How To Design Low-Pressure-Drop Cyclones For Pneumatic Conveying

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Design Background and Objectives

Cyclone separators have been an integral part of pneumatic conveying systems for decades, serving as efficient devices for separating particulate matter from gas streams. The evolution of cyclone technology can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. As industrial processes became more sophisticated, the demand for more efficient and low-pressure-drop cyclones grew, particularly in applications where energy conservation is crucial.

The primary objective in designing low-pressure-drop cyclones for pneumatic conveying is to achieve high separation efficiency while minimizing the energy loss associated with the pressure drop across the device. This goal aligns with the broader industry trends of energy efficiency and sustainable operations. The challenge lies in optimizing the cyclone geometry to enhance particle separation without significantly increasing the pressure drop, which directly impacts the overall system's energy consumption.

Recent technological advancements have focused on improving cyclone designs through computational fluid dynamics (CFD) simulations and experimental studies. These efforts have led to a better understanding of the complex flow patterns within cyclones and their impact on separation efficiency and pressure drop. The trend is moving towards more sophisticated designs that incorporate features such as spiral inlets, optimized vortex finders, and innovative body shapes to enhance performance.

The current technological landscape is characterized by a push towards miniaturization and modular designs, allowing for more flexible and space-efficient installations. Additionally, there is a growing interest in developing cyclones capable of handling a wider range of particle sizes and densities, addressing the diverse needs of various industries, from food processing to pharmaceutical manufacturing.

Looking ahead, the field of cyclone design for pneumatic conveying systems is expected to continue evolving, with a focus on smart, adaptive designs that can adjust their performance based on real-time process conditions. The integration of sensors and control systems may lead to cyclones that can optimize their operation dynamically, further reducing energy consumption and improving separation efficiency across varying load conditions.

As environmental regulations become more stringent, there is also an increasing emphasis on developing cyclones that can effectively capture finer particles, pushing the boundaries of traditional cyclone capabilities. This trend is likely to drive innovation in materials and surface treatments that can enhance particle capture without compromising on pressure drop performance.

The primary objective in designing low-pressure-drop cyclones for pneumatic conveying is to achieve high separation efficiency while minimizing the energy loss associated with the pressure drop across the device. This goal aligns with the broader industry trends of energy efficiency and sustainable operations. The challenge lies in optimizing the cyclone geometry to enhance particle separation without significantly increasing the pressure drop, which directly impacts the overall system's energy consumption.

Recent technological advancements have focused on improving cyclone designs through computational fluid dynamics (CFD) simulations and experimental studies. These efforts have led to a better understanding of the complex flow patterns within cyclones and their impact on separation efficiency and pressure drop. The trend is moving towards more sophisticated designs that incorporate features such as spiral inlets, optimized vortex finders, and innovative body shapes to enhance performance.

The current technological landscape is characterized by a push towards miniaturization and modular designs, allowing for more flexible and space-efficient installations. Additionally, there is a growing interest in developing cyclones capable of handling a wider range of particle sizes and densities, addressing the diverse needs of various industries, from food processing to pharmaceutical manufacturing.

Looking ahead, the field of cyclone design for pneumatic conveying systems is expected to continue evolving, with a focus on smart, adaptive designs that can adjust their performance based on real-time process conditions. The integration of sensors and control systems may lead to cyclones that can optimize their operation dynamically, further reducing energy consumption and improving separation efficiency across varying load conditions.

As environmental regulations become more stringent, there is also an increasing emphasis on developing cyclones that can effectively capture finer particles, pushing the boundaries of traditional cyclone capabilities. This trend is likely to drive innovation in materials and surface treatments that can enhance particle capture without compromising on pressure drop performance.

Market Demand Analysis for Low-Pressure-Drop Cyclones

The market demand for low-pressure-drop cyclones in pneumatic conveying systems has been steadily increasing due to the growing emphasis on energy efficiency and environmental sustainability across various industries. These cyclones play a crucial role in separating particles from gas streams, making them essential components in industries such as food processing, pharmaceuticals, chemicals, and cement manufacturing.

The global pneumatic conveying systems market, which includes low-pressure-drop cyclones, is experiencing significant growth. This expansion is driven by the need for more efficient material handling solutions, increased automation in manufacturing processes, and stringent regulations regarding air quality and emissions control. Industries are increasingly recognizing the benefits of low-pressure-drop cyclones in reducing energy consumption and improving overall system performance.

