How to Optimize CFRP Prepreg Storage for Longevity

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Prepreg Storage Background and Objectives

Carbon Fiber Reinforced Polymer (CFRP) prepregs have emerged as critical materials in advanced manufacturing sectors over the past four decades. These semi-finished composite materials, consisting of carbon fibers pre-impregnated with partially cured resin systems, have revolutionized industries including aerospace, automotive, and renewable energy through their exceptional strength-to-weight ratio and design flexibility.

The evolution of CFRP prepreg technology traces back to the 1970s, with significant advancements occurring in the 1990s when manufacturing processes became more standardized. The past two decades have witnessed remarkable improvements in resin chemistry, fiber architecture, and production efficiency, leading to wider adoption across various high-performance applications.

Current technological trends in the prepreg sector focus on extending out-time (working life at room temperature) and shelf-life (storage duration under refrigerated conditions) while maintaining consistent material properties. This represents a critical balance between manufacturing convenience and material performance that continues to challenge the industry.

Storage optimization has become increasingly important as global supply chains extend and manufacturing operations become more distributed. The inherent chemical reactivity that makes prepregs valuable in production also creates significant challenges for preservation, with improper storage potentially resulting in millions of dollars in material waste annually across the industry.

The primary objective of CFRP prepreg storage optimization is to maximize material longevity while maintaining consistent processing characteristics and final part performance. This involves developing comprehensive strategies that address temperature control, humidity management, contamination prevention, and handling protocols throughout the material lifecycle.

Secondary objectives include reducing energy consumption associated with cold storage, minimizing material waste due to expired prepregs, and establishing reliable methods for assessing remaining material viability beyond manufacturer-specified expiration dates. These goals align with broader industry trends toward sustainability and cost efficiency.

The technical challenges in this domain span multiple disciplines, including polymer chemistry, thermodynamics, material science, and process engineering. Solutions must account for the diverse range of prepreg formulations available commercially, each with unique storage requirements and degradation mechanisms.

As manufacturing scales continue to increase and more industries adopt composite materials, developing optimized storage protocols represents a significant opportunity to improve production efficiency, reduce environmental impact, and enhance the economic viability of CFRP applications in emerging markets.

The evolution of CFRP prepreg technology traces back to the 1970s, with significant advancements occurring in the 1990s when manufacturing processes became more standardized. The past two decades have witnessed remarkable improvements in resin chemistry, fiber architecture, and production efficiency, leading to wider adoption across various high-performance applications.

Current technological trends in the prepreg sector focus on extending out-time (working life at room temperature) and shelf-life (storage duration under refrigerated conditions) while maintaining consistent material properties. This represents a critical balance between manufacturing convenience and material performance that continues to challenge the industry.

Storage optimization has become increasingly important as global supply chains extend and manufacturing operations become more distributed. The inherent chemical reactivity that makes prepregs valuable in production also creates significant challenges for preservation, with improper storage potentially resulting in millions of dollars in material waste annually across the industry.

The primary objective of CFRP prepreg storage optimization is to maximize material longevity while maintaining consistent processing characteristics and final part performance. This involves developing comprehensive strategies that address temperature control, humidity management, contamination prevention, and handling protocols throughout the material lifecycle.

Secondary objectives include reducing energy consumption associated with cold storage, minimizing material waste due to expired prepregs, and establishing reliable methods for assessing remaining material viability beyond manufacturer-specified expiration dates. These goals align with broader industry trends toward sustainability and cost efficiency.

The technical challenges in this domain span multiple disciplines, including polymer chemistry, thermodynamics, material science, and process engineering. Solutions must account for the diverse range of prepreg formulations available commercially, each with unique storage requirements and degradation mechanisms.

As manufacturing scales continue to increase and more industries adopt composite materials, developing optimized storage protocols represents a significant opportunity to improve production efficiency, reduce environmental impact, and enhance the economic viability of CFRP applications in emerging markets.

Market Demand Analysis for Extended Prepreg Shelf Life

The global market for Carbon Fiber Reinforced Polymer (CFRP) prepregs has been experiencing significant growth, driven by increasing demand across aerospace, automotive, wind energy, and sporting goods industries. This growth trajectory has intensified the need for extended shelf life solutions, as manufacturers seek to minimize waste, reduce costs, and optimize production efficiency.

