How To Reduce Erosion And Maintenance In Cyclone Units

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Erosion Challenges

Cyclone units, widely used in various industrial processes for particle separation and gas cleaning, face significant challenges related to erosion and maintenance. The high-velocity particle-laden gas streams within these units create an environment conducive to severe wear and tear on internal components. This erosion not only reduces the efficiency of the cyclone but also leads to frequent maintenance requirements, resulting in increased operational costs and downtime.

The primary cause of erosion in cyclone units is the abrasive action of solid particles impinging on the cyclone walls at high velocities. These particles, often hard and angular, can cause substantial material loss, particularly in areas of high impact such as the inlet, cone section, and dust outlet. The severity of erosion depends on various factors, including particle size, shape, hardness, and concentration, as well as the gas velocity and the material properties of the cyclone walls.

Another significant challenge is the uneven wear pattern within the cyclone. Certain areas, such as the inlet zone and the cone section, experience more severe erosion due to higher particle velocities and impact angles. This non-uniform wear can lead to localized weak spots, potentially causing premature failure of the cyclone unit. Additionally, the erosion process can alter the internal geometry of the cyclone, affecting its separation efficiency and overall performance over time.

The maintenance challenges associated with cyclone erosion are multifaceted. Regular inspections are necessary to assess the extent of wear and identify areas requiring repair or replacement. However, these inspections often require shutting down the process, leading to production losses. The repair process itself can be complex, especially for large industrial cyclones, and may involve welding, patching, or complete replacement of eroded sections.

Furthermore, the selection of appropriate materials for cyclone construction presents a significant challenge. While harder materials may offer better erosion resistance, they are often more expensive and can be difficult to fabricate or repair. Balancing cost-effectiveness with durability is a key consideration in cyclone design and maintenance strategies.

The erosion problem also extends to the environmental and safety aspects of cyclone operation. Eroded cyclones may lead to increased particulate emissions, potentially violating environmental regulations. In severe cases, erosion can compromise the structural integrity of the cyclone, posing safety risks to personnel and surrounding equipment.

Addressing these challenges requires a multifaceted approach, combining innovative material science, advanced design techniques, and optimized operational practices. Researchers and engineers are continually exploring new solutions, such as advanced coating technologies, optimized flow designs, and predictive maintenance strategies, to mitigate the erosion problem and enhance the longevity and efficiency of cyclone units.

The primary cause of erosion in cyclone units is the abrasive action of solid particles impinging on the cyclone walls at high velocities. These particles, often hard and angular, can cause substantial material loss, particularly in areas of high impact such as the inlet, cone section, and dust outlet. The severity of erosion depends on various factors, including particle size, shape, hardness, and concentration, as well as the gas velocity and the material properties of the cyclone walls.

Another significant challenge is the uneven wear pattern within the cyclone. Certain areas, such as the inlet zone and the cone section, experience more severe erosion due to higher particle velocities and impact angles. This non-uniform wear can lead to localized weak spots, potentially causing premature failure of the cyclone unit. Additionally, the erosion process can alter the internal geometry of the cyclone, affecting its separation efficiency and overall performance over time.

The maintenance challenges associated with cyclone erosion are multifaceted. Regular inspections are necessary to assess the extent of wear and identify areas requiring repair or replacement. However, these inspections often require shutting down the process, leading to production losses. The repair process itself can be complex, especially for large industrial cyclones, and may involve welding, patching, or complete replacement of eroded sections.

Furthermore, the selection of appropriate materials for cyclone construction presents a significant challenge. While harder materials may offer better erosion resistance, they are often more expensive and can be difficult to fabricate or repair. Balancing cost-effectiveness with durability is a key consideration in cyclone design and maintenance strategies.

The erosion problem also extends to the environmental and safety aspects of cyclone operation. Eroded cyclones may lead to increased particulate emissions, potentially violating environmental regulations. In severe cases, erosion can compromise the structural integrity of the cyclone, posing safety risks to personnel and surrounding equipment.

