How To Measure Separation Efficiency For Biomass Combustion Dust

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Dust Separation Goals

The primary goal of biomass dust separation in combustion processes is to enhance overall system efficiency, reduce emissions, and improve the quality of combustion. Efficient separation of dust particles from biomass fuel is crucial for optimizing the combustion process and minimizing environmental impact.

One of the key objectives is to achieve a high separation efficiency, typically aiming for 90% or higher removal of particulate matter. This level of efficiency ensures that the majority of dust particles are captured before entering the combustion chamber, leading to cleaner burning and reduced ash formation. The target particle size for separation is usually in the range of 1-100 microns, with a focus on removing the smallest particles that pose the greatest health and environmental risks.

Another important goal is to maintain consistent separation performance across varying biomass feedstocks and operating conditions. Biomass fuels can vary significantly in composition, moisture content, and particle size distribution, making it challenging to achieve uniform separation. Developing robust separation technologies that can adapt to these variations is essential for widespread adoption in industrial applications.

Reducing pressure drop across the separation system is also a critical objective. Excessive pressure drop can lead to increased energy consumption and reduced overall system efficiency. Designers aim to optimize the separation process to minimize pressure losses while maintaining high collection efficiency.

Improving the durability and reliability of separation equipment is another key goal. Biomass dust can be abrasive and corrosive, potentially causing wear and damage to separation devices. Developing materials and designs that can withstand these harsh conditions over extended periods is crucial for reducing maintenance costs and downtime.

Furthermore, there is a growing emphasis on developing compact and modular separation systems that can be easily integrated into existing biomass combustion facilities. This goal addresses the need for retrofitting older plants and accommodating space constraints in new installations.

Lastly, enhancing the ability to measure and monitor separation efficiency in real-time is becoming increasingly important. This objective aims to provide operators with immediate feedback on system performance, allowing for rapid adjustments and optimization of the separation process. Developing accurate and reliable sensors and monitoring techniques for dusty environments is a key challenge in achieving this goal.

One of the key objectives is to achieve a high separation efficiency, typically aiming for 90% or higher removal of particulate matter. This level of efficiency ensures that the majority of dust particles are captured before entering the combustion chamber, leading to cleaner burning and reduced ash formation. The target particle size for separation is usually in the range of 1-100 microns, with a focus on removing the smallest particles that pose the greatest health and environmental risks.

Another important goal is to maintain consistent separation performance across varying biomass feedstocks and operating conditions. Biomass fuels can vary significantly in composition, moisture content, and particle size distribution, making it challenging to achieve uniform separation. Developing robust separation technologies that can adapt to these variations is essential for widespread adoption in industrial applications.

Reducing pressure drop across the separation system is also a critical objective. Excessive pressure drop can lead to increased energy consumption and reduced overall system efficiency. Designers aim to optimize the separation process to minimize pressure losses while maintaining high collection efficiency.

Improving the durability and reliability of separation equipment is another key goal. Biomass dust can be abrasive and corrosive, potentially causing wear and damage to separation devices. Developing materials and designs that can withstand these harsh conditions over extended periods is crucial for reducing maintenance costs and downtime.

Furthermore, there is a growing emphasis on developing compact and modular separation systems that can be easily integrated into existing biomass combustion facilities. This goal addresses the need for retrofitting older plants and accommodating space constraints in new installations.

Lastly, enhancing the ability to measure and monitor separation efficiency in real-time is becoming increasingly important. This objective aims to provide operators with immediate feedback on system performance, allowing for rapid adjustments and optimization of the separation process. Developing accurate and reliable sensors and monitoring techniques for dusty environments is a key challenge in achieving this goal.

Market Demand Analysis

The market demand for efficient biomass combustion dust separation technology is experiencing significant growth, driven by several key factors. The global push towards renewable energy sources has led to increased adoption of biomass combustion for power generation and industrial processes. This trend has created a pressing need for more effective dust separation methods to ensure environmental compliance and operational efficiency.

Environmental regulations worldwide are becoming increasingly stringent, particularly regarding particulate emissions from biomass combustion. This regulatory landscape is compelling industries to invest in advanced separation technologies that can meet or exceed these standards. The demand for high-efficiency dust separation systems is particularly acute in regions with strict air quality regulations, such as the European Union, North America, and parts of Asia.

