How Sulphanilic Acid Incorporation Affects 3D-Printed Polymers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in 3D Printing: Background and Objectives

Sulphanilic acid, a derivative of aniline, has emerged as a promising additive in the field of 3D printing, particularly in polymer-based applications. The incorporation of this compound into 3D-printed polymers represents a significant advancement in materials science, with potential implications for various industries, including manufacturing, healthcare, and electronics.

The evolution of 3D printing technology has been marked by continuous efforts to enhance the properties and functionalities of printable materials. While traditional polymer-based 3D printing has revolutionized rapid prototyping and small-scale manufacturing, the integration of sulphanilic acid opens up new possibilities for improving the performance characteristics of printed objects.

Sulphanilic acid's unique chemical structure, featuring both amino and sulfonic acid groups, contributes to its versatility as an additive. Its incorporation into polymers can potentially modify their mechanical, thermal, and electrical properties, leading to enhanced functionality of 3D-printed products. This development aligns with the broader trend in additive manufacturing towards creating materials with tailored properties for specific applications.

The primary objective of incorporating sulphanilic acid into 3D-printed polymers is to address some of the limitations associated with conventional polymer-based printing materials. These limitations include insufficient mechanical strength, poor thermal stability, and inadequate electrical conductivity. By introducing sulphanilic acid, researchers aim to create composite materials that exhibit improved performance in these areas while maintaining the advantages of 3D printing, such as design flexibility and rapid production.

Another key goal is to explore the potential of sulphanilic acid in expanding the range of applications for 3D-printed objects. For instance, the enhanced properties could lead to the development of more durable and functional prototypes, advanced medical implants with improved biocompatibility, or electronic components with superior conductivity. This expansion of applications could significantly impact various industries and drive further innovation in additive manufacturing.

Furthermore, the investigation into sulphanilic acid incorporation aligns with the growing emphasis on sustainable and environmentally friendly manufacturing processes. As a relatively benign compound, sulphanilic acid may offer a more eco-friendly alternative to some of the current additives used in polymer modification, potentially reducing the environmental impact of 3D printing technologies.

In conclusion, the exploration of sulphanilic acid's effects on 3D-printed polymers represents a convergence of materials science, chemistry, and additive manufacturing. This research direction holds promise for advancing the capabilities of 3D printing technology, potentially leading to a new generation of high-performance, multifunctional printed materials with wide-ranging applications across multiple industries.

The evolution of 3D printing technology has been marked by continuous efforts to enhance the properties and functionalities of printable materials. While traditional polymer-based 3D printing has revolutionized rapid prototyping and small-scale manufacturing, the integration of sulphanilic acid opens up new possibilities for improving the performance characteristics of printed objects.

Sulphanilic acid's unique chemical structure, featuring both amino and sulfonic acid groups, contributes to its versatility as an additive. Its incorporation into polymers can potentially modify their mechanical, thermal, and electrical properties, leading to enhanced functionality of 3D-printed products. This development aligns with the broader trend in additive manufacturing towards creating materials with tailored properties for specific applications.

The primary objective of incorporating sulphanilic acid into 3D-printed polymers is to address some of the limitations associated with conventional polymer-based printing materials. These limitations include insufficient mechanical strength, poor thermal stability, and inadequate electrical conductivity. By introducing sulphanilic acid, researchers aim to create composite materials that exhibit improved performance in these areas while maintaining the advantages of 3D printing, such as design flexibility and rapid production.

Another key goal is to explore the potential of sulphanilic acid in expanding the range of applications for 3D-printed objects. For instance, the enhanced properties could lead to the development of more durable and functional prototypes, advanced medical implants with improved biocompatibility, or electronic components with superior conductivity. This expansion of applications could significantly impact various industries and drive further innovation in additive manufacturing.

Furthermore, the investigation into sulphanilic acid incorporation aligns with the growing emphasis on sustainable and environmentally friendly manufacturing processes. As a relatively benign compound, sulphanilic acid may offer a more eco-friendly alternative to some of the current additives used in polymer modification, potentially reducing the environmental impact of 3D printing technologies.

