How to Choose a Phase Change Material (PCM) for Industrial Heat Storage: Temperature, Latent Heat & Cost Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Selection Criteria and Objectives

The selection of an appropriate Phase Change Material (PCM) for industrial heat storage applications is a critical process that requires careful consideration of multiple factors. The primary objective is to identify a PCM that can efficiently store and release thermal energy within the desired temperature range of the industrial process. This selection process must balance technical performance with economic viability to ensure optimal system efficiency and cost-effectiveness.

Temperature is the foremost criterion in PCM selection. The material's melting point must closely match the operating temperature of the industrial process to maximize heat storage capacity. Additionally, the PCM should exhibit a narrow phase transition temperature range to ensure consistent performance. The selection process should consider both the charging and discharging temperatures of the system, as well as any potential temperature fluctuations in the industrial environment.

Latent heat capacity is another crucial metric in PCM selection. Materials with higher latent heat values can store more energy per unit mass, leading to more compact and efficient storage systems. The latent heat capacity directly influences the amount of PCM required for a given application, impacting both system size and cost. It is essential to evaluate the latent heat capacity in conjunction with the specific heat capacity of the material in both solid and liquid phases to determine overall thermal storage efficiency.

Cost considerations play a significant role in PCM selection, particularly for large-scale industrial applications. The evaluation should encompass not only the initial material cost but also long-term expenses related to system maintenance, potential material degradation, and replacement cycles. Cost-effectiveness must be assessed in the context of the PCM's performance characteristics and expected lifespan to determine the true value proposition for the industrial heat storage system.

Additional selection criteria include thermal conductivity, which affects heat transfer rates and system response times, and volumetric expansion during phase change, which impacts containment design and safety considerations. Chemical stability, compatibility with containment materials, and environmental impact are also important factors that must be carefully evaluated to ensure long-term reliability and sustainability of the heat storage solution.

The selection process should aim to strike an optimal balance between these various criteria, recognizing that trade-offs may be necessary depending on the specific requirements of the industrial application. A systematic approach, potentially involving multi-criteria decision analysis tools, can help in objectively evaluating and comparing different PCM options against the defined objectives and constraints of the industrial heat storage project.

Temperature is the foremost criterion in PCM selection. The material's melting point must closely match the operating temperature of the industrial process to maximize heat storage capacity. Additionally, the PCM should exhibit a narrow phase transition temperature range to ensure consistent performance. The selection process should consider both the charging and discharging temperatures of the system, as well as any potential temperature fluctuations in the industrial environment.

Latent heat capacity is another crucial metric in PCM selection. Materials with higher latent heat values can store more energy per unit mass, leading to more compact and efficient storage systems. The latent heat capacity directly influences the amount of PCM required for a given application, impacting both system size and cost. It is essential to evaluate the latent heat capacity in conjunction with the specific heat capacity of the material in both solid and liquid phases to determine overall thermal storage efficiency.

Cost considerations play a significant role in PCM selection, particularly for large-scale industrial applications. The evaluation should encompass not only the initial material cost but also long-term expenses related to system maintenance, potential material degradation, and replacement cycles. Cost-effectiveness must be assessed in the context of the PCM's performance characteristics and expected lifespan to determine the true value proposition for the industrial heat storage system.

Additional selection criteria include thermal conductivity, which affects heat transfer rates and system response times, and volumetric expansion during phase change, which impacts containment design and safety considerations. Chemical stability, compatibility with containment materials, and environmental impact are also important factors that must be carefully evaluated to ensure long-term reliability and sustainability of the heat storage solution.

The selection process should aim to strike an optimal balance between these various criteria, recognizing that trade-offs may be necessary depending on the specific requirements of the industrial application. A systematic approach, potentially involving multi-criteria decision analysis tools, can help in objectively evaluating and comparing different PCM options against the defined objectives and constraints of the industrial heat storage project.