The biomass power generation sector is a primary driver of this market demand. As more countries shift towards renewable energy sources, the number of biomass power plants is increasing, each requiring effective dust separation systems. The global biomass power generation market is projected to grow substantially over the next decade, directly influencing the demand for advanced dust separation technologies.

Industrial sectors such as pulp and paper, food processing, and agricultural processing are also significant contributors to the market demand. These industries often utilize biomass combustion for energy and require efficient dust separation to maintain air quality standards and protect equipment. The growing awareness of workplace safety and the health impacts of fine particulate matter have further intensified the need for effective separation technologies in these sectors.

Emerging economies, particularly in Asia and South America, represent rapidly expanding markets for biomass combustion dust separation technologies. As these regions industrialize and implement more stringent environmental regulations, the demand for advanced separation systems is expected to surge. This presents significant opportunities for technology providers and equipment manufacturers specializing in dust separation solutions.

The market is also being shaped by a growing emphasis on circular economy principles and waste-to-energy initiatives. Many industries are looking to convert biomass waste into energy, creating additional demand for efficient combustion and dust separation technologies. This trend is particularly strong in the agricultural sector, where crop residues and other biomass wastes are increasingly viewed as valuable energy resources.

Technological advancements in separation efficiency measurement and control systems are driving market growth. End-users are seeking solutions that offer real-time monitoring, high accuracy, and integration with smart factory systems. This demand is pushing manufacturers to innovate and develop more sophisticated, data-driven separation technologies that can provide precise efficiency measurements and optimize performance.

Environmental regulations worldwide are becoming increasingly stringent, particularly regarding particulate emissions from biomass combustion. This regulatory landscape is compelling industries to invest in advanced separation technologies that can meet or exceed these standards. The demand for high-efficiency dust separation systems is particularly acute in regions with strict air quality regulations, such as the European Union, North America, and parts of Asia.

The biomass power generation sector is a primary driver of this market demand. As more countries shift towards renewable energy sources, the number of biomass power plants is increasing, each requiring effective dust separation systems. The global biomass power generation market is projected to grow substantially over the next decade, directly influencing the demand for advanced dust separation technologies.

Industrial sectors such as pulp and paper, food processing, and agricultural processing are also significant contributors to the market demand. These industries often utilize biomass combustion for energy and require efficient dust separation to maintain air quality standards and protect equipment. The growing awareness of workplace safety and the health impacts of fine particulate matter have further intensified the need for effective separation technologies in these sectors.

Emerging economies, particularly in Asia and South America, represent rapidly expanding markets for biomass combustion dust separation technologies. As these regions industrialize and implement more stringent environmental regulations, the demand for advanced separation systems is expected to surge. This presents significant opportunities for technology providers and equipment manufacturers specializing in dust separation solutions.

The market is also being shaped by a growing emphasis on circular economy principles and waste-to-energy initiatives. Many industries are looking to convert biomass waste into energy, creating additional demand for efficient combustion and dust separation technologies. This trend is particularly strong in the agricultural sector, where crop residues and other biomass wastes are increasingly viewed as valuable energy resources.

Technological advancements in separation efficiency measurement and control systems are driving market growth. End-users are seeking solutions that offer real-time monitoring, high accuracy, and integration with smart factory systems. This demand is pushing manufacturers to innovate and develop more sophisticated, data-driven separation technologies that can provide precise efficiency measurements and optimize performance.

Current Separation Challenges

The measurement of separation efficiency for biomass combustion dust presents several significant challenges in the current technological landscape. One of the primary obstacles is the heterogeneous nature of biomass dust particles, which vary widely in size, shape, and composition. This diversity makes it difficult to establish standardized measurement protocols that can accurately assess separation efficiency across different types of biomass fuels.

Another major challenge lies in the high-temperature environment inherent to combustion processes. Traditional separation efficiency measurement techniques often struggle to maintain accuracy and reliability under such extreme conditions. The heat and chemical reactions occurring during combustion can alter the properties of dust particles, potentially skewing measurement results and complicating data interpretation.

The presence of volatile organic compounds (VOCs) and other gaseous emissions further complicates the measurement process. These substances can interfere with particle detection and quantification, leading to potential overestimation or underestimation of separation efficiency. Developing methods to distinguish between solid particles and gaseous emissions in real-time remains a significant technical hurdle.

