How To Select Cyclone Materials For High-Temperature Flue Gas

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temp Cyclone Background and Objectives

Cyclone separators have been widely used in industrial processes for over a century, primarily for removing particulate matter from gas streams. In recent years, there has been a growing interest in applying cyclone technology to high-temperature flue gas treatment, particularly in power plants, waste incineration facilities, and various industrial processes. This shift towards high-temperature applications has necessitated a reevaluation of cyclone materials to ensure optimal performance and longevity under extreme conditions.

The evolution of cyclone technology for high-temperature flue gas treatment has been driven by increasingly stringent environmental regulations and the need for more efficient particulate removal systems. Traditional cyclone designs, while effective at lower temperatures, face significant challenges when exposed to hot flue gases, which can reach temperatures of up to 1000°C or higher. These extreme conditions place severe demands on the materials used in cyclone construction, requiring them to withstand not only high temperatures but also corrosive environments and abrasive particulates.

The primary objective of selecting appropriate cyclone materials for high-temperature flue gas applications is to ensure the long-term reliability and efficiency of the separation process. This involves identifying materials that can maintain their structural integrity, resist thermal deformation, and withstand chemical attack under prolonged exposure to harsh operating conditions. Additionally, the selected materials must be cost-effective and readily available to make their implementation economically viable for industrial applications.

Another crucial aspect of material selection is the potential for improving cyclone performance through advanced material properties. For instance, materials with enhanced heat resistance may allow for higher operating temperatures, potentially increasing the overall efficiency of the flue gas treatment process. Similarly, materials with superior wear resistance could extend the operational lifespan of cyclones, reducing maintenance costs and downtime.

The technological trend in this field is moving towards the development and application of advanced ceramics, high-temperature alloys, and composite materials. These materials offer promising combinations of thermal stability, corrosion resistance, and mechanical strength. However, their widespread adoption faces challenges related to manufacturing complexity, cost, and the need for extensive testing and validation in real-world operating conditions.

As research in this area progresses, the goals extend beyond mere material selection to encompass the optimization of cyclone design in conjunction with advanced materials. This holistic approach aims to create next-generation cyclone systems capable of handling increasingly demanding flue gas conditions while meeting or exceeding environmental standards and operational efficiency targets.

The evolution of cyclone technology for high-temperature flue gas treatment has been driven by increasingly stringent environmental regulations and the need for more efficient particulate removal systems. Traditional cyclone designs, while effective at lower temperatures, face significant challenges when exposed to hot flue gases, which can reach temperatures of up to 1000°C or higher. These extreme conditions place severe demands on the materials used in cyclone construction, requiring them to withstand not only high temperatures but also corrosive environments and abrasive particulates.

The primary objective of selecting appropriate cyclone materials for high-temperature flue gas applications is to ensure the long-term reliability and efficiency of the separation process. This involves identifying materials that can maintain their structural integrity, resist thermal deformation, and withstand chemical attack under prolonged exposure to harsh operating conditions. Additionally, the selected materials must be cost-effective and readily available to make their implementation economically viable for industrial applications.

Another crucial aspect of material selection is the potential for improving cyclone performance through advanced material properties. For instance, materials with enhanced heat resistance may allow for higher operating temperatures, potentially increasing the overall efficiency of the flue gas treatment process. Similarly, materials with superior wear resistance could extend the operational lifespan of cyclones, reducing maintenance costs and downtime.

The technological trend in this field is moving towards the development and application of advanced ceramics, high-temperature alloys, and composite materials. These materials offer promising combinations of thermal stability, corrosion resistance, and mechanical strength. However, their widespread adoption faces challenges related to manufacturing complexity, cost, and the need for extensive testing and validation in real-world operating conditions.

As research in this area progresses, the goals extend beyond mere material selection to encompass the optimization of cyclone design in conjunction with advanced materials. This holistic approach aims to create next-generation cyclone systems capable of handling increasingly demanding flue gas conditions while meeting or exceeding environmental standards and operational efficiency targets.

Market Analysis for High-Temp Gas Treatment

The market for high-temperature flue gas treatment technologies is experiencing significant growth, driven by stringent environmental regulations and increasing industrial activities worldwide. The global market for air pollution control systems is projected to reach $98.2 billion by 2025, with a substantial portion attributed to high-temperature gas treatment solutions. This growth is particularly evident in regions with heavy industrial presence, such as China, India, and Southeast Asian countries, where rapid industrialization has led to increased emissions and a subsequent demand for effective treatment technologies.