Market Analysis for Industrial Heat Storage

The industrial heat storage market is experiencing significant growth, driven by the increasing demand for energy efficiency and sustainable solutions across various industries. This market segment is closely tied to the broader thermal energy storage (TES) sector, which is projected to reach a global value of $6.2 billion by 2025, with a compound annual growth rate (CAGR) of 10.4% from 2020 to 2025.

The adoption of phase change materials (PCMs) for industrial heat storage is gaining traction due to their ability to store and release large amounts of energy during phase transitions. This technology is particularly attractive in industries with high thermal energy demands, such as manufacturing, food processing, and chemical production. The market for PCM-based heat storage solutions is expected to grow at a CAGR of 15.8% from 2021 to 2026, outpacing the overall TES market growth.

Key factors driving the demand for industrial heat storage include the need for energy conservation, stringent environmental regulations, and the push for decarbonization in industrial processes. Industries are increasingly looking for ways to capture and reuse waste heat, leading to a growing interest in thermal energy storage technologies, including PCMs.

The market for industrial heat storage is segmented based on end-use industries, with the manufacturing sector holding the largest share. This is followed by the oil and gas industry, where thermal energy storage plays a crucial role in enhancing process efficiency and reducing energy costs. The food and beverage industry is also emerging as a significant market for PCM-based heat storage solutions, particularly in applications such as temperature-controlled transportation and cold storage.

Geographically, Europe leads the industrial heat storage market, driven by stringent energy efficiency regulations and government incentives for sustainable technologies. North America follows closely, with a strong focus on industrial energy management and waste heat recovery. The Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization and increasing awareness of energy conservation in countries like China and India.

The market landscape is characterized by a mix of established players and innovative startups. Key companies in the industrial heat storage sector are investing heavily in research and development to improve the performance and cost-effectiveness of PCM-based solutions. This has led to the development of advanced PCMs with higher energy density and better thermal stability, addressing the specific needs of different industrial applications.

As industries continue to prioritize energy efficiency and sustainability, the demand for PCM-based industrial heat storage solutions is expected to rise. The market is likely to see further innovations in material science and system design, leading to more efficient and cost-effective heat storage solutions tailored to specific industrial requirements.

The adoption of phase change materials (PCMs) for industrial heat storage is gaining traction due to their ability to store and release large amounts of energy during phase transitions. This technology is particularly attractive in industries with high thermal energy demands, such as manufacturing, food processing, and chemical production. The market for PCM-based heat storage solutions is expected to grow at a CAGR of 15.8% from 2021 to 2026, outpacing the overall TES market growth.

Key factors driving the demand for industrial heat storage include the need for energy conservation, stringent environmental regulations, and the push for decarbonization in industrial processes. Industries are increasingly looking for ways to capture and reuse waste heat, leading to a growing interest in thermal energy storage technologies, including PCMs.

The market for industrial heat storage is segmented based on end-use industries, with the manufacturing sector holding the largest share. This is followed by the oil and gas industry, where thermal energy storage plays a crucial role in enhancing process efficiency and reducing energy costs. The food and beverage industry is also emerging as a significant market for PCM-based heat storage solutions, particularly in applications such as temperature-controlled transportation and cold storage.

Geographically, Europe leads the industrial heat storage market, driven by stringent energy efficiency regulations and government incentives for sustainable technologies. North America follows closely, with a strong focus on industrial energy management and waste heat recovery. The Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization and increasing awareness of energy conservation in countries like China and India.

The market landscape is characterized by a mix of established players and innovative startups. Key companies in the industrial heat storage sector are investing heavily in research and development to improve the performance and cost-effectiveness of PCM-based solutions. This has led to the development of advanced PCMs with higher energy density and better thermal stability, addressing the specific needs of different industrial applications.

As industries continue to prioritize energy efficiency and sustainability, the demand for PCM-based industrial heat storage solutions is expected to rise. The market is likely to see further innovations in material science and system design, leading to more efficient and cost-effective heat storage solutions tailored to specific industrial requirements.

