How to Expand Cellophane’s Role in Food Security Solutions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane in Food Security: Background and Objectives

Cellophane, a thin transparent sheet made from regenerated cellulose, has been a staple in food packaging for decades. Its role in food security solutions, however, is evolving and expanding beyond traditional applications. The primary objective of this technical research is to explore innovative ways to leverage cellophane's unique properties to address pressing food security challenges globally.

The development of cellophane dates back to 1900 when Jacques E. Brandenberger invented the material. Initially used for packaging various products, cellophane quickly found its niche in food preservation due to its transparency, flexibility, and barrier properties. As food security concerns have grown in recent years, the potential for cellophane to contribute to solutions has garnered renewed interest from researchers and industry professionals alike.

Current food security challenges include reducing food waste, extending shelf life, ensuring safe transportation of perishables, and improving accessibility to fresh produce in remote areas. Cellophane's inherent characteristics position it as a promising material to tackle these issues. Its biodegradability aligns with sustainability goals, while its barrier properties against moisture and gases can significantly enhance food preservation efforts.

The technological evolution of cellophane has seen advancements in its production processes and modifications to enhance its functionality. Recent developments include the incorporation of antimicrobial agents, improved barrier properties, and the creation of "smart" cellophane that can indicate food freshness. These innovations aim to expand cellophane's role from a passive packaging material to an active participant in food security solutions.

As we look towards the future, the objective is to push the boundaries of cellophane's capabilities in food preservation and distribution. This includes exploring nanotechnology applications to create ultra-thin, super-strong cellophane films, developing biodegradable sensors integrated into cellophane packaging, and investigating the potential for cellophane-based edible packaging.

The global nature of food security challenges necessitates a multifaceted approach. Cellophane's versatility makes it an ideal candidate for adaptation to various cultural and geographical contexts. From extending the shelf life of tropical fruits in humid climates to protecting grains from pests in arid regions, the goal is to tailor cellophane solutions to specific food security needs worldwide.

In conclusion, this technical research aims to comprehensively explore and expand cellophane's role in addressing food security challenges. By examining its historical context, current applications, and potential future developments, we seek to unlock new possibilities for this versatile material in safeguarding global food supplies.

The development of cellophane dates back to 1900 when Jacques E. Brandenberger invented the material. Initially used for packaging various products, cellophane quickly found its niche in food preservation due to its transparency, flexibility, and barrier properties. As food security concerns have grown in recent years, the potential for cellophane to contribute to solutions has garnered renewed interest from researchers and industry professionals alike.

Current food security challenges include reducing food waste, extending shelf life, ensuring safe transportation of perishables, and improving accessibility to fresh produce in remote areas. Cellophane's inherent characteristics position it as a promising material to tackle these issues. Its biodegradability aligns with sustainability goals, while its barrier properties against moisture and gases can significantly enhance food preservation efforts.

The technological evolution of cellophane has seen advancements in its production processes and modifications to enhance its functionality. Recent developments include the incorporation of antimicrobial agents, improved barrier properties, and the creation of "smart" cellophane that can indicate food freshness. These innovations aim to expand cellophane's role from a passive packaging material to an active participant in food security solutions.

As we look towards the future, the objective is to push the boundaries of cellophane's capabilities in food preservation and distribution. This includes exploring nanotechnology applications to create ultra-thin, super-strong cellophane films, developing biodegradable sensors integrated into cellophane packaging, and investigating the potential for cellophane-based edible packaging.

The global nature of food security challenges necessitates a multifaceted approach. Cellophane's versatility makes it an ideal candidate for adaptation to various cultural and geographical contexts. From extending the shelf life of tropical fruits in humid climates to protecting grains from pests in arid regions, the goal is to tailor cellophane solutions to specific food security needs worldwide.

In conclusion, this technical research aims to comprehensively explore and expand cellophane's role in addressing food security challenges. By examining its historical context, current applications, and potential future developments, we seek to unlock new possibilities for this versatile material in safeguarding global food supplies.

Market Analysis for Cellophane-Based Food Packaging

The global market for cellophane-based food packaging is experiencing significant growth, driven by increasing consumer demand for sustainable and eco-friendly packaging solutions. As concerns about food security and environmental sustainability continue to rise, cellophane has emerged as a promising material for addressing these challenges. The market is characterized by a shift towards biodegradable and compostable packaging options, with cellophane offering a viable alternative to traditional plastic materials.