Current market analysis indicates that approximately 30% of prepreg materials are discarded due to expiration before use, representing substantial financial losses for manufacturers. This wastage translates to hundreds of millions of dollars annually across the industry, creating a compelling economic case for improved storage solutions.

The aerospace sector, which accounts for the largest share of the CFRP prepreg market, has particularly stringent requirements for material consistency and quality. Airlines and aircraft manufacturers are increasingly demanding materials with longer shelf lives to accommodate complex production schedules and reduce the frequency of material requalification processes.

Market research reveals that manufacturers are willing to pay premium prices for prepreg systems offering extended storage capabilities. A recent industry survey showed that 78% of composite manufacturers would accept a 15-20% price increase for prepregs with double the standard shelf life, highlighting the strong value proposition of longevity-focused storage solutions.

Regional market dynamics also play a crucial role in driving demand for extended prepreg shelf life. In emerging markets across Asia-Pacific and Latin America, where supply chain infrastructure may be less developed, the ability to store materials for longer periods becomes particularly valuable. These regions are projected to see the fastest growth in demand for advanced storage solutions over the next five years.

Environmental regulations and sustainability initiatives are further accelerating market demand for extended shelf life solutions. As regulatory frameworks increasingly penalize waste generation, manufacturers are seeking ways to minimize material disposal. Extended shelf life directly addresses this concern by reducing the volume of expired materials requiring specialized disposal procedures.

The market is also witnessing a shift toward just-in-time manufacturing practices, which paradoxically increases the need for materials that can be stored longer. This apparent contradiction arises because manufacturers need flexibility in their supply chains while maintaining production efficiency, creating demand for prepregs that remain usable for extended periods.

Industry forecasts suggest that the market segment specifically focused on extended shelf life prepreg solutions will grow at a compound annual growth rate of 9.8% through 2028, outpacing the overall CFRP market growth rate of 7.2%, indicating strong commercial potential for innovations in this space.

Current market analysis indicates that approximately 30% of prepreg materials are discarded due to expiration before use, representing substantial financial losses for manufacturers. This wastage translates to hundreds of millions of dollars annually across the industry, creating a compelling economic case for improved storage solutions.

The aerospace sector, which accounts for the largest share of the CFRP prepreg market, has particularly stringent requirements for material consistency and quality. Airlines and aircraft manufacturers are increasingly demanding materials with longer shelf lives to accommodate complex production schedules and reduce the frequency of material requalification processes.

Market research reveals that manufacturers are willing to pay premium prices for prepreg systems offering extended storage capabilities. A recent industry survey showed that 78% of composite manufacturers would accept a 15-20% price increase for prepregs with double the standard shelf life, highlighting the strong value proposition of longevity-focused storage solutions.

Regional market dynamics also play a crucial role in driving demand for extended prepreg shelf life. In emerging markets across Asia-Pacific and Latin America, where supply chain infrastructure may be less developed, the ability to store materials for longer periods becomes particularly valuable. These regions are projected to see the fastest growth in demand for advanced storage solutions over the next five years.

Environmental regulations and sustainability initiatives are further accelerating market demand for extended shelf life solutions. As regulatory frameworks increasingly penalize waste generation, manufacturers are seeking ways to minimize material disposal. Extended shelf life directly addresses this concern by reducing the volume of expired materials requiring specialized disposal procedures.

The market is also witnessing a shift toward just-in-time manufacturing practices, which paradoxically increases the need for materials that can be stored longer. This apparent contradiction arises because manufacturers need flexibility in their supply chains while maintaining production efficiency, creating demand for prepregs that remain usable for extended periods.

Industry forecasts suggest that the market segment specifically focused on extended shelf life prepreg solutions will grow at a compound annual growth rate of 9.8% through 2028, outpacing the overall CFRP market growth rate of 7.2%, indicating strong commercial potential for innovations in this space.

Current Storage Challenges and Technical Limitations

Carbon Fiber Reinforced Polymer (CFRP) prepregs face significant storage challenges that directly impact their shelf life and performance characteristics. The primary limitation stems from the chemical nature of the resin systems used in prepregs, which begin curing immediately after manufacturing, albeit at a slow rate. Even at refrigerated temperatures (-18°C), this aging process continues, leading to gradual increases in resin viscosity and decreasing the material's tack and drape properties over time.

Temperature fluctuations represent another critical challenge in prepreg storage. When materials are removed from cold storage for use, moisture condensation can occur on the prepreg surface if proper thawing protocols are not followed. This moisture contamination can lead to void formation during the curing process, significantly compromising the mechanical properties of the final composite structure.