Current PCM Technologies and Challenges

Phase Change Materials (PCMs) have gained significant attention in industrial heat storage applications due to their ability to absorb, store, and release large amounts of energy during phase transitions. However, the current state of PCM technologies presents several challenges that need to be addressed for widespread adoption.

One of the primary challenges is the selection of appropriate PCMs for specific temperature ranges. While there is a wide variety of PCMs available, each with its own melting point and latent heat capacity, matching these properties to the exact requirements of industrial processes can be complex. This is particularly challenging in industries with fluctuating temperature needs or those requiring precise temperature control.

The thermal conductivity of many PCMs is relatively low, which can limit the rate of heat transfer during charging and discharging cycles. This issue is especially pronounced in large-scale applications where rapid heat exchange is crucial. Researchers are exploring various methods to enhance thermal conductivity, such as the incorporation of high-conductivity materials or the use of extended surfaces, but these solutions often come with increased complexity and cost.

Containment and encapsulation of PCMs present another significant challenge. Many PCMs, particularly those used for high-temperature applications, can be corrosive or reactive with common container materials. This necessitates the use of specialized, often expensive, containment systems that can withstand repeated thermal cycling without degradation or leakage.

Long-term stability and cycling performance of PCMs are also areas of concern. Some materials may experience phase segregation, subcooling, or changes in their thermophysical properties over multiple charge-discharge cycles. This can lead to reduced efficiency and shortened lifespan of the heat storage system, impacting the overall economic viability of PCM-based solutions.

Cost remains a significant barrier to widespread adoption of PCM technologies in industrial settings. While some PCMs, like certain salt hydrates, are relatively inexpensive, others, particularly those designed for specific temperature ranges or with enhanced properties, can be costly. The total system cost, including containment, heat exchange equipment, and integration with existing processes, can be prohibitive for many potential applications.

Environmental and safety considerations also pose challenges. Some PCMs may be toxic, flammable, or have other hazardous properties that require careful handling and containment. Additionally, the environmental impact of PCM production, use, and disposal needs to be carefully evaluated, especially as the scale of deployment increases.

Despite these challenges, ongoing research and development efforts are making significant strides in addressing these issues. Innovations in material science are leading to the development of new PCMs with improved properties, while advancements in system design and integration are enhancing the overall performance and cost-effectiveness of PCM-based heat storage solutions.

One of the primary challenges is the selection of appropriate PCMs for specific temperature ranges. While there is a wide variety of PCMs available, each with its own melting point and latent heat capacity, matching these properties to the exact requirements of industrial processes can be complex. This is particularly challenging in industries with fluctuating temperature needs or those requiring precise temperature control.

The thermal conductivity of many PCMs is relatively low, which can limit the rate of heat transfer during charging and discharging cycles. This issue is especially pronounced in large-scale applications where rapid heat exchange is crucial. Researchers are exploring various methods to enhance thermal conductivity, such as the incorporation of high-conductivity materials or the use of extended surfaces, but these solutions often come with increased complexity and cost.

Containment and encapsulation of PCMs present another significant challenge. Many PCMs, particularly those used for high-temperature applications, can be corrosive or reactive with common container materials. This necessitates the use of specialized, often expensive, containment systems that can withstand repeated thermal cycling without degradation or leakage.

Long-term stability and cycling performance of PCMs are also areas of concern. Some materials may experience phase segregation, subcooling, or changes in their thermophysical properties over multiple charge-discharge cycles. This can lead to reduced efficiency and shortened lifespan of the heat storage system, impacting the overall economic viability of PCM-based solutions.

Cost remains a significant barrier to widespread adoption of PCM technologies in industrial settings. While some PCMs, like certain salt hydrates, are relatively inexpensive, others, particularly those designed for specific temperature ranges or with enhanced properties, can be costly. The total system cost, including containment, heat exchange equipment, and integration with existing processes, can be prohibitive for many potential applications.