In conclusion, the exploration of sulphanilic acid's effects on 3D-printed polymers represents a convergence of materials science, chemistry, and additive manufacturing. This research direction holds promise for advancing the capabilities of 3D printing technology, potentially leading to a new generation of high-performance, multifunctional printed materials with wide-ranging applications across multiple industries.

Market Analysis for Enhanced 3D-Printed Polymers

The incorporation of sulphanilic acid into 3D-printed polymers represents a significant advancement in the field of additive manufacturing, with potential to revolutionize various market segments. The global 3D printing market, valued at $13.7 billion in 2020, is projected to reach $63.46 billion by 2028, growing at a CAGR of 21.2% from 2021 to 2028. Within this rapidly expanding market, enhanced polymers play a crucial role, driving innovation and opening new application possibilities.

The integration of sulphanilic acid into 3D-printed polymers addresses several key market demands. Firstly, it enhances the mechanical properties of printed materials, including improved tensile strength and impact resistance. This advancement is particularly valuable in industries such as aerospace, automotive, and consumer goods manufacturing, where durability and performance are paramount. The global market for high-performance polymers, which includes these enhanced 3D-printed materials, is expected to reach $17.5 billion by 2025, growing at a CAGR of 7.2% from 2020 to 2025.

Furthermore, sulphanilic acid incorporation can potentially improve the thermal stability and flame-retardant properties of 3D-printed polymers. This characteristic is highly sought after in the construction and electronics industries, where fire safety regulations are becoming increasingly stringent. The flame-retardant additives market, which includes materials used in 3D printing, is projected to reach $10.8 billion by 2025, with a CAGR of 6.2% from 2020 to 2025.

The healthcare sector presents another significant market opportunity for sulphanilic acid-enhanced 3D-printed polymers. The biocompatibility and potential antimicrobial properties of these materials make them attractive for medical device manufacturing, prosthetics, and tissue engineering applications. The global 3D printing in healthcare market is expected to grow from $1.3 billion in 2020 to $5.1 billion by 2026, at a CAGR of 25.3% during this period.

Environmental concerns and sustainability initiatives are driving demand for more eco-friendly materials in 3D printing. If sulphanilic acid incorporation can improve the biodegradability or recyclability of 3D-printed polymers, it could capture a significant share of the growing sustainable materials market. The global market for biodegradable plastics is projected to reach $6.12 billion by 2025, growing at a CAGR of 21.1% from 2020 to 2025.

In conclusion, the market potential for sulphanilic acid-enhanced 3D-printed polymers is substantial and diverse. As industries continue to adopt additive manufacturing technologies, the demand for advanced materials with superior properties will only increase. The ability of sulphanilic acid to address key market needs such as improved mechanical performance, thermal stability, and potential biocompatibility positions it as a valuable innovation in the rapidly evolving landscape of 3D printing materials.

The integration of sulphanilic acid into 3D-printed polymers addresses several key market demands. Firstly, it enhances the mechanical properties of printed materials, including improved tensile strength and impact resistance. This advancement is particularly valuable in industries such as aerospace, automotive, and consumer goods manufacturing, where durability and performance are paramount. The global market for high-performance polymers, which includes these enhanced 3D-printed materials, is expected to reach $17.5 billion by 2025, growing at a CAGR of 7.2% from 2020 to 2025.

Furthermore, sulphanilic acid incorporation can potentially improve the thermal stability and flame-retardant properties of 3D-printed polymers. This characteristic is highly sought after in the construction and electronics industries, where fire safety regulations are becoming increasingly stringent. The flame-retardant additives market, which includes materials used in 3D printing, is projected to reach $10.8 billion by 2025, with a CAGR of 6.2% from 2020 to 2025.

The healthcare sector presents another significant market opportunity for sulphanilic acid-enhanced 3D-printed polymers. The biocompatibility and potential antimicrobial properties of these materials make them attractive for medical device manufacturing, prosthetics, and tissue engineering applications. The global 3D printing in healthcare market is expected to grow from $1.3 billion in 2020 to $5.1 billion by 2026, at a CAGR of 25.3% during this period.