Addressing these challenges requires a multifaceted approach, combining innovative material science, advanced design techniques, and optimized operational practices. Researchers and engineers are continually exploring new solutions, such as advanced coating technologies, optimized flow designs, and predictive maintenance strategies, to mitigate the erosion problem and enhance the longevity and efficiency of cyclone units.

Industrial Demand Analysis

The demand for cyclone units in industrial applications remains robust, driven by their critical role in separating particles from gas streams across various sectors. Industries such as oil and gas, mining, cement production, and power generation heavily rely on cyclone separators for efficient particulate removal. However, the persistent challenge of erosion and high maintenance requirements in these units has created a significant market need for improved solutions.

Erosion in cyclone units is a major concern for industrial operators, as it leads to reduced efficiency, increased downtime, and higher operational costs. The abrasive nature of particles in high-velocity gas streams causes wear on cyclone walls, particularly in areas of high impact. This erosion not only compromises the unit's performance but also necessitates frequent maintenance and part replacements, resulting in substantial financial burdens for companies.

The global market for cyclone separators is projected to grow steadily, with a particular emphasis on technologies that can mitigate erosion and reduce maintenance needs. Industries are increasingly seeking cyclone units that offer longer operational lifespans, improved separation efficiency, and reduced total cost of ownership. This demand is further amplified by stringent environmental regulations that require more effective particulate control in industrial processes.

In the oil and gas sector, where cyclones are extensively used in gas processing and offshore platforms, the need for erosion-resistant cyclones is particularly acute. The harsh operating conditions and the presence of abrasive particles in hydrocarbon streams make erosion a persistent issue. Similarly, in the mining industry, where cyclones are employed in mineral processing, the handling of highly abrasive ore particles creates a substantial demand for more durable cyclone designs.

The power generation industry, especially coal-fired power plants, faces similar challenges with fly ash removal. As these plants strive to meet increasingly strict emission standards, the efficiency and longevity of cyclone units become paramount. The cement industry, another major user of cyclone technology in preheaters and calciners, also seeks solutions to combat the erosive effects of hot, particle-laden gases.

Market analysis indicates a growing preference for cyclone units incorporating advanced materials and innovative designs that can withstand erosive conditions. There is a notable trend towards the adoption of computational fluid dynamics (CFD) in cyclone design, allowing for optimized flow patterns that reduce particle impact and subsequent erosion. Additionally, the integration of smart monitoring systems for predictive maintenance is gaining traction, as industries aim to minimize unplanned downtime and optimize maintenance schedules.

The demand for erosion-resistant cyclone units is not limited to new installations. A significant market segment exists for retrofitting and upgrading existing cyclone systems with erosion mitigation technologies. This presents opportunities for solutions that can be easily integrated into operational plants without requiring extensive modifications or prolonged shutdowns.

Erosion in cyclone units is a major concern for industrial operators, as it leads to reduced efficiency, increased downtime, and higher operational costs. The abrasive nature of particles in high-velocity gas streams causes wear on cyclone walls, particularly in areas of high impact. This erosion not only compromises the unit's performance but also necessitates frequent maintenance and part replacements, resulting in substantial financial burdens for companies.

The global market for cyclone separators is projected to grow steadily, with a particular emphasis on technologies that can mitigate erosion and reduce maintenance needs. Industries are increasingly seeking cyclone units that offer longer operational lifespans, improved separation efficiency, and reduced total cost of ownership. This demand is further amplified by stringent environmental regulations that require more effective particulate control in industrial processes.

In the oil and gas sector, where cyclones are extensively used in gas processing and offshore platforms, the need for erosion-resistant cyclones is particularly acute. The harsh operating conditions and the presence of abrasive particles in hydrocarbon streams make erosion a persistent issue. Similarly, in the mining industry, where cyclones are employed in mineral processing, the handling of highly abrasive ore particles creates a substantial demand for more durable cyclone designs.