In recent years, the food packaging industry has witnessed a surge in demand for cellophane-based products, particularly in developed regions such as North America and Europe. This trend is largely attributed to stringent regulations on single-use plastics and growing consumer awareness of environmental issues. The Asia-Pacific region is also showing rapid growth potential, with countries like China and India investing heavily in sustainable packaging technologies.

The market for cellophane-based food packaging is segmented based on application, including fresh produce, bakery items, confectionery, and processed foods. Fresh produce packaging represents a significant portion of the market share, as cellophane's breathable properties help extend the shelf life of fruits and vegetables. The bakery segment is also experiencing robust growth, with cellophane providing an effective barrier against moisture and contaminants while maintaining product freshness.

Key market drivers include the increasing adoption of sustainable packaging practices by food manufacturers, rising consumer preference for transparent packaging that allows product visibility, and the growing emphasis on food safety and hygiene. Additionally, the versatility of cellophane in terms of printability and customization options has made it an attractive choice for brand owners looking to enhance their product appeal.

However, the market faces challenges such as the higher production costs associated with cellophane compared to conventional plastics and the need for improved recycling infrastructure. Despite these obstacles, technological advancements in cellophane production and the development of bio-based alternatives are expected to drive market growth in the coming years.

The competitive landscape of the cellophane-based food packaging market is characterized by the presence of both established players and new entrants. Major companies are investing in research and development to enhance the performance characteristics of cellophane and expand its applications in food packaging. Collaborations between packaging manufacturers and food producers are becoming increasingly common, fostering innovation and market expansion.

Looking ahead, the market for cellophane-based food packaging is projected to continue its upward trajectory, with a focus on developing more advanced, cost-effective, and environmentally friendly solutions. The integration of smart packaging technologies and the exploration of new raw material sources for cellophane production are expected to open up new opportunities in the market, further solidifying cellophane's role in addressing food security challenges.

In recent years, the food packaging industry has witnessed a surge in demand for cellophane-based products, particularly in developed regions such as North America and Europe. This trend is largely attributed to stringent regulations on single-use plastics and growing consumer awareness of environmental issues. The Asia-Pacific region is also showing rapid growth potential, with countries like China and India investing heavily in sustainable packaging technologies.

The market for cellophane-based food packaging is segmented based on application, including fresh produce, bakery items, confectionery, and processed foods. Fresh produce packaging represents a significant portion of the market share, as cellophane's breathable properties help extend the shelf life of fruits and vegetables. The bakery segment is also experiencing robust growth, with cellophane providing an effective barrier against moisture and contaminants while maintaining product freshness.

Key market drivers include the increasing adoption of sustainable packaging practices by food manufacturers, rising consumer preference for transparent packaging that allows product visibility, and the growing emphasis on food safety and hygiene. Additionally, the versatility of cellophane in terms of printability and customization options has made it an attractive choice for brand owners looking to enhance their product appeal.

However, the market faces challenges such as the higher production costs associated with cellophane compared to conventional plastics and the need for improved recycling infrastructure. Despite these obstacles, technological advancements in cellophane production and the development of bio-based alternatives are expected to drive market growth in the coming years.

The competitive landscape of the cellophane-based food packaging market is characterized by the presence of both established players and new entrants. Major companies are investing in research and development to enhance the performance characteristics of cellophane and expand its applications in food packaging. Collaborations between packaging manufacturers and food producers are becoming increasingly common, fostering innovation and market expansion.

Looking ahead, the market for cellophane-based food packaging is projected to continue its upward trajectory, with a focus on developing more advanced, cost-effective, and environmentally friendly solutions. The integration of smart packaging technologies and the exploration of new raw material sources for cellophane production are expected to open up new opportunities in the market, further solidifying cellophane's role in addressing food security challenges.

Current Challenges in Cellophane Food Preservation

Cellophane, a transparent film made from regenerated cellulose, has long been used in food packaging due to its excellent barrier properties against moisture and gases. However, as the global food security challenges intensify, the limitations of traditional cellophane in food preservation have become increasingly apparent.

One of the primary challenges facing cellophane in food preservation is its limited ability to extend shelf life beyond a certain point. While cellophane provides an effective barrier against external contaminants, it does not actively combat microbial growth or oxidation processes that occur naturally within packaged foods. This limitation becomes particularly problematic for perishable items that require extended storage periods or transportation across long distances.

Another significant challenge is cellophane's susceptibility to temperature fluctuations. In varying environmental conditions, such as those encountered during transportation or storage, cellophane's barrier properties can be compromised, leading to moisture ingress or gas permeation. This vulnerability can result in accelerated food spoilage, especially in regions with unstable climates or inadequate cold chain infrastructure.