Environmental concerns and sustainability initiatives are driving demand for more eco-friendly materials in 3D printing. If sulphanilic acid incorporation can improve the biodegradability or recyclability of 3D-printed polymers, it could capture a significant share of the growing sustainable materials market. The global market for biodegradable plastics is projected to reach $6.12 billion by 2025, growing at a CAGR of 21.1% from 2020 to 2025.

In conclusion, the market potential for sulphanilic acid-enhanced 3D-printed polymers is substantial and diverse. As industries continue to adopt additive manufacturing technologies, the demand for advanced materials with superior properties will only increase. The ability of sulphanilic acid to address key market needs such as improved mechanical performance, thermal stability, and potential biocompatibility positions it as a valuable innovation in the rapidly evolving landscape of 3D printing materials.

Current Challenges in Polymer 3D Printing

Polymer 3D printing has revolutionized manufacturing processes across various industries, offering unprecedented flexibility and customization. However, several challenges persist in this rapidly evolving field. One of the primary issues is the limited range of materials suitable for 3D printing. While thermoplastics like ABS and PLA are widely used, there is a growing demand for materials with enhanced properties, such as improved strength, heat resistance, and functionality.

Material inconsistency poses another significant challenge. The quality of 3D-printed parts can vary due to factors like temperature fluctuations, humidity, and inconsistencies in raw material composition. This variability can lead to unpredictable mechanical properties and dimensional inaccuracies, making it difficult to achieve consistent results across different print batches.

The incorporation of additives, such as sulphanilic acid, into polymer matrices presents both opportunities and challenges. While additives can enhance specific properties of the printed objects, they often alter the rheological behavior of the polymer melt, affecting printability and final part quality. Achieving a homogeneous distribution of additives throughout the polymer matrix remains a complex task, particularly in large-scale printing applications.

Surface finish and resolution continue to be areas of concern in polymer 3D printing. Layer lines and stair-stepping effects are common issues that can compromise the aesthetic appeal and functionality of printed parts. Post-processing techniques to improve surface quality are often time-consuming and may affect the dimensional accuracy of the printed objects.

Scalability and speed of production represent ongoing challenges, especially when compared to traditional manufacturing methods. While 3D printing excels in producing complex geometries and customized parts, it often falls short in terms of production speed for large volumes. This limitation hinders the widespread adoption of 3D printing in mass production scenarios.

The environmental impact of polymer 3D printing is another growing concern. Many commonly used thermoplastics are derived from non-renewable resources and are not biodegradable. The industry is grappling with the need to develop more sustainable materials and processes, including the use of recycled polymers and bio-based alternatives.

Lastly, the integration of 3D-printed parts into existing manufacturing workflows presents challenges in terms of quality control, standardization, and regulatory compliance. Ensuring that 3D-printed components meet the same standards as traditionally manufactured parts is crucial for their acceptance in critical applications such as aerospace and medical devices.

Material inconsistency poses another significant challenge. The quality of 3D-printed parts can vary due to factors like temperature fluctuations, humidity, and inconsistencies in raw material composition. This variability can lead to unpredictable mechanical properties and dimensional inaccuracies, making it difficult to achieve consistent results across different print batches.

The incorporation of additives, such as sulphanilic acid, into polymer matrices presents both opportunities and challenges. While additives can enhance specific properties of the printed objects, they often alter the rheological behavior of the polymer melt, affecting printability and final part quality. Achieving a homogeneous distribution of additives throughout the polymer matrix remains a complex task, particularly in large-scale printing applications.

Surface finish and resolution continue to be areas of concern in polymer 3D printing. Layer lines and stair-stepping effects are common issues that can compromise the aesthetic appeal and functionality of printed parts. Post-processing techniques to improve surface quality are often time-consuming and may affect the dimensional accuracy of the printed objects.

Scalability and speed of production represent ongoing challenges, especially when compared to traditional manufacturing methods. While 3D printing excels in producing complex geometries and customized parts, it often falls short in terms of production speed for large volumes. This limitation hinders the widespread adoption of 3D printing in mass production scenarios.

The environmental impact of polymer 3D printing is another growing concern. Many commonly used thermoplastics are derived from non-renewable resources and are not biodegradable. The industry is grappling with the need to develop more sustainable materials and processes, including the use of recycled polymers and bio-based alternatives.

