How To Scale Cyclone Separator Designs From Lab To Plant

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Evolution and Objectives

Cyclone separators have been a cornerstone in industrial separation processes for over a century, evolving from simple dust collectors to sophisticated multiphase separation devices. The journey of cyclone separator technology began in the late 19th century with the first patent by John M. Finch in 1885. Initially designed for removing dust from air in lumber mills, these early cyclones laid the foundation for future advancements in particle separation technology.

As industrial processes became more complex, the demand for efficient separation methods grew, driving the evolution of cyclone separators. The mid-20th century saw significant improvements in cyclone design, with researchers like Lapple and Shepherd developing mathematical models to predict cyclone performance. These models marked a turning point, enabling engineers to optimize cyclone designs for specific applications and scale them more effectively.

The advent of computational fluid dynamics (CFD) in the latter part of the 20th century revolutionized cyclone separator design. CFD simulations allowed for detailed analysis of flow patterns and separation efficiency, leading to more sophisticated cyclone geometries and improved performance across various scales. This technological leap facilitated the transition from empirical design methods to more scientific, simulation-based approaches.

Recent years have witnessed a surge in research focused on enhancing cyclone efficiency and adaptability. Innovations such as the development of high-efficiency cyclones, reverse-flow cyclones, and multi-cyclone systems have expanded the application range of this technology. These advancements have been driven by the increasing need for more efficient and environmentally friendly separation processes in industries ranging from petrochemicals to pharmaceuticals.

The primary objective in scaling cyclone separator designs from laboratory to plant is to maintain or improve separation efficiency while adapting to the increased flow rates and particle loads encountered in industrial settings. This scaling process involves careful consideration of geometric similarities, flow dynamics, and material properties. Researchers aim to develop robust scaling methodologies that can accurately predict cyclone performance across different sizes and operating conditions.

Another critical objective is to optimize cyclone designs for specific industrial applications. This includes tailoring cyclones for various particle size distributions, handling different fluid viscosities, and operating under diverse pressure and temperature conditions. The goal is to create versatile cyclone designs that can be easily adapted to meet the unique requirements of different industrial processes.

Furthermore, there is a growing emphasis on developing cyclone separators that are more energy-efficient and have a reduced environmental footprint. This objective aligns with global sustainability goals and drives research into novel materials, improved manufacturing techniques, and innovative cyclone configurations that can achieve higher separation efficiencies with lower pressure drops.

As industrial processes became more complex, the demand for efficient separation methods grew, driving the evolution of cyclone separators. The mid-20th century saw significant improvements in cyclone design, with researchers like Lapple and Shepherd developing mathematical models to predict cyclone performance. These models marked a turning point, enabling engineers to optimize cyclone designs for specific applications and scale them more effectively.

The advent of computational fluid dynamics (CFD) in the latter part of the 20th century revolutionized cyclone separator design. CFD simulations allowed for detailed analysis of flow patterns and separation efficiency, leading to more sophisticated cyclone geometries and improved performance across various scales. This technological leap facilitated the transition from empirical design methods to more scientific, simulation-based approaches.

Recent years have witnessed a surge in research focused on enhancing cyclone efficiency and adaptability. Innovations such as the development of high-efficiency cyclones, reverse-flow cyclones, and multi-cyclone systems have expanded the application range of this technology. These advancements have been driven by the increasing need for more efficient and environmentally friendly separation processes in industries ranging from petrochemicals to pharmaceuticals.

The primary objective in scaling cyclone separator designs from laboratory to plant is to maintain or improve separation efficiency while adapting to the increased flow rates and particle loads encountered in industrial settings. This scaling process involves careful consideration of geometric similarities, flow dynamics, and material properties. Researchers aim to develop robust scaling methodologies that can accurately predict cyclone performance across different sizes and operating conditions.

Another critical objective is to optimize cyclone designs for specific industrial applications. This includes tailoring cyclones for various particle size distributions, handling different fluid viscosities, and operating under diverse pressure and temperature conditions. The goal is to create versatile cyclone designs that can be easily adapted to meet the unique requirements of different industrial processes.