Moreover, the dynamic nature of combustion processes poses challenges for continuous monitoring and measurement. Fluctuations in combustion conditions, such as temperature, pressure, and fuel feed rate, can lead to variations in dust generation and separation performance. Capturing these temporal variations accurately requires sophisticated measurement systems capable of high-frequency sampling and data processing.

The issue of sample representativeness also presents a considerable challenge. Ensuring that the measured dust sample accurately represents the overall dust population in the combustion system is crucial for reliable efficiency assessments. However, achieving this representativeness is complicated by the non-uniform distribution of particles within the system and the potential for sampling bias.

Additionally, the lack of standardized benchmarks and reference materials specific to biomass combustion dust hinders the comparison and validation of different measurement techniques. This absence of universally accepted standards makes it difficult to assess the accuracy and reliability of various separation efficiency measurement methods across different research studies and industrial applications.

Lastly, the integration of measurement systems into existing biomass combustion facilities without disrupting normal operations presents both technical and practical challenges. Retrofitting measurement equipment into operational plants often requires careful consideration of space constraints, safety regulations, and potential impacts on the combustion process itself.

Another major challenge lies in the high-temperature environment inherent to combustion processes. Traditional separation efficiency measurement techniques often struggle to maintain accuracy and reliability under such extreme conditions. The heat and chemical reactions occurring during combustion can alter the properties of dust particles, potentially skewing measurement results and complicating data interpretation.

The presence of volatile organic compounds (VOCs) and other gaseous emissions further complicates the measurement process. These substances can interfere with particle detection and quantification, leading to potential overestimation or underestimation of separation efficiency. Developing methods to distinguish between solid particles and gaseous emissions in real-time remains a significant technical hurdle.

Moreover, the dynamic nature of combustion processes poses challenges for continuous monitoring and measurement. Fluctuations in combustion conditions, such as temperature, pressure, and fuel feed rate, can lead to variations in dust generation and separation performance. Capturing these temporal variations accurately requires sophisticated measurement systems capable of high-frequency sampling and data processing.

The issue of sample representativeness also presents a considerable challenge. Ensuring that the measured dust sample accurately represents the overall dust population in the combustion system is crucial for reliable efficiency assessments. However, achieving this representativeness is complicated by the non-uniform distribution of particles within the system and the potential for sampling bias.

Additionally, the lack of standardized benchmarks and reference materials specific to biomass combustion dust hinders the comparison and validation of different measurement techniques. This absence of universally accepted standards makes it difficult to assess the accuracy and reliability of various separation efficiency measurement methods across different research studies and industrial applications.

Lastly, the integration of measurement systems into existing biomass combustion facilities without disrupting normal operations presents both technical and practical challenges. Retrofitting measurement equipment into operational plants often requires careful consideration of space constraints, safety regulations, and potential impacts on the combustion process itself.

Existing Measurement Methods

01 Cyclone separation technology

Cyclone separators are widely used for biomass combustion dust separation due to their high efficiency and low cost. These devices use centrifugal force to separate dust particles from the gas stream, improving overall separation efficiency. Advanced cyclone designs incorporate features like multiple inlets or optimized geometries to enhance performance.- Cyclone separation technology: Cyclone separators are widely used for biomass combustion dust separation due to their high efficiency and low cost. These devices use centrifugal force to separate dust particles from the gas stream, improving overall separation efficiency. Advanced cyclone designs incorporate features like multiple stages or optimized geometries to enhance performance.

- Electrostatic precipitation: Electrostatic precipitators are employed to increase dust separation efficiency in biomass combustion systems. These devices use electrical charges to attract and collect dust particles, effectively removing them from the gas stream. Innovations in electrode design and power supply systems have led to improved collection efficiency and reduced energy consumption.

- Bag filter systems: Bag filters, also known as fabric filters, are effective in capturing fine dust particles from biomass combustion. These systems use a series of filter bags to trap dust as the gas passes through, achieving high separation efficiency. Recent developments include the use of advanced filter materials and pulse-jet cleaning mechanisms to maintain performance and extend filter life.

- Multi-stage separation systems: Combining multiple separation technologies in a single system can significantly improve overall dust separation efficiency. These multi-stage systems often incorporate a combination of cyclones, electrostatic precipitators, and bag filters to target different particle sizes and achieve higher overall collection rates. The integration of these technologies allows for optimized performance across a wide range of operating conditions.