The power generation industry, especially coal-fired power plants, faces similar challenges with fly ash removal. As these plants strive to meet increasingly strict emission standards, the efficiency and longevity of cyclone units become paramount. The cement industry, another major user of cyclone technology in preheaters and calciners, also seeks solutions to combat the erosive effects of hot, particle-laden gases.

Market analysis indicates a growing preference for cyclone units incorporating advanced materials and innovative designs that can withstand erosive conditions. There is a notable trend towards the adoption of computational fluid dynamics (CFD) in cyclone design, allowing for optimized flow patterns that reduce particle impact and subsequent erosion. Additionally, the integration of smart monitoring systems for predictive maintenance is gaining traction, as industries aim to minimize unplanned downtime and optimize maintenance schedules.

The demand for erosion-resistant cyclone units is not limited to new installations. A significant market segment exists for retrofitting and upgrading existing cyclone systems with erosion mitigation technologies. This presents opportunities for solutions that can be easily integrated into operational plants without requiring extensive modifications or prolonged shutdowns.

Current Erosion Issues

Cyclone units, widely used in various industrial processes for particle separation and gas cleaning, face significant challenges due to erosion issues. The high-velocity particle-laden gas streams within these units cause substantial wear on internal surfaces, leading to reduced efficiency and increased maintenance requirements.

The primary erosion mechanism in cyclone units involves the impact of solid particles on the walls and other internal components. As the gas stream enters the cyclone at high speeds, it forms a vortex, forcing particles towards the outer walls. This continuous bombardment of particles, especially in areas of high turbulence or directional changes, results in material loss and surface degradation over time.

Erosion patterns in cyclones are not uniform, with certain areas experiencing more severe wear than others. The inlet zone, where the gas stream first enters the cyclone, is particularly susceptible to erosion due to the high-velocity impact of particles. The cone section, where the separated particles are collected, also suffers significant wear as particles slide along its surface towards the outlet.

The severity of erosion depends on several factors, including particle characteristics (size, shape, hardness), gas velocity, and the properties of the cyclone material. Abrasive particles, such as those found in mining or cement industries, can cause rapid deterioration of cyclone surfaces. Higher gas velocities, while improving separation efficiency, also increase erosion rates.

Current erosion issues in cyclone units lead to several operational problems. Thinning of cyclone walls can result in perforations and gas leakage, compromising the unit's performance and potentially causing environmental hazards. Erosion of internal components, such as vortex finders or cone sections, can alter the cyclone's geometry, affecting its separation efficiency and pressure drop characteristics.

The economic impact of erosion in cyclone units is substantial. Frequent maintenance shutdowns for repairs or replacements of eroded components result in production losses and increased operational costs. In severe cases, catastrophic failure of cyclone units due to erosion can lead to significant safety risks and extended downtime.

Addressing these erosion issues requires a multifaceted approach. Current strategies include the use of wear-resistant materials, such as ceramics or hardened steels, for critical components. Some designs incorporate replaceable wear liners to facilitate easier maintenance. However, these solutions often come with trade-offs in terms of cost, weight, or manufacturing complexity.

The primary erosion mechanism in cyclone units involves the impact of solid particles on the walls and other internal components. As the gas stream enters the cyclone at high speeds, it forms a vortex, forcing particles towards the outer walls. This continuous bombardment of particles, especially in areas of high turbulence or directional changes, results in material loss and surface degradation over time.

Erosion patterns in cyclones are not uniform, with certain areas experiencing more severe wear than others. The inlet zone, where the gas stream first enters the cyclone, is particularly susceptible to erosion due to the high-velocity impact of particles. The cone section, where the separated particles are collected, also suffers significant wear as particles slide along its surface towards the outlet.

The severity of erosion depends on several factors, including particle characteristics (size, shape, hardness), gas velocity, and the properties of the cyclone material. Abrasive particles, such as those found in mining or cement industries, can cause rapid deterioration of cyclone surfaces. Higher gas velocities, while improving separation efficiency, also increase erosion rates.