In the food and beverage industry, there is a rising demand for low-pressure-drop cyclones due to the need for hygienic processing and the handling of sensitive materials. These cyclones help maintain product integrity while ensuring efficient separation of particles from air streams. Similarly, in the pharmaceutical sector, the demand is fueled by the requirement for contamination-free environments and precise material handling during drug manufacturing processes.

The chemical industry is another significant market for low-pressure-drop cyclones. With the increasing focus on process optimization and reducing operational costs, companies are investing in advanced separation technologies. Low-pressure-drop cyclones offer an effective solution for removing particulates from gas streams while minimizing energy losses, making them attractive for chemical processing applications.

In the cement industry, where large volumes of materials are handled, the demand for low-pressure-drop cyclones is driven by the need to improve energy efficiency and reduce environmental impact. These cyclones help in the efficient separation of cement particles from air streams, contributing to cleaner emissions and improved product quality.

The market demand is also influenced by the growing trend towards sustainable manufacturing practices. Companies are increasingly looking for ways to reduce their carbon footprint and energy consumption. Low-pressure-drop cyclones align with these objectives by offering improved separation efficiency with reduced energy requirements, making them an attractive option for environmentally conscious businesses.

Geographically, the demand for low-pressure-drop cyclones is particularly strong in regions with stringent environmental regulations, such as Europe and North America. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest as they modernize their industrial infrastructure and adopt more efficient technologies.

As industries continue to prioritize operational efficiency and environmental compliance, the market for low-pressure-drop cyclones is expected to expand further. Manufacturers are likely to focus on developing innovative designs that offer even lower pressure drops, higher separation efficiencies, and improved durability to meet the evolving needs of various industries.

The global pneumatic conveying systems market, which includes low-pressure-drop cyclones, is experiencing significant growth. This expansion is driven by the need for more efficient material handling solutions, increased automation in manufacturing processes, and stringent regulations regarding air quality and emissions control. Industries are increasingly recognizing the benefits of low-pressure-drop cyclones in reducing energy consumption and improving overall system performance.

In the food and beverage industry, there is a rising demand for low-pressure-drop cyclones due to the need for hygienic processing and the handling of sensitive materials. These cyclones help maintain product integrity while ensuring efficient separation of particles from air streams. Similarly, in the pharmaceutical sector, the demand is fueled by the requirement for contamination-free environments and precise material handling during drug manufacturing processes.

The chemical industry is another significant market for low-pressure-drop cyclones. With the increasing focus on process optimization and reducing operational costs, companies are investing in advanced separation technologies. Low-pressure-drop cyclones offer an effective solution for removing particulates from gas streams while minimizing energy losses, making them attractive for chemical processing applications.

In the cement industry, where large volumes of materials are handled, the demand for low-pressure-drop cyclones is driven by the need to improve energy efficiency and reduce environmental impact. These cyclones help in the efficient separation of cement particles from air streams, contributing to cleaner emissions and improved product quality.

The market demand is also influenced by the growing trend towards sustainable manufacturing practices. Companies are increasingly looking for ways to reduce their carbon footprint and energy consumption. Low-pressure-drop cyclones align with these objectives by offering improved separation efficiency with reduced energy requirements, making them an attractive option for environmentally conscious businesses.

Geographically, the demand for low-pressure-drop cyclones is particularly strong in regions with stringent environmental regulations, such as Europe and North America. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest as they modernize their industrial infrastructure and adopt more efficient technologies.

As industries continue to prioritize operational efficiency and environmental compliance, the market for low-pressure-drop cyclones is expected to expand further. Manufacturers are likely to focus on developing innovative designs that offer even lower pressure drops, higher separation efficiencies, and improved durability to meet the evolving needs of various industries.

Current Challenges in Cyclone Design

Cyclone separators are critical components in pneumatic conveying systems, yet their design faces several significant challenges in achieving low-pressure drop performance. One of the primary obstacles is balancing separation efficiency with pressure loss. As the cyclone's efficiency increases, typically through higher tangential velocities or longer body lengths, the pressure drop also rises, leading to increased energy consumption and operational costs.

