How to Conduct Life Cycle Analysis on PLA Products?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA LCA Background and Objectives

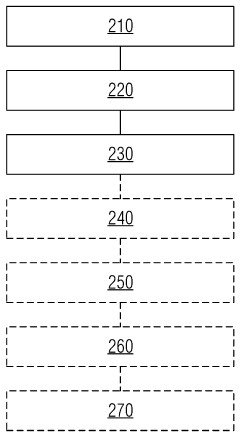

Life Cycle Analysis (LCA) on Polylactic Acid (PLA) products has gained significant attention in recent years due to the growing demand for sustainable and biodegradable materials. PLA, derived from renewable resources such as corn starch or sugarcane, has emerged as a promising alternative to conventional petroleum-based plastics. The primary objective of conducting LCA on PLA products is to comprehensively assess their environmental impact throughout their entire life cycle, from raw material extraction to disposal or recycling.

The development of PLA technology can be traced back to the 1930s when Wallace Carothers first polymerized lactic acid. However, it wasn't until the 1990s that PLA production became commercially viable. Since then, advancements in biotechnology and polymer science have led to significant improvements in PLA properties and production efficiency. Today, PLA is used in various applications, including packaging, textiles, and medical devices, driving the need for accurate and standardized LCA methodologies.

The technical evolution of PLA LCA has been closely linked to the development of international standards and guidelines for life cycle assessment. The ISO 14040 and 14044 standards, established in the late 1990s and updated in 2006, provide a framework for conducting LCA studies. These standards have been instrumental in shaping the approach to PLA LCA, ensuring consistency and comparability across different studies and products.

One of the key trends in PLA LCA is the focus on cradle-to-grave analysis, which encompasses all stages of a product's life cycle. This approach allows for a more comprehensive understanding of the environmental impacts associated with PLA products, including resource consumption, energy use, greenhouse gas emissions, and end-of-life scenarios. Additionally, there is a growing emphasis on incorporating regional and local data into LCA studies to improve the accuracy and relevance of results.

The technical goals of PLA LCA include developing more accurate and comprehensive inventory databases, improving modeling techniques for complex biological systems, and enhancing the integration of economic and social factors into environmental assessments. There is also a push towards standardizing allocation methods for bio-based materials and refining end-of-life scenarios to better reflect real-world conditions.

As the PLA market continues to expand, the importance of robust LCA methodologies becomes increasingly critical. These assessments not only inform product development and optimization but also play a crucial role in policy-making, consumer education, and sustainable business practices. The ongoing research and development in PLA LCA aim to address current limitations and uncertainties, ultimately contributing to the broader goal of transitioning towards a more sustainable and circular economy.

The development of PLA technology can be traced back to the 1930s when Wallace Carothers first polymerized lactic acid. However, it wasn't until the 1990s that PLA production became commercially viable. Since then, advancements in biotechnology and polymer science have led to significant improvements in PLA properties and production efficiency. Today, PLA is used in various applications, including packaging, textiles, and medical devices, driving the need for accurate and standardized LCA methodologies.

The technical evolution of PLA LCA has been closely linked to the development of international standards and guidelines for life cycle assessment. The ISO 14040 and 14044 standards, established in the late 1990s and updated in 2006, provide a framework for conducting LCA studies. These standards have been instrumental in shaping the approach to PLA LCA, ensuring consistency and comparability across different studies and products.

One of the key trends in PLA LCA is the focus on cradle-to-grave analysis, which encompasses all stages of a product's life cycle. This approach allows for a more comprehensive understanding of the environmental impacts associated with PLA products, including resource consumption, energy use, greenhouse gas emissions, and end-of-life scenarios. Additionally, there is a growing emphasis on incorporating regional and local data into LCA studies to improve the accuracy and relevance of results.

The technical goals of PLA LCA include developing more accurate and comprehensive inventory databases, improving modeling techniques for complex biological systems, and enhancing the integration of economic and social factors into environmental assessments. There is also a push towards standardizing allocation methods for bio-based materials and refining end-of-life scenarios to better reflect real-world conditions.

As the PLA market continues to expand, the importance of robust LCA methodologies becomes increasingly critical. These assessments not only inform product development and optimization but also play a crucial role in policy-making, consumer education, and sustainable business practices. The ongoing research and development in PLA LCA aim to address current limitations and uncertainties, ultimately contributing to the broader goal of transitioning towards a more sustainable and circular economy.

