar for its use in high-performance equipment such as bicycles, kayaks, and protective gear for extreme sports. This sector's demand is fueled by consumers' increasing interest in lightweight, durable, and high-performance products. Moreover, the electronics industry has found applications for Kevlar in the production of smartphones, tablets, and other devices, where its strength-to-weight ratio contributes to the development of thinner and more durable products.

The marine industry has also shown a growing interest in Kevlar for boat hulls, sails, and ropes, capitalizing on its resistance to corrosion and high tensile strength. This trend is expected to continue as manufacturers seek materials that can withstand harsh marine environments while maintaining performance. In the energy sector, Kevlar's application in oil and gas exploration, particularly in deep-sea drilling operations, has created a niche market demand due to its ability to withstand high pressures and temperatures.

As environmental concerns gain prominence, the demand for sustainable and recyclable materials has impacted the Kevlar market. Manufacturers are exploring ways to incorporate Kevlar into eco-friendly products and develop recycling processes for Kevlar-based materials. This shift towards sustainability is likely to open new market opportunities and drive innovation in Kevlar applications across industries.

The global Kevlar market is projected to continue its growth trajectory, with emerging economies in Asia-Pacific and Latin America presenting significant opportunities for expansion. These regions are experiencing rapid industrialization and infrastructure development, which is expected to fuel the demand for high-performance materials like Kevlar. Furthermore, ongoing research and development efforts to enhance Kevlar's properties and explore new applications are likely to create additional market segments and sustain long-term growth in the industry.

In the defense and law enforcement sectors, Kevlar remains a crucial material for personal protective equipment, including bulletproof vests and helmets. The ongoing global security concerns and technological advancements in weaponry continue to drive the demand for more effective and lightweight protective gear. Additionally, the construction industry has recognized Kevlar's potential in reinforcing concrete structures and enhancing the durability of building materials, leading to a growing market in infrastructure development.

The sports and recreation industry has embraced Kevlar for its use in high-performance equipment such as bicycles, kayaks, and protective gear for extreme sports. This sector's demand is fueled by consumers' increasing interest in lightweight, durable, and high-performance products. Moreover, the electronics industry has found applications for Kevlar in the production of smartphones, tablets, and other devices, where its strength-to-weight ratio contributes to the development of thinner and more durable products.

The marine industry has also shown a growing interest in Kevlar for boat hulls, sails, and ropes, capitalizing on its resistance to corrosion and high tensile strength. This trend is expected to continue as manufacturers seek materials that can withstand harsh marine environments while maintaining performance. In the energy sector, Kevlar's application in oil and gas exploration, particularly in deep-sea drilling operations, has created a niche market demand due to its ability to withstand high pressures and temperatures.

As environmental concerns gain prominence, the demand for sustainable and recyclable materials has impacted the Kevlar market. Manufacturers are exploring ways to incorporate Kevlar into eco-friendly products and develop recycling processes for Kevlar-based materials. This shift towards sustainability is likely to open new market opportunities and drive innovation in Kevlar applications across industries.

The global Kevlar market is projected to continue its growth trajectory, with emerging economies in Asia-Pacific and Latin America presenting significant opportunities for expansion. These regions are experiencing rapid industrialization and infrastructure development, which is expected to fuel the demand for high-performance materials like Kevlar. Furthermore, ongoing research and development efforts to enhance Kevlar's properties and explore new applications are likely to create additional market segments and sustain long-term growth in the industry.

Kevlar Tech Challenges

Despite its remarkable properties, Kevlar faces several technological challenges that limit its full potential in various applications. One of the primary issues is its susceptibility to degradation when exposed to ultraviolet (UV) light. This sensitivity to UV radiation can lead to a reduction in strength and durability over time, particularly in outdoor applications. Researchers are actively seeking solutions to enhance Kevlar's UV resistance without compromising its other beneficial properties.

Another significant challenge lies in Kevlar's inherent stiffness, which can make it difficult to process and incorporate into certain products. While this rigidity contributes to its strength, it also limits flexibility in design and manufacturing. Engineers are exploring methods to improve Kevlar's processability and increase its compatibility with other materials, aiming to expand its use in more diverse applications.

The high cost of Kevlar production remains a persistent obstacle to its widespread adoption. The complex manufacturing process and the specialized equipment required contribute to its elevated price point. This economic barrier often restricts Kevlar's use to high-end or specialized applications, limiting its potential impact in more cost-sensitive markets. Efforts are underway to optimize production techniques and explore alternative precursors to reduce costs without sacrificing performance.