Current erosion issues in cyclone units lead to several operational problems. Thinning of cyclone walls can result in perforations and gas leakage, compromising the unit's performance and potentially causing environmental hazards. Erosion of internal components, such as vortex finders or cone sections, can alter the cyclone's geometry, affecting its separation efficiency and pressure drop characteristics.

The economic impact of erosion in cyclone units is substantial. Frequent maintenance shutdowns for repairs or replacements of eroded components result in production losses and increased operational costs. In severe cases, catastrophic failure of cyclone units due to erosion can lead to significant safety risks and extended downtime.

Addressing these erosion issues requires a multifaceted approach. Current strategies include the use of wear-resistant materials, such as ceramics or hardened steels, for critical components. Some designs incorporate replaceable wear liners to facilitate easier maintenance. However, these solutions often come with trade-offs in terms of cost, weight, or manufacturing complexity.

Existing Erosion Solutions

01 Erosion-resistant materials for cyclone units

Utilizing erosion-resistant materials in the construction of cyclone units can significantly reduce wear and extend the lifespan of the equipment. These materials may include specialized alloys, ceramics, or composite materials that are designed to withstand the abrasive effects of high-velocity particles in the cyclone flow.- Erosion-resistant materials for cyclone units: Utilizing erosion-resistant materials in the construction of cyclone units can significantly reduce wear and extend the lifespan of the equipment. These materials may include specialized alloys, ceramics, or composite materials that are designed to withstand the abrasive effects of high-velocity particles in the cyclone flow.

- Protective coatings for cyclone components: Applying protective coatings to cyclone unit components can enhance their resistance to erosion. These coatings may be made of hard-wearing materials or have self-healing properties, providing an additional layer of protection against the abrasive effects of particulate matter in the cyclone stream.

- Optimized cyclone geometry to reduce erosion: Designing cyclone units with optimized geometry can help minimize erosion by reducing turbulence and improving flow patterns. This may involve modifications to the inlet, vortex finder, or cone section of the cyclone to reduce particle impact and abrasion on critical surfaces.

- Particle separation techniques to minimize erosion: Implementing advanced particle separation techniques within cyclone units can help reduce erosion by removing larger, more abrasive particles earlier in the separation process. This may involve the use of pre-separators, multi-stage cyclones, or other innovative separation methods to protect downstream components from erosive wear.

- Monitoring and maintenance strategies for erosion prevention: Developing effective monitoring and maintenance strategies can help prevent and mitigate erosion in cyclone units. This may include the use of sensors to detect wear patterns, implementing predictive maintenance schedules, and developing quick-replacement components to minimize downtime and extend the overall lifespan of the cyclone system.

02 Protective coatings for cyclone components

Applying protective coatings to cyclone unit components can enhance their resistance to erosion. These coatings may be made of hard materials such as tungsten carbide or ceramic compounds, which are applied to the surfaces most susceptible to wear, such as the cyclone walls and separation cones.Expand Specific Solutions03 Optimized cyclone geometry to reduce erosion

Designing cyclone units with optimized geometry can help minimize erosion by reducing turbulence and improving flow patterns. This may involve modifications to the inlet design, cone angle, or vortex finder configuration to reduce particle impact on critical surfaces.Expand Specific Solutions04 Particle separation techniques to minimize erosion

Implementing advanced particle separation techniques within the cyclone unit can help reduce erosion by removing larger, more abrasive particles earlier in the separation process. This may include the use of pre-separators, multi-stage cyclones, or innovative internal baffles to redirect particle flow.Expand Specific Solutions05 Monitoring and maintenance strategies for erosion prevention

Developing comprehensive monitoring and maintenance strategies can help prevent severe erosion in cyclone units. This may include the use of sensors to detect wear patterns, regular inspections, and scheduled component replacements to address erosion before it becomes critical.Expand Specific Solutions

Key Industry Players

The cyclone unit erosion and maintenance reduction market is in a growth phase, driven by increasing industrial demand for efficient separation processes. The global market size is estimated to be in the billions, with steady growth projected. Technologically, solutions are advancing but still evolving, as evidenced by ongoing research and development efforts from key players. Companies like Dyson Technology Ltd., MANN+HUMMEL GmbH, and UOP LLC are at the forefront, leveraging their expertise in fluid dynamics and materials science to develop more durable and efficient cyclone units. Other players such as Chevron U.S.A., Inc. and Total Raffinage Marketing SA are likely focusing on application-specific improvements for the oil and gas sector.