Another challenge lies in the complex flow patterns within cyclones. The internal aerodynamics involve turbulent, swirling flows that are difficult to model accurately. This complexity makes it challenging to predict and optimize cyclone performance, especially when dealing with varying particle sizes and concentrations in the conveyed material. The interaction between particles and gas flow further complicates the design process, as it can lead to unexpected pressure losses and reduced separation efficiency.

The geometry of cyclones presents its own set of challenges. The inlet design, vortex finder dimensions, and cone angle all significantly impact pressure drop and separation efficiency. Optimizing these parameters often involves trade-offs, and finding the right balance for specific applications can be a time-consuming and iterative process. Additionally, the scale-up of cyclone designs from laboratory to industrial sizes often results in unexpected performance changes, requiring further adjustments and refinements.

Material properties of the conveyed particles add another layer of complexity to cyclone design. Variations in particle size distribution, density, and shape can dramatically affect cyclone performance. Designing a low-pressure-drop cyclone that maintains high efficiency across a wide range of material characteristics is a significant challenge, particularly in industries where the conveyed material properties may fluctuate.

Operational conditions such as flow rate fluctuations and temperature variations also pose challenges in cyclone design. These variations can lead to inconsistent performance and increased pressure drop. Designing cyclones that maintain low-pressure drop characteristics under varying operational conditions requires sophisticated control systems and adaptive design features, which can increase complexity and cost.

The need for compact designs in many industrial applications further complicates the achievement of low-pressure drop. Space constraints often necessitate smaller cyclones, which typically exhibit higher pressure drops due to increased gas velocities. Balancing size requirements with performance objectives remains a persistent challenge in cyclone design for pneumatic conveying systems.

Another challenge lies in the complex flow patterns within cyclones. The internal aerodynamics involve turbulent, swirling flows that are difficult to model accurately. This complexity makes it challenging to predict and optimize cyclone performance, especially when dealing with varying particle sizes and concentrations in the conveyed material. The interaction between particles and gas flow further complicates the design process, as it can lead to unexpected pressure losses and reduced separation efficiency.

The geometry of cyclones presents its own set of challenges. The inlet design, vortex finder dimensions, and cone angle all significantly impact pressure drop and separation efficiency. Optimizing these parameters often involves trade-offs, and finding the right balance for specific applications can be a time-consuming and iterative process. Additionally, the scale-up of cyclone designs from laboratory to industrial sizes often results in unexpected performance changes, requiring further adjustments and refinements.

Material properties of the conveyed particles add another layer of complexity to cyclone design. Variations in particle size distribution, density, and shape can dramatically affect cyclone performance. Designing a low-pressure-drop cyclone that maintains high efficiency across a wide range of material characteristics is a significant challenge, particularly in industries where the conveyed material properties may fluctuate.

Operational conditions such as flow rate fluctuations and temperature variations also pose challenges in cyclone design. These variations can lead to inconsistent performance and increased pressure drop. Designing cyclones that maintain low-pressure drop characteristics under varying operational conditions requires sophisticated control systems and adaptive design features, which can increase complexity and cost.

The need for compact designs in many industrial applications further complicates the achievement of low-pressure drop. Space constraints often necessitate smaller cyclones, which typically exhibit higher pressure drops due to increased gas velocities. Balancing size requirements with performance objectives remains a persistent challenge in cyclone design for pneumatic conveying systems.

Existing Low-Pressure-Drop Cyclone Solutions

01 Cyclone design optimization for pressure drop reduction

Optimizing cyclone design parameters such as inlet geometry, body dimensions, and outlet configuration can significantly reduce pressure drop while maintaining separation efficiency. This includes adjusting the cyclone's diameter, length, and cone angle to minimize energy loss and improve overall performance.- Cyclone design optimization for pressure drop reduction: Various design modifications can be implemented to optimize cyclone performance and reduce pressure drop. These include adjustments to the cyclone geometry, such as inlet configuration, body dimensions, and cone angle. Advanced computational fluid dynamics (CFD) simulations and experimental studies are used to analyze and improve cyclone efficiency while minimizing pressure losses.

- Pressure drop measurement and control in cyclone systems: Accurate measurement and control of pressure drop in cyclone systems are crucial for maintaining optimal performance. This involves the use of pressure sensors, flow meters, and advanced control systems to monitor and adjust operating parameters. Real-time data analysis and feedback mechanisms help maintain desired pressure drop levels and overall system efficiency.