Kevlar's limited heat resistance poses challenges in environments with extreme temperatures. While it maintains its strength at moderate temperatures, exposure to high heat can cause degradation of its mechanical properties. This limitation restricts its use in certain high-temperature applications where thermal stability is crucial. Research is focused on developing heat-resistant coatings or modifying Kevlar's chemical structure to enhance its thermal performance.

The recyclability and environmental impact of Kevlar present ongoing challenges. As a synthetic polymer, Kevlar is not biodegradable, raising concerns about its long-term environmental effects. The difficulty in recycling Kevlar fibers efficiently adds to these environmental considerations. Scientists are investigating eco-friendly alternatives and recycling methods to address these sustainability issues and improve Kevlar's lifecycle management.

Lastly, the integration of Kevlar with smart technologies and responsive materials represents a frontier challenge. As industries move towards more intelligent and adaptive materials, there is a growing need to enhance Kevlar's functionality beyond its mechanical properties. Researchers are exploring ways to incorporate sensors, actuators, and other smart features into Kevlar-based materials to create multifunctional composites that can respond to environmental stimuli or provide real-time data.

Another significant challenge lies in Kevlar's inherent stiffness, which can make it difficult to process and incorporate into certain products. While this rigidity contributes to its strength, it also limits flexibility in design and manufacturing. Engineers are exploring methods to improve Kevlar's processability and increase its compatibility with other materials, aiming to expand its use in more diverse applications.

The high cost of Kevlar production remains a persistent obstacle to its widespread adoption. The complex manufacturing process and the specialized equipment required contribute to its elevated price point. This economic barrier often restricts Kevlar's use to high-end or specialized applications, limiting its potential impact in more cost-sensitive markets. Efforts are underway to optimize production techniques and explore alternative precursors to reduce costs without sacrificing performance.

Kevlar's limited heat resistance poses challenges in environments with extreme temperatures. While it maintains its strength at moderate temperatures, exposure to high heat can cause degradation of its mechanical properties. This limitation restricts its use in certain high-temperature applications where thermal stability is crucial. Research is focused on developing heat-resistant coatings or modifying Kevlar's chemical structure to enhance its thermal performance.

The recyclability and environmental impact of Kevlar present ongoing challenges. As a synthetic polymer, Kevlar is not biodegradable, raising concerns about its long-term environmental effects. The difficulty in recycling Kevlar fibers efficiently adds to these environmental considerations. Scientists are investigating eco-friendly alternatives and recycling methods to address these sustainability issues and improve Kevlar's lifecycle management.

Lastly, the integration of Kevlar with smart technologies and responsive materials represents a frontier challenge. As industries move towards more intelligent and adaptive materials, there is a growing need to enhance Kevlar's functionality beyond its mechanical properties. Researchers are exploring ways to incorporate sensors, actuators, and other smart features into Kevlar-based materials to create multifunctional composites that can respond to environmental stimuli or provide real-time data.

Current Kevlar Applications

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar improves the overall performance and lightweight properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the development of protective gear such as bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and heat-resistant properties make it ideal for applications requiring impact and ballistic protection. Innovations in this area focus on improving comfort, flexibility, and overall protective capabilities.

- Kevlar in textile and fabric applications: Kevlar fibers are incorporated into various textiles and fabrics to enhance their strength, cut-resistance, and durability. These applications include high-performance clothing, industrial gloves, and specialized fabrics for extreme environments. Research in this area aims to improve the integration of Kevlar with other materials and enhance its properties for specific use cases.

- Kevlar in automotive and transportation: The automotive and transportation industries utilize Kevlar in various components to reduce weight, improve fuel efficiency, and enhance safety. Applications include reinforced tires, brake pads, and structural components. Ongoing research focuses on optimizing Kevlar's integration with other materials for improved performance and cost-effectiveness.

- Kevlar in advanced manufacturing processes: Advanced manufacturing techniques are being developed to optimize the use of Kevlar in various applications. These processes include innovative weaving methods, 3D printing with Kevlar-reinforced materials, and novel surface treatments to enhance bonding and performance characteristics. The focus is on improving production efficiency and expanding the range of possible applications for Kevlar-based products.