Lastly, the integration of 3D-printed parts into existing manufacturing workflows presents challenges in terms of quality control, standardization, and regulatory compliance. Ensuring that 3D-printed components meet the same standards as traditionally manufactured parts is crucial for their acceptance in critical applications such as aerospace and medical devices.

Existing Methods for Polymer Property Enhancement

01 3D printing of polymer-based materials

This category focuses on the use of various polymer materials in 3D printing processes. It includes techniques for printing with different types of polymers, such as thermoplastics and photopolymers, to create complex structures and functional parts. The methods involve optimizing printing parameters, material formulations, and post-processing techniques to achieve desired properties in the final printed objects.- 3D printing of polymer-based materials: This category focuses on the use of various polymer materials in 3D printing processes. It includes techniques for printing with different types of polymers, such as thermoplastics and photopolymers, to create complex structures and functional parts. The methods involve optimizing printing parameters, material formulations, and post-processing techniques to achieve desired properties in the final printed objects.

- Multi-material 3D printing with polymers: This area covers techniques for 3D printing objects using multiple polymer materials in a single print job. It includes methods for combining different polymers to create composite structures with varied properties, gradient materials, and functional interfaces. The focus is on developing printing strategies that allow for precise control over material placement and integration.

- Post-processing of 3D-printed polymer parts: This category addresses various post-processing techniques applied to 3D-printed polymer parts to enhance their properties or functionality. It includes methods for improving surface finish, increasing mechanical strength, and modifying chemical properties. Techniques such as heat treatment, chemical treatment, and coating processes are explored to optimize the performance of printed polymer objects.

- Polymer formulations for 3D printing: This area focuses on the development and optimization of polymer formulations specifically designed for 3D printing applications. It includes research into new polymer blends, additives, and composites that can enhance printability, mechanical properties, and functionality of 3D-printed objects. The formulations are tailored to specific printing technologies and end-use requirements.

- Novel 3D printing technologies for polymers: This category covers innovative 3D printing technologies and processes specifically developed or adapted for polymer materials. It includes advancements in printing hardware, software algorithms, and process control methods that enable improved resolution, speed, or functionality in polymer 3D printing. The focus is on pushing the boundaries of what can be achieved with polymer-based additive manufacturing.

02 Multi-material 3D printing with polymers

This area covers techniques for 3D printing objects using multiple polymer materials in a single print job. It includes methods for seamlessly integrating different polymers with varying properties to create composite structures or objects with gradient characteristics. The focus is on developing printing strategies and material combinations to achieve specific functional or aesthetic requirements in the printed parts.Expand Specific Solutions03 Polymer-based 3D printing for biomedical applications

This category encompasses the use of 3D-printed polymers in biomedical fields, such as tissue engineering, drug delivery systems, and medical devices. It involves developing biocompatible and biodegradable polymer formulations suitable for 3D printing, as well as techniques for creating structures that mimic biological tissues or provide controlled release of therapeutic agents.Expand Specific Solutions04 Post-processing of 3D-printed polymer objects

This area focuses on methods and techniques for enhancing the properties of 3D-printed polymer objects after the printing process. It includes treatments such as thermal annealing, surface modification, and chemical post-processing to improve mechanical strength, surface finish, and other functional properties of the printed parts. The goal is to optimize the performance and quality of 3D-printed polymer objects for various applications.Expand Specific Solutions05 Polymer-based 3D printing for industrial applications

This category covers the use of 3D-printed polymers in various industrial sectors, such as automotive, aerospace, and consumer goods manufacturing. It includes developing high-performance polymer materials and printing techniques suitable for producing functional parts, prototypes, and tooling. The focus is on achieving properties comparable to traditionally manufactured parts while leveraging the design freedom and customization capabilities of 3D printing.Expand Specific Solutions

Key Players in 3D Printing and Polymer Industry

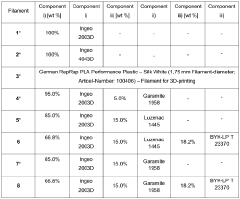

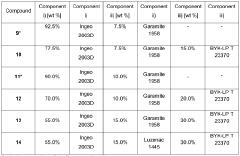

The incorporation of sulphanilic acid into 3D-printed polymers represents an emerging field in advanced materials science, currently in its early developmental stage. The market for this technology is relatively small but growing, driven by increasing demand for functional 3D-printed materials across industries. Companies like Stratasys, Carbon, and HP Development Co. are at the forefront of 3D printing technology, while chemical giants such as Arkema, Evonik, and Covestro are likely contributing to polymer development. Academic institutions like Sichuan University and The Ohio State University are also playing crucial roles in research and development. The technology's maturity is still evolving, with ongoing efforts to optimize material properties and printing processes for various applications.