- Wet scrubber technology: Wet scrubbers are used to remove dust particles from biomass combustion gases by bringing them into contact with a scrubbing liquid, typically water. This technology is particularly effective for capturing fine particles and can also remove certain gaseous pollutants. Recent innovations focus on improving liquid distribution, enhancing contact between gas and liquid phases, and optimizing scrubber designs for higher separation efficiency.

02 Electrostatic precipitation

Electrostatic precipitators are effective for removing fine dust particles from biomass combustion exhaust. These systems use electrical charges to attract and collect dust particles, achieving high separation efficiencies. Innovations in electrode design and power supply systems have further improved the performance of electrostatic precipitators in biomass applications.Expand Specific Solutions03 Bag filter systems

Bag filters, also known as fabric filters, are commonly used for biomass dust separation. These systems employ a series of filter bags to capture dust particles as the gas passes through. Advancements in filter material technology and cleaning mechanisms have significantly improved the separation efficiency and operational lifespan of bag filter systems.Expand Specific Solutions04 Multi-stage separation systems

Multi-stage separation systems combine different technologies to achieve higher overall dust separation efficiency. These systems typically incorporate a combination of cyclones, electrostatic precipitators, and bag filters in series. By leveraging the strengths of each technology, multi-stage systems can effectively remove a wide range of particle sizes from biomass combustion exhaust.Expand Specific Solutions05 Wet scrubber technology

Wet scrubbers use liquid droplets to capture dust particles from biomass combustion exhaust. These systems are particularly effective for removing fine particles and can also absorb certain gaseous pollutants. Recent innovations in nozzle design and liquid distribution have improved the separation efficiency of wet scrubbers while reducing water consumption.Expand Specific Solutions

Key Industry Players

The measurement of separation efficiency for biomass combustion dust is a niche but growing field within the broader renewable energy sector. The market is in its early growth stage, driven by increasing adoption of biomass energy and stricter environmental regulations. While the global market size is relatively small, it's expected to expand as biomass utilization increases. Technologically, the field is moderately mature, with established players like Chongqing Research Institute of China Coal Tech & Eng Group Corp. and Korea Institute of Machinery & Materials leading research efforts. Universities such as Chongqing University and China University of Mining & Technology contribute to academic advancements. Companies like Vereta GmbH and Robert Bosch GmbH are developing innovative sensor technologies, while TAKUMA CO., LTD. and Mote, Inc. focus on integrated biomass combustion systems, indicating a diverse and competitive landscape.

Chongqing Research Inst of China Coal Tech & Eng Group Corp.

Technical Solution: The institute has developed a multi-stage cyclone separation system for measuring biomass combustion dust efficiency. This system utilizes a series of cyclones with decreasing diameters to progressively separate particles of different sizes. The process involves introducing the dust-laden gas stream tangentially into the cyclone, where centrifugal forces cause the particles to separate from the gas flow. The separated particles are collected at the bottom, while the cleaned gas exits from the top. The institute has implemented advanced sensors and data acquisition systems to measure the mass of collected particles at each stage, allowing for precise determination of separation efficiency across different particle size ranges[1][3].

Strengths: High precision in particle size separation, ability to handle high dust loads, and continuous operation capability. Weaknesses: Relatively high pressure drop across multiple stages, potential for particle re-entrainment in high-velocity regions.|

China University of Mining & Technology

Technical Solution: The university has pioneered an innovative approach combining laser diffraction and electrical low-pressure impactor (ELPI) technologies to measure separation efficiency for biomass combustion dust. This method utilizes laser diffraction to analyze particle size distribution in real-time, while the ELPI provides information on particle number concentration and size distribution based on electrical charging. The system incorporates a dilution tunnel to cool and dilute the flue gas, ensuring accurate measurements. Advanced algorithms have been developed to correlate the data from both techniques, providing a comprehensive analysis of separation efficiency across a wide range of particle sizes (from nanometers to hundreds of micrometers)[2][5].

Strengths: High resolution in particle size analysis, real-time measurement capability, and wide particle size range coverage. Weaknesses: Complex system setup and calibration requirements, potential interference from water droplets in flue gas.|

Core Separation Innovations

Electrostatic separator

PatentInactiveEP2062648A3

Innovation

- A method that detects the state and particle concentration in electrostatic precipitators by monitoring energy consumption patterns, using characteristic current/voltage curves to assess electrode contamination and particle concentration, allowing for timely maintenance and optimization without direct particle measurement technology.