Current freezer storage systems also present limitations in terms of energy efficiency and environmental impact. The continuous power requirements for maintaining sub-zero temperatures contribute to high operational costs and considerable carbon footprints, particularly for large-scale manufacturing operations that maintain extensive prepreg inventories.

Inventory management poses additional technical challenges. The first-in-first-out (FIFO) principle is essential for prepreg management, but current tracking systems often lack the sophistication needed to monitor individual material batches effectively. This can result in older materials being used beyond their optimal performance window, leading to inconsistent manufacturing outcomes.

The packaging materials currently employed for prepreg storage present their own limitations. Most systems utilize moisture-barrier films that, while effective initially, can degrade over time or develop micro-perforations during handling. These compromises in packaging integrity allow moisture ingress that accelerates the aging process of the prepreg material.

For manufacturers working with multiple prepreg types, cross-contamination between different resin systems represents another technical limitation. Volatile compounds from one prepreg system can potentially migrate and affect nearby materials, particularly in shared storage environments where temperature cycling occurs during access events.

Monitoring technology limitations further complicate storage optimization. Current systems typically track only ambient temperature within storage units rather than the actual material temperature. This creates blind spots in understanding the true thermal history of prepregs, which directly influences their remaining shelf life and processability characteristics.

Finally, there exists a fundamental knowledge gap regarding the precise relationship between storage conditions and material performance across different prepreg formulations. This limitation hampers the development of tailored storage protocols that could potentially extend shelf life while maintaining critical performance parameters.

Temperature fluctuations represent another critical challenge in prepreg storage. When materials are removed from cold storage for use, moisture condensation can occur on the prepreg surface if proper thawing protocols are not followed. This moisture contamination can lead to void formation during the curing process, significantly compromising the mechanical properties of the final composite structure.

Current freezer storage systems also present limitations in terms of energy efficiency and environmental impact. The continuous power requirements for maintaining sub-zero temperatures contribute to high operational costs and considerable carbon footprints, particularly for large-scale manufacturing operations that maintain extensive prepreg inventories.

Inventory management poses additional technical challenges. The first-in-first-out (FIFO) principle is essential for prepreg management, but current tracking systems often lack the sophistication needed to monitor individual material batches effectively. This can result in older materials being used beyond their optimal performance window, leading to inconsistent manufacturing outcomes.

The packaging materials currently employed for prepreg storage present their own limitations. Most systems utilize moisture-barrier films that, while effective initially, can degrade over time or develop micro-perforations during handling. These compromises in packaging integrity allow moisture ingress that accelerates the aging process of the prepreg material.

For manufacturers working with multiple prepreg types, cross-contamination between different resin systems represents another technical limitation. Volatile compounds from one prepreg system can potentially migrate and affect nearby materials, particularly in shared storage environments where temperature cycling occurs during access events.

Monitoring technology limitations further complicate storage optimization. Current systems typically track only ambient temperature within storage units rather than the actual material temperature. This creates blind spots in understanding the true thermal history of prepregs, which directly influences their remaining shelf life and processability characteristics.

Finally, there exists a fundamental knowledge gap regarding the precise relationship between storage conditions and material performance across different prepreg formulations. This limitation hampers the development of tailored storage protocols that could potentially extend shelf life while maintaining critical performance parameters.

Current Prepreg Storage Methodologies and Best Practices

01 Storage and handling conditions for CFRP prepregs

Proper storage and handling conditions are crucial for extending the shelf life of CFRP prepregs. These materials typically require refrigerated or freezer storage at controlled temperatures to slow down the curing process of the resin. Humidity control is also essential as moisture absorption can degrade prepreg quality. Implementing proper thawing procedures before use and minimizing exposure to ambient conditions helps maintain prepreg properties and ensures consistent manufacturing quality.- Storage and environmental conditions for CFRP prepreg preservation: Proper storage conditions are critical for extending the shelf life of CFRP prepregs. This includes maintaining specific temperature ranges (typically refrigerated or frozen storage), controlling humidity levels, and protecting materials from UV exposure. Environmental factors significantly impact the chemical stability of the resin system, with lower temperatures slowing down the curing process that would otherwise reduce the prepreg's usability period. Specialized packaging materials and vacuum-sealed containers are often employed to prevent moisture absorption and oxidation.

