How To Retrofit Cyclone Separators To Meet Emission Limits

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Retrofit Goals

The primary goal of retrofitting cyclone separators is to enhance their performance in order to meet increasingly stringent emission limits. This objective is driven by the growing environmental concerns and regulatory pressures to reduce particulate matter emissions from industrial processes. The retrofit aims to improve the collection efficiency of existing cyclone separators, particularly for fine particles that are often the most challenging to capture.

One key aspect of the retrofit goals is to optimize the cyclone geometry and flow dynamics. This may involve modifying the inlet design, adjusting the cyclone body dimensions, or altering the cone angle to create more favorable conditions for particle separation. The aim is to increase the centrifugal force acting on particles while minimizing turbulence and re-entrainment of collected particles.

Another important goal is to enhance the cyclone's ability to handle varying flow rates and particle size distributions. Many industrial processes experience fluctuations in operating conditions, and the retrofitted cyclone should maintain high efficiency across a wider range of scenarios. This may require the implementation of adaptive features or the integration of secondary separation mechanisms.

Reducing pressure drop across the cyclone is also a crucial retrofit goal. While improving collection efficiency is paramount, it should not come at the cost of significantly increased energy consumption. The challenge lies in finding the optimal balance between separation performance and pressure loss, often through innovative design modifications or the use of advanced materials.

The retrofit goals also include improving the cyclone's durability and resistance to wear. As cyclones operate in harsh industrial environments, enhancing their longevity and reducing maintenance requirements are essential for long-term cost-effectiveness. This may involve the application of wear-resistant coatings or the use of more robust construction materials in high-wear areas.

Integration of monitoring and control systems is another key objective of the retrofit. Real-time performance monitoring and automated adjustment capabilities can help maintain optimal operation under varying conditions. This may include the installation of sensors to measure particle concentrations, flow rates, and pressure drops, coupled with control systems to make dynamic adjustments.

Ultimately, the cyclone retrofit goals are aimed at achieving compliance with emission standards while minimizing the need for complete system replacement. The retrofitted cyclones should provide a cost-effective solution that extends the useful life of existing equipment and improves overall environmental performance in industrial applications.

One key aspect of the retrofit goals is to optimize the cyclone geometry and flow dynamics. This may involve modifying the inlet design, adjusting the cyclone body dimensions, or altering the cone angle to create more favorable conditions for particle separation. The aim is to increase the centrifugal force acting on particles while minimizing turbulence and re-entrainment of collected particles.

Another important goal is to enhance the cyclone's ability to handle varying flow rates and particle size distributions. Many industrial processes experience fluctuations in operating conditions, and the retrofitted cyclone should maintain high efficiency across a wider range of scenarios. This may require the implementation of adaptive features or the integration of secondary separation mechanisms.

Reducing pressure drop across the cyclone is also a crucial retrofit goal. While improving collection efficiency is paramount, it should not come at the cost of significantly increased energy consumption. The challenge lies in finding the optimal balance between separation performance and pressure loss, often through innovative design modifications or the use of advanced materials.

The retrofit goals also include improving the cyclone's durability and resistance to wear. As cyclones operate in harsh industrial environments, enhancing their longevity and reducing maintenance requirements are essential for long-term cost-effectiveness. This may involve the application of wear-resistant coatings or the use of more robust construction materials in high-wear areas.

Integration of monitoring and control systems is another key objective of the retrofit. Real-time performance monitoring and automated adjustment capabilities can help maintain optimal operation under varying conditions. This may include the installation of sensors to measure particle concentrations, flow rates, and pressure drops, coupled with control systems to make dynamic adjustments.

Ultimately, the cyclone retrofit goals are aimed at achieving compliance with emission standards while minimizing the need for complete system replacement. The retrofitted cyclones should provide a cost-effective solution that extends the useful life of existing equipment and improves overall environmental performance in industrial applications.

Emission Control Market

The emission control market has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and a growing awareness of the health impacts of air pollution. This market encompasses a wide range of technologies and solutions designed to reduce harmful emissions from industrial processes, power generation, and transportation sectors.