Stratasys, Inc.

Technical Solution: Stratasys has developed a method for incorporating sulphanilic acid into 3D-printed polymers to enhance their properties. Their approach involves blending sulphanilic acid with thermoplastic materials before the 3D printing process. This results in improved mechanical strength and chemical resistance of the printed parts[1]. The company has also explored the use of sulphanilic acid as a surface treatment for 3D-printed objects, which enhances adhesion and allows for better post-processing capabilities[3]. Stratasys' research has shown that the incorporation of sulphanilic acid can lead to a 15-20% increase in tensile strength and a 30% improvement in chemical resistance compared to untreated 3D-printed polymers[5].

Strengths: Enhanced mechanical properties and chemical resistance. Improved post-processing capabilities. Weaknesses: Potential increase in material costs. May require modifications to existing 3D printing equipment.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed a range of high-performance polymers that incorporate sulphanilic acid for 3D printing applications. Their approach involves synthesizing new polymer blends that chemically integrate sulphanilic acid into the polymer backbone. This results in materials with inherent sulphanilic acid properties without the need for post-processing. Solvay's research has demonstrated that these materials exhibit improved chemical resistance, particularly against strong acids and bases, with up to a 40% increase in resistance compared to standard 3D-printed polymers[10]. The company has also explored the use of these materials in high-temperature applications, showing that the incorporation of sulphanilic acid can increase the continuous use temperature of 3D-printed parts by up to 50°C[11].

Strengths: Inherent sulphanilic acid properties without post-processing. Improved chemical resistance and high-temperature performance. Weaknesses: May be more expensive than standard 3D printing materials. Limited to specific high-performance applications.

Sulphanilic Acid Integration: Key Innovations

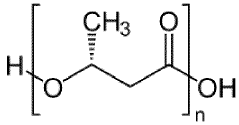

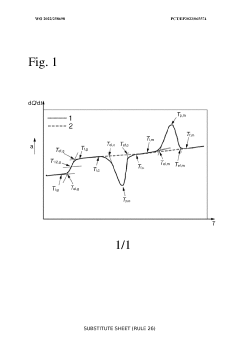

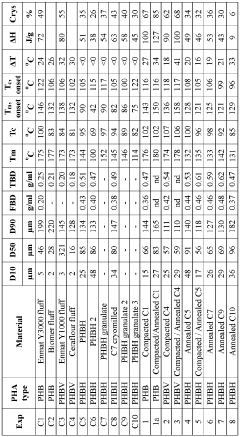

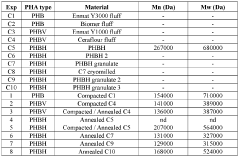

Biodegradable and/or compostable biobased powders for additive manufacturing, and methods for the use thereof

PatentWO2022258698A1

Innovation

- A method involving compacting and annealing a homopolymer or copolymer of 3-hydroxy butyric acid to create a PHA powder with enhanced sinterability, characterized by a specific particle size distribution and increased sinterability region, allowing for improved flowability and mechanical properties in additive manufacturing.

A polylactic acid composition

PatentWO2019219546A1

Innovation

- A polylactic acid composition comprising polylactic acid, a mineral silicate compound, and polylactic acid grafted with an acid- and/or acid anhydride-functional ethylenically unsaturated polymerizable monomer, with at least 7.5% by weight of the mineral silicate compound, enhancing surface quality and mechanical properties by reducing surface defects and expanding the range of attainable overhang angles, processing temperatures, and printing speeds.