- Multi-stage cyclone arrangements for pressure drop management: Multi-stage cyclone configurations can be employed to manage pressure drop more effectively. By distributing the separation process across multiple stages, the overall pressure drop can be reduced while maintaining or improving separation efficiency. This approach allows for better control of particle size distribution and gas flow characteristics throughout the system.

- Novel cyclone inlet designs for pressure drop reduction: Innovative inlet designs can significantly impact cyclone pressure drop. These designs focus on optimizing gas flow patterns, reducing turbulence, and improving particle distribution at the cyclone entrance. Techniques such as tangential, spiral, or volute inlets are explored to enhance separation efficiency while minimizing pressure losses.

- Integration of pressure drop reduction technologies in industrial cyclone applications: Various pressure drop reduction technologies are being integrated into industrial cyclone applications. These include the use of advanced materials, surface treatments, and auxiliary devices such as vortex finders or anti-creep skirts. The integration of these technologies aims to enhance overall system performance, energy efficiency, and operational flexibility in diverse industrial settings.

02 Pressure drop control in multi-cyclone systems

In multi-cyclone systems, pressure drop can be managed through proper arrangement and interconnection of individual cyclones. This may involve parallel or series configurations, balanced flow distribution, and optimized manifold designs to minimize overall system pressure loss while maintaining separation efficiency.Expand Specific Solutions03 Vortex finder modifications for pressure drop reduction

Modifications to the vortex finder, such as adjusting its length, diameter, or shape, can help reduce pressure drop in cyclones. These modifications aim to minimize turbulence and flow resistance in the cyclone's core, leading to improved overall performance and energy efficiency.Expand Specific Solutions04 Inlet flow control techniques for cyclone pressure drop management

Implementing inlet flow control techniques, such as guide vanes, swirl generators, or flow straighteners, can help manage pressure drop in cyclones. These methods aim to optimize the inlet flow pattern, reduce turbulence, and improve the overall separation efficiency while minimizing energy loss.Expand Specific Solutions05 Advanced materials and surface treatments for cyclone pressure drop reduction

Utilizing advanced materials or applying surface treatments to cyclone components can help reduce friction and pressure drop. This may include using low-friction coatings, textured surfaces, or novel materials that minimize wall interactions and improve flow characteristics within the cyclone.Expand Specific Solutions

Key Players in Cyclone Manufacturing

The design of low-pressure-drop cyclones for pneumatic conveying is in a mature stage of industry development, with a well-established market and proven technology. The global market size for cyclone separators is estimated to reach several billion dollars by 2025, driven by increasing demand in various industries. Technologically, companies like China Petroleum & Chemical Corp., Sinopec Engineering, and SINOPEC Engineering (Group) Co., Ltd. have made significant advancements in cyclone design, optimizing efficiency and reducing pressure drop. Other players such as Goodyear Tire & Rubber Co. and Festo SE & Co. KG have also contributed to innovations in this field, particularly in materials and control systems for pneumatic conveying applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced low-pressure-drop cyclones for pneumatic conveying in petrochemical processes. Their design incorporates a tangential inlet with optimized geometry to reduce pressure loss while maintaining separation efficiency. The cyclone body features a conical section with a carefully calculated angle to enhance particle separation. They have implemented a vortex finder with adjustable length to fine-tune the cut-off size of particles. Sinopec's cyclones utilize computational fluid dynamics (CFD) simulations to optimize flow patterns and minimize turbulence[1]. The company has also integrated a secondary air injection system near the cyclone bottom to re-entrain settled particles, reducing the risk of blockages[3].

Strengths: Extensive experience in petrochemical applications, advanced CFD optimization, and innovative features like adjustable vortex finders. Weaknesses: May be over-specialized for petrochemical use, potentially limiting adaptability to other industries.

Sinopec Engineering, Inc.

Technical Solution: Sinopec Engineering, Inc. has developed a novel approach to low-pressure-drop cyclone design for pneumatic conveying systems. Their cyclones feature a unique helical inlet that gradually introduces the particle-laden gas stream into the separation chamber, reducing turbulence and pressure drop. The company has implemented a dual-vortex system, where an outer vortex descends along the cyclone walls while an inner vortex ascends through the center, enhancing separation efficiency without increasing pressure drop[2]. Sinopec Engineering's cyclones also incorporate a "smart" pressure equalization system that automatically adjusts the vortex finder position based on real-time pressure measurements, ensuring optimal performance across varying flow conditions[4]. The cyclone body is constructed using advanced materials with low friction coefficients to further minimize pressure losses.