The cyclone separator market, a key component in high-temperature flue gas treatment, is expected to grow at a CAGR of 4.5% from 2021 to 2026. This growth is fueled by the rising need for efficient particulate matter removal in various industries, including power generation, cement production, and metal processing. The demand for cyclone separators capable of withstanding high-temperature environments is particularly strong, as industries seek to optimize their processes and meet increasingly stringent emission standards.

In the power generation sector, the shift towards cleaner energy sources has not diminished the importance of high-temperature flue gas treatment. Coal-fired power plants, which still account for a significant portion of global electricity production, require advanced cyclone systems to manage emissions effectively. The market for these systems in the power sector is expected to grow steadily, especially in developing economies where coal remains a primary energy source.

The cement industry represents another major market for high-temperature cyclone separators. With global cement production projected to increase by 12-23% by 2050, the demand for efficient and durable cyclone materials capable of withstanding the harsh conditions in cement kilns is set to rise. This sector's requirements are driving innovations in material science, pushing manufacturers to develop cyclones that can maintain performance under extreme temperatures and abrasive conditions.

The metal processing industry, particularly steel production, is also a significant contributor to the demand for high-temperature cyclone materials. As steel production continues to grow globally, with an expected increase of 30% by 2050, the need for robust gas treatment solutions becomes more critical. This sector's requirements are particularly challenging, given the presence of corrosive gases and high-temperature particulates in the flue gas streams.

Emerging trends in the market include the development of advanced ceramic and metal alloy materials that offer superior heat resistance and durability. There is also a growing interest in hybrid systems that combine cyclone technology with other filtration methods to achieve higher efficiency in particulate removal. These innovations are expected to drive market growth and open new opportunities for manufacturers and material scientists in the coming years.

The cyclone separator market, a key component in high-temperature flue gas treatment, is expected to grow at a CAGR of 4.5% from 2021 to 2026. This growth is fueled by the rising need for efficient particulate matter removal in various industries, including power generation, cement production, and metal processing. The demand for cyclone separators capable of withstanding high-temperature environments is particularly strong, as industries seek to optimize their processes and meet increasingly stringent emission standards.

In the power generation sector, the shift towards cleaner energy sources has not diminished the importance of high-temperature flue gas treatment. Coal-fired power plants, which still account for a significant portion of global electricity production, require advanced cyclone systems to manage emissions effectively. The market for these systems in the power sector is expected to grow steadily, especially in developing economies where coal remains a primary energy source.

The cement industry represents another major market for high-temperature cyclone separators. With global cement production projected to increase by 12-23% by 2050, the demand for efficient and durable cyclone materials capable of withstanding the harsh conditions in cement kilns is set to rise. This sector's requirements are driving innovations in material science, pushing manufacturers to develop cyclones that can maintain performance under extreme temperatures and abrasive conditions.

The metal processing industry, particularly steel production, is also a significant contributor to the demand for high-temperature cyclone materials. As steel production continues to grow globally, with an expected increase of 30% by 2050, the need for robust gas treatment solutions becomes more critical. This sector's requirements are particularly challenging, given the presence of corrosive gases and high-temperature particulates in the flue gas streams.

Emerging trends in the market include the development of advanced ceramic and metal alloy materials that offer superior heat resistance and durability. There is also a growing interest in hybrid systems that combine cyclone technology with other filtration methods to achieve higher efficiency in particulate removal. These innovations are expected to drive market growth and open new opportunities for manufacturers and material scientists in the coming years.

Current Challenges in Cyclone Material Selection

The selection of appropriate materials for cyclones operating in high-temperature flue gas environments presents several significant challenges. One of the primary issues is the extreme thermal conditions these materials must withstand. Flue gases can reach temperatures exceeding 1000°C, placing immense stress on the cyclone structure. This high-temperature exposure can lead to thermal fatigue, creep, and accelerated oxidation of the materials, potentially compromising the cyclone's structural integrity and performance over time.

Another critical challenge is the corrosive nature of flue gases. These gases often contain a complex mixture of acidic compounds, such as sulfur oxides and hydrogen chloride, which can aggressively attack many conventional materials. The corrosion rates are typically exacerbated by the elevated temperatures, creating a harsh environment that rapidly degrades unsuitable materials. This corrosion can lead to thinning of cyclone walls, pitting, and eventual failure if not properly addressed in the material selection process.