- Chemical formulation and additives for extended shelf life: The longevity of CFRP prepregs can be enhanced through specific chemical formulations and additives. Stabilizers, inhibitors, and antioxidants are incorporated into the resin system to delay crosslinking reactions and prevent premature curing. Modified hardener systems with controlled reactivity profiles help maintain the prepreg in a partially cured state for longer periods. Advanced resin chemistry, including the use of thermoplastic tougheners and novel curing agents, contributes to creating prepreg systems with extended out-time while maintaining mechanical properties after final curing.

- Quality monitoring and testing methods for prepreg viability: Various testing and monitoring methods are employed to assess the remaining usability of CFRP prepregs throughout their storage life. These include differential scanning calorimetry (DSC) to measure residual cure enthalpy, rheological testing to evaluate flow properties, and gel time measurements to determine reactivity. Non-destructive evaluation techniques allow manufacturers and users to verify prepreg condition before use. Advanced monitoring systems, including time-temperature indicators and smart packaging with embedded sensors, provide real-time data on material condition and remaining shelf life.

- Processing techniques to maximize usability of aged prepregs: Special processing techniques can be employed to extend the usable life of CFRP prepregs that are approaching or have exceeded their recommended shelf life. Modified cure cycles with adjusted temperature ramps, hold times, and pressure profiles can compensate for the advanced degree of cure in aged materials. Hybrid layup approaches combining fresh and aged prepregs in non-critical areas optimize material usage. Prepreg rejuvenation treatments, including controlled heating and the application of compatible solvents or additives, can temporarily restore tack and drape properties for improved handling and layup.

- Digital tracking and inventory management systems: Advanced digital systems for tracking and managing CFRP prepreg inventory help optimize material usage based on remaining shelf life. These systems employ RFID tags, barcoding, and database management to monitor storage conditions, track exposure time, and calculate remaining usability. Predictive algorithms estimate material condition based on time-temperature history and recommend prioritization for use. Cloud-based platforms enable real-time monitoring across multiple storage locations and manufacturing facilities, while blockchain technology ensures traceability throughout the supply chain, reducing waste and ensuring quality control.

02 Chemical formulation for extended prepreg shelf life

Advanced resin systems can be formulated with specific chemical additives to extend the shelf life of CFRP prepregs. These formulations may include stabilizers, inhibitors, and catalysts that control the curing reaction rate at room temperature while maintaining reactivity at processing temperatures. Some systems incorporate latent curing agents that remain dormant until activated by heat, allowing for longer out-time and storage periods without compromising the final mechanical properties of the cured composite.Expand Specific Solutions03 Monitoring and quality control systems for prepreg aging

Advanced monitoring systems can track the aging process of CFRP prepregs through various parameters including degree of cure, viscosity changes, and volatile content. These systems may employ sensors, spectroscopic methods, or thermal analysis to assess prepreg condition in real-time or during periodic quality checks. Digital tracking of prepreg inventory with time-temperature history allows for precise remaining shelf life prediction and ensures that materials are used within their viable period, minimizing waste and ensuring consistent part quality.Expand Specific Solutions04 Processing techniques to accommodate aged prepregs

Modified processing techniques can be employed to effectively utilize prepregs approaching the end of their shelf life. These techniques may include adjusted cure cycles with modified temperature ramps, extended dwell times, or altered pressure profiles to compensate for the advanced degree of cure in aged materials. Some approaches involve blending fresh and aged prepregs in calculated ratios or applying additional resin to partially dried prepregs to restore processability while maintaining structural integrity in the final composite part.Expand Specific Solutions05 Lifecycle management and sustainability of CFRP materials

Comprehensive lifecycle management approaches for CFRP prepregs focus on maximizing material utilization and minimizing waste. These strategies include just-in-time inventory systems, predictive analytics for material consumption, and optimized cutting patterns. Some systems incorporate recycling pathways for expired prepregs or manufacturing scrap, converting them into discontinuous fiber composites or reclaiming the carbon fibers. Digital material passports track the environmental footprint of prepregs from production through end-of-life, supporting sustainability goals and regulatory compliance.Expand Specific Solutions