Strengths: Innovative helical inlet design, adaptive pressure equalization system, and use of advanced low-friction materials. Weaknesses: Potentially higher manufacturing costs due to complex design and materials, which may limit adoption in cost-sensitive applications.

Core Innovations in Cyclone Design

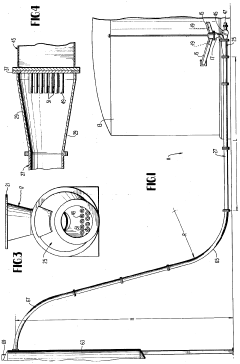

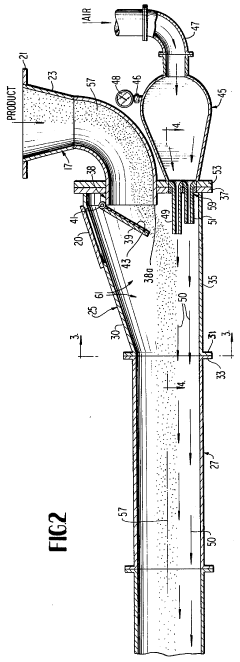

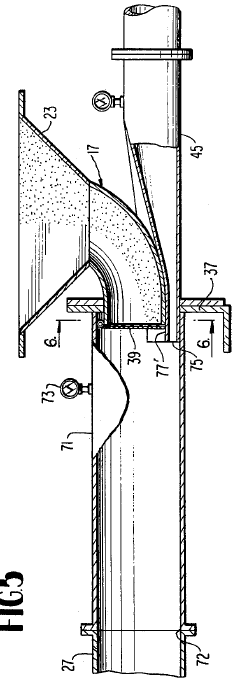

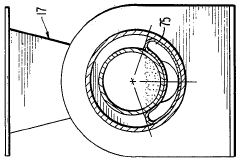

Pneumatic conveying apparatus and method

PatentInactiveUS4009912A

Innovation

- A pneumatic conveying apparatus and method that uses a minimum number of moving parts, eliminates the need for screw feeders or rotary gate valves, and employs a pressure-responsive system with a transition chamber and check valve to prevent blowbacks, utilizing a high-velocity air stream to convey materials efficiently and quietly.

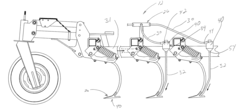

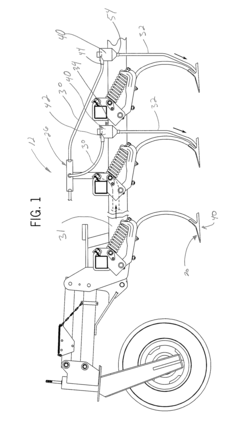

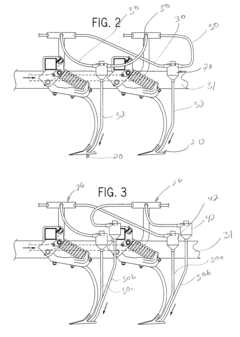

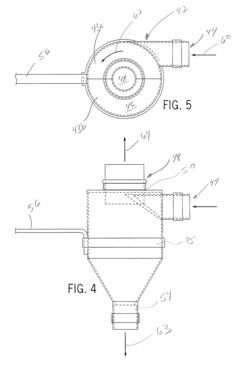

Cyclone assisted product delivery system for soil openers

PatentActiveUS20080121154A1

Innovation

- A pneumatic agricultural product delivery system utilizing a cyclone that is rigidly mounted to the tool bar, capable of receiving multiple product supply lines and adjusting air flow, which reduces air velocity to near zero, ensuring accurate product placement and handling mixed products with adjustable exhaust tubes to manage air pressure and velocity.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the design of low-pressure-drop cyclones for pneumatic conveying systems. These cyclones play a vital role in separating particles from the conveying air stream, and their efficiency directly impacts the overall energy consumption of the system. To optimize energy efficiency, designers must focus on minimizing pressure drop while maintaining high separation efficiency.