Market Demand for PLA LCA

The market demand for Life Cycle Analysis (LCA) on Polylactic Acid (PLA) products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations on sustainable materials. PLA, a biodegradable and renewable polymer derived from plant-based resources, has gained significant attention in various industries as an eco-friendly alternative to traditional plastics.

The packaging industry, particularly in food and beverage sectors, has shown a strong interest in PLA LCA due to the material's potential to reduce carbon footprint and address plastic waste concerns. Major food and beverage companies are actively seeking comprehensive LCA data on PLA products to support their sustainability claims and meet consumer demands for environmentally responsible packaging solutions.

In the automotive and electronics industries, there is a growing demand for PLA LCA to evaluate the environmental impact of bio-based components and compare them with conventional materials. This trend is fueled by the increasing adoption of circular economy principles and the push for more sustainable product design across these sectors.

The textile and fashion industry has also emerged as a significant market for PLA LCA, with manufacturers and brands exploring the use of PLA fibers as an alternative to petroleum-based synthetic fibers. LCA studies in this sector are crucial for assessing the true environmental benefits of PLA-based textiles throughout their lifecycle, from production to disposal or recycling.

Government agencies and environmental organizations are driving demand for PLA LCA as they develop policies and standards for sustainable materials. These entities require robust LCA data to inform decision-making processes and establish guidelines for the use of bio-based plastics in various applications.

The academic and research community represents another significant market segment for PLA LCA, with ongoing studies focusing on improving LCA methodologies specific to bio-based materials and exploring the potential of PLA in new applications. This research demand is essential for advancing the understanding of PLA's environmental performance and identifying areas for improvement in its production and end-of-life management.

As consumer awareness of environmental issues continues to grow, there is an increasing demand for transparent and credible information about the sustainability of products. This has led many companies to invest in LCA studies for their PLA-based offerings, using the results in marketing communications and to differentiate their products in the marketplace.

The global nature of supply chains has also contributed to the demand for PLA LCA, as companies seek to understand and optimize the environmental impact of their products across different geographical regions and production scenarios. This has created a need for standardized LCA methodologies that can account for regional variations in energy sources, waste management practices, and other factors that influence the lifecycle impact of PLA products.

The packaging industry, particularly in food and beverage sectors, has shown a strong interest in PLA LCA due to the material's potential to reduce carbon footprint and address plastic waste concerns. Major food and beverage companies are actively seeking comprehensive LCA data on PLA products to support their sustainability claims and meet consumer demands for environmentally responsible packaging solutions.

In the automotive and electronics industries, there is a growing demand for PLA LCA to evaluate the environmental impact of bio-based components and compare them with conventional materials. This trend is fueled by the increasing adoption of circular economy principles and the push for more sustainable product design across these sectors.

The textile and fashion industry has also emerged as a significant market for PLA LCA, with manufacturers and brands exploring the use of PLA fibers as an alternative to petroleum-based synthetic fibers. LCA studies in this sector are crucial for assessing the true environmental benefits of PLA-based textiles throughout their lifecycle, from production to disposal or recycling.

Government agencies and environmental organizations are driving demand for PLA LCA as they develop policies and standards for sustainable materials. These entities require robust LCA data to inform decision-making processes and establish guidelines for the use of bio-based plastics in various applications.

The academic and research community represents another significant market segment for PLA LCA, with ongoing studies focusing on improving LCA methodologies specific to bio-based materials and exploring the potential of PLA in new applications. This research demand is essential for advancing the understanding of PLA's environmental performance and identifying areas for improvement in its production and end-of-life management.

As consumer awareness of environmental issues continues to grow, there is an increasing demand for transparent and credible information about the sustainability of products. This has led many companies to invest in LCA studies for their PLA-based offerings, using the results in marketing communications and to differentiate their products in the marketplace.

The global nature of supply chains has also contributed to the demand for PLA LCA, as companies seek to understand and optimize the environmental impact of their products across different geographical regions and production scenarios. This has created a need for standardized LCA methodologies that can account for regional variations in energy sources, waste management practices, and other factors that influence the lifecycle impact of PLA products.

PLA LCA Challenges and Limitations

Conducting Life Cycle Analysis (LCA) on PLA (Polylactic Acid) products presents several challenges and limitations that researchers and industry professionals must navigate. One of the primary difficulties lies in the complexity of PLA production processes, which can vary significantly depending on the feedstock and manufacturing techniques used. This variability makes it challenging to establish consistent boundaries for the LCA study and can lead to discrepancies in results across different analyses.