The recyclability and biodegradability of cellophane also present challenges in the context of sustainable food security solutions. While cellophane is derived from renewable resources, its disposal and recycling processes are not as straightforward as those of some synthetic plastics. This complexity can lead to increased environmental impact and hinder the adoption of cellophane in large-scale food preservation initiatives.

Furthermore, the cost-effectiveness of cellophane compared to newer, technologically advanced packaging materials poses a challenge to its expanded role in food security. As innovative materials with enhanced preservation capabilities enter the market, the relative performance-to-cost ratio of cellophane becomes less favorable, potentially limiting its adoption in resource-constrained settings.

The inability of traditional cellophane to incorporate active packaging technologies is another significant limitation. Unlike some modern packaging materials, cellophane does not easily accommodate antimicrobial agents, oxygen scavengers, or ethylene absorbers. This shortcoming restricts its effectiveness in creating intelligent packaging systems that can dynamically respond to food degradation processes.

Lastly, the scalability of cellophane production to meet the growing demands of global food security presents a challenge. The manufacturing process of cellophane, while well-established, may face difficulties in rapidly scaling up to address sudden increases in demand or to adapt to diverse packaging requirements across different food types and preservation needs.

One of the primary challenges facing cellophane in food preservation is its limited ability to extend shelf life beyond a certain point. While cellophane provides an effective barrier against external contaminants, it does not actively combat microbial growth or oxidation processes that occur naturally within packaged foods. This limitation becomes particularly problematic for perishable items that require extended storage periods or transportation across long distances.

Another significant challenge is cellophane's susceptibility to temperature fluctuations. In varying environmental conditions, such as those encountered during transportation or storage, cellophane's barrier properties can be compromised, leading to moisture ingress or gas permeation. This vulnerability can result in accelerated food spoilage, especially in regions with unstable climates or inadequate cold chain infrastructure.

The recyclability and biodegradability of cellophane also present challenges in the context of sustainable food security solutions. While cellophane is derived from renewable resources, its disposal and recycling processes are not as straightforward as those of some synthetic plastics. This complexity can lead to increased environmental impact and hinder the adoption of cellophane in large-scale food preservation initiatives.

Furthermore, the cost-effectiveness of cellophane compared to newer, technologically advanced packaging materials poses a challenge to its expanded role in food security. As innovative materials with enhanced preservation capabilities enter the market, the relative performance-to-cost ratio of cellophane becomes less favorable, potentially limiting its adoption in resource-constrained settings.

The inability of traditional cellophane to incorporate active packaging technologies is another significant limitation. Unlike some modern packaging materials, cellophane does not easily accommodate antimicrobial agents, oxygen scavengers, or ethylene absorbers. This shortcoming restricts its effectiveness in creating intelligent packaging systems that can dynamically respond to food degradation processes.

Lastly, the scalability of cellophane production to meet the growing demands of global food security presents a challenge. The manufacturing process of cellophane, while well-established, may face difficulties in rapidly scaling up to address sudden increases in demand or to adapt to diverse packaging requirements across different food types and preservation needs.

Existing Cellophane Solutions for Food Security

01 Cellophane production and modification

Various methods and processes for producing and modifying cellophane are described. These include techniques for improving the properties of cellophane, such as its strength, flexibility, and barrier characteristics. The production processes may involve chemical treatments, physical modifications, or the incorporation of additives to enhance the performance of cellophane for specific applications.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is commonly employed in food packaging, gift wrapping, and industrial packaging. The material's ability to protect products from moisture and air makes it suitable for various packaging needs.

- Biodegradable cellophane alternatives: Research is being conducted to develop biodegradable alternatives to traditional cellophane. These eco-friendly materials aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area focus on using renewable resources and improving the material's compostability.

- Cellophane in textile and fiber applications: Cellophane finds applications in the textile and fiber industry. It can be used to create unique fabric effects, as a component in composite materials, or as a protective layer for textiles. The material's properties allow for innovative uses in clothing and industrial textiles.

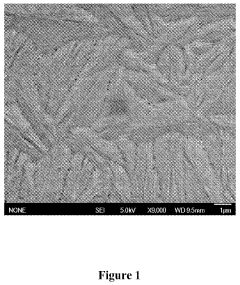

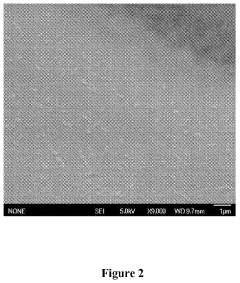

- Modified cellophane for enhanced properties: Researchers are developing modified cellophane materials with enhanced properties. These modifications aim to improve the material's strength, barrier properties, or add functionalities such as antimicrobial properties. Such advancements expand the potential applications of cellophane in various industries.