One of the primary strategies for improving energy efficiency is to optimize the cyclone geometry. This includes carefully selecting the cyclone diameter, height, inlet dimensions, and outlet configurations. A well-designed cyclone with streamlined internal surfaces can significantly reduce turbulence and friction losses, thereby minimizing pressure drop and energy consumption. Computational Fluid Dynamics (CFD) simulations have become invaluable tools in this optimization process, allowing designers to evaluate multiple geometric configurations and their impact on energy efficiency.

The inlet design of the cyclone is particularly crucial for energy efficiency. A tangential inlet with a properly sized and shaped entry can help maintain the momentum of the incoming air-particle mixture, reducing energy losses during the initial separation phase. Some advanced designs incorporate guide vanes or spiral inlets to further enhance the cyclonic motion while minimizing turbulence and pressure drop.

Material selection also plays a role in energy efficiency. Using smooth, wear-resistant materials for the cyclone's internal surfaces can reduce friction and prevent surface degradation over time, maintaining optimal performance and energy efficiency throughout the cyclone's operational life. Additionally, lightweight materials can be considered for certain components to reduce the overall mass of the system, potentially leading to energy savings in mobile or portable applications.

The vortex finder, a critical component of the cyclone, requires careful design to balance separation efficiency and pressure drop. An optimized vortex finder length and diameter can help maintain a stable vortex while minimizing energy losses. Some innovative designs incorporate adjustable vortex finders, allowing for real-time optimization based on varying operating conditions.

System-level considerations are equally important for maximizing energy efficiency. This includes proper sizing of the cyclone relative to the conveying system's flow rate and particle characteristics. Oversized cyclones can lead to unnecessary pressure drops, while undersized units may result in poor separation and increased energy consumption in downstream processes. Furthermore, integrating cyclones with other system components, such as fans and filters, can lead to synergistic energy savings.

Advanced control systems and monitoring technologies can further enhance energy efficiency by allowing for dynamic adjustment of operating parameters. Real-time monitoring of pressure drop, flow rates, and separation efficiency can enable adaptive control strategies that optimize performance under varying conditions, ensuring consistent energy efficiency across different operational scenarios.

One of the primary strategies for improving energy efficiency is to optimize the cyclone geometry. This includes carefully selecting the cyclone diameter, height, inlet dimensions, and outlet configurations. A well-designed cyclone with streamlined internal surfaces can significantly reduce turbulence and friction losses, thereby minimizing pressure drop and energy consumption. Computational Fluid Dynamics (CFD) simulations have become invaluable tools in this optimization process, allowing designers to evaluate multiple geometric configurations and their impact on energy efficiency.

The inlet design of the cyclone is particularly crucial for energy efficiency. A tangential inlet with a properly sized and shaped entry can help maintain the momentum of the incoming air-particle mixture, reducing energy losses during the initial separation phase. Some advanced designs incorporate guide vanes or spiral inlets to further enhance the cyclonic motion while minimizing turbulence and pressure drop.

Material selection also plays a role in energy efficiency. Using smooth, wear-resistant materials for the cyclone's internal surfaces can reduce friction and prevent surface degradation over time, maintaining optimal performance and energy efficiency throughout the cyclone's operational life. Additionally, lightweight materials can be considered for certain components to reduce the overall mass of the system, potentially leading to energy savings in mobile or portable applications.

The vortex finder, a critical component of the cyclone, requires careful design to balance separation efficiency and pressure drop. An optimized vortex finder length and diameter can help maintain a stable vortex while minimizing energy losses. Some innovative designs incorporate adjustable vortex finders, allowing for real-time optimization based on varying operating conditions.

System-level considerations are equally important for maximizing energy efficiency. This includes proper sizing of the cyclone relative to the conveying system's flow rate and particle characteristics. Oversized cyclones can lead to unnecessary pressure drops, while undersized units may result in poor separation and increased energy consumption in downstream processes. Furthermore, integrating cyclones with other system components, such as fans and filters, can lead to synergistic energy savings.

Advanced control systems and monitoring technologies can further enhance energy efficiency by allowing for dynamic adjustment of operating parameters. Real-time monitoring of pressure drop, flow rates, and separation efficiency can enable adaptive control strategies that optimize performance under varying conditions, ensuring consistent energy efficiency across different operational scenarios.

Environmental Impact Assessment

The environmental impact assessment of low-pressure-drop cyclones for pneumatic conveying systems is crucial for understanding their sustainability and ecological footprint. These cyclones, designed to separate particles from gas streams with minimal pressure loss, offer significant environmental benefits compared to traditional high-pressure-drop systems.