Environmental and safety considerations also pose challenges. Some PCMs may be toxic, flammable, or have other hazardous properties that require careful handling and containment. Additionally, the environmental impact of PCM production, use, and disposal needs to be carefully evaluated, especially as the scale of deployment increases.

Despite these challenges, ongoing research and development efforts are making significant strides in addressing these issues. Innovations in material science are leading to the development of new PCMs with improved properties, while advancements in system design and integration are enhancing the overall performance and cost-effectiveness of PCM-based heat storage solutions.

Existing PCM Selection Methodologies

01 Temperature range and selection of PCMs

Phase Change Materials (PCMs) are selected based on their melting and freezing temperatures, which typically range from -20°C to 100°C. The choice of PCM depends on the specific application and desired temperature range for thermal energy storage. Different types of PCMs, such as organic, inorganic, and eutectic mixtures, offer various temperature ranges and can be tailored to meet specific thermal management requirements.- Temperature range of PCMs: Phase Change Materials (PCMs) are designed to operate within specific temperature ranges, typically between -20°C to 80°C for various applications. The selection of PCM depends on the desired phase change temperature for the intended use, such as building thermal management or energy storage systems.

- Latent heat capacity of PCMs: The latent heat capacity of PCMs is a crucial factor in their effectiveness for thermal energy storage. PCMs with high latent heat values can store and release large amounts of energy during phase transitions, making them ideal for applications requiring efficient heat management and energy conservation.

- Cost considerations for PCMs: The cost of PCMs varies depending on factors such as material composition, purity, and manufacturing process. While some advanced PCMs may have higher initial costs, their long-term energy savings and efficiency benefits can offset the investment. Researchers are continuously working on developing cost-effective PCM solutions for widespread adoption.

- PCM encapsulation techniques: Encapsulation of PCMs is essential for their practical application and longevity. Various encapsulation methods, including microencapsulation and macroencapsulation, are used to contain the PCM and prevent leakage during phase transitions. These techniques also enhance the thermal conductivity and stability of the PCM system.

- Applications of PCMs in thermal management: PCMs find diverse applications in thermal management across various industries. They are used in building materials for passive temperature control, in textiles for personal thermal comfort, in electronic devices for heat dissipation, and in renewable energy systems for energy storage. The selection of PCM properties is tailored to the specific requirements of each application.

02 Latent heat capacity and energy storage

The latent heat of PCMs is a crucial factor in their effectiveness for thermal energy storage. PCMs with higher latent heat capacities can store and release more thermal energy during phase transitions. This property is essential for applications requiring efficient heat absorption or release. The latent heat of PCMs can range from 100 to 300 kJ/kg, depending on the material composition and type.Expand Specific Solutions03 Cost considerations and material selection

The cost of PCMs varies widely depending on the type, purity, and manufacturing process. Organic PCMs, such as paraffins, are generally less expensive but may have lower thermal conductivity. Inorganic PCMs, like salt hydrates, can be more cost-effective for large-scale applications. The selection of PCMs often involves balancing performance requirements with cost constraints to achieve optimal thermal management solutions.Expand Specific Solutions04 Encapsulation and integration techniques

Encapsulation of PCMs is crucial for their effective integration into various applications. Microencapsulation and macroencapsulation techniques are used to contain the PCM and prevent leakage during phase change. These methods also improve the stability and handling of PCMs. The encapsulation process can affect the overall cost and performance of the PCM-based thermal management system.Expand Specific Solutions05 Performance enhancement and composite PCMs

Research focuses on enhancing PCM performance through the development of composite materials. These composites often combine PCMs with high thermal conductivity materials or nanoparticles to improve heat transfer rates. Advanced PCM formulations aim to address issues such as supercooling, phase segregation, and long-term stability while optimizing temperature control and energy storage capacity.Expand Specific Solutions