02 Kevlar in protective gear and clothing

Kevlar is extensively used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.Expand Specific Solutions03 Kevlar-based fire-resistant materials

Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and building materials to enhance fire protection and safety.Expand Specific Solutions04 Kevlar in automotive applications

Kevlar is employed in various automotive components to reduce weight while maintaining strength. It is used in tires, belts, hoses, and body panels to improve fuel efficiency and overall vehicle performance.Expand Specific Solutions05 Kevlar in sporting goods and equipment

Kevlar is incorporated into sporting goods and equipment to enhance performance and durability. It is used in products such as tennis rackets, bicycle frames, and kayaks to provide strength and lightweight properties.Expand Specific Solutions

Key Kevlar Manufacturers

The Kevlar technology market is in a mature stage, with established players and widespread applications across various industries. The global market size for Kevlar and similar aramid fibers is estimated to be in the billions of dollars, with steady growth projected. Technologically, Kevlar has reached a high level of maturity, but ongoing research continues to expand its capabilities and applications. Key players in this field include DuPont (the original developer of Kevlar), as well as companies like Teijin and Honeywell. Academic institutions such as Harvard College and Tsinghua University contribute to research and development efforts. Companies like Applied Materials, Inc. and Northrop Grumman Systems Corp. utilize Kevlar in advanced technological applications, demonstrating its importance in supporting technological advancements across multiple sectors.

Applied Materials, Inc.

Technical Solution: Applied Materials has been leveraging Kevlar technology in the development of advanced manufacturing processes and equipment for the semiconductor and display industries. Their approach focuses on integrating Kevlar-based components into high-precision machinery and tools used in the production of microchips and flat panel displays. The company has developed specialized Kevlar-reinforced materials for use in critical parts of semiconductor manufacturing equipment, such as wafer handling systems and robotic arms, where high strength, low weight, and dimensional stability are crucial[13]. Applied Materials has also implemented Kevlar-based solutions in their chemical mechanical planarization (CMP) systems, utilizing the material's unique properties to enhance polishing performance and reduce contamination risks[14]. Furthermore, the company has explored the use of Kevlar composites in advanced packaging technologies for next-generation electronic devices, leveraging the material's thermal management and electrical insulation properties[15].

Strengths: Expertise in integrating advanced materials into high-tech manufacturing processes, strong industry presence, and ability to drive adoption in the semiconductor sector. Weaknesses: Limited focus on Kevlar applications outside of semiconductor and display industries.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has leveraged Kevlar technology in developing advanced aerospace and defense systems. Their approach focuses on integrating Kevlar-based materials into lightweight, high-strength structures for aircraft, spacecraft, and military equipment. The company has developed proprietary manufacturing processes to create complex Kevlar-reinforced composite structures, optimizing weight reduction while maintaining structural integrity. Northrop Grumman's technology includes the use of hybrid composites, combining Kevlar with other advanced materials like carbon fiber and ceramics to achieve specific performance characteristics[2]. They have also implemented advanced modeling and simulation techniques to predict and optimize the behavior of Kevlar-based structures under various operational conditions[4]. Additionally, the company has developed specialized Kevlar-based armor solutions for both personnel and vehicle protection, incorporating novel energy-absorbing designs[6].

Strengths: Cutting-edge aerospace and defense applications, advanced manufacturing capabilities, and integration with other high-performance materials. Weaknesses: High development costs and potential limitations in non-military applications.

Kevlar Innovations Analysis

Protective material

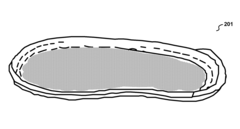

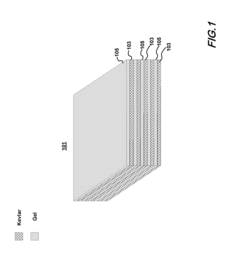

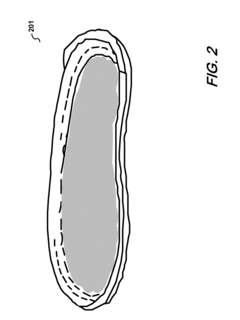

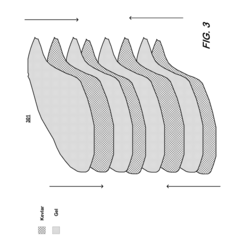

PatentInactiveUS20180292181A1

Innovation

- An enhanced ballistic material is created by interleaving layers of high tensile strength synthetic or polymeric fibers in a mesh weave with a gel matrix material, which remains soft and flexible, allowing for effective projectile stopping while maintaining comfort and flexibility, achieved through the use of heat and pressure to impregnate the gel matrix into the weave layers.