Furthermore, there is a growing emphasis on developing cyclone separators that are more energy-efficient and have a reduced environmental footprint. This objective aligns with global sustainability goals and drives research into novel materials, improved manufacturing techniques, and innovative cyclone configurations that can achieve higher separation efficiencies with lower pressure drops.

Industrial Demand Analysis

The industrial demand for cyclone separators has been steadily increasing across various sectors, driven by the need for efficient particle separation and gas cleaning processes. The scale-up of cyclone separator designs from laboratory to plant level is crucial to meet this growing demand. In the chemical and petrochemical industries, cyclone separators play a vital role in removing particulate matter from gas streams, improving product quality and reducing environmental impact. The oil and gas sector relies heavily on cyclone separators for removing sand and other solid particles from production fluids, enhancing equipment longevity and operational efficiency.

The power generation industry, particularly coal-fired power plants, utilizes cyclone separators for flue gas cleaning, meeting stringent emission standards. As renewable energy sources gain prominence, biomass power plants also require efficient cyclone separators to remove ash and other particulates from combustion gases. In the pharmaceutical industry, cyclone separators are essential for powder processing and handling, ensuring product purity and consistency.

The food and beverage sector employs cyclone separators for various applications, including separating solid particles from liquids and gases in processing lines. This demand is driven by the need for improved product quality and compliance with food safety regulations. The mining industry relies on cyclone separators for mineral processing and dust collection, enhancing operational efficiency and worker safety.

The cement industry utilizes cyclone separators in preheater towers and as part of the air pollution control system, addressing environmental concerns and improving process efficiency. In the pulp and paper industry, cyclone separators are used for fiber recovery and effluent treatment, contributing to resource conservation and environmental protection.

The growing focus on environmental sustainability and stringent air quality regulations across industries has further intensified the demand for efficient cyclone separators. This trend is particularly evident in emerging economies, where rapid industrialization is accompanied by increased environmental awareness. The need for cost-effective and energy-efficient separation technologies has also contributed to the rising demand for optimized cyclone separator designs.

As industries strive for process intensification and improved resource utilization, the ability to scale up cyclone separator designs effectively becomes increasingly critical. This scaling process must address challenges such as maintaining separation efficiency, minimizing pressure drop, and ensuring structural integrity at larger scales. The industrial demand for scalable cyclone separator designs is thus driven by the need to balance performance, cost-effectiveness, and regulatory compliance across diverse applications and operating conditions.

The power generation industry, particularly coal-fired power plants, utilizes cyclone separators for flue gas cleaning, meeting stringent emission standards. As renewable energy sources gain prominence, biomass power plants also require efficient cyclone separators to remove ash and other particulates from combustion gases. In the pharmaceutical industry, cyclone separators are essential for powder processing and handling, ensuring product purity and consistency.

The food and beverage sector employs cyclone separators for various applications, including separating solid particles from liquids and gases in processing lines. This demand is driven by the need for improved product quality and compliance with food safety regulations. The mining industry relies on cyclone separators for mineral processing and dust collection, enhancing operational efficiency and worker safety.

The cement industry utilizes cyclone separators in preheater towers and as part of the air pollution control system, addressing environmental concerns and improving process efficiency. In the pulp and paper industry, cyclone separators are used for fiber recovery and effluent treatment, contributing to resource conservation and environmental protection.

The growing focus on environmental sustainability and stringent air quality regulations across industries has further intensified the demand for efficient cyclone separators. This trend is particularly evident in emerging economies, where rapid industrialization is accompanied by increased environmental awareness. The need for cost-effective and energy-efficient separation technologies has also contributed to the rising demand for optimized cyclone separator designs.

As industries strive for process intensification and improved resource utilization, the ability to scale up cyclone separator designs effectively becomes increasingly critical. This scaling process must address challenges such as maintaining separation efficiency, minimizing pressure drop, and ensuring structural integrity at larger scales. The industrial demand for scalable cyclone separator designs is thus driven by the need to balance performance, cost-effectiveness, and regulatory compliance across diverse applications and operating conditions.