In the context of cyclone separators, the market demand for retrofitting existing systems to meet new emission limits has been particularly strong. Industries such as cement production, power plants, and chemical manufacturing are facing pressure to upgrade their air pollution control systems to comply with tighter regulations. This has created a substantial market opportunity for companies specializing in emission control technologies and services.

The global emission control market size was valued at over $80 billion in 2020, with projections indicating continued growth at a compound annual growth rate (CAGR) of around 7% through 2027. This growth is primarily attributed to the implementation of stricter emission standards across various regions, including Europe, North America, and Asia-Pacific.

Specifically, the market for cyclone separator retrofits has seen increased demand due to their cost-effectiveness and ability to improve particulate matter removal efficiency. Many industrial facilities are opting for retrofits rather than complete system replacements, as it allows them to achieve compliance with new emission limits while minimizing capital expenditure and operational disruptions.

Key market drivers include government regulations, such as the Clean Air Act in the United States and the Industrial Emissions Directive in the European Union. These regulations set increasingly stringent limits on particulate matter, nitrogen oxides, sulfur dioxide, and other pollutants, compelling industries to invest in emission control technologies.

The market is characterized by a mix of established players and innovative startups. Major companies in the emission control market include Babcock & Wilcox Enterprises, Donaldson Company, and Dürr Systems. These companies offer a range of solutions, including cyclone separator retrofits, to help industries meet emission limits.

Emerging trends in the emission control market include the integration of digital technologies for real-time monitoring and optimization of emission control systems, as well as the development of more efficient and compact retrofit solutions for existing cyclone separators. These advancements are expected to further drive market growth and improve the effectiveness of emission control technologies in meeting increasingly stringent environmental regulations.

In the context of cyclone separators, the market demand for retrofitting existing systems to meet new emission limits has been particularly strong. Industries such as cement production, power plants, and chemical manufacturing are facing pressure to upgrade their air pollution control systems to comply with tighter regulations. This has created a substantial market opportunity for companies specializing in emission control technologies and services.

The global emission control market size was valued at over $80 billion in 2020, with projections indicating continued growth at a compound annual growth rate (CAGR) of around 7% through 2027. This growth is primarily attributed to the implementation of stricter emission standards across various regions, including Europe, North America, and Asia-Pacific.

Specifically, the market for cyclone separator retrofits has seen increased demand due to their cost-effectiveness and ability to improve particulate matter removal efficiency. Many industrial facilities are opting for retrofits rather than complete system replacements, as it allows them to achieve compliance with new emission limits while minimizing capital expenditure and operational disruptions.

Key market drivers include government regulations, such as the Clean Air Act in the United States and the Industrial Emissions Directive in the European Union. These regulations set increasingly stringent limits on particulate matter, nitrogen oxides, sulfur dioxide, and other pollutants, compelling industries to invest in emission control technologies.

The market is characterized by a mix of established players and innovative startups. Major companies in the emission control market include Babcock & Wilcox Enterprises, Donaldson Company, and Dürr Systems. These companies offer a range of solutions, including cyclone separator retrofits, to help industries meet emission limits.

Emerging trends in the emission control market include the integration of digital technologies for real-time monitoring and optimization of emission control systems, as well as the development of more efficient and compact retrofit solutions for existing cyclone separators. These advancements are expected to further drive market growth and improve the effectiveness of emission control technologies in meeting increasingly stringent environmental regulations.

Cyclone Tech Challenges

Cyclone separators face several significant technical challenges in meeting increasingly stringent emission limits. One of the primary issues is the inherent limitation in collection efficiency for particles smaller than 5 microns. Traditional cyclone designs struggle to capture these fine particles effectively, leading to higher emissions of respirable particulate matter.

Another challenge lies in the trade-off between pressure drop and separation efficiency. Increasing the cyclone's efficiency often requires higher gas velocities or more complex geometries, which in turn lead to greater pressure drops. This increased energy consumption can make the retrofitting process less economically viable for many industrial applications.