Erosion resistance is also a significant concern in cyclone material selection. The high-velocity particulate matter carried by the flue gas can cause severe abrasive wear on the cyclone surfaces, particularly at the inlet and along the cyclone body where particle impingement is most intense. This erosion can lead to premature material loss and potentially alter the cyclone's geometry, affecting its separation efficiency over time.

The need for materials that maintain their mechanical properties at high temperatures poses another challenge. Many materials that exhibit excellent strength and toughness at room temperature may become brittle or lose their structural integrity when exposed to the extreme temperatures of flue gases. This necessitates the use of specialized high-temperature alloys or ceramics, which can significantly increase the cost and complexity of cyclone construction.

Thermal expansion and thermal shock resistance are additional factors that complicate material selection. The cyclone materials must be able to withstand rapid temperature changes without cracking or warping. Differential thermal expansion between different components of the cyclone can lead to stress concentrations and potential failure points, requiring careful consideration of material compatibility and design tolerances.

Lastly, the long-term stability and durability of materials in these harsh environments remain a persistent challenge. Cyclones are often expected to operate continuously for extended periods, sometimes years, without significant maintenance or replacement. This demands materials that not only survive the initial exposure to high-temperature flue gases but also maintain their properties and performance over prolonged periods, resisting phenomena such as phase transformations, grain growth, and other microstructural changes that could compromise their functionality.

Another critical challenge is the corrosive nature of flue gases. These gases often contain a complex mixture of acidic compounds, such as sulfur oxides and hydrogen chloride, which can aggressively attack many conventional materials. The corrosion rates are typically exacerbated by the elevated temperatures, creating a harsh environment that rapidly degrades unsuitable materials. This corrosion can lead to thinning of cyclone walls, pitting, and eventual failure if not properly addressed in the material selection process.

Erosion resistance is also a significant concern in cyclone material selection. The high-velocity particulate matter carried by the flue gas can cause severe abrasive wear on the cyclone surfaces, particularly at the inlet and along the cyclone body where particle impingement is most intense. This erosion can lead to premature material loss and potentially alter the cyclone's geometry, affecting its separation efficiency over time.

The need for materials that maintain their mechanical properties at high temperatures poses another challenge. Many materials that exhibit excellent strength and toughness at room temperature may become brittle or lose their structural integrity when exposed to the extreme temperatures of flue gases. This necessitates the use of specialized high-temperature alloys or ceramics, which can significantly increase the cost and complexity of cyclone construction.

Thermal expansion and thermal shock resistance are additional factors that complicate material selection. The cyclone materials must be able to withstand rapid temperature changes without cracking or warping. Differential thermal expansion between different components of the cyclone can lead to stress concentrations and potential failure points, requiring careful consideration of material compatibility and design tolerances.

Lastly, the long-term stability and durability of materials in these harsh environments remain a persistent challenge. Cyclones are often expected to operate continuously for extended periods, sometimes years, without significant maintenance or replacement. This demands materials that not only survive the initial exposure to high-temperature flue gases but also maintain their properties and performance over prolonged periods, resisting phenomena such as phase transformations, grain growth, and other microstructural changes that could compromise their functionality.

Existing High-Temp Cyclone Material Solutions

01 High-temperature resistant materials for cyclone components

Various high-temperature resistant materials are used in cyclone components to withstand extreme operating conditions. These materials include special alloys, ceramics, and composite materials that can maintain their structural integrity and performance at elevated temperatures. The use of such materials enhances the durability and efficiency of cyclone systems in high-temperature applications.- High-temperature resistant materials for cyclone components: Various high-temperature resistant materials are used in cyclone components to withstand extreme heat conditions. These materials include special alloys, ceramics, and composite materials that can maintain their structural integrity and performance at elevated temperatures. The use of such materials enhances the overall efficiency and lifespan of cyclone systems in high-temperature applications.

- Thermal insulation and cooling systems for cyclones: Cyclone systems often incorporate thermal insulation and cooling mechanisms to protect temperature-sensitive components and maintain optimal operating conditions. These may include insulation layers, cooling jackets, or air circulation systems. Such features help to regulate the internal temperature of the cyclone and prevent overheating of critical parts.

- Temperature-resistant coatings and surface treatments: Specialized coatings and surface treatments are applied to cyclone components to enhance their temperature resistance. These coatings can provide additional protection against heat, corrosion, and wear. Advanced coating technologies, such as thermal barrier coatings or ceramic-based treatments, are used to improve the durability and performance of cyclone materials in high-temperature environments.