Data availability and quality pose another significant hurdle in PLA LCA studies. Many aspects of PLA production, especially in emerging markets or for novel applications, lack comprehensive and reliable data. This scarcity of information can result in the use of proxy data or estimations, potentially compromising the accuracy of the LCA results. Furthermore, the rapidly evolving nature of PLA technology means that available data may quickly become outdated, necessitating frequent updates to maintain the relevance of LCA studies.

The end-of-life phase of PLA products presents unique challenges for LCA practitioners. While PLA is often touted for its biodegradability, the actual environmental impact of its disposal depends heavily on local waste management infrastructure and practices. Accurately modeling the decomposition process and its associated emissions in various disposal scenarios (e.g., industrial composting, landfill, incineration) can be complex and subject to significant uncertainties.

Allocation methods for co-products and by-products in PLA production can significantly influence LCA results. Deciding how to distribute environmental impacts among various outputs of the production process is often subjective and can lead to divergent conclusions depending on the chosen allocation approach. This challenge is particularly pronounced when considering the agricultural phase of PLA production, where crops may serve multiple purposes beyond PLA feedstock.

The comparative nature of many PLA LCA studies introduces additional complexities. When comparing PLA products to conventional plastics or other materials, ensuring a fair and equivalent basis for comparison can be challenging. Differences in product functionality, durability, and end-of-life scenarios must be carefully considered to avoid misleading conclusions about the relative environmental performance of PLA.

Temporal aspects of environmental impacts pose another limitation in PLA LCA studies. The long-term effects of biodegradation, carbon sequestration in agricultural feedstocks, and potential land-use changes associated with increased biomass production for PLA are difficult to quantify accurately within the typical scope of an LCA. These long-term impacts may significantly affect the overall environmental profile of PLA products but are often inadequately addressed in current LCA methodologies.

Lastly, the interpretation and communication of LCA results for PLA products can be challenging due to the complexity of the analysis and the potential for conflicting environmental trade-offs. Balancing different impact categories, such as global warming potential versus land use or water consumption, requires careful consideration and can lead to ambiguous conclusions about the overall sustainability of PLA products.

Data availability and quality pose another significant hurdle in PLA LCA studies. Many aspects of PLA production, especially in emerging markets or for novel applications, lack comprehensive and reliable data. This scarcity of information can result in the use of proxy data or estimations, potentially compromising the accuracy of the LCA results. Furthermore, the rapidly evolving nature of PLA technology means that available data may quickly become outdated, necessitating frequent updates to maintain the relevance of LCA studies.

The end-of-life phase of PLA products presents unique challenges for LCA practitioners. While PLA is often touted for its biodegradability, the actual environmental impact of its disposal depends heavily on local waste management infrastructure and practices. Accurately modeling the decomposition process and its associated emissions in various disposal scenarios (e.g., industrial composting, landfill, incineration) can be complex and subject to significant uncertainties.

Allocation methods for co-products and by-products in PLA production can significantly influence LCA results. Deciding how to distribute environmental impacts among various outputs of the production process is often subjective and can lead to divergent conclusions depending on the chosen allocation approach. This challenge is particularly pronounced when considering the agricultural phase of PLA production, where crops may serve multiple purposes beyond PLA feedstock.

The comparative nature of many PLA LCA studies introduces additional complexities. When comparing PLA products to conventional plastics or other materials, ensuring a fair and equivalent basis for comparison can be challenging. Differences in product functionality, durability, and end-of-life scenarios must be carefully considered to avoid misleading conclusions about the relative environmental performance of PLA.

Temporal aspects of environmental impacts pose another limitation in PLA LCA studies. The long-term effects of biodegradation, carbon sequestration in agricultural feedstocks, and potential land-use changes associated with increased biomass production for PLA are difficult to quantify accurately within the typical scope of an LCA. These long-term impacts may significantly affect the overall environmental profile of PLA products but are often inadequately addressed in current LCA methodologies.

Lastly, the interpretation and communication of LCA results for PLA products can be challenging due to the complexity of the analysis and the potential for conflicting environmental trade-offs. Balancing different impact categories, such as global warming potential versus land use or water consumption, requires careful consideration and can lead to ambiguous conclusions about the overall sustainability of PLA products.