Lab-to-Plant Scaling Challenges

Scaling cyclone separator designs from laboratory to plant scale presents numerous challenges that require careful consideration and systematic approaches. One of the primary difficulties lies in maintaining the performance characteristics observed in small-scale prototypes when transitioning to larger industrial units. The complex fluid dynamics within cyclone separators are highly sensitive to changes in geometry and operating conditions, making direct scaling problematic.

A significant challenge is the preservation of separation efficiency across different scales. As the size of the cyclone increases, the centrifugal forces that drive particle separation may not scale linearly, potentially leading to reduced performance in larger units. This necessitates a deep understanding of the scaling laws governing cyclone operation and their implications on separation efficiency, pressure drop, and cut size.

The impact of Reynolds number on cyclone performance becomes more pronounced during scale-up. Laboratory-scale cyclones often operate in laminar or transitional flow regimes, while industrial-scale units typically function in fully turbulent conditions. This shift in flow characteristics can significantly alter the separation behavior and efficiency of the cyclone, requiring adjustments to design parameters and operating conditions.

Material properties and particle behavior also pose challenges in scaling. The interaction between particles and fluid, as well as particle-particle interactions, may change with scale. Phenomena such as agglomeration, re-entrainment, and wall effects can become more prominent in larger cyclones, affecting overall separation performance and potentially necessitating design modifications.

The influence of inlet and outlet configurations on cyclone performance becomes more critical at larger scales. Ensuring uniform flow distribution and minimizing turbulence at the inlet, as well as optimizing the vortex finder design, are crucial for maintaining separation efficiency. These aspects often require refinement and adaptation when scaling up from laboratory prototypes to industrial units.

Mechanical and structural considerations also come into play during scale-up. Larger cyclones must withstand increased mechanical stresses and vibrations, necessitating robust design and material selection. Additionally, the manufacturing and assembly of large-scale cyclones present their own set of challenges, requiring careful attention to tolerances and fabrication techniques.

Addressing these scaling challenges requires a multifaceted approach combining theoretical modeling, computational fluid dynamics (CFD) simulations, and experimental validation. Dimensional analysis and similarity principles play a crucial role in developing scaling relationships that can guide the design of larger cyclones. However, these theoretical approaches must be complemented by empirical data and pilot-scale testing to account for real-world complexities and validate scaling predictions.

A significant challenge is the preservation of separation efficiency across different scales. As the size of the cyclone increases, the centrifugal forces that drive particle separation may not scale linearly, potentially leading to reduced performance in larger units. This necessitates a deep understanding of the scaling laws governing cyclone operation and their implications on separation efficiency, pressure drop, and cut size.

The impact of Reynolds number on cyclone performance becomes more pronounced during scale-up. Laboratory-scale cyclones often operate in laminar or transitional flow regimes, while industrial-scale units typically function in fully turbulent conditions. This shift in flow characteristics can significantly alter the separation behavior and efficiency of the cyclone, requiring adjustments to design parameters and operating conditions.

Material properties and particle behavior also pose challenges in scaling. The interaction between particles and fluid, as well as particle-particle interactions, may change with scale. Phenomena such as agglomeration, re-entrainment, and wall effects can become more prominent in larger cyclones, affecting overall separation performance and potentially necessitating design modifications.

The influence of inlet and outlet configurations on cyclone performance becomes more critical at larger scales. Ensuring uniform flow distribution and minimizing turbulence at the inlet, as well as optimizing the vortex finder design, are crucial for maintaining separation efficiency. These aspects often require refinement and adaptation when scaling up from laboratory prototypes to industrial units.

Mechanical and structural considerations also come into play during scale-up. Larger cyclones must withstand increased mechanical stresses and vibrations, necessitating robust design and material selection. Additionally, the manufacturing and assembly of large-scale cyclones present their own set of challenges, requiring careful attention to tolerances and fabrication techniques.

Addressing these scaling challenges requires a multifaceted approach combining theoretical modeling, computational fluid dynamics (CFD) simulations, and experimental validation. Dimensional analysis and similarity principles play a crucial role in developing scaling relationships that can guide the design of larger cyclones. However, these theoretical approaches must be complemented by empirical data and pilot-scale testing to account for real-world complexities and validate scaling predictions.