Key Players in PCM Industry

The phase change material (PCM) market for industrial heat storage is in a growth stage, driven by increasing demand for energy-efficient solutions. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, PCMs are advancing rapidly, with companies like Phase Change Solutions, Inc. and SABIC Global Technologies BV leading innovation. Established players such as DuPont de Nemours, Inc. and Honeywell International Technologies Ltd. are also contributing to the field's maturity. Research institutions like Trent University and King Fahd University of Petroleum & Minerals are further advancing PCM technology, indicating a collaborative ecosystem of industry and academia driving progress in this sector.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has leveraged its expertise in advanced materials to develop PCMs for industrial heat storage applications. Their PCM portfolio includes both organic and inorganic materials, covering a temperature range of -50°C to 200°C. Honeywell's PCMs feature a unique microencapsulation technology that enhances thermal cycling stability and prevents leakage, crucial for long-term industrial use [10]. The company has developed a proprietary selection tool that incorporates machine learning algorithms to analyze industrial heat storage requirements and recommend the most suitable PCM based on temperature needs, latent heat capacity, and cost considerations [11]. Honeywell's PCMs also boast improved fire safety characteristics, addressing a key concern in industrial applications [12].

Strengths: Wide temperature range, advanced microencapsulation, and AI-driven selection process. Weaknesses: Potentially higher costs due to advanced technologies and possible limitations in extreme industrial environments.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a series of PCMs based on their expertise in polymer and chemical technologies. Their PCM solutions focus on high-performance materials for industrial heat storage, offering melting points from -10°C to 120°C. SABIC's PCMs are characterized by their high thermal conductivity, which can reach up to 1 W/mK, significantly improving heat transfer rates in industrial applications [7]. The company has introduced a novel cost-optimization approach that balances the PCM's latent heat capacity with material costs, resulting in a performance-to-price ratio metric for easier selection [8]. SABIC also offers custom PCM blends tailored to specific industrial processes, allowing for fine-tuned temperature control and energy management [9].

Strengths: High thermal conductivity, customizable solutions, and cost-optimization approach. Weaknesses: Limited temperature range compared to some competitors and potential scalability challenges for highly specialized formulations.

Innovative PCM Materials and Properties

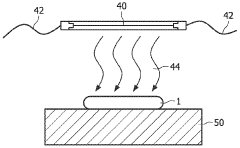

Infrared heatable device, and infrared heating system and method

PatentWO2008072169A2

Innovation

- An infrared heatable device with a body-wearable container containing a core material with high infrared-A (IR-A) transmission and phase change materials, allowing for combined heat supply from both internal storage and external IR-A radiation, which penetrates deeper and provides prolonged heating.

A vapour compression apparatus

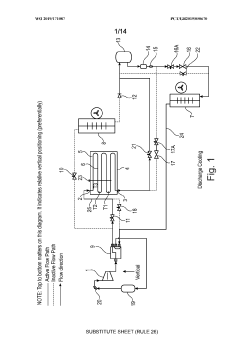

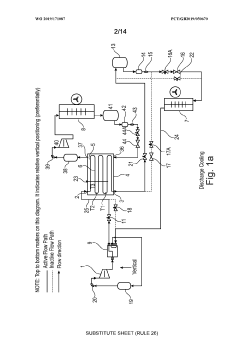

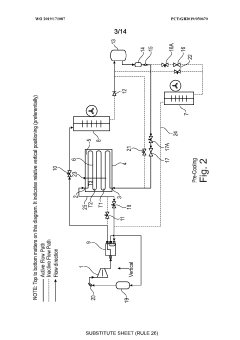

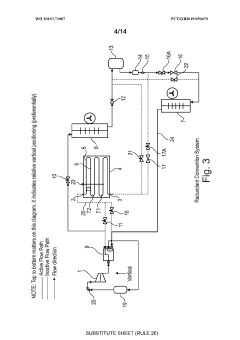

PatentWO2019171087A2

Innovation

- A vapor compression apparatus with an intermediary heat battery using phase change materials (PCMs) that can discharge or charge energy to control the temperature of a heat source or heat sink, integrated with temperature and pressure sensors for real-time monitoring and control, allowing for efficient energy management and adaptable operation between heating and cooling cycles.