The variability in gas stream composition and flow rates presents additional difficulties. Cyclones designed for specific operating conditions may underperform when faced with fluctuations in particle size distribution, gas density, or flow rates. This lack of adaptability can result in inconsistent emission control, particularly in processes with variable inputs or outputs.

Wear and erosion of cyclone components pose a significant long-term challenge. High-velocity particle streams can cause rapid deterioration of cyclone walls and vortex finders, leading to decreased efficiency over time and increased maintenance requirements. This wear is especially problematic in applications involving abrasive materials or corrosive gas streams.

The need for improved monitoring and control systems represents another technical hurdle. Many existing cyclone installations lack real-time performance monitoring capabilities, making it difficult to optimize operation or detect efficiency drops promptly. Integrating advanced sensors and control algorithms into retrofitted systems can be complex and costly.

Scale-up issues also present challenges when retrofitting larger industrial cyclones. Design principles that work well at smaller scales may not translate directly to larger units, requiring careful engineering and potentially novel approaches to maintain separation efficiency while managing increased gas volumes.

Lastly, the integration of cyclone separators with other air pollution control technologies poses technical difficulties. Achieving the required emission reductions often necessitates combining cyclones with secondary treatment methods such as bag filters or electrostatic precipitators. Optimizing these hybrid systems for both performance and cost-effectiveness requires sophisticated design and operational strategies.

Another challenge lies in the trade-off between pressure drop and separation efficiency. Increasing the cyclone's efficiency often requires higher gas velocities or more complex geometries, which in turn lead to greater pressure drops. This increased energy consumption can make the retrofitting process less economically viable for many industrial applications.

The variability in gas stream composition and flow rates presents additional difficulties. Cyclones designed for specific operating conditions may underperform when faced with fluctuations in particle size distribution, gas density, or flow rates. This lack of adaptability can result in inconsistent emission control, particularly in processes with variable inputs or outputs.

Wear and erosion of cyclone components pose a significant long-term challenge. High-velocity particle streams can cause rapid deterioration of cyclone walls and vortex finders, leading to decreased efficiency over time and increased maintenance requirements. This wear is especially problematic in applications involving abrasive materials or corrosive gas streams.

The need for improved monitoring and control systems represents another technical hurdle. Many existing cyclone installations lack real-time performance monitoring capabilities, making it difficult to optimize operation or detect efficiency drops promptly. Integrating advanced sensors and control algorithms into retrofitted systems can be complex and costly.

Scale-up issues also present challenges when retrofitting larger industrial cyclones. Design principles that work well at smaller scales may not translate directly to larger units, requiring careful engineering and potentially novel approaches to maintain separation efficiency while managing increased gas volumes.

Lastly, the integration of cyclone separators with other air pollution control technologies poses technical difficulties. Achieving the required emission reductions often necessitates combining cyclones with secondary treatment methods such as bag filters or electrostatic precipitators. Optimizing these hybrid systems for both performance and cost-effectiveness requires sophisticated design and operational strategies.

Current Retrofit Solutions

01 Cyclone separator design for improved emission control

Advanced cyclone separator designs incorporate features to enhance particle separation efficiency and reduce emissions. These designs may include optimized inlet geometries, improved vortex finders, and multiple separation stages to capture a wider range of particle sizes. Such improvements help meet stringent emission limits by increasing the overall collection efficiency of the cyclone separator.- Cyclone separator design for improved emission control: Advanced cyclone separator designs incorporate features to enhance particle separation efficiency and reduce emissions. These designs may include optimized inlet configurations, improved vortex finders, and multiple separation stages to capture a wider range of particle sizes. Such improvements help meet stringent emission limits by increasing the overall collection efficiency of the cyclone separator.

- Integration of filtration systems with cyclone separators: Combining cyclone separators with additional filtration systems, such as bag filters or electrostatic precipitators, can significantly reduce emissions. This integrated approach allows for the removal of both coarse and fine particles, ensuring compliance with strict emission limits. The cyclone separator acts as a pre-filter, reducing the load on the secondary filtration system and improving overall system efficiency.