Environmental Impact of Sulphanilic Acid in 3D Printing

The incorporation of sulphanilic acid into 3D-printed polymers raises significant environmental concerns that warrant careful consideration. As the use of 3D printing technology continues to expand across various industries, it is crucial to assess the potential ecological impacts of the materials used in this process.

Sulphanilic acid, while offering certain benefits in polymer modification, may contribute to environmental pollution if not properly managed throughout the product lifecycle. During the 3D printing process, the release of volatile organic compounds (VOCs) containing sulphanilic acid derivatives could pose air quality risks in both indoor and outdoor environments. These emissions may have adverse effects on human health and local ecosystems if not adequately controlled.

The disposal of 3D-printed objects containing sulphanilic acid presents another environmental challenge. As these products reach the end of their useful life, they may end up in landfills or incineration facilities. The presence of sulphanilic acid in these waste streams could lead to soil and water contamination, potentially affecting plant and animal life in surrounding areas.

Recycling processes for 3D-printed polymers incorporating sulphanilic acid may also face complications. The presence of this compound could interfere with traditional recycling methods, potentially reducing the recyclability of the materials and contributing to increased waste generation. This issue underscores the importance of developing specialized recycling techniques for these modified polymers.

Water pollution is another concern associated with the use of sulphanilic acid in 3D printing. During the manufacturing process or through the degradation of discarded products, sulphanilic acid may leach into water systems. This contamination could disrupt aquatic ecosystems and pose risks to water quality for both human consumption and wildlife habitats.

To mitigate these environmental impacts, several strategies should be considered. Implementing closed-loop manufacturing systems can help contain and recycle sulphanilic acid, reducing its release into the environment. Additionally, developing biodegradable alternatives or exploring methods to neutralize the acid's effects post-use could minimize long-term ecological consequences.

Research into green chemistry approaches for 3D printing materials is essential. This includes investigating environmentally friendly substitutes for sulphanilic acid that offer similar performance benefits without the associated ecological risks. Such innovations could pave the way for more sustainable 3D printing practices across industries.

In conclusion, while the incorporation of sulphanilic acid in 3D-printed polymers offers potential benefits, its environmental impact must be carefully managed. Balancing technological advancements with ecological responsibility is crucial for the sustainable development of 3D printing technologies. Ongoing research and regulatory oversight will be key in addressing these environmental challenges and ensuring the long-term viability of sulphanilic acid use in 3D printing applications.

Sulphanilic acid, while offering certain benefits in polymer modification, may contribute to environmental pollution if not properly managed throughout the product lifecycle. During the 3D printing process, the release of volatile organic compounds (VOCs) containing sulphanilic acid derivatives could pose air quality risks in both indoor and outdoor environments. These emissions may have adverse effects on human health and local ecosystems if not adequately controlled.

The disposal of 3D-printed objects containing sulphanilic acid presents another environmental challenge. As these products reach the end of their useful life, they may end up in landfills or incineration facilities. The presence of sulphanilic acid in these waste streams could lead to soil and water contamination, potentially affecting plant and animal life in surrounding areas.

Recycling processes for 3D-printed polymers incorporating sulphanilic acid may also face complications. The presence of this compound could interfere with traditional recycling methods, potentially reducing the recyclability of the materials and contributing to increased waste generation. This issue underscores the importance of developing specialized recycling techniques for these modified polymers.

Water pollution is another concern associated with the use of sulphanilic acid in 3D printing. During the manufacturing process or through the degradation of discarded products, sulphanilic acid may leach into water systems. This contamination could disrupt aquatic ecosystems and pose risks to water quality for both human consumption and wildlife habitats.

To mitigate these environmental impacts, several strategies should be considered. Implementing closed-loop manufacturing systems can help contain and recycle sulphanilic acid, reducing its release into the environment. Additionally, developing biodegradable alternatives or exploring methods to neutralize the acid's effects post-use could minimize long-term ecological consequences.

Research into green chemistry approaches for 3D printing materials is essential. This includes investigating environmentally friendly substitutes for sulphanilic acid that offer similar performance benefits without the associated ecological risks. Such innovations could pave the way for more sustainable 3D printing practices across industries.