Dyson Technology Ltd.

Technical Solution: Dyson has developed a cyclone technology with a unique conical shape and optimized air flow patterns. Their cyclones use centrifugal force to spin dust and debris out of the airflow, reducing erosion on the cyclone walls. They have implemented a multi-cyclone system, where air passes through several cyclones in series, each removing progressively smaller particles[1]. This design helps distribute the erosive forces across multiple surfaces, reducing wear on any single component. Additionally, Dyson has incorporated advanced materials such as polycarbonate and specialized coatings to enhance durability and resist abrasion[2].

Strengths: Efficient particle separation, reduced wear on individual components, and use of erosion-resistant materials. Weaknesses: Potentially higher manufacturing costs and complexity in design.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL has developed cyclone pre-separators for air filtration systems, focusing on reducing erosion in automotive and industrial applications. Their design incorporates a spiral flow accelerator that enhances particle separation efficiency while reducing wall contact. They have implemented a multi-stage cyclone system with progressively finer separation capabilities[5]. MANN+HUMMEL has also developed a self-cleaning mechanism that periodically removes accumulated particles, reducing the need for manual maintenance. Additionally, they have utilized advanced polymers and composite materials in cyclone construction to enhance durability and resist erosion[6].

Strengths: High separation efficiency, reduced maintenance requirements, and use of erosion-resistant materials. Weaknesses: May have limitations in extremely high-temperature or corrosive environments.

Innovative Anti-Erosion Tech

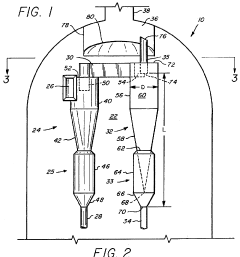

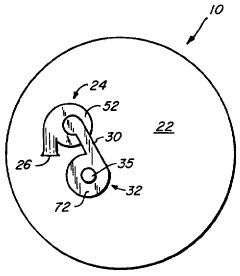

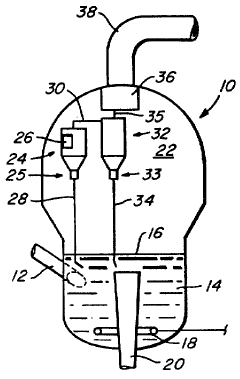

Method of increasing the degree of separation in a cyclone, and cyclone for carrying out said method

PatentInactiveEP0141073A3

Innovation

- A method that slows down particles before entering the cyclone using a T-shaped branch pipe, allowing larger particles to maintain velocities below 20 m/s while accelerating smaller particles to higher velocities, achieving a desired velocity profile for enhanced separation without increasing erosion.

Method for shaping, forming and assembling a highly efficient cyclone separator

PatentInactiveUS4380105A

Innovation

- The cyclone separator design is optimized by controlling specific geometrical parameters, including gas inlet and outlet velocities, area ratios, and the distance between outlets, to minimize erosion and enhance separation efficiency, with a preferred gas inlet velocity of 80 ft/sec, a gas outlet velocity of 178 ft/sec, and a L/D ratio calculated by the equation L/D=4.49-1.09(O/I), which reduces wear on both the separator walls and catalyst particles.

Material Science Advances

Recent advancements in material science have opened new avenues for addressing erosion and maintenance challenges in cyclone units. Innovative materials with enhanced wear resistance and self-healing properties are at the forefront of these developments. Ceramic matrix composites (CMCs) have emerged as promising candidates for cyclone linings due to their exceptional hardness, thermal stability, and resistance to abrasive wear. These materials combine the high-temperature capabilities of ceramics with the toughness of composite structures, offering superior performance in harsh cyclone environments.