- Design optimization for temperature management: The design of cyclone systems is optimized to manage temperature-related challenges. This includes the use of advanced computational fluid dynamics (CFD) simulations to analyze heat distribution and flow patterns. Design features such as improved vortex finders, optimized inlet geometries, and strategic placement of temperature-resistant components are implemented to enhance overall temperature resistance and system efficiency.

- Monitoring and control systems for temperature regulation: Advanced monitoring and control systems are integrated into cyclone setups to regulate temperature and ensure safe operation. These systems may include temperature sensors, automated cooling mechanisms, and intelligent control algorithms. Real-time monitoring and adjustment of operating parameters help maintain optimal temperature conditions and prevent thermal damage to cyclone components.

02 Thermal insulation and cooling systems for cyclones

Cyclone systems often incorporate thermal insulation and cooling mechanisms to protect temperature-sensitive components and maintain optimal operating conditions. These may include insulation layers, cooling jackets, or air gaps designed to reduce heat transfer and prevent overheating of critical parts. Such systems help extend the lifespan of cyclone equipment and improve overall performance in high-temperature environments.Expand Specific Solutions03 Temperature-resistant coatings and surface treatments

Specialized coatings and surface treatments are applied to cyclone components to enhance their temperature resistance. These treatments can include thermal barrier coatings, ceramic coatings, or other advanced surface modification techniques that provide an additional layer of protection against high temperatures and thermal cycling. Such coatings help prevent material degradation and extend the service life of cyclone equipment.Expand Specific Solutions04 Design optimizations for improved temperature resistance

Cyclone designs are optimized to enhance temperature resistance through various structural and geometric modifications. These may include the use of heat-dissipating fins, strategic placement of thermal expansion joints, or the incorporation of temperature-resistant liners. Such design optimizations help distribute thermal loads more effectively and minimize the impact of high temperatures on critical components.Expand Specific Solutions05 Temperature monitoring and control systems

Advanced temperature monitoring and control systems are integrated into cyclone equipment to ensure safe and efficient operation in high-temperature environments. These systems may include temperature sensors, automated cooling mechanisms, and intelligent control algorithms that adjust operating parameters based on real-time temperature data. Such systems help prevent overheating, optimize performance, and protect temperature-sensitive components.Expand Specific Solutions

Key Players in High-Temp Cyclone Industry

The competition landscape for high-temperature flue gas cyclone materials is characterized by a mature market with established players and ongoing technological advancements. The industry is in a growth phase, driven by increasing environmental regulations and energy efficiency demands. Key players like ROCKWOOL A/S, Sinopec Engineering, Inc., and FLSmidth A/S are leading the market with their specialized solutions. The technology is well-developed, but companies such as Chongqing Sanfeng Environmental Group and Tianjin Cement Industry Design & Research Institute are continuously innovating to improve material performance and durability. The market size is substantial, with applications spanning across various industries, including cement, petrochemicals, and power generation.

ROCKWOOL A/S

Technical Solution: ROCKWOOL A/S has developed advanced stone wool-based cyclone materials for high-temperature flue gas applications. Their solution utilizes a proprietary blend of volcanic rock and recycled materials to create highly durable and heat-resistant fibers. These fibers are engineered into a structured matrix that can withstand temperatures up to 1000°C (1832°F) while maintaining excellent particulate capture efficiency[1]. The material's unique composition allows for improved thermal insulation and reduced heat loss in the cyclone system, enhancing overall energy efficiency. ROCKWOOL's cyclone materials also feature a non-wetting surface that resists condensation and chemical attack from acidic flue gases, extending the operational lifespan of the cyclone[2].

Strengths: Exceptional heat resistance, improved energy efficiency, and chemical resistance. Weaknesses: Potentially higher initial cost compared to traditional materials, and may require specialized installation techniques.

Sinopec Engineering, Inc.

Technical Solution: Sinopec Engineering has developed a novel approach to cyclone material selection for high-temperature flue gas applications, focusing on ceramic-based composites. Their technology incorporates advanced ceramic materials with high alumina content, typically exceeding 85%, which are specially formulated to withstand extreme temperatures above 1200°C (2192°F)[3]. The company has implemented a multi-layer design, where the inner layer consists of highly abrasion-resistant ceramics, while the outer layers provide thermal insulation and structural support. This layered approach allows for optimized performance in different zones of the cyclone. Sinopec's materials also feature a unique surface treatment that enhances particle separation efficiency and reduces the risk of material build-up on cyclone walls[4].

Strengths: Extremely high temperature resistance, excellent abrasion resistance, and enhanced separation efficiency. Weaknesses: Higher manufacturing complexity and potentially increased weight of the cyclone structure.