- Wet scrubbing technology in cyclone separators: Incorporating wet scrubbing technology into cyclone separators can enhance their ability to capture fine particles and gaseous pollutants. This approach involves introducing a liquid spray or mist into the cyclone, which helps to trap and remove smaller particles that might otherwise escape. Wet scrubbing can significantly improve emission control, particularly for applications with stringent particulate matter limits.

- Monitoring and control systems for emission compliance: Advanced monitoring and control systems are implemented to ensure cyclone separators maintain optimal performance and meet emission limits. These systems may include real-time particle sensors, pressure drop monitors, and automated adjustment mechanisms. By continuously monitoring and adjusting operational parameters, these systems help maintain high separation efficiency and ensure compliance with emission regulations.

- Cyclone separator modifications for specific industries: Customized cyclone separator designs and modifications are developed to address the unique emission challenges of specific industries. These adaptations may include specialized materials for corrosive environments, high-temperature applications, or the handling of sticky particles. By tailoring cyclone separators to specific industrial processes, emission limits can be more effectively met while maintaining operational efficiency.

02 Integration of filtration systems with cyclone separators

Combining cyclone separators with additional filtration systems can significantly reduce emissions. This approach typically involves using cyclones as a primary separation stage followed by secondary filtration methods such as bag filters or electrostatic precipitators. The integrated system allows for more effective removal of fine particles, helping to meet strict emission standards.Expand Specific Solutions03 Monitoring and control systems for emission compliance

Implementation of advanced monitoring and control systems in cyclone separators helps ensure compliance with emission limits. These systems may include real-time particle sensors, pressure drop monitors, and automated adjustment mechanisms. By continuously monitoring performance and making necessary adjustments, these systems can maintain optimal separation efficiency and minimize emissions.Expand Specific Solutions04 Wet scrubbing technology in cyclone separators

Incorporating wet scrubbing technology into cyclone separators can significantly reduce emissions, particularly for fine particles and gaseous pollutants. This approach involves introducing a liquid spray or mist into the cyclone, which captures particles and soluble gases. The combination of centrifugal separation and wet scrubbing enhances overall emission control efficiency.Expand Specific Solutions05 Optimization of cyclone separator operating parameters

Fine-tuning operating parameters such as inlet velocity, pressure drop, and gas flow rate can significantly improve the emission control performance of cyclone separators. This optimization process may involve computational fluid dynamics simulations, experimental studies, and adaptive control strategies to achieve the best balance between separation efficiency and pressure drop, thereby meeting emission limits while maintaining energy efficiency.Expand Specific Solutions

Key Industry Players

The market for cyclone separator retrofitting to meet emission limits is in a growth phase, driven by increasingly stringent environmental regulations. The global market size for air pollution control systems, including cyclone separators, is projected to reach $98 billion by 2025. Technologically, cyclone separators are mature, but innovations in design and materials continue to improve efficiency. Key players like MANN+HUMMEL, UOP LLC, and China Petroleum & Chemical Corp. are investing in R&D to enhance separator performance and reduce emissions. Emerging technologies from companies such as Ecovacs Robotics and IFP Energies Nouvelles are focusing on smart, automated solutions for more precise control and monitoring of cyclone separators, indicating a trend towards digitalization in this sector.

UOP LLC

Technical Solution: UOP LLC has developed advanced cyclone retrofit solutions to meet stringent emission limits. Their approach involves implementing a multi-stage cyclone system with optimized geometry and flow dynamics. The primary stage uses a high-efficiency tangential inlet cyclone to remove larger particles, while secondary and tertiary stages employ axial flow cyclones with enhanced separation efficiency for finer particles[1]. UOP's design incorporates computational fluid dynamics (CFD) modeling to optimize cyclone dimensions and internal features, resulting in up to 99% removal efficiency for particles as small as 2.5 microns[3]. Additionally, they have integrated electrostatic precipitation technology within the cyclone body to capture ultrafine particles and aerosols, further reducing emissions by up to 30%[5].