Environmental Impact of PCMs

The environmental impact of Phase Change Materials (PCMs) in industrial heat storage applications is a critical consideration for sustainable energy management. PCMs offer significant potential for energy conservation and efficiency improvement, but their lifecycle environmental effects must be carefully evaluated.

PCMs contribute to energy savings by reducing the need for active cooling and heating systems. This leads to decreased electricity consumption and, consequently, lower greenhouse gas emissions associated with power generation. In industrial settings, PCMs can help stabilize temperatures in manufacturing processes, potentially reducing energy waste and improving overall efficiency.

However, the production and disposal of PCMs also have environmental implications. Many PCMs are derived from petroleum-based products or other non-renewable resources. The extraction and processing of these materials can result in habitat disruption, air and water pollution, and carbon emissions. Additionally, some PCMs may contain toxic substances that pose risks to ecosystems if not properly managed at the end of their lifecycle.

The longevity of PCM systems is an important factor in their environmental impact. Materials with high thermal cycling stability can maintain their performance over many phase change cycles, reducing the frequency of replacement and associated waste. Conversely, PCMs with poor long-term stability may require more frequent replacement, increasing their environmental footprint.

Recyclability and biodegradability are emerging focus areas in PCM development. Bio-based PCMs derived from renewable sources, such as fatty acids or sugar alcohols, offer promising alternatives with potentially lower environmental impacts. These materials can be more easily recycled or biodegraded at the end of their useful life, reducing waste and resource depletion.

The choice of PCM can also affect the overall environmental performance of the heat storage system. Materials with higher latent heat capacity allow for more compact storage solutions, potentially reducing the amount of material needed and minimizing transportation-related emissions. Furthermore, PCMs that operate at temperatures closer to ambient conditions may require less energy for temperature maintenance, further enhancing their environmental benefits.

In conclusion, while PCMs offer significant potential for improving energy efficiency and reducing environmental impact in industrial heat storage applications, their full lifecycle effects must be carefully considered. Balancing factors such as energy savings, material sourcing, production processes, and end-of-life management is crucial for maximizing the environmental benefits of PCM-based heat storage systems.

PCMs contribute to energy savings by reducing the need for active cooling and heating systems. This leads to decreased electricity consumption and, consequently, lower greenhouse gas emissions associated with power generation. In industrial settings, PCMs can help stabilize temperatures in manufacturing processes, potentially reducing energy waste and improving overall efficiency.

However, the production and disposal of PCMs also have environmental implications. Many PCMs are derived from petroleum-based products or other non-renewable resources. The extraction and processing of these materials can result in habitat disruption, air and water pollution, and carbon emissions. Additionally, some PCMs may contain toxic substances that pose risks to ecosystems if not properly managed at the end of their lifecycle.

The longevity of PCM systems is an important factor in their environmental impact. Materials with high thermal cycling stability can maintain their performance over many phase change cycles, reducing the frequency of replacement and associated waste. Conversely, PCMs with poor long-term stability may require more frequent replacement, increasing their environmental footprint.

Recyclability and biodegradability are emerging focus areas in PCM development. Bio-based PCMs derived from renewable sources, such as fatty acids or sugar alcohols, offer promising alternatives with potentially lower environmental impacts. These materials can be more easily recycled or biodegraded at the end of their useful life, reducing waste and resource depletion.

The choice of PCM can also affect the overall environmental performance of the heat storage system. Materials with higher latent heat capacity allow for more compact storage solutions, potentially reducing the amount of material needed and minimizing transportation-related emissions. Furthermore, PCMs that operate at temperatures closer to ambient conditions may require less energy for temperature maintenance, further enhancing their environmental benefits.