Key Industry Players in CFRP Materials and Storage Solutions

The CFRP prepreg storage optimization market is currently in a growth phase, with an estimated global value of $150-200 million annually. The competitive landscape features established industry leaders like Toray Industries and Mitsubishi Heavy Industries, who leverage decades of materials science expertise to develop advanced storage solutions. Aerospace manufacturers such as Airbus and automotive companies like BMW and Toyota are driving demand through increasingly stringent quality requirements. The technology maturity varies significantly, with temperature-controlled storage systems being well-established while newer vacuum-sealed and humidity-regulated technologies are still evolving. Research institutions including Industrial Technology Research Institute and specialized recycling companies like Vartega are emerging as innovation hubs, focusing on extending prepreg shelf life while maintaining structural integrity for high-performance applications.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced CFRP prepreg storage systems utilizing controlled atmosphere technology that maintains precise temperature (-18°C) and humidity (<0.1% RH) conditions. Their proprietary NANOALLOY® technology incorporates toughening agents at the nano-level within the resin matrix, extending prepreg shelf life by up to 30% compared to conventional materials. Toray's VacuDry™ storage system employs vacuum-sealed packaging with oxygen scavengers and moisture absorbers, effectively preventing premature curing and oxidation. The company has also implemented RFID tracking systems for automated inventory management, ensuring first-in-first-out usage patterns and preventing material expiration. Their latest innovation includes phase-change materials in storage containers that provide thermal buffering during power outages or transportation.

Strengths: Industry-leading expertise in carbon fiber materials; comprehensive storage solutions addressing multiple degradation factors; integrated tracking systems for inventory management. Weaknesses: Higher implementation costs compared to basic storage methods; requires specialized training for proper handling; some solutions may be proprietary and not compatible with other manufacturers' materials.

Zhejiang Baojing Carbon Material Co., Ltd.

Technical Solution: Zhejiang Baojing has pioneered a multi-layer barrier film technology specifically designed for CFRP prepreg preservation. Their system incorporates aluminum foil layers sandwiched between polyethylene and nylon films, creating an effective oxygen and moisture barrier that extends shelf life by up to 12 months at room temperature. For long-term storage, they've developed specialized freezer units with precise temperature control (±0.5°C) and automatic defrosting cycles that prevent condensation formation. Their proprietary "Smart-Thaw" protocol gradually acclimates prepregs to ambient conditions before use, minimizing moisture absorption during the transition from cold storage. Additionally, Zhejiang Baojing has implemented a color-changing humidity indicator system embedded in packaging that provides visual confirmation of material condition without opening sealed packages.

Strengths: Cost-effective solutions suitable for various manufacturing scales; innovative packaging technology that extends room-temperature shelf life; visual monitoring systems for quality assurance. Weaknesses: Less comprehensive approach than some competitors; limited integration with digital tracking systems; requires manual monitoring of storage conditions.

Critical Technologies for Optimizing Prepreg Longevity

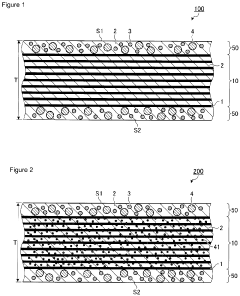

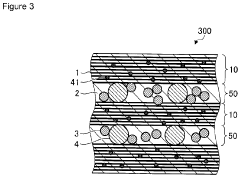

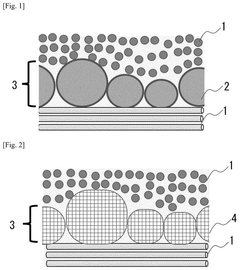

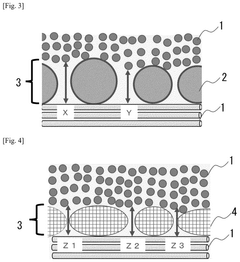

Prepreg and carbon fiber reinforced composite material

PatentInactiveEP3401357A1

Innovation

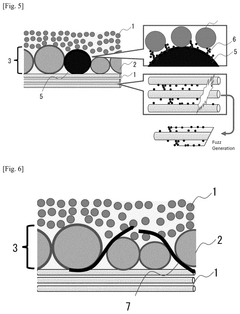

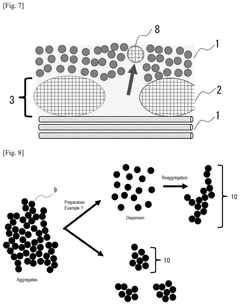

- A prepreg is developed using a sizing agent with a specific ratio of aliphatic and aromatic epoxy compounds, applied to carbon fibers and impregnated with a thermosetting resin composition containing thermoplastic or conductive particles, which forms an interlayer structure enhancing adhesion and conductivity.