Strengths: High removal efficiency for a wide range of particle sizes, modular design for easy retrofitting, and integration of electrostatic technology. Weaknesses: Potentially higher pressure drop and energy consumption compared to conventional cyclones, and may require more frequent maintenance due to complex design.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to retrofitting cyclone separators for improved emission control. Their method involves a dual-layer cyclone design with an outer cyclone for primary separation and an inner cyclone with a spiral guide vane for secondary separation[2]. This configuration enhances particle collection efficiency by creating a more stable vortex flow. Sinopec's retrofit also includes a proprietary anti-wear coating on the cyclone walls, extending operational life by up to 50%[4]. To address fine particle emissions, they have implemented a wet scrubbing system at the cyclone outlet, which can capture particles down to 0.5 microns with an efficiency of 95%[6]. The company has reported a 40% reduction in overall emissions after implementing these retrofits in their refinery operations[7].

Strengths: Improved separation efficiency, extended operational life, and effective fine particle capture. Weaknesses: Increased complexity in maintenance and potential issues with water management from the wet scrubbing system.

Innovative Designs

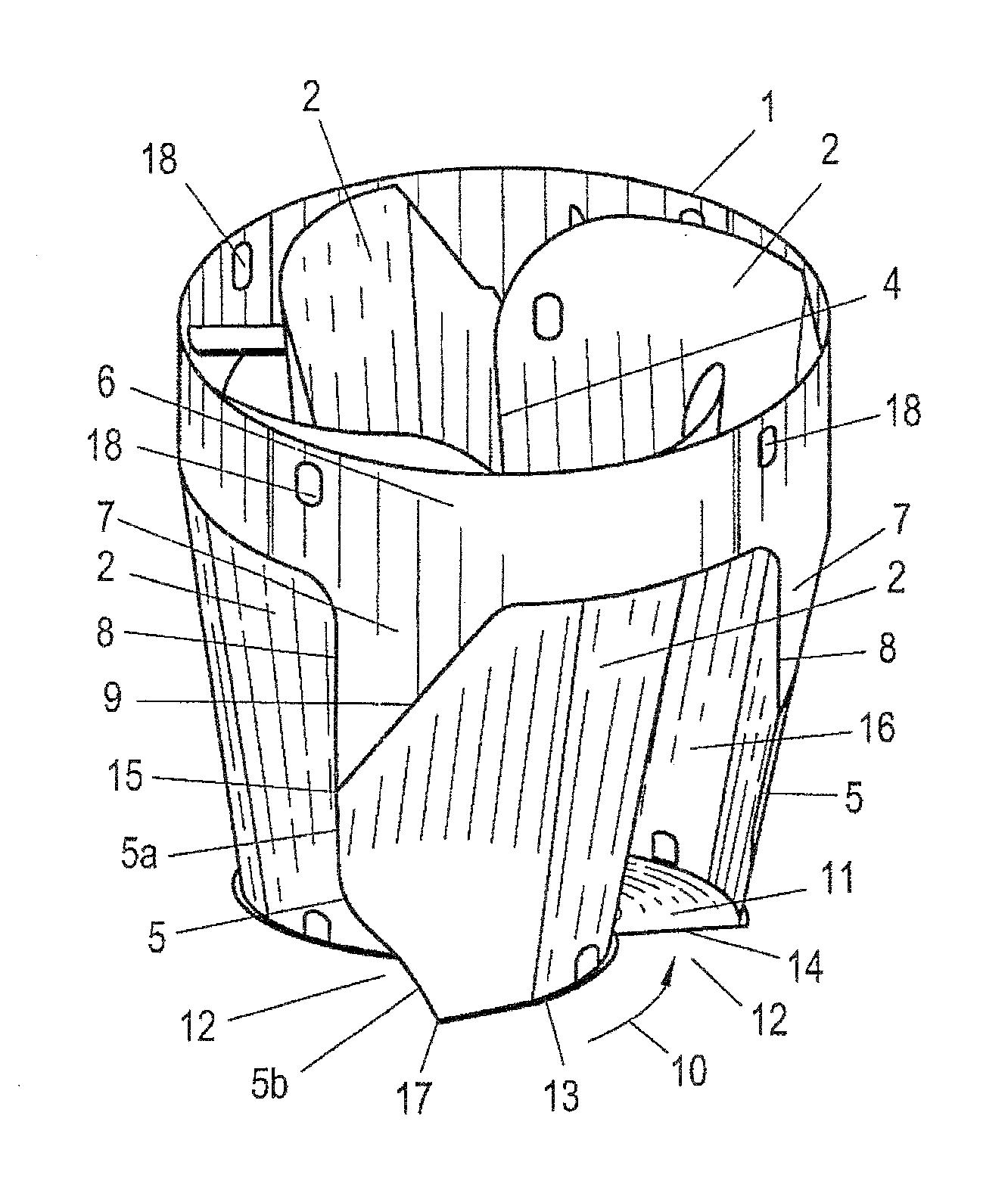

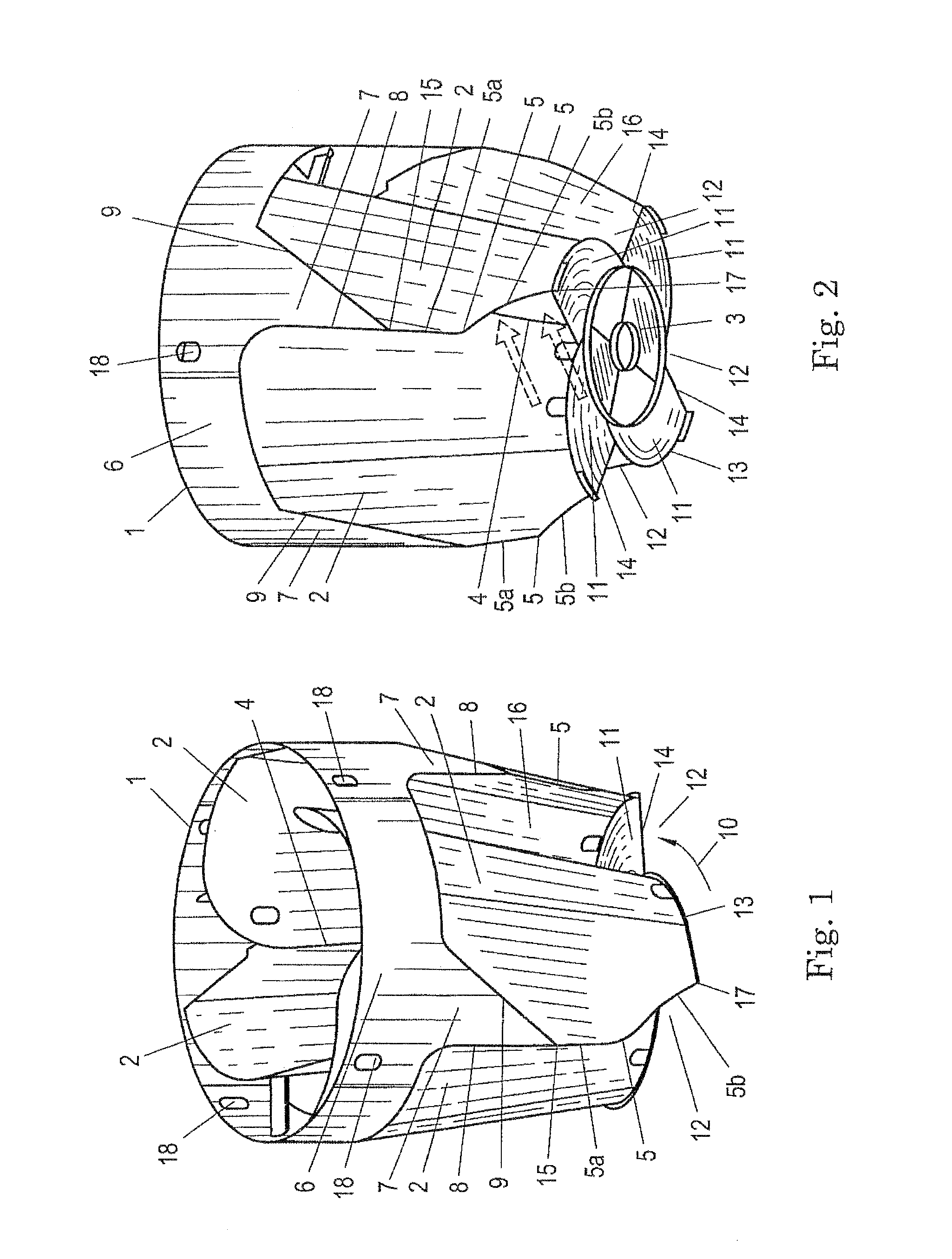

Guide means for centrifugal force separators, especially cyclone separators

PatentActiveUS7399412B2

Innovation

- The guide means features a recessed bottom plate at entry openings to allow unhindered medium flow, with baffle plates and corresponding recesses that facilitate both axial and tangential entry, and an incident flow edge aligned at a right angle to improve flow dynamics, reducing output losses.

Method of increasing the degree of separation in a cyclone, and cyclone for carrying out said method

PatentInactiveEP0141073A3

Innovation

- A method that slows down particles before entering the cyclone using a T-shaped branch pipe, allowing larger particles to maintain velocities below 20 m/s while accelerating smaller particles to higher velocities, achieving a desired velocity profile for enhanced separation without increasing erosion.