- Cellophane in medical and pharmaceutical applications: Cellophane has found use in medical and pharmaceutical applications. Its properties make it suitable for certain medical packaging, drug delivery systems, or as a component in medical devices. The material's biocompatibility and barrier properties contribute to its utility in this field.

02 Packaging applications of cellophane

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. The patents describe various packaging solutions utilizing cellophane, including food packaging, consumer product packaging, and industrial packaging. Some innovations focus on improving the sealing properties, printability, and environmental sustainability of cellophane-based packaging materials.Expand Specific Solutions03 Cellophane-based composite materials

The development of composite materials incorporating cellophane is discussed in several patents. These composites may combine cellophane with other materials such as polymers, fibers, or nanoparticles to create materials with enhanced properties. Applications for these composites include packaging, textiles, and various industrial uses.Expand Specific Solutions04 Biodegradable and eco-friendly cellophane

Innovations in making cellophane more environmentally friendly are described. These include developing biodegradable cellophane formulations, improving the recyclability of cellophane products, and creating cellophane alternatives from renewable resources. The focus is on reducing the environmental impact of cellophane while maintaining its desirable properties.Expand Specific Solutions05 Cellophane in medical and pharmaceutical applications

The use of cellophane in medical and pharmaceutical applications is explored in several patents. These applications may include drug delivery systems, wound dressings, and medical packaging. The patents describe methods for modifying cellophane to improve its biocompatibility, sterilizability, and controlled release properties for medical use.Expand Specific Solutions

Key Players in Cellophane and Food Packaging Sector

The cellophane market for food security solutions is in a growth phase, driven by increasing demand for sustainable packaging. The market size is expanding, with potential for significant growth in developing economies. Technologically, cellophane is evolving to meet stricter environmental and performance standards. Key players like Cargill, Novozymes, and Danisco are investing in R&D to enhance cellophane's properties and applications. Universities such as California and Minnesota are contributing to fundamental research. Companies like Zoono Group and Codexis are exploring innovative uses in antimicrobial and enzymatic applications, respectively. The competitive landscape is diverse, with both established firms and emerging players vying for market share.

Cargill, Inc.

Technical Solution: Cargill has made significant strides in expanding cellophane's role in food security solutions. The company has developed a bio-based cellophane alternative derived from agricultural waste products, reducing reliance on petroleum-based materials[1]. This innovative approach not only addresses sustainability concerns but also improves the material's barrier properties. Cargill's cellophane technology incorporates natural antimicrobial agents derived from plant extracts, enhancing food preservation capabilities[2]. They have also pioneered a cellophane-based edible coating for fruits and vegetables, which forms a protective layer that slows down ripening and reduces moisture loss[3]. Furthermore, Cargill has developed a cellophane-based packaging solution with oxygen-scavenging properties, actively removing oxygen from the package headspace to extend product shelf life[4]. The company has also invested in research to improve the heat-sealing properties of cellophane, making it more versatile for various packaging applications[5].

Strengths: Bio-based sourcing, natural antimicrobial properties, edible coating technology, and oxygen-scavenging capabilities. Weaknesses: Potential higher costs associated with bio-based materials and challenges in achieving the same performance as synthetic alternatives in all applications.

Novozymes A/S

Technical Solution: Novozymes has focused on enzymatic solutions to enhance cellophane's properties for food security applications. The company has developed enzyme treatments that modify the surface of cellophane, improving its barrier properties against oxygen and moisture[1]. This enzymatic approach allows for tailored cellophane properties without the need for additional chemical treatments. Novozymes has also created a bio-based adhesive system specifically for cellophane packaging, improving seal integrity and reducing the risk of contamination[2]. Their research has led to the development of cellophane films with enhanced biodegradability, addressing end-of-life concerns for packaging materials[3]. Additionally, Novozymes has pioneered the use of enzymes to create antimicrobial peptides that can be incorporated into cellophane, providing an active defense against food spoilage organisms[4]. The company has also developed enzyme-based coatings for cellophane that improve its printability and compatibility with various food products[5].