Nanotechnology has also played a crucial role in developing erosion-resistant coatings. Nanostructured coatings, such as those based on titanium nitride (TiN) or chromium nitride (CrN), have demonstrated remarkable resistance to particle impact and erosion. These coatings can be applied to existing cyclone components, significantly extending their operational lifespan and reducing maintenance frequency.

Self-healing materials represent another breakthrough in erosion mitigation. Polymer-based self-healing coatings containing microcapsules filled with healing agents have shown promising results in laboratory tests. When erosion occurs, these microcapsules rupture, releasing the healing agent to repair the damaged area autonomously. This technology has the potential to dramatically reduce maintenance requirements and extend the service life of cyclone components.

Advanced composite materials, such as carbon fiber-reinforced polymers (CFRPs), are being explored for their potential to replace traditional metal components in cyclone units. These materials offer excellent strength-to-weight ratios and can be engineered to provide specific erosion-resistant properties. By strategically incorporating CFRPs into cyclone designs, manufacturers can create lighter, more durable units that require less frequent maintenance.

Surface engineering techniques, such as laser surface texturing and plasma electrolytic oxidation, have shown promise in enhancing the erosion resistance of cyclone components. These processes can create micro-structured surfaces that reduce particle impact energy and improve wear resistance. When combined with advanced materials, these surface treatments can provide a synergistic effect, further enhancing the overall erosion resistance of cyclone units.

The development of smart materials with embedded sensors is another area of material science that holds potential for cyclone maintenance reduction. These materials can monitor their own condition in real-time, providing early warning of erosion or damage. This predictive maintenance approach allows for timely interventions, preventing catastrophic failures and optimizing maintenance schedules.

Nanotechnology has also played a crucial role in developing erosion-resistant coatings. Nanostructured coatings, such as those based on titanium nitride (TiN) or chromium nitride (CrN), have demonstrated remarkable resistance to particle impact and erosion. These coatings can be applied to existing cyclone components, significantly extending their operational lifespan and reducing maintenance frequency.

Self-healing materials represent another breakthrough in erosion mitigation. Polymer-based self-healing coatings containing microcapsules filled with healing agents have shown promising results in laboratory tests. When erosion occurs, these microcapsules rupture, releasing the healing agent to repair the damaged area autonomously. This technology has the potential to dramatically reduce maintenance requirements and extend the service life of cyclone components.

Advanced composite materials, such as carbon fiber-reinforced polymers (CFRPs), are being explored for their potential to replace traditional metal components in cyclone units. These materials offer excellent strength-to-weight ratios and can be engineered to provide specific erosion-resistant properties. By strategically incorporating CFRPs into cyclone designs, manufacturers can create lighter, more durable units that require less frequent maintenance.

Surface engineering techniques, such as laser surface texturing and plasma electrolytic oxidation, have shown promise in enhancing the erosion resistance of cyclone components. These processes can create micro-structured surfaces that reduce particle impact energy and improve wear resistance. When combined with advanced materials, these surface treatments can provide a synergistic effect, further enhancing the overall erosion resistance of cyclone units.

The development of smart materials with embedded sensors is another area of material science that holds potential for cyclone maintenance reduction. These materials can monitor their own condition in real-time, providing early warning of erosion or damage. This predictive maintenance approach allows for timely interventions, preventing catastrophic failures and optimizing maintenance schedules.

Operational Optimization

Operational optimization plays a crucial role in reducing erosion and maintenance requirements in cyclone units. By fine-tuning various operational parameters, the overall performance and longevity of cyclone units can be significantly improved.

One key aspect of operational optimization is controlling the inlet velocity. Maintaining an optimal inlet velocity is essential for balancing separation efficiency and erosion rates. Excessively high velocities can lead to increased wear on cyclone walls, while too low velocities may result in poor separation performance. Implementing variable speed drives on feed pumps or fans allows for precise control of inlet velocity, adapting to changing process conditions.