Current PLA LCA Methodologies

01 PLA-based biodegradable materials

Development of biodegradable materials using polylactic acid (PLA) for various applications. These materials offer environmentally friendly alternatives to traditional plastics, with a focus on improving their properties and processing methods.- PLA-based biodegradable materials: Polylactic acid (PLA) is used to create biodegradable materials for various applications. These materials offer environmentally friendly alternatives to traditional plastics, with improved sustainability and reduced environmental impact. PLA-based products can be used in packaging, disposable items, and other consumer goods.

- PLA composites and blends: PLA can be combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or other characteristics of the final product. Such composites and blends expand the range of applications for PLA-based materials.

- PLA processing techniques: Various processing techniques are employed to manufacture PLA products, including extrusion, injection molding, and 3D printing. These methods allow for the creation of diverse PLA-based items with different shapes, sizes, and properties, catering to various industrial and consumer needs.

- PLA product applications: PLA products find applications in numerous fields, including medical devices, food packaging, textiles, and automotive parts. The versatility of PLA allows for its use in both disposable and durable goods, offering sustainable alternatives in various industries.

- PLA product performance enhancement: Research focuses on improving the performance of PLA products through various methods, such as chemical modifications, additives, or novel processing techniques. These enhancements aim to address limitations of PLA, such as brittleness or low heat resistance, expanding its potential applications.

02 PLA composites and blends

Creation of PLA composites and blends with other materials to enhance performance characteristics. These combinations aim to improve mechanical properties, thermal stability, and overall functionality of PLA-based products.Expand Specific Solutions03 PLA processing techniques

Innovative processing techniques for PLA, including extrusion, injection molding, and 3D printing. These methods focus on optimizing production efficiency and enhancing the quality of PLA products for various industries.Expand Specific Solutions04 PLA applications in packaging

Utilization of PLA in packaging solutions, particularly for food and beverage industries. This includes the development of PLA-based films, containers, and other packaging materials that offer biodegradability and sustainability benefits.Expand Specific Solutions05 PLA modifications for improved properties

Chemical and physical modifications of PLA to enhance its properties such as heat resistance, flexibility, and barrier characteristics. These modifications aim to expand the range of applications for PLA-based products in various industries.Expand Specific Solutions

Key Players in PLA LCA Research

The life cycle analysis of PLA products is an emerging field in the sustainable materials industry, currently in its growth phase. The market for biodegradable plastics, including PLA, is expanding rapidly, with a projected global market size of $7.8 billion by 2025. The technology's maturity varies across different applications, with companies like NatureWorks and Total Research Corp leading in PLA production. Microsoft Technology Licensing LLC and Dassault Systèmes SE are contributing to the development of advanced LCA software tools, while research institutions such as the University of Coimbra and King's College London are advancing the scientific understanding of PLA's environmental impact. Companies like Interface, Inc. and 3M Innovative Properties Co. are integrating LCA into their product development processes, driving innovation in sustainable materials and manufacturing techniques.

Novacart SpA

Technical Solution: Novacart specializes in the production of food packaging solutions using PLA and other biodegradable materials. Their approach to life cycle analysis involves a comprehensive assessment of their products from raw material sourcing to end-of-life disposal. They have developed a proprietary coating technology that enhances the barrier properties of PLA-based packaging without compromising its biodegradability. Novacart's LCA methodology includes evaluating the carbon footprint of their production processes, transportation, and the environmental impact of their products' disposal in various scenarios.

Strengths: Specialized focus on food packaging, innovative barrier technology, and comprehensive LCA approach. Weaknesses: Limited to specific application areas and potential challenges in scaling up production.

Zeus Industrial Products, Inc.

Technical Solution: Zeus has developed advanced extrusion and molding techniques for PLA-based medical devices and components. Their approach to life cycle analysis focuses on the entire lifecycle of medical products, from raw material selection to sterilization processes and disposal. Zeus has implemented a clean room manufacturing environment to ensure the highest quality and purity of PLA products for medical applications. Their LCA methodology includes assessing the environmental impact of sterilization processes, packaging, and disposal methods specific to the healthcare industry.

Strengths: Specialized expertise in medical-grade PLA products, stringent quality control, and industry-specific LCA methodology. Weaknesses: Narrow focus on medical applications and potential regulatory challenges in different markets.