Strengths: Enzymatic surface modification, bio-based adhesive systems, enhanced biodegradability, and antimicrobial peptide incorporation. Weaknesses: Potential scalability challenges for enzymatic treatments and higher production costs compared to traditional cellophane manufacturing methods.

Innovative Cellophane Technologies for Food Preservation

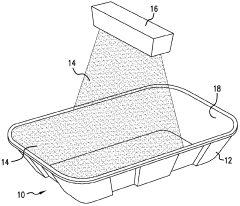

Methods And Articles For Keeping Food Fresher For Longer And Shelf-Life Extension To Enhance Food Security And Safety

PatentPendingAU2022291538A1

Innovation

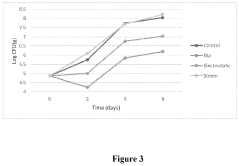

- A composition comprising benzalkonium chloride, hydrogen peroxide or phenoxyethanol, 3-(trimethoxysilyl)propyldimethyl octadecyl ammonium chloride, and deionized water is applied to food-contacting surfaces and packaging materials to create an antimicrobial coating that reduces bacterial counts by up to 90% and extends shelf-life without altering the food's quality.

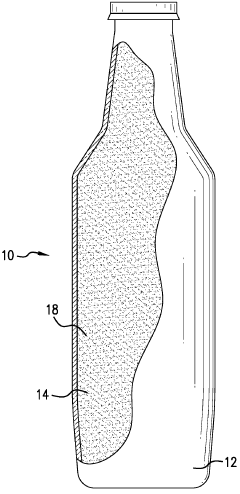

Methods for Use in Food Processing and Preservation

PatentPendingUS20220395003A1

Innovation

- A novel food coating composition comprising a combination of low, medium, and high molecular weight chitosan, sulfite, and acid, applied as an antimicrobial coating using methods such as steam application, dipping, or spraying, to form a uniform film on food surfaces, inhibiting microbial growth and discoloration.

Environmental Impact of Cellophane in Food Packaging

The environmental impact of cellophane in food packaging is a critical consideration as we explore ways to expand its role in food security solutions. Cellophane, a biodegradable material derived from cellulose, offers several advantages over traditional plastic packaging in terms of environmental sustainability.

One of the primary benefits of cellophane is its biodegradability. Unlike conventional plastics that can persist in the environment for hundreds of years, cellophane breaks down naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term accumulation of packaging waste in landfills and oceans, mitigating the harmful effects on wildlife and ecosystems.

Furthermore, cellophane's production process has a lower carbon footprint compared to many synthetic plastics. The raw material, cellulose, is derived from renewable sources such as wood pulp or cotton linters, making it a more sustainable option. The manufacturing process also typically requires less energy and produces fewer greenhouse gas emissions than the production of petroleum-based plastics.

However, it is important to note that the environmental benefits of cellophane are not without caveats. The production of cellophane still involves chemical processes and energy consumption, which contribute to its overall environmental impact. Additionally, while cellophane is biodegradable, it may not decompose efficiently in all environments, particularly in anaerobic conditions found in some landfills.

In terms of food preservation, cellophane's permeability to moisture and gases can be both an advantage and a disadvantage. Its breathability can help maintain the freshness of certain foods by allowing for controlled moisture exchange, potentially reducing food waste. However, this same property may limit its effectiveness in preserving highly perishable foods that require a complete barrier against moisture and oxygen.

To maximize the environmental benefits of cellophane in food packaging, it is crucial to consider its entire lifecycle. This includes optimizing production processes to minimize energy use and chemical inputs, developing more efficient recycling and composting systems for cellophane waste, and educating consumers on proper disposal methods.

As the food industry seeks to improve its environmental footprint, cellophane presents an opportunity to reduce reliance on non-biodegradable plastics. By addressing its limitations and leveraging its strengths, cellophane can play an increasingly important role in sustainable food packaging solutions, contributing to both food security and environmental conservation efforts.

One of the primary benefits of cellophane is its biodegradability. Unlike conventional plastics that can persist in the environment for hundreds of years, cellophane breaks down naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term accumulation of packaging waste in landfills and oceans, mitigating the harmful effects on wildlife and ecosystems.

Furthermore, cellophane's production process has a lower carbon footprint compared to many synthetic plastics. The raw material, cellulose, is derived from renewable sources such as wood pulp or cotton linters, making it a more sustainable option. The manufacturing process also typically requires less energy and produces fewer greenhouse gas emissions than the production of petroleum-based plastics.