Proper solids loading is another critical factor. Overloading the cyclone with solids can cause accelerated erosion and reduced efficiency. Implementing real-time monitoring systems to measure and control solids concentration in the feed stream helps maintain optimal loading conditions. This can be achieved through the use of density meters or other inline measurement devices.

Optimizing the vortex finder length and diameter is essential for improving separation efficiency and reducing erosion. Adjustable vortex finders allow for fine-tuning based on specific process requirements and feed characteristics. Regular inspection and adjustment of the vortex finder position can help maintain optimal performance over time.

The underflow discharge configuration also plays a significant role in erosion reduction. Implementing a variable apex system allows for dynamic adjustment of the underflow opening, maintaining an optimal balance between separation efficiency and wear reduction. This can be particularly beneficial in processes with varying feed compositions or flow rates.

Implementing advanced control systems, such as model predictive control (MPC), can significantly enhance cyclone performance. These systems can continuously optimize multiple operational parameters simultaneously, taking into account complex interactions and process constraints. By leveraging real-time data and predictive algorithms, MPC can maintain optimal cyclone performance across a wide range of operating conditions.

Regular monitoring and analysis of cyclone performance metrics are essential for ongoing optimization. Key performance indicators such as pressure drop, separation efficiency, and wear rates should be tracked and analyzed to identify trends and potential areas for improvement. This data-driven approach enables proactive adjustments to operational parameters, minimizing erosion and extending maintenance intervals.

In conclusion, operational optimization offers a powerful approach to reducing erosion and maintenance requirements in cyclone units. By focusing on key parameters such as inlet velocity, solids loading, vortex finder configuration, and underflow discharge, significant improvements in cyclone performance and longevity can be achieved. Implementing advanced control systems and maintaining a data-driven optimization approach ensures continued performance enhancement and reduced maintenance needs over time.

One key aspect of operational optimization is controlling the inlet velocity. Maintaining an optimal inlet velocity is essential for balancing separation efficiency and erosion rates. Excessively high velocities can lead to increased wear on cyclone walls, while too low velocities may result in poor separation performance. Implementing variable speed drives on feed pumps or fans allows for precise control of inlet velocity, adapting to changing process conditions.

Proper solids loading is another critical factor. Overloading the cyclone with solids can cause accelerated erosion and reduced efficiency. Implementing real-time monitoring systems to measure and control solids concentration in the feed stream helps maintain optimal loading conditions. This can be achieved through the use of density meters or other inline measurement devices.

Optimizing the vortex finder length and diameter is essential for improving separation efficiency and reducing erosion. Adjustable vortex finders allow for fine-tuning based on specific process requirements and feed characteristics. Regular inspection and adjustment of the vortex finder position can help maintain optimal performance over time.

The underflow discharge configuration also plays a significant role in erosion reduction. Implementing a variable apex system allows for dynamic adjustment of the underflow opening, maintaining an optimal balance between separation efficiency and wear reduction. This can be particularly beneficial in processes with varying feed compositions or flow rates.

Implementing advanced control systems, such as model predictive control (MPC), can significantly enhance cyclone performance. These systems can continuously optimize multiple operational parameters simultaneously, taking into account complex interactions and process constraints. By leveraging real-time data and predictive algorithms, MPC can maintain optimal cyclone performance across a wide range of operating conditions.

Regular monitoring and analysis of cyclone performance metrics are essential for ongoing optimization. Key performance indicators such as pressure drop, separation efficiency, and wear rates should be tracked and analyzed to identify trends and potential areas for improvement. This data-driven approach enables proactive adjustments to operational parameters, minimizing erosion and extending maintenance intervals.

In conclusion, operational optimization offers a powerful approach to reducing erosion and maintenance requirements in cyclone units. By focusing on key parameters such as inlet velocity, solids loading, vortex finder configuration, and underflow discharge, significant improvements in cyclone performance and longevity can be achieved. Implementing advanced control systems and maintaining a data-driven optimization approach ensures continued performance enhancement and reduced maintenance needs over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!