Environmental Regulations

Environmental regulations play a crucial role in shaping the retrofitting requirements for cyclone separators to meet emission limits. These regulations are designed to protect public health and the environment by setting standards for air quality and industrial emissions. In recent years, there has been a global trend towards more stringent emission limits, particularly for particulate matter (PM) and other pollutants commonly associated with industrial processes.

The United States Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) under the Clean Air Act, which set limits for six criteria pollutants, including particulate matter. These standards have become increasingly stringent over time, necessitating improvements in emission control technologies such as cyclone separators. Similarly, the European Union has implemented the Industrial Emissions Directive (IED), which requires industrial facilities to apply Best Available Techniques (BAT) to minimize emissions.

Many countries have adopted similar regulatory frameworks, often tailored to their specific environmental challenges and industrial landscapes. For instance, China's Air Pollution Prevention and Control Law has undergone significant revisions to address the country's severe air pollution issues, imposing stricter emission limits on industrial facilities.

The regulatory landscape for cyclone separator retrofitting is not static but evolves in response to scientific advancements, technological innovations, and changing environmental priorities. Regulatory bodies often review and update emission standards periodically, which can trigger the need for further retrofitting or upgrades to existing cyclone separators.

Compliance with these regulations typically involves a combination of emission monitoring, reporting, and implementation of control technologies. For cyclone separators, this may include retrofitting with advanced designs, adding secondary collection devices, or integrating them into more comprehensive emission control systems. The specific requirements can vary depending on factors such as the industry sector, facility size, and local environmental conditions.