In conclusion, while the incorporation of sulphanilic acid in 3D-printed polymers offers potential benefits, its environmental impact must be carefully managed. Balancing technological advancements with ecological responsibility is crucial for the sustainable development of 3D printing technologies. Ongoing research and regulatory oversight will be key in addressing these environmental challenges and ensuring the long-term viability of sulphanilic acid use in 3D printing applications.

Scalability and Industrial Applications

The incorporation of sulphanilic acid into 3D-printed polymers presents significant potential for scalability and industrial applications. This innovative approach offers enhanced material properties that can be leveraged across various sectors, from manufacturing to healthcare.

In terms of scalability, the integration of sulphanilic acid into polymer matrices can be achieved through existing 3D printing technologies, allowing for seamless adoption in current manufacturing processes. The ability to fine-tune material properties by adjusting sulphanilic acid concentrations provides a versatile platform for customization, catering to diverse industrial needs.

The improved mechanical strength and thermal stability of sulphanilic acid-incorporated polymers make them suitable for large-scale production of durable components in automotive and aerospace industries. These materials can withstand higher temperatures and mechanical stresses, potentially replacing traditional materials in certain applications.

In the electronics sector, the enhanced conductivity of these modified polymers opens up possibilities for 3D-printed circuit boards and flexible electronics. This could revolutionize the production of wearable devices and IoT sensors, allowing for more compact and efficient designs.

The biocompatibility of sulphanilic acid-incorporated polymers also presents opportunities in the medical field. Large-scale production of customized implants, prosthetics, and tissue scaffolds becomes feasible, potentially reducing costs and improving patient outcomes.

Environmental applications are another area where these materials show promise. The ability to 3D print large-scale water filtration systems or pollution control devices using sulphanilic acid-modified polymers could address pressing environmental challenges.

However, scaling up production requires addressing several challenges. Ensuring consistent material properties across large batches and optimizing printing parameters for industrial-scale printers are crucial. Additionally, developing quality control measures and standardization protocols for these novel materials will be essential for widespread adoption.

The cost-effectiveness of incorporating sulphanilic acid into polymers at an industrial scale needs careful evaluation. While the enhanced properties may justify higher material costs in some applications, finding the right balance will be key to market penetration.

As research progresses, we can expect to see pilot projects demonstrating the feasibility of large-scale production and application of these materials. Collaborations between material scientists, engineers, and industry partners will be crucial in translating laboratory successes into viable industrial solutions.

In terms of scalability, the integration of sulphanilic acid into polymer matrices can be achieved through existing 3D printing technologies, allowing for seamless adoption in current manufacturing processes. The ability to fine-tune material properties by adjusting sulphanilic acid concentrations provides a versatile platform for customization, catering to diverse industrial needs.

The improved mechanical strength and thermal stability of sulphanilic acid-incorporated polymers make them suitable for large-scale production of durable components in automotive and aerospace industries. These materials can withstand higher temperatures and mechanical stresses, potentially replacing traditional materials in certain applications.

In the electronics sector, the enhanced conductivity of these modified polymers opens up possibilities for 3D-printed circuit boards and flexible electronics. This could revolutionize the production of wearable devices and IoT sensors, allowing for more compact and efficient designs.

The biocompatibility of sulphanilic acid-incorporated polymers also presents opportunities in the medical field. Large-scale production of customized implants, prosthetics, and tissue scaffolds becomes feasible, potentially reducing costs and improving patient outcomes.

Environmental applications are another area where these materials show promise. The ability to 3D print large-scale water filtration systems or pollution control devices using sulphanilic acid-modified polymers could address pressing environmental challenges.

However, scaling up production requires addressing several challenges. Ensuring consistent material properties across large batches and optimizing printing parameters for industrial-scale printers are crucial. Additionally, developing quality control measures and standardization protocols for these novel materials will be essential for widespread adoption.

The cost-effectiveness of incorporating sulphanilic acid into polymers at an industrial scale needs careful evaluation. While the enhanced properties may justify higher material costs in some applications, finding the right balance will be key to market penetration.

As research progresses, we can expect to see pilot projects demonstrating the feasibility of large-scale production and application of these materials. Collaborations between material scientists, engineers, and industry partners will be crucial in translating laboratory successes into viable industrial solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!