However, it is important to note that the environmental benefits of cellophane are not without caveats. The production of cellophane still involves chemical processes and energy consumption, which contribute to its overall environmental impact. Additionally, while cellophane is biodegradable, it may not decompose efficiently in all environments, particularly in anaerobic conditions found in some landfills.

In terms of food preservation, cellophane's permeability to moisture and gases can be both an advantage and a disadvantage. Its breathability can help maintain the freshness of certain foods by allowing for controlled moisture exchange, potentially reducing food waste. However, this same property may limit its effectiveness in preserving highly perishable foods that require a complete barrier against moisture and oxygen.

To maximize the environmental benefits of cellophane in food packaging, it is crucial to consider its entire lifecycle. This includes optimizing production processes to minimize energy use and chemical inputs, developing more efficient recycling and composting systems for cellophane waste, and educating consumers on proper disposal methods.

As the food industry seeks to improve its environmental footprint, cellophane presents an opportunity to reduce reliance on non-biodegradable plastics. By addressing its limitations and leveraging its strengths, cellophane can play an increasingly important role in sustainable food packaging solutions, contributing to both food security and environmental conservation efforts.

Regulatory Framework for Food-Grade Cellophane Materials

The regulatory framework for food-grade cellophane materials plays a crucial role in ensuring the safety and quality of cellophane used in food packaging and preservation. As cellophane's potential in food security solutions expands, it becomes increasingly important to establish and maintain comprehensive regulations that govern its production, use, and disposal.

At the international level, organizations such as the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) provide guidelines for food contact materials, including cellophane. These guidelines serve as a foundation for national regulatory bodies to develop their own standards and regulations. The Codex Alimentarius Commission, a joint FAO/WHO initiative, has established international food standards that include specifications for food packaging materials.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including cellophane, under the Federal Food, Drug, and Cosmetic Act. The FDA's regulations for cellophane are outlined in Title 21 of the Code of Federal Regulations (CFR), specifically in Part 177. These regulations detail the permissible raw materials, additives, and manufacturing processes for cellophane intended for food contact use.

The European Union has established a comprehensive framework for food contact materials through Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, which includes certain types of cellophane.

In Asia, countries like Japan and China have their own regulatory systems for food contact materials. Japan's Ministry of Health, Labour and Welfare has established the Food Sanitation Act, which includes provisions for food packaging materials. China's GB standards, administered by the National Medical Products Administration, provide guidelines for food contact materials, including cellophane.

As the use of cellophane in food security solutions evolves, regulatory frameworks must adapt to address new applications and potential risks. This includes considerations for biodegradable and compostable cellophane variants, as well as the use of cellophane in active and intelligent packaging systems. Regulators must also consider the environmental impact of cellophane production and disposal, aligning food safety regulations with sustainability goals.

To ensure compliance and promote innovation, collaboration between regulatory bodies, industry stakeholders, and research institutions is essential. This collaboration can lead to the development of standardized testing methods, the establishment of migration limits for specific substances, and the creation of guidelines for novel cellophane applications in food security.

At the international level, organizations such as the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) provide guidelines for food contact materials, including cellophane. These guidelines serve as a foundation for national regulatory bodies to develop their own standards and regulations. The Codex Alimentarius Commission, a joint FAO/WHO initiative, has established international food standards that include specifications for food packaging materials.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including cellophane, under the Federal Food, Drug, and Cosmetic Act. The FDA's regulations for cellophane are outlined in Title 21 of the Code of Federal Regulations (CFR), specifically in Part 177. These regulations detail the permissible raw materials, additives, and manufacturing processes for cellophane intended for food contact use.

The European Union has established a comprehensive framework for food contact materials through Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, which includes certain types of cellophane.

In Asia, countries like Japan and China have their own regulatory systems for food contact materials. Japan's Ministry of Health, Labour and Welfare has established the Food Sanitation Act, which includes provisions for food packaging materials. China's GB standards, administered by the National Medical Products Administration, provide guidelines for food contact materials, including cellophane.

As the use of cellophane in food security solutions evolves, regulatory frameworks must adapt to address new applications and potential risks. This includes considerations for biodegradable and compostable cellophane variants, as well as the use of cellophane in active and intelligent packaging systems. Regulators must also consider the environmental impact of cellophane production and disposal, aligning food safety regulations with sustainability goals.

To ensure compliance and promote innovation, collaboration between regulatory bodies, industry stakeholders, and research institutions is essential. This collaboration can lead to the development of standardized testing methods, the establishment of migration limits for specific substances, and the creation of guidelines for novel cellophane applications in food security.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!