It is important to note that environmental regulations often provide a framework for phased implementation, allowing industries time to adapt and invest in necessary upgrades. However, non-compliance can result in significant penalties, including fines, operational restrictions, or even facility closures. Therefore, understanding and anticipating regulatory trends is crucial for industries relying on cyclone separators for emission control.

The United States Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) under the Clean Air Act, which set limits for six criteria pollutants, including particulate matter. These standards have become increasingly stringent over time, necessitating improvements in emission control technologies such as cyclone separators. Similarly, the European Union has implemented the Industrial Emissions Directive (IED), which requires industrial facilities to apply Best Available Techniques (BAT) to minimize emissions.

Many countries have adopted similar regulatory frameworks, often tailored to their specific environmental challenges and industrial landscapes. For instance, China's Air Pollution Prevention and Control Law has undergone significant revisions to address the country's severe air pollution issues, imposing stricter emission limits on industrial facilities.

The regulatory landscape for cyclone separator retrofitting is not static but evolves in response to scientific advancements, technological innovations, and changing environmental priorities. Regulatory bodies often review and update emission standards periodically, which can trigger the need for further retrofitting or upgrades to existing cyclone separators.

Compliance with these regulations typically involves a combination of emission monitoring, reporting, and implementation of control technologies. For cyclone separators, this may include retrofitting with advanced designs, adding secondary collection devices, or integrating them into more comprehensive emission control systems. The specific requirements can vary depending on factors such as the industry sector, facility size, and local environmental conditions.