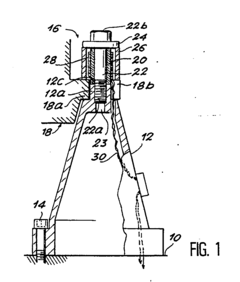

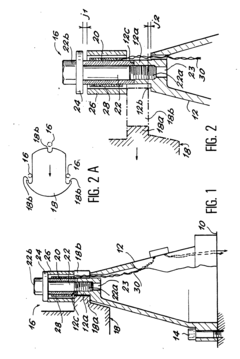

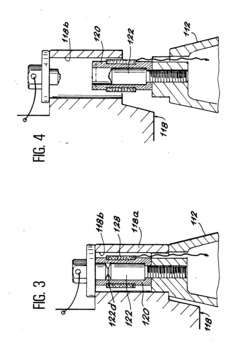

Device for a temporary connection, especially for the appendix of an artificial satellite and process of opening this connection

PatentInactiveEP0402263A1

Innovation

- A temporary connection device utilizing a holding mechanism with a release member made of shape-memory material that changes shape or dimensions when heated above its structural transformation temperature, allowing for controlled elongation or breakage of tie rods or tilting brackets, eliminating mechanical tension and enabling relative movement between elements.

Environmental Impact of Kevlar

Kevlar, a high-strength synthetic fiber developed by DuPont, has revolutionized numerous industries since its introduction in the 1970s. While its exceptional properties have led to widespread adoption, it is crucial to examine the environmental impact of Kevlar throughout its lifecycle.

The production of Kevlar involves energy-intensive processes and the use of various chemicals. The primary raw materials, para-phenylenediamine and terephthaloyl chloride, are derived from petroleum products, contributing to the depletion of non-renewable resources. The manufacturing process also generates emissions and waste, which require careful management to minimize environmental harm.

However, Kevlar's durability and longevity offer significant environmental benefits. Its exceptional strength-to-weight ratio allows for the creation of lighter, more fuel-efficient vehicles and aircraft, reducing overall carbon emissions during their operational lifetimes. In construction applications, Kevlar-reinforced materials can extend the lifespan of structures, reducing the need for frequent replacements and associated resource consumption.

Kevlar's resistance to degradation presents both advantages and challenges from an environmental perspective. While its durability reduces the frequency of replacement and waste generation, it also means that Kevlar products persist in the environment for extended periods when discarded. This persistence raises concerns about long-term accumulation in landfills and potential impacts on ecosystems.

Recycling Kevlar presents technical challenges due to its complex molecular structure. Current recycling methods often result in downgraded materials with limited applications. However, ongoing research aims to develop more efficient recycling processes, which could significantly improve the material's end-of-life environmental profile.

In the realm of environmental protection, Kevlar finds applications in filtration systems for industrial emissions and wastewater treatment. Its chemical resistance and durability make it an effective material for removing pollutants, contributing to cleaner air and water resources.

The use of Kevlar in protective gear for environmental workers and first responders indirectly supports environmental conservation efforts. By providing superior protection, it enables personnel to operate more effectively in hazardous environments, including those affected by natural disasters or industrial accidents.

As sustainability becomes an increasingly critical factor in material selection, the Kevlar industry is exploring bio-based alternatives and more environmentally friendly production methods. These efforts aim to reduce the material's carbon footprint and improve its overall environmental performance throughout its lifecycle.

In conclusion, while Kevlar's production and end-of-life management present environmental challenges, its unique properties offer significant benefits in terms of resource efficiency and environmental protection applications. Balancing these factors is crucial for the sustainable use of Kevlar in future technological advancements.

The production of Kevlar involves energy-intensive processes and the use of various chemicals. The primary raw materials, para-phenylenediamine and terephthaloyl chloride, are derived from petroleum products, contributing to the depletion of non-renewable resources. The manufacturing process also generates emissions and waste, which require careful management to minimize environmental harm.

However, Kevlar's durability and longevity offer significant environmental benefits. Its exceptional strength-to-weight ratio allows for the creation of lighter, more fuel-efficient vehicles and aircraft, reducing overall carbon emissions during their operational lifetimes. In construction applications, Kevlar-reinforced materials can extend the lifespan of structures, reducing the need for frequent replacements and associated resource consumption.

Kevlar's resistance to degradation presents both advantages and challenges from an environmental perspective. While its durability reduces the frequency of replacement and waste generation, it also means that Kevlar products persist in the environment for extended periods when discarded. This persistence raises concerns about long-term accumulation in landfills and potential impacts on ecosystems.

Recycling Kevlar presents technical challenges due to its complex molecular structure. Current recycling methods often result in downgraded materials with limited applications. However, ongoing research aims to develop more efficient recycling processes, which could significantly improve the material's end-of-life environmental profile.

In the realm of environmental protection, Kevlar finds applications in filtration systems for industrial emissions and wastewater treatment. Its chemical resistance and durability make it an effective material for removing pollutants, contributing to cleaner air and water resources.