In conclusion, while PCMs offer significant potential for improving energy efficiency and reducing environmental impact in industrial heat storage applications, their full lifecycle effects must be carefully considered. Balancing factors such as energy savings, material sourcing, production processes, and end-of-life management is crucial for maximizing the environmental benefits of PCM-based heat storage systems.

Economic Feasibility of PCM Implementation

The economic feasibility of implementing Phase Change Materials (PCMs) for industrial heat storage is a critical consideration for businesses looking to optimize their energy management systems. This analysis involves evaluating the cost-effectiveness of PCM integration against traditional heat storage methods and potential energy savings over time.

Initial investment costs for PCM implementation can be substantial, including the purchase of the material itself, containment systems, and necessary modifications to existing infrastructure. However, these upfront expenses must be weighed against long-term operational benefits. PCMs offer the potential for significant energy savings by reducing peak energy demand and improving overall thermal efficiency.

The payback period for PCM implementation varies depending on factors such as the specific application, energy prices, and the efficiency of the chosen PCM. In some cases, return on investment can be realized within 2-5 years, making it an attractive option for industries with high energy consumption.

One of the key economic advantages of PCMs is their ability to shift energy consumption to off-peak hours, potentially reducing electricity costs in regions with time-of-use pricing. This load-shifting capability can lead to substantial savings on energy bills, particularly for large-scale industrial operations.

Maintenance costs for PCM systems are generally low compared to mechanical heat storage alternatives. PCMs have no moving parts and typically require minimal upkeep, contributing to their long-term cost-effectiveness. However, the lifespan of the PCM and its containment system must be factored into the overall economic assessment.

The scalability of PCM solutions also impacts their economic viability. As production volumes increase, the cost per unit of PCM tends to decrease, making large-scale implementations more economically attractive. This economy of scale can significantly improve the cost-benefit ratio for industrial applications.

Government incentives and environmental regulations play a crucial role in the economic feasibility of PCM implementation. In regions where energy efficiency is prioritized, businesses may benefit from tax credits, grants, or other financial incentives that offset initial costs and accelerate the return on investment.

When evaluating the economic feasibility of PCM implementation, it is essential to conduct a comprehensive life cycle cost analysis. This should include not only the initial investment and operational savings but also factors such as potential increases in property value, improved process efficiency, and enhanced environmental performance.

Initial investment costs for PCM implementation can be substantial, including the purchase of the material itself, containment systems, and necessary modifications to existing infrastructure. However, these upfront expenses must be weighed against long-term operational benefits. PCMs offer the potential for significant energy savings by reducing peak energy demand and improving overall thermal efficiency.

The payback period for PCM implementation varies depending on factors such as the specific application, energy prices, and the efficiency of the chosen PCM. In some cases, return on investment can be realized within 2-5 years, making it an attractive option for industries with high energy consumption.

One of the key economic advantages of PCMs is their ability to shift energy consumption to off-peak hours, potentially reducing electricity costs in regions with time-of-use pricing. This load-shifting capability can lead to substantial savings on energy bills, particularly for large-scale industrial operations.

Maintenance costs for PCM systems are generally low compared to mechanical heat storage alternatives. PCMs have no moving parts and typically require minimal upkeep, contributing to their long-term cost-effectiveness. However, the lifespan of the PCM and its containment system must be factored into the overall economic assessment.

The scalability of PCM solutions also impacts their economic viability. As production volumes increase, the cost per unit of PCM tends to decrease, making large-scale implementations more economically attractive. This economy of scale can significantly improve the cost-benefit ratio for industrial applications.

Government incentives and environmental regulations play a crucial role in the economic feasibility of PCM implementation. In regions where energy efficiency is prioritized, businesses may benefit from tax credits, grants, or other financial incentives that offset initial costs and accelerate the return on investment.

When evaluating the economic feasibility of PCM implementation, it is essential to conduct a comprehensive life cycle cost analysis. This should include not only the initial investment and operational savings but also factors such as potential increases in property value, improved process efficiency, and enhanced environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!