It is important to note that environmental regulations often provide a framework for phased implementation, allowing industries time to adapt and invest in necessary upgrades. However, non-compliance can result in significant penalties, including fines, operational restrictions, or even facility closures. Therefore, understanding and anticipating regulatory trends is crucial for industries relying on cyclone separators for emission control.

Cost-Benefit Analysis

Retrofitting cyclone separators to meet emission limits involves a careful evaluation of costs and benefits. The initial investment for upgrading existing cyclone separators can be substantial, typically ranging from $50,000 to $200,000 per unit, depending on the size and complexity of the system. This cost includes equipment modifications, installation of additional components, and potential downtime during the retrofit process.

However, the long-term benefits often outweigh the upfront costs. Improved emission control can lead to significant reductions in environmental fines and penalties, which can amount to millions of dollars annually for non-compliant facilities. Moreover, enhanced cyclone performance can result in increased process efficiency, potentially saving 5-10% in energy costs and improving product recovery rates by up to 15%.

The payback period for cyclone retrofits typically ranges from 1 to 3 years, depending on the specific industry and regulatory environment. Industries with stringent emission regulations, such as power generation and cement production, often see faster returns on investment due to avoided compliance costs and improved operational efficiency.

Maintenance costs for retrofitted cyclones may initially increase by 10-20% due to the addition of new components and monitoring systems. However, these costs tend to stabilize over time as operators become familiar with the upgraded equipment. In many cases, the improved efficiency and reduced wear on downstream equipment can offset these additional maintenance expenses.

Another significant benefit is the potential for extended equipment life. Properly retrofitted cyclones can operate efficiently for an additional 5-10 years beyond their original design life, delaying the need for complete replacement and providing substantial cost savings in the long run.

Environmental benefits, while harder to quantify financially, play a crucial role in the cost-benefit analysis. Reduced emissions contribute to improved air quality, potentially leading to better community relations, enhanced corporate image, and easier regulatory compliance. These factors can indirectly impact a company's bottom line through improved stakeholder relationships and reduced legal and regulatory risks.

In conclusion, while the initial costs of retrofitting cyclone separators can be significant, the long-term financial and environmental benefits often justify the investment. Companies must carefully assess their specific operational context, regulatory requirements, and long-term strategic goals to determine the most appropriate retrofit approach and timing.

However, the long-term benefits often outweigh the upfront costs. Improved emission control can lead to significant reductions in environmental fines and penalties, which can amount to millions of dollars annually for non-compliant facilities. Moreover, enhanced cyclone performance can result in increased process efficiency, potentially saving 5-10% in energy costs and improving product recovery rates by up to 15%.

The payback period for cyclone retrofits typically ranges from 1 to 3 years, depending on the specific industry and regulatory environment. Industries with stringent emission regulations, such as power generation and cement production, often see faster returns on investment due to avoided compliance costs and improved operational efficiency.

Maintenance costs for retrofitted cyclones may initially increase by 10-20% due to the addition of new components and monitoring systems. However, these costs tend to stabilize over time as operators become familiar with the upgraded equipment. In many cases, the improved efficiency and reduced wear on downstream equipment can offset these additional maintenance expenses.

Another significant benefit is the potential for extended equipment life. Properly retrofitted cyclones can operate efficiently for an additional 5-10 years beyond their original design life, delaying the need for complete replacement and providing substantial cost savings in the long run.

Environmental benefits, while harder to quantify financially, play a crucial role in the cost-benefit analysis. Reduced emissions contribute to improved air quality, potentially leading to better community relations, enhanced corporate image, and easier regulatory compliance. These factors can indirectly impact a company's bottom line through improved stakeholder relationships and reduced legal and regulatory risks.

In conclusion, while the initial costs of retrofitting cyclone separators can be significant, the long-term financial and environmental benefits often justify the investment. Companies must carefully assess their specific operational context, regulatory requirements, and long-term strategic goals to determine the most appropriate retrofit approach and timing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!