One of the primary environmental advantages of low-pressure-drop cyclones is their energy efficiency. By reducing the pressure drop across the system, these cyclones require less power for operation, leading to decreased energy consumption and, consequently, lower greenhouse gas emissions. This reduction in energy use contributes to the overall sustainability of industrial processes that employ pneumatic conveying systems.

The improved particle separation efficiency of low-pressure-drop cyclones also has positive environmental implications. By effectively removing particulate matter from gas streams, these cyclones help minimize air pollution and reduce the release of potentially harmful particles into the atmosphere. This is particularly important in industries where fine dust or particulates are generated as byproducts of manufacturing processes.

Furthermore, the design of low-pressure-drop cyclones often allows for the recovery and reuse of valuable materials that would otherwise be lost in the conveying process. This resource efficiency not only reduces waste but also minimizes the need for raw material extraction, thereby lessening the environmental impact associated with mining and processing activities.

The longevity and durability of low-pressure-drop cyclones contribute to their positive environmental profile. With fewer moving parts and less wear due to reduced pressure, these cyclones typically have longer operational lifespans compared to conventional designs. This extended service life translates to reduced waste generation and less frequent need for replacement, further minimizing the environmental footprint of industrial operations.

In terms of water usage, low-pressure-drop cyclones generally require minimal or no water for their operation, unlike some other particle separation technologies. This characteristic is particularly beneficial in water-stressed regions or industries where water conservation is a priority, contributing to overall water resource management efforts.

However, it is important to consider the potential negative environmental impacts associated with the manufacturing and disposal of low-pressure-drop cyclones. The production of these devices may involve energy-intensive processes and the use of materials with their own environmental considerations. End-of-life disposal or recycling of cyclone components should also be factored into the overall environmental assessment.

In conclusion, the environmental impact assessment of low-pressure-drop cyclones for pneumatic conveying systems generally reveals a positive contribution to sustainability efforts. Their energy efficiency, improved particle separation, resource recovery capabilities, and reduced maintenance requirements offer significant environmental benefits. However, a comprehensive life cycle analysis should be conducted to fully understand and quantify their net environmental impact across all stages of production, use, and disposal.

One of the primary environmental advantages of low-pressure-drop cyclones is their energy efficiency. By reducing the pressure drop across the system, these cyclones require less power for operation, leading to decreased energy consumption and, consequently, lower greenhouse gas emissions. This reduction in energy use contributes to the overall sustainability of industrial processes that employ pneumatic conveying systems.

The improved particle separation efficiency of low-pressure-drop cyclones also has positive environmental implications. By effectively removing particulate matter from gas streams, these cyclones help minimize air pollution and reduce the release of potentially harmful particles into the atmosphere. This is particularly important in industries where fine dust or particulates are generated as byproducts of manufacturing processes.

Furthermore, the design of low-pressure-drop cyclones often allows for the recovery and reuse of valuable materials that would otherwise be lost in the conveying process. This resource efficiency not only reduces waste but also minimizes the need for raw material extraction, thereby lessening the environmental impact associated with mining and processing activities.

The longevity and durability of low-pressure-drop cyclones contribute to their positive environmental profile. With fewer moving parts and less wear due to reduced pressure, these cyclones typically have longer operational lifespans compared to conventional designs. This extended service life translates to reduced waste generation and less frequent need for replacement, further minimizing the environmental footprint of industrial operations.

In terms of water usage, low-pressure-drop cyclones generally require minimal or no water for their operation, unlike some other particle separation technologies. This characteristic is particularly beneficial in water-stressed regions or industries where water conservation is a priority, contributing to overall water resource management efforts.

However, it is important to consider the potential negative environmental impacts associated with the manufacturing and disposal of low-pressure-drop cyclones. The production of these devices may involve energy-intensive processes and the use of materials with their own environmental considerations. End-of-life disposal or recycling of cyclone components should also be factored into the overall environmental assessment.

In conclusion, the environmental impact assessment of low-pressure-drop cyclones for pneumatic conveying systems generally reveals a positive contribution to sustainability efforts. Their energy efficiency, improved particle separation, resource recovery capabilities, and reduced maintenance requirements offer significant environmental benefits. However, a comprehensive life cycle analysis should be conducted to fully understand and quantify their net environmental impact across all stages of production, use, and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!