Current Scaling Methodologies

01 Improved cyclone separator design for scale removal

Enhanced cyclone separator designs specifically tailored for efficient scale removal in various industrial applications. These designs incorporate features such as optimized inlet geometry, improved vortex finder configurations, and specialized collection chambers to effectively separate and collect scale particles from fluid streams.- Cyclone separator design improvements: Various design improvements have been made to cyclone separators to enhance their efficiency and performance. These include modifications to the separator body, inlet, and outlet configurations to optimize particle separation and reduce pressure drop. Some designs incorporate multiple cyclones or stages for better separation of different particle sizes.

- Scale prevention and removal mechanisms: To address the issue of scale buildup in cyclone separators, innovative mechanisms have been developed. These include self-cleaning features, anti-scaling coatings, and integrated scale removal systems. Some designs incorporate vibration or ultrasonic devices to prevent scale formation or facilitate its removal during operation.

- Monitoring and control systems: Advanced monitoring and control systems have been integrated into cyclone separators to optimize performance and detect scale formation. These systems may include sensors for pressure, temperature, and particle concentration, as well as automated control mechanisms to adjust operating parameters based on real-time data.

- Material selection for scale resistance: Research has focused on selecting appropriate materials for cyclone separator construction to enhance scale resistance. This includes the use of corrosion-resistant alloys, specialized coatings, and composite materials that minimize scale adhesion and improve overall separator longevity.

- Integration with other separation technologies: Cyclone separators have been combined with other separation technologies to improve overall performance and reduce scale formation. These hybrid systems may incorporate features from filtration, electrostatic precipitation, or chemical treatment processes to enhance separation efficiency and minimize scale-related issues.

02 Integration of scale prevention mechanisms

Incorporation of scale prevention mechanisms within cyclone separators to minimize scale buildup and enhance long-term performance. These mechanisms may include anti-scaling coatings, ultrasonic vibration systems, or chemical injection ports to prevent scale formation on internal surfaces.Expand Specific Solutions03 Multi-stage cyclone systems for improved scale separation

Development of multi-stage cyclone systems that utilize a series of cyclone separators to progressively remove scale particles of varying sizes. This approach allows for more efficient separation of fine scale particles and improves overall system performance.Expand Specific Solutions04 Automated cleaning and maintenance systems

Implementation of automated cleaning and maintenance systems for cyclone separators to address scale buildup. These systems may include self-cleaning mechanisms, robotic cleaning devices, or programmable flushing cycles to maintain optimal separator performance and reduce downtime.Expand Specific Solutions05 Advanced monitoring and control systems

Integration of advanced monitoring and control systems to optimize cyclone separator performance in scale removal applications. These systems may incorporate sensors, data analytics, and machine learning algorithms to detect scale buildup, adjust operating parameters, and predict maintenance needs.Expand Specific Solutions

Key Industry Players

The cyclone separator design scaling from lab to plant is in a mature development stage, with established market players and proven technologies. The market size is significant, driven by industrial applications in various sectors. Technologically, the field is well-developed, with companies like The Babcock & Wilcox Co., Sinopec Engineering, and China Petroleum & Chemical Corp. leading innovation. These firms have extensive experience in scaling and optimizing cyclone separators for large-scale industrial use. Universities such as Donghua University and China Petroleum University Beijing contribute to ongoing research and development, ensuring continuous technological advancements in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to scaling cyclone separator designs from lab to plant. Their method involves a combination of computational fluid dynamics (CFD) simulations and physical modeling. They use advanced CFD software to simulate the flow patterns and separation efficiency of cyclones at different scales, allowing for optimization of design parameters such as inlet velocity, body diameter, and cone angle[1]. Sinopec also employs dimensional analysis and similarity principles to ensure that key dimensionless numbers, such as the Euler number and Reynolds number, are maintained during scale-up[3]. Additionally, they have implemented a pilot-scale testing facility that bridges the gap between lab-scale prototypes and full-scale industrial units, enabling validation of CFD predictions and fine-tuning of designs before final implementation[5].