Critical PLA LCA Studies and Findings

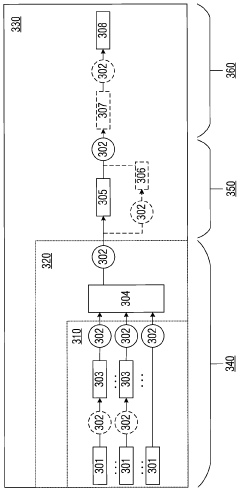

Life cycle assessment method and device

PatentWO2024045094A1

Innovation

- By establishing a general parametric LCA model for similar products, experts only need to build an LCA model once for a representative product, and then parameterize it to generate a general LCA model for similar products, which non-professional users can use for environmental impact assessment.

Surface coverings including carbon sequestration materials and methods of making the same

PatentActiveCN113661288B

Innovation

- The use of fossil fuels is reduced by using natural materials, bio-based materials or recycled materials in the upper wear-resistant and backing layers of the ground cover, combined with high purity biochar as filler, and the total amount of material is reduced by precision manufacturing.

Environmental Regulations Impact on PLA LCA

Environmental regulations play a crucial role in shaping the life cycle analysis (LCA) of polylactic acid (PLA) products. These regulations, which vary across regions and countries, significantly influence the production, use, and disposal of PLA materials. In the European Union, for instance, the Waste Framework Directive and the Packaging and Packaging Waste Directive set stringent requirements for biodegradable plastics, including PLA. These directives mandate specific recycling and recovery targets, impacting the end-of-life phase of PLA products in LCA studies.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for conducting LCAs, which include considerations for bioplastics like PLA. These guidelines emphasize the importance of assessing the environmental impacts across all stages of a product's life cycle, from raw material extraction to disposal. The EPA's focus on greenhouse gas emissions and waste reduction has led to increased scrutiny of PLA's carbon footprint and end-of-life management options.

The implementation of Extended Producer Responsibility (EPR) policies in various countries has further influenced PLA LCAs. These policies hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. For PLA products, this has led to a greater emphasis on designing for recyclability and exploring innovative end-of-life solutions, such as industrial composting facilities.

International standards, such as ISO 14040 and ISO 14044, provide a framework for conducting LCAs that comply with global environmental regulations. These standards ensure consistency and comparability in LCA methodologies, which is particularly important for PLA products as they often compete with conventional plastics in global markets.

The growing focus on circular economy principles in environmental regulations has also impacted PLA LCAs. Regulations promoting circular economy models encourage the development of closed-loop systems for PLA products, influencing how LCAs account for material recovery and reuse. This shift has led to increased attention on the potential for PLA to be recycled or composted, and how these end-of-life scenarios compare to traditional disposal methods in terms of environmental impact.

Climate change mitigation policies, such as carbon pricing mechanisms and emissions trading schemes, have further implications for PLA LCAs. These policies incentivize the use of materials with lower carbon footprints, potentially favoring PLA over fossil-based plastics in certain applications. However, they also necessitate more comprehensive LCAs that accurately account for the carbon emissions throughout the PLA lifecycle, including agricultural practices used in feedstock production.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for conducting LCAs, which include considerations for bioplastics like PLA. These guidelines emphasize the importance of assessing the environmental impacts across all stages of a product's life cycle, from raw material extraction to disposal. The EPA's focus on greenhouse gas emissions and waste reduction has led to increased scrutiny of PLA's carbon footprint and end-of-life management options.

The implementation of Extended Producer Responsibility (EPR) policies in various countries has further influenced PLA LCAs. These policies hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. For PLA products, this has led to a greater emphasis on designing for recyclability and exploring innovative end-of-life solutions, such as industrial composting facilities.

International standards, such as ISO 14040 and ISO 14044, provide a framework for conducting LCAs that comply with global environmental regulations. These standards ensure consistency and comparability in LCA methodologies, which is particularly important for PLA products as they often compete with conventional plastics in global markets.

The growing focus on circular economy principles in environmental regulations has also impacted PLA LCAs. Regulations promoting circular economy models encourage the development of closed-loop systems for PLA products, influencing how LCAs account for material recovery and reuse. This shift has led to increased attention on the potential for PLA to be recycled or composted, and how these end-of-life scenarios compare to traditional disposal methods in terms of environmental impact.

Climate change mitigation policies, such as carbon pricing mechanisms and emissions trading schemes, have further implications for PLA LCAs. These policies incentivize the use of materials with lower carbon footprints, potentially favoring PLA over fossil-based plastics in certain applications. However, they also necessitate more comprehensive LCAs that accurately account for the carbon emissions throughout the PLA lifecycle, including agricultural practices used in feedstock production.