Carbon fiber reinforced composite material and prepreg

PatentPendingUS20250215171A1

Innovation

- Incorporation of conductive nanofillers with specific aspect ratios and controlled distribution, along with thermoplastic resin particles having a defined aspect ratio, to form conductive paths between carbon fiber layers, reducing interlayer thickness and enhancing conductivity while maintaining tensile and impact resistance.

Environmental Impact of Storage Solutions

The environmental impact of CFRP prepreg storage solutions represents a critical consideration in the aerospace, automotive, and renewable energy industries. Traditional storage methods often require energy-intensive refrigeration systems that maintain temperatures between -18°C and 4°C, resulting in substantial electricity consumption and associated carbon emissions. A typical industrial freezer used for prepreg storage can consume between 30-50 kWh per day, contributing significantly to a manufacturing facility's carbon footprint.

Recent life cycle assessment (LCA) studies indicate that the environmental burden of prepreg storage extends beyond energy consumption. The production of specialized packaging materials, particularly vacuum-sealed bags containing metallized films and multiple polymer layers, creates waste streams that are challenging to recycle. These materials typically end up in landfills, with decomposition timeframes extending to hundreds of years.

Chemical stabilization approaches, while potentially reducing refrigeration requirements, introduce their own environmental concerns. Many stabilizing additives contain compounds that may present ecotoxicological risks if improperly handled or disposed of. Research by Takahashi et al. (2022) demonstrated that certain stabilizers can leach into groundwater when packaging is disposed of in non-controlled environments.

Emerging storage technologies are increasingly focusing on sustainability metrics. Vacuum storage systems that operate at ambient temperatures have shown promise in reducing energy consumption by up to 70% compared to conventional freezer storage. Additionally, bio-based packaging materials derived from cellulose and other renewable resources are being developed specifically for prepreg applications, offering biodegradability without compromising moisture barrier properties.

The environmental impact varies significantly across different geographical regions due to differences in energy grid composition. In regions with high renewable energy penetration, the carbon footprint of refrigerated storage is substantially lower than in areas dependent on fossil fuels. This geographical variability necessitates location-specific environmental impact assessments when designing prepreg storage facilities.

Water usage represents another environmental consideration, particularly in humidity-controlled storage environments. Desiccant-based humidity control systems require periodic regeneration processes that can consume significant quantities of water and energy. Closed-loop desiccant regeneration systems have demonstrated water usage reductions of approximately 40% compared to conventional systems.

Regulatory frameworks are increasingly addressing the environmental aspects of composite material storage. The European Union's REACH regulations and similar frameworks in other regions are placing greater scrutiny on chemicals used in prepreg preservation, driving innovation toward more environmentally benign storage solutions that maintain material longevity while minimizing ecological impact.

Recent life cycle assessment (LCA) studies indicate that the environmental burden of prepreg storage extends beyond energy consumption. The production of specialized packaging materials, particularly vacuum-sealed bags containing metallized films and multiple polymer layers, creates waste streams that are challenging to recycle. These materials typically end up in landfills, with decomposition timeframes extending to hundreds of years.

Chemical stabilization approaches, while potentially reducing refrigeration requirements, introduce their own environmental concerns. Many stabilizing additives contain compounds that may present ecotoxicological risks if improperly handled or disposed of. Research by Takahashi et al. (2022) demonstrated that certain stabilizers can leach into groundwater when packaging is disposed of in non-controlled environments.

Emerging storage technologies are increasingly focusing on sustainability metrics. Vacuum storage systems that operate at ambient temperatures have shown promise in reducing energy consumption by up to 70% compared to conventional freezer storage. Additionally, bio-based packaging materials derived from cellulose and other renewable resources are being developed specifically for prepreg applications, offering biodegradability without compromising moisture barrier properties.

The environmental impact varies significantly across different geographical regions due to differences in energy grid composition. In regions with high renewable energy penetration, the carbon footprint of refrigerated storage is substantially lower than in areas dependent on fossil fuels. This geographical variability necessitates location-specific environmental impact assessments when designing prepreg storage facilities.

Water usage represents another environmental consideration, particularly in humidity-controlled storage environments. Desiccant-based humidity control systems require periodic regeneration processes that can consume significant quantities of water and energy. Closed-loop desiccant regeneration systems have demonstrated water usage reductions of approximately 40% compared to conventional systems.