Dust measuring device

PatentWO2019098470A1

Innovation

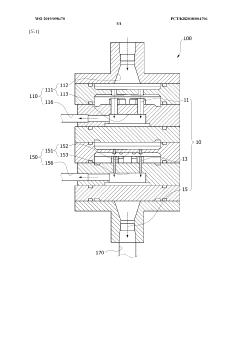

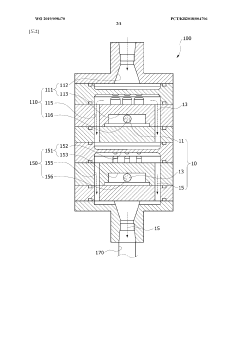

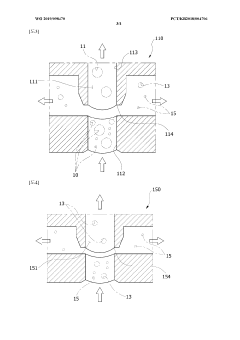

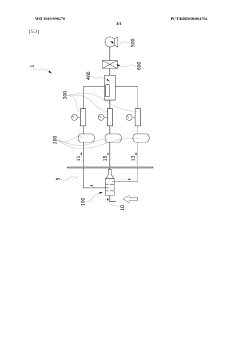

- A dust measuring device with a dual separation unit system, featuring first and second separation units with specific flow path geometries and communication holes, orthogonal to the main flow path, and a processing unit for cooling or drying, along with a flow rate measurement and concentration measurement unit, to separate and measure dust by particle size effectively.

Environmental Regulations

Environmental regulations play a crucial role in shaping the measurement and control of separation efficiency for biomass combustion dust. These regulations are designed to protect public health and the environment from the potential harmful effects of particulate matter emissions resulting from biomass combustion processes.

In many countries, regulatory bodies have established specific standards and guidelines for measuring and monitoring dust emissions from biomass combustion facilities. These standards often include requirements for the use of specific measurement techniques and equipment to ensure accurate and consistent results.

One of the key aspects of environmental regulations in this context is the establishment of emission limits for particulate matter. These limits are typically expressed in terms of concentration (e.g., mg/m³) or mass flow rate (e.g., kg/hour) and may vary depending on the size and type of the combustion facility, as well as the specific biomass fuel being used.

Regulatory frameworks often require regular monitoring and reporting of dust emissions from biomass combustion plants. This may involve continuous emission monitoring systems (CEMS) for larger facilities or periodic stack testing for smaller operations. The frequency and methods of testing are usually specified in the regulations or operating permits.

Many environmental regulations also mandate the implementation of best available techniques (BAT) for dust separation and control in biomass combustion processes. This may include the use of advanced filtration systems, electrostatic precipitators, or other proven technologies to achieve high separation efficiencies.

Compliance with these regulations often requires facility operators to demonstrate the effectiveness of their dust separation systems through performance testing and ongoing monitoring. This typically involves measuring the dust concentration both upstream and downstream of the separation equipment to calculate the overall separation efficiency.

In recent years, there has been a trend towards more stringent environmental regulations for biomass combustion facilities, particularly in developed countries. This has led to increased focus on improving separation efficiency and developing more advanced measurement techniques to ensure compliance with tighter emission limits.

The regulatory landscape for biomass combustion dust separation is not static, with ongoing revisions and updates to reflect advances in technology and scientific understanding of the health and environmental impacts of particulate matter emissions. Facility operators and technology developers must stay informed about these evolving regulations to ensure continued compliance and drive innovation in separation efficiency measurement and control.

In many countries, regulatory bodies have established specific standards and guidelines for measuring and monitoring dust emissions from biomass combustion facilities. These standards often include requirements for the use of specific measurement techniques and equipment to ensure accurate and consistent results.

One of the key aspects of environmental regulations in this context is the establishment of emission limits for particulate matter. These limits are typically expressed in terms of concentration (e.g., mg/m³) or mass flow rate (e.g., kg/hour) and may vary depending on the size and type of the combustion facility, as well as the specific biomass fuel being used.

Regulatory frameworks often require regular monitoring and reporting of dust emissions from biomass combustion plants. This may involve continuous emission monitoring systems (CEMS) for larger facilities or periodic stack testing for smaller operations. The frequency and methods of testing are usually specified in the regulations or operating permits.