Strengths: Comprehensive approach combining CFD, physical modeling, and pilot-scale testing. Access to extensive industrial data for validation. Weaknesses: May require significant computational resources and time for complex simulations. Potential challenges in accurately replicating all real-world conditions in simulations.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed an innovative approach to scaling cyclone separator designs using a combination of experimental techniques and advanced modeling. Their method incorporates laser-based flow visualization techniques to capture detailed flow patterns within cyclones at different scales[2]. This data is then used to refine and validate their proprietary computational models. IFP's scaling methodology focuses on maintaining geometric similarity while adjusting operating conditions to preserve key dimensionless parameters, such as the Stokes number and the ratio of centrifugal to gravitational forces[4]. They have also developed a novel scaling law that accounts for the effects of particle agglomeration and re-entrainment, which become increasingly important at larger scales[6]. To bridge the gap between lab and plant scales, IFP utilizes a modular pilot plant approach, allowing for testing of multiple cyclone configurations under various operating conditions.

Strengths: Advanced flow visualization techniques provide detailed insights. Proprietary scaling laws account for complex phenomena like particle agglomeration. Weaknesses: May require specialized equipment for flow visualization. Scaling laws may need adjustment for different types of particulate matter.

Innovative Scaling Techniques

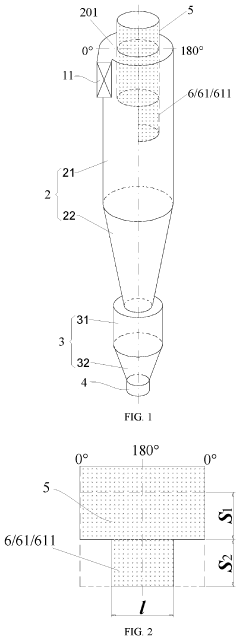

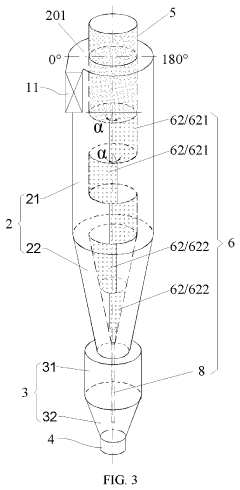

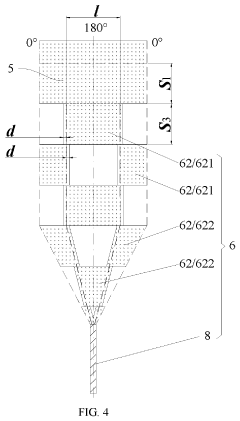

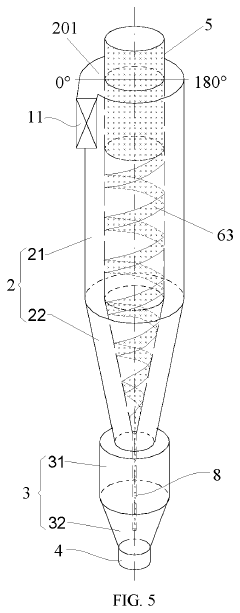

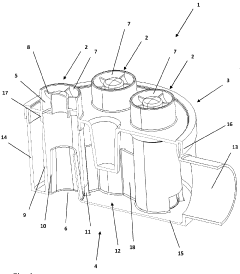

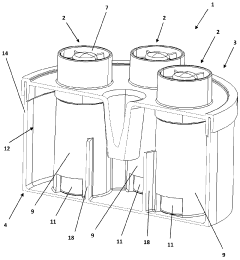

Cyclone separator and cyclone separation method

PatentPendingUS20240017275A1

Innovation

- A baffle structure is implemented within the cyclone separator to cut off short-circuit flows, weaken inner vortex flows, and prevent back-mixing of particles, improving separation efficiency for fine particles and reducing pressure drops by isolating the particle spiral band from the inner vortex flow.

Two-part cyclone separator

PatentWO2012010621A1

Innovation

- A two-piece cyclone separator design where the cyclone tube and dip tube are integrated into a common housing component, eliminating leaks and allowing for a defined separation area, with the cyclone tube having an opening for particle discharge, and using a plug-in connection for easy assembly and maintenance, and potentially a one-piece plastic housing pot for cost-effectiveness.