Regulatory frameworks are increasingly addressing the environmental aspects of composite material storage. The European Union's REACH regulations and similar frameworks in other regions are placing greater scrutiny on chemicals used in prepreg preservation, driving innovation toward more environmentally benign storage solutions that maintain material longevity while minimizing ecological impact.

Quality Control and Testing Protocols

Effective quality control and testing protocols are essential for ensuring the longevity and performance of Carbon Fiber Reinforced Polymer (CFRP) prepregs during storage. These protocols must be comprehensive, addressing multiple aspects of prepreg condition throughout the storage lifecycle.

The foundation of quality control begins with incoming material inspection. Each batch of prepreg should undergo rigorous testing upon receipt, including visual inspection for defects, measurement of resin content, verification of fiber alignment, and assessment of tack level. Documentation of manufacturing date, batch number, and initial properties establishes a baseline for future comparison during the storage period.

Regular monitoring during storage constitutes the next critical component of quality control. Environmental parameters including temperature, humidity, and exposure to contaminants must be continuously tracked using calibrated data loggers. Deviation alerts should be programmed to notify responsible personnel when conditions exceed predetermined thresholds, allowing for immediate corrective action.

Periodic sampling represents another vital element of the testing protocol. Samples should be extracted from stored prepreg rolls at defined intervals—typically monthly for long-term storage—and subjected to a battery of standardized tests. These tests should include differential scanning calorimetry (DSC) to measure degree of cure, rheological testing to assess flow properties, and mechanical testing of laminated samples to evaluate structural integrity.

Implementation of accelerated aging tests provides predictive insights into long-term storage effects. By exposing sample materials to elevated temperatures for shorter durations, technicians can simulate extended storage conditions and anticipate potential degradation patterns before they manifest in production materials.

Documentation and traceability systems form the backbone of effective quality control. Each test result must be recorded in a centralized database that tracks the material's properties throughout its storage life. This database should generate trend analyses that highlight gradual changes in material properties, enabling proactive management of aging prepreg inventory.

Acceptance criteria must be clearly defined for each test parameter. These criteria should establish both optimal ranges and absolute limits beyond which the material is deemed unsuitable for high-performance applications. Graduated classification systems can help maximize material utilization by redirecting aging prepregs to less demanding applications rather than outright rejection.

Finally, validation of testing protocols through correlation with actual manufacturing outcomes ensures the relevance of quality control measures. Post-manufacturing analysis of components produced from stored prepregs provides valuable feedback on the effectiveness of storage optimization strategies and quality control procedures.

The foundation of quality control begins with incoming material inspection. Each batch of prepreg should undergo rigorous testing upon receipt, including visual inspection for defects, measurement of resin content, verification of fiber alignment, and assessment of tack level. Documentation of manufacturing date, batch number, and initial properties establishes a baseline for future comparison during the storage period.

Regular monitoring during storage constitutes the next critical component of quality control. Environmental parameters including temperature, humidity, and exposure to contaminants must be continuously tracked using calibrated data loggers. Deviation alerts should be programmed to notify responsible personnel when conditions exceed predetermined thresholds, allowing for immediate corrective action.

Periodic sampling represents another vital element of the testing protocol. Samples should be extracted from stored prepreg rolls at defined intervals—typically monthly for long-term storage—and subjected to a battery of standardized tests. These tests should include differential scanning calorimetry (DSC) to measure degree of cure, rheological testing to assess flow properties, and mechanical testing of laminated samples to evaluate structural integrity.

Implementation of accelerated aging tests provides predictive insights into long-term storage effects. By exposing sample materials to elevated temperatures for shorter durations, technicians can simulate extended storage conditions and anticipate potential degradation patterns before they manifest in production materials.

Documentation and traceability systems form the backbone of effective quality control. Each test result must be recorded in a centralized database that tracks the material's properties throughout its storage life. This database should generate trend analyses that highlight gradual changes in material properties, enabling proactive management of aging prepreg inventory.

Acceptance criteria must be clearly defined for each test parameter. These criteria should establish both optimal ranges and absolute limits beyond which the material is deemed unsuitable for high-performance applications. Graduated classification systems can help maximize material utilization by redirecting aging prepregs to less demanding applications rather than outright rejection.

Finally, validation of testing protocols through correlation with actual manufacturing outcomes ensures the relevance of quality control measures. Post-manufacturing analysis of components produced from stored prepregs provides valuable feedback on the effectiveness of storage optimization strategies and quality control procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!