Innovative Materials for High-Temp Cyclones

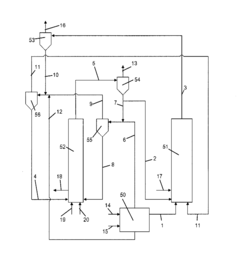

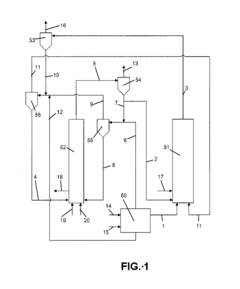

METHODS AND INSTALLATIONS FOR PREHEATING PARTICULATE OR POWDER MATERIALS

PatentInactiveID45449A

Innovation

- Introducing a portion of the material into the first section of the ascending pipeline to be heated from a maximum temperature of 450°C to at least 550°C.

- Introducing the residual material into the last section of the ascending pipeline, creating a staged preheating process.

- Reducing SO2 emissions during cement preheating without increasing energy consumption.

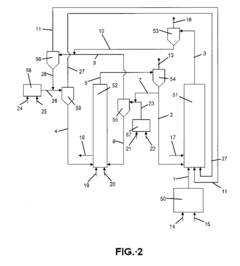

System for CO2 Capture from a Combustion Flue Gas using a CaO/CaCO3 Chemical Loop

PatentInactiveUS20140352581A1

Innovation

- A system that employs direct heat exchange between high temperature flue gases and recirculating solid streams to reduce heat requirements in the calciner, using a network of cyclones to preheat carbonated and calcined solids, thereby minimizing the need for external fuel and O2 in the calciner.

Environmental Regulations Impact

Environmental regulations play a crucial role in shaping the selection of cyclone materials for high-temperature flue gas treatment. As governments worldwide intensify efforts to combat air pollution and reduce industrial emissions, stringent regulations have been implemented, significantly impacting the design and operation of cyclone separators.

These regulations typically set limits on particulate matter emissions, often specifying maximum allowable concentrations for different particle sizes. For instance, the European Union's Industrial Emissions Directive (IED) and the United States Environmental Protection Agency's (EPA) National Emission Standards for Hazardous Air Pollutants (NESHAP) both impose strict emission limits on various industrial processes.

To comply with these regulations, industries must ensure that their cyclone separators achieve high collection efficiencies, particularly for fine particles. This requirement directly influences the selection of cyclone materials, as they must not only withstand high temperatures but also maintain their structural integrity and performance over extended periods to consistently meet emission standards.

The choice of materials is further complicated by regulations addressing the potential release of hazardous substances from the cyclone itself. For example, some materials may degrade or emit toxic compounds when exposed to high-temperature flue gases, potentially violating air quality standards. Consequently, materials selection must consider both the ability to withstand harsh operating conditions and the potential for secondary emissions.

Regulatory bodies also often mandate regular inspections and maintenance of air pollution control equipment, including cyclones. This necessitates the use of materials that not only perform well but also facilitate easy inspection and maintenance without compromising the system's integrity or efficiency.

Furthermore, environmental regulations are increasingly focusing on the entire lifecycle of industrial equipment. This trend is pushing manufacturers to consider the environmental impact of cyclone materials from production to disposal. Materials that can be recycled or safely disposed of at the end of their service life are gaining preference, aligning with broader sustainability goals and circular economy principles.

As regulations continue to evolve, there is a growing emphasis on continuous emissions monitoring systems (CEMS). This trend is driving the development of cyclone materials that are compatible with advanced monitoring technologies, ensuring real-time compliance with emission standards and enabling proactive maintenance strategies.

These regulations typically set limits on particulate matter emissions, often specifying maximum allowable concentrations for different particle sizes. For instance, the European Union's Industrial Emissions Directive (IED) and the United States Environmental Protection Agency's (EPA) National Emission Standards for Hazardous Air Pollutants (NESHAP) both impose strict emission limits on various industrial processes.

To comply with these regulations, industries must ensure that their cyclone separators achieve high collection efficiencies, particularly for fine particles. This requirement directly influences the selection of cyclone materials, as they must not only withstand high temperatures but also maintain their structural integrity and performance over extended periods to consistently meet emission standards.

The choice of materials is further complicated by regulations addressing the potential release of hazardous substances from the cyclone itself. For example, some materials may degrade or emit toxic compounds when exposed to high-temperature flue gases, potentially violating air quality standards. Consequently, materials selection must consider both the ability to withstand harsh operating conditions and the potential for secondary emissions.