CFD Simulation in Scaling

Computational Fluid Dynamics (CFD) simulation plays a crucial role in scaling cyclone separator designs from laboratory to plant scale. This advanced numerical modeling technique allows engineers to predict and optimize the performance of cyclone separators across different scales, reducing the need for costly and time-consuming physical experiments.

CFD simulations provide detailed insights into the complex flow patterns, particle trajectories, and separation efficiency within cyclone separators. By accurately modeling the fluid dynamics and particle behavior, engineers can identify potential issues and optimize design parameters before full-scale implementation. This approach significantly reduces the risks associated with scaling up and helps ensure that the performance observed in laboratory-scale prototypes can be effectively translated to industrial-scale applications.

One of the key advantages of CFD simulation in scaling cyclone separators is its ability to account for the non-linear effects that occur during scale-up. As the size of a cyclone separator increases, factors such as wall effects, turbulence, and particle interactions can change dramatically. CFD models can capture these scale-dependent phenomena, allowing engineers to make informed decisions about design modifications necessary for successful scale-up.

Moreover, CFD simulations enable the exploration of a wide range of operating conditions and design variations without the need for physical prototypes. This capability is particularly valuable when scaling cyclone separators, as it allows for rapid iteration and optimization of design parameters such as inlet velocity, body dimensions, and outlet configurations. By conducting virtual experiments, engineers can identify the most promising designs for further physical testing, significantly streamlining the development process.

Another critical aspect of CFD simulation in cyclone separator scaling is its ability to predict performance metrics that are difficult or impossible to measure experimentally, especially at larger scales. These may include local pressure distributions, velocity profiles, and particle concentration fields throughout the separator. Such detailed information helps engineers understand the underlying mechanisms of separation and make data-driven decisions to improve efficiency and reliability during scale-up.

Furthermore, CFD simulations can be coupled with other modeling techniques, such as population balance models or discrete element methods, to provide a more comprehensive understanding of the scaling process. This multi-physics approach allows for the consideration of additional factors like particle agglomeration or breakage, which can become increasingly important as the scale of operation increases.

CFD simulations provide detailed insights into the complex flow patterns, particle trajectories, and separation efficiency within cyclone separators. By accurately modeling the fluid dynamics and particle behavior, engineers can identify potential issues and optimize design parameters before full-scale implementation. This approach significantly reduces the risks associated with scaling up and helps ensure that the performance observed in laboratory-scale prototypes can be effectively translated to industrial-scale applications.

One of the key advantages of CFD simulation in scaling cyclone separators is its ability to account for the non-linear effects that occur during scale-up. As the size of a cyclone separator increases, factors such as wall effects, turbulence, and particle interactions can change dramatically. CFD models can capture these scale-dependent phenomena, allowing engineers to make informed decisions about design modifications necessary for successful scale-up.

Moreover, CFD simulations enable the exploration of a wide range of operating conditions and design variations without the need for physical prototypes. This capability is particularly valuable when scaling cyclone separators, as it allows for rapid iteration and optimization of design parameters such as inlet velocity, body dimensions, and outlet configurations. By conducting virtual experiments, engineers can identify the most promising designs for further physical testing, significantly streamlining the development process.

Another critical aspect of CFD simulation in cyclone separator scaling is its ability to predict performance metrics that are difficult or impossible to measure experimentally, especially at larger scales. These may include local pressure distributions, velocity profiles, and particle concentration fields throughout the separator. Such detailed information helps engineers understand the underlying mechanisms of separation and make data-driven decisions to improve efficiency and reliability during scale-up.

Furthermore, CFD simulations can be coupled with other modeling techniques, such as population balance models or discrete element methods, to provide a more comprehensive understanding of the scaling process. This multi-physics approach allows for the consideration of additional factors like particle agglomeration or breakage, which can become increasingly important as the scale of operation increases.