The use of Kevlar in protective gear for environmental workers and first responders indirectly supports environmental conservation efforts. By providing superior protection, it enables personnel to operate more effectively in hazardous environments, including those affected by natural disasters or industrial accidents.

As sustainability becomes an increasingly critical factor in material selection, the Kevlar industry is exploring bio-based alternatives and more environmentally friendly production methods. These efforts aim to reduce the material's carbon footprint and improve its overall environmental performance throughout its lifecycle.

In conclusion, while Kevlar's production and end-of-life management present environmental challenges, its unique properties offer significant benefits in terms of resource efficiency and environmental protection applications. Balancing these factors is crucial for the sustainable use of Kevlar in future technological advancements.

Kevlar in Emerging Industries

Kevlar, a high-strength synthetic fiber, is finding its way into numerous emerging industries, revolutionizing product development and enabling technological advancements. In the field of aerospace, Kevlar is being utilized to create lightweight yet durable components for aircraft and spacecraft. Its exceptional strength-to-weight ratio makes it an ideal material for reducing fuel consumption while maintaining structural integrity.

In the renewable energy sector, Kevlar is playing a crucial role in the development of more efficient wind turbine blades. The material's high tensile strength and resistance to fatigue allow for the construction of longer, more flexible blades that can capture wind energy more effectively. This advancement is contributing to the increased adoption of wind power as a viable alternative to fossil fuels.

The automotive industry is also benefiting from Kevlar's unique properties. As electric vehicles gain popularity, manufacturers are incorporating Kevlar into battery casings to enhance safety and durability. The material's heat-resistant qualities and ability to withstand impact make it an excellent choice for protecting sensitive battery components.

In the field of wearable technology, Kevlar is being integrated into smart fabrics and flexible electronics. Its durability and lightweight nature allow for the creation of comfortable, long-lasting wearable devices that can monitor health metrics, track physical activity, and even provide haptic feedback. This integration is pushing the boundaries of what's possible in personal health monitoring and human-computer interaction.

The marine industry is exploring Kevlar's potential in developing advanced hull materials for boats and submarines. The material's resistance to corrosion and high strength make it an attractive option for creating vessels that are both lightweight and capable of withstanding harsh ocean environments. This application could lead to more fuel-efficient and durable marine vessels, revolutionizing maritime transportation and exploration.

In the realm of sports equipment, Kevlar is being used to create high-performance gear that offers enhanced protection and improved performance. From bicycle tires to protective gear for extreme sports, the material's strength and flexibility are enabling athletes to push their limits while minimizing the risk of injury.

As these emerging industries continue to evolve, Kevlar's versatility and unique properties are likely to play an increasingly important role in driving innovation and technological advancements. The material's ability to combine strength, lightness, and durability makes it a valuable asset in addressing the complex challenges faced by various sectors, from energy production to personal safety and beyond.

In the renewable energy sector, Kevlar is playing a crucial role in the development of more efficient wind turbine blades. The material's high tensile strength and resistance to fatigue allow for the construction of longer, more flexible blades that can capture wind energy more effectively. This advancement is contributing to the increased adoption of wind power as a viable alternative to fossil fuels.

The automotive industry is also benefiting from Kevlar's unique properties. As electric vehicles gain popularity, manufacturers are incorporating Kevlar into battery casings to enhance safety and durability. The material's heat-resistant qualities and ability to withstand impact make it an excellent choice for protecting sensitive battery components.

In the field of wearable technology, Kevlar is being integrated into smart fabrics and flexible electronics. Its durability and lightweight nature allow for the creation of comfortable, long-lasting wearable devices that can monitor health metrics, track physical activity, and even provide haptic feedback. This integration is pushing the boundaries of what's possible in personal health monitoring and human-computer interaction.

The marine industry is exploring Kevlar's potential in developing advanced hull materials for boats and submarines. The material's resistance to corrosion and high strength make it an attractive option for creating vessels that are both lightweight and capable of withstanding harsh ocean environments. This application could lead to more fuel-efficient and durable marine vessels, revolutionizing maritime transportation and exploration.

In the realm of sports equipment, Kevlar is being used to create high-performance gear that offers enhanced protection and improved performance. From bicycle tires to protective gear for extreme sports, the material's strength and flexibility are enabling athletes to push their limits while minimizing the risk of injury.

As these emerging industries continue to evolve, Kevlar's versatility and unique properties are likely to play an increasingly important role in driving innovation and technological advancements. The material's ability to combine strength, lightness, and durability makes it a valuable asset in addressing the complex challenges faced by various sectors, from energy production to personal safety and beyond.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!