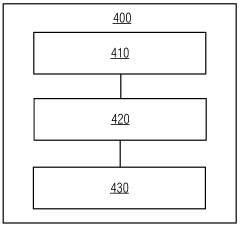

PLA LCA Data Management and Tools

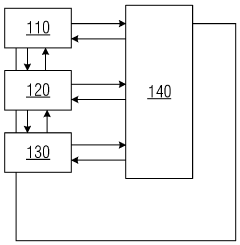

Effective data management and appropriate tools are crucial for conducting comprehensive Life Cycle Analysis (LCA) on PLA products. The complexity of LCA requires robust systems to handle large volumes of data from various sources throughout the product's life cycle. Several specialized software tools have been developed to streamline the LCA process for PLA and other materials.

One of the most widely used LCA software tools is SimaPro, which offers extensive databases and allows for detailed modeling of PLA product life cycles. It provides a user-friendly interface for inputting data, performing calculations, and generating reports. SimaPro also supports the integration of various impact assessment methods, enabling a thorough evaluation of PLA products' environmental impacts across multiple categories.

GaBi is another powerful LCA software that offers specific features for analyzing bioplastics like PLA. It includes comprehensive databases and allows for the creation of custom datasets, which is particularly useful for PLA products with unique production processes or end-of-life scenarios. GaBi's ability to model complex supply chains makes it valuable for assessing the entire life cycle of PLA products, from raw material extraction to disposal or recycling.

OpenLCA is an open-source alternative that has gained popularity in recent years. It provides a flexible platform for conducting LCA on PLA products and offers the advantage of being freely available and customizable. While it may require more technical expertise to use effectively, OpenLCA can be a cost-effective solution for organizations with in-house LCA capabilities.

For data management, many organizations utilize specialized LCA databases such as ecoinvent or GaBi databases, which contain extensive information on materials, processes, and environmental impacts. These databases can be integrated with LCA software tools to ensure consistent and reliable data inputs for PLA product assessments.

Cloud-based LCA platforms are emerging as powerful tools for collaborative data management and analysis. These platforms allow multiple stakeholders to access and contribute to LCA projects simultaneously, facilitating data sharing and version control. This is particularly beneficial for complex PLA product assessments that may involve multiple suppliers or manufacturing locations.

To ensure data quality and consistency, organizations often implement data management protocols specific to PLA LCA. These may include guidelines for data collection, validation processes, and regular updates to reflect changes in production methods or supply chains. Implementing such protocols helps maintain the accuracy and relevance of LCA results for PLA products over time.

One of the most widely used LCA software tools is SimaPro, which offers extensive databases and allows for detailed modeling of PLA product life cycles. It provides a user-friendly interface for inputting data, performing calculations, and generating reports. SimaPro also supports the integration of various impact assessment methods, enabling a thorough evaluation of PLA products' environmental impacts across multiple categories.

GaBi is another powerful LCA software that offers specific features for analyzing bioplastics like PLA. It includes comprehensive databases and allows for the creation of custom datasets, which is particularly useful for PLA products with unique production processes or end-of-life scenarios. GaBi's ability to model complex supply chains makes it valuable for assessing the entire life cycle of PLA products, from raw material extraction to disposal or recycling.

OpenLCA is an open-source alternative that has gained popularity in recent years. It provides a flexible platform for conducting LCA on PLA products and offers the advantage of being freely available and customizable. While it may require more technical expertise to use effectively, OpenLCA can be a cost-effective solution for organizations with in-house LCA capabilities.

For data management, many organizations utilize specialized LCA databases such as ecoinvent or GaBi databases, which contain extensive information on materials, processes, and environmental impacts. These databases can be integrated with LCA software tools to ensure consistent and reliable data inputs for PLA product assessments.

Cloud-based LCA platforms are emerging as powerful tools for collaborative data management and analysis. These platforms allow multiple stakeholders to access and contribute to LCA projects simultaneously, facilitating data sharing and version control. This is particularly beneficial for complex PLA product assessments that may involve multiple suppliers or manufacturing locations.

To ensure data quality and consistency, organizations often implement data management protocols specific to PLA LCA. These may include guidelines for data collection, validation processes, and regular updates to reflect changes in production methods or supply chains. Implementing such protocols helps maintain the accuracy and relevance of LCA results for PLA products over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!