Environmental Regulations

Environmental regulations play a crucial role in the scaling of cyclone separator designs from laboratory to industrial plant applications. As industries strive to meet increasingly stringent emission standards, the design and implementation of cyclone separators must evolve to comply with these regulations while maintaining operational efficiency.

In many countries, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States or the European Environment Agency (EEA) in Europe set limits on particulate matter emissions from industrial processes. These regulations often specify maximum allowable concentrations of different particle sizes, such as PM10 and PM2.5, which directly impact cyclone separator design requirements.

The scaling process must consider the specific environmental regulations applicable to the industry and location where the cyclone separator will be deployed. This includes understanding the local air quality standards, emission limits, and monitoring requirements. Designers must ensure that the scaled-up cyclone separator can achieve the necessary collection efficiency to meet these regulatory thresholds.

Furthermore, environmental regulations may dictate the need for additional pollution control equipment in conjunction with cyclone separators. For instance, some jurisdictions may require the installation of secondary filtration systems or scrubbers to further reduce emissions. This necessitates a holistic approach to scaling, considering how the cyclone separator integrates with other pollution control technologies.

Regulatory compliance also extends to the materials used in cyclone separator construction. Certain industries, such as food processing or pharmaceuticals, may have specific requirements for food-grade or corrosion-resistant materials. Scaling up designs must account for these material constraints while maintaining performance characteristics.

Environmental impact assessments may be required as part of the scaling process, particularly for large industrial installations. These assessments evaluate the potential environmental effects of the cyclone separator operation, including noise pollution, visual impact, and potential releases during maintenance or malfunction. Designers must incorporate features that minimize these impacts and facilitate compliance with environmental regulations.

As regulations evolve, cyclone separator designs must be adaptable to future requirements. This may involve incorporating modular components or designing for easy retrofitting to accommodate potential changes in emission standards or the introduction of new pollutant categories.

In conclusion, scaling cyclone separator designs from laboratory to plant applications requires a comprehensive understanding of applicable environmental regulations. Designers must balance performance optimization with regulatory compliance, ensuring that the scaled-up systems meet both operational and environmental requirements. This process demands close collaboration between engineers, environmental specialists, and regulatory experts to navigate the complex landscape of environmental regulations successfully.

In many countries, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States or the European Environment Agency (EEA) in Europe set limits on particulate matter emissions from industrial processes. These regulations often specify maximum allowable concentrations of different particle sizes, such as PM10 and PM2.5, which directly impact cyclone separator design requirements.

The scaling process must consider the specific environmental regulations applicable to the industry and location where the cyclone separator will be deployed. This includes understanding the local air quality standards, emission limits, and monitoring requirements. Designers must ensure that the scaled-up cyclone separator can achieve the necessary collection efficiency to meet these regulatory thresholds.

Furthermore, environmental regulations may dictate the need for additional pollution control equipment in conjunction with cyclone separators. For instance, some jurisdictions may require the installation of secondary filtration systems or scrubbers to further reduce emissions. This necessitates a holistic approach to scaling, considering how the cyclone separator integrates with other pollution control technologies.

Regulatory compliance also extends to the materials used in cyclone separator construction. Certain industries, such as food processing or pharmaceuticals, may have specific requirements for food-grade or corrosion-resistant materials. Scaling up designs must account for these material constraints while maintaining performance characteristics.

Environmental impact assessments may be required as part of the scaling process, particularly for large industrial installations. These assessments evaluate the potential environmental effects of the cyclone separator operation, including noise pollution, visual impact, and potential releases during maintenance or malfunction. Designers must incorporate features that minimize these impacts and facilitate compliance with environmental regulations.

As regulations evolve, cyclone separator designs must be adaptable to future requirements. This may involve incorporating modular components or designing for easy retrofitting to accommodate potential changes in emission standards or the introduction of new pollutant categories.

In conclusion, scaling cyclone separator designs from laboratory to plant applications requires a comprehensive understanding of applicable environmental regulations. Designers must balance performance optimization with regulatory compliance, ensuring that the scaled-up systems meet both operational and environmental requirements. This process demands close collaboration between engineers, environmental specialists, and regulatory experts to navigate the complex landscape of environmental regulations successfully.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!