Many environmental regulations also mandate the implementation of best available techniques (BAT) for dust separation and control in biomass combustion processes. This may include the use of advanced filtration systems, electrostatic precipitators, or other proven technologies to achieve high separation efficiencies.

Compliance with these regulations often requires facility operators to demonstrate the effectiveness of their dust separation systems through performance testing and ongoing monitoring. This typically involves measuring the dust concentration both upstream and downstream of the separation equipment to calculate the overall separation efficiency.

In recent years, there has been a trend towards more stringent environmental regulations for biomass combustion facilities, particularly in developed countries. This has led to increased focus on improving separation efficiency and developing more advanced measurement techniques to ensure compliance with tighter emission limits.

The regulatory landscape for biomass combustion dust separation is not static, with ongoing revisions and updates to reflect advances in technology and scientific understanding of the health and environmental impacts of particulate matter emissions. Facility operators and technology developers must stay informed about these evolving regulations to ensure continued compliance and drive innovation in separation efficiency measurement and control.

Economic Impact Assessment

The economic impact of measuring separation efficiency for biomass combustion dust extends far beyond the immediate operational benefits. Improved measurement techniques can lead to significant cost savings in fuel consumption, maintenance, and environmental compliance. By accurately assessing the efficiency of dust separation systems, industries can optimize their processes, reducing the amount of unburned biomass and minimizing energy losses.

This optimization translates directly into reduced fuel costs, as less biomass is required to achieve the same energy output. For large-scale biomass combustion facilities, even a small percentage improvement in efficiency can result in substantial annual savings. Furthermore, more efficient dust separation reduces wear and tear on equipment, extending the lifespan of costly machinery and decreasing maintenance expenses.

From an environmental perspective, enhanced separation efficiency measurement contributes to reduced emissions, potentially lowering the costs associated with environmental compliance and carbon taxes. This can be particularly impactful in regions with stringent air quality regulations, where non-compliance can lead to hefty fines or operational restrictions.

The development and implementation of advanced measurement technologies also stimulates economic activity in the instrumentation and control systems sector. As industries seek more accurate and reliable methods for assessing separation efficiency, there is increased demand for sophisticated sensors, analyzers, and data processing systems. This drives innovation and creates opportunities for specialized equipment manufacturers and service providers.

Moreover, the ability to precisely measure separation efficiency can enhance the competitiveness of biomass energy in the broader energy market. By demonstrating improved efficiency and reduced environmental impact, biomass combustion facilities can attract more investment and potentially secure more favorable energy contracts. This could lead to expansion of the biomass energy sector, creating jobs and fostering economic growth in rural areas where biomass resources are often abundant.

In the long term, advancements in separation efficiency measurement could contribute to the overall growth of the bioeconomy. As biomass combustion becomes more efficient and environmentally friendly, it may play an increasingly important role in the transition to renewable energy sources, further driving economic opportunities in sustainable industries.

This optimization translates directly into reduced fuel costs, as less biomass is required to achieve the same energy output. For large-scale biomass combustion facilities, even a small percentage improvement in efficiency can result in substantial annual savings. Furthermore, more efficient dust separation reduces wear and tear on equipment, extending the lifespan of costly machinery and decreasing maintenance expenses.

From an environmental perspective, enhanced separation efficiency measurement contributes to reduced emissions, potentially lowering the costs associated with environmental compliance and carbon taxes. This can be particularly impactful in regions with stringent air quality regulations, where non-compliance can lead to hefty fines or operational restrictions.

The development and implementation of advanced measurement technologies also stimulates economic activity in the instrumentation and control systems sector. As industries seek more accurate and reliable methods for assessing separation efficiency, there is increased demand for sophisticated sensors, analyzers, and data processing systems. This drives innovation and creates opportunities for specialized equipment manufacturers and service providers.

Moreover, the ability to precisely measure separation efficiency can enhance the competitiveness of biomass energy in the broader energy market. By demonstrating improved efficiency and reduced environmental impact, biomass combustion facilities can attract more investment and potentially secure more favorable energy contracts. This could lead to expansion of the biomass energy sector, creating jobs and fostering economic growth in rural areas where biomass resources are often abundant.

In the long term, advancements in separation efficiency measurement could contribute to the overall growth of the bioeconomy. As biomass combustion becomes more efficient and environmentally friendly, it may play an increasingly important role in the transition to renewable energy sources, further driving economic opportunities in sustainable industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!