Regulatory bodies also often mandate regular inspections and maintenance of air pollution control equipment, including cyclones. This necessitates the use of materials that not only perform well but also facilitate easy inspection and maintenance without compromising the system's integrity or efficiency.

Furthermore, environmental regulations are increasingly focusing on the entire lifecycle of industrial equipment. This trend is pushing manufacturers to consider the environmental impact of cyclone materials from production to disposal. Materials that can be recycled or safely disposed of at the end of their service life are gaining preference, aligning with broader sustainability goals and circular economy principles.

As regulations continue to evolve, there is a growing emphasis on continuous emissions monitoring systems (CEMS). This trend is driving the development of cyclone materials that are compatible with advanced monitoring technologies, ensuring real-time compliance with emission standards and enabling proactive maintenance strategies.

Cost-Benefit Analysis of Materials

When selecting cyclone materials for high-temperature flue gas applications, a comprehensive cost-benefit analysis is crucial to ensure optimal performance and economic viability. The initial investment in high-quality materials may be substantial, but it often leads to significant long-term savings through improved durability and reduced maintenance requirements.

Stainless steel alloys, such as 316L and 310S, are popular choices for cyclone construction due to their excellent corrosion resistance and high-temperature strength. While these materials come at a higher upfront cost compared to carbon steel, they offer superior longevity in harsh flue gas environments. The extended service life of stainless steel cyclones can offset the initial expense by reducing the frequency of replacements and minimizing production downtime.

Refractory materials, including ceramic and high-alumina linings, present another cost-effective option for cyclone construction. These materials excel in extreme temperature conditions and provide excellent wear resistance. Although the initial installation costs may be higher, the exceptional durability of refractory linings can result in lower long-term expenses, particularly in applications where abrasive particles are present in the flue gas.

Advanced composite materials, such as fiber-reinforced polymers (FRP), are emerging as innovative solutions for cyclone construction. While their upfront costs can be higher than traditional materials, FRP cyclones offer benefits such as lightweight construction, corrosion resistance, and ease of installation. These factors can lead to reduced transportation and maintenance costs, potentially yielding a favorable return on investment over time.

When evaluating the cost-benefit ratio of different materials, it is essential to consider factors beyond the initial purchase price. Operational efficiency, energy consumption, and maintenance requirements all contribute to the total cost of ownership. For instance, materials with smoother surfaces may improve cyclone efficiency and reduce pressure drop, leading to lower energy costs during operation.

The selection of cyclone materials should also take into account the specific characteristics of the flue gas, such as temperature, acidity, and particulate composition. Matching the material properties to the operating conditions can prevent premature failure and extend the cyclone's lifespan, ultimately reducing long-term costs.

In conclusion, while high-performance materials for cyclones may require a larger initial investment, their superior durability, resistance to corrosion and wear, and potential for improved operational efficiency often result in lower total costs over the cyclone's lifetime. A thorough cost-benefit analysis, considering both immediate expenses and long-term savings, is essential for making informed decisions in cyclone material selection for high-temperature flue gas applications.

Stainless steel alloys, such as 316L and 310S, are popular choices for cyclone construction due to their excellent corrosion resistance and high-temperature strength. While these materials come at a higher upfront cost compared to carbon steel, they offer superior longevity in harsh flue gas environments. The extended service life of stainless steel cyclones can offset the initial expense by reducing the frequency of replacements and minimizing production downtime.

Refractory materials, including ceramic and high-alumina linings, present another cost-effective option for cyclone construction. These materials excel in extreme temperature conditions and provide excellent wear resistance. Although the initial installation costs may be higher, the exceptional durability of refractory linings can result in lower long-term expenses, particularly in applications where abrasive particles are present in the flue gas.

Advanced composite materials, such as fiber-reinforced polymers (FRP), are emerging as innovative solutions for cyclone construction. While their upfront costs can be higher than traditional materials, FRP cyclones offer benefits such as lightweight construction, corrosion resistance, and ease of installation. These factors can lead to reduced transportation and maintenance costs, potentially yielding a favorable return on investment over time.

When evaluating the cost-benefit ratio of different materials, it is essential to consider factors beyond the initial purchase price. Operational efficiency, energy consumption, and maintenance requirements all contribute to the total cost of ownership. For instance, materials with smoother surfaces may improve cyclone efficiency and reduce pressure drop, leading to lower energy costs during operation.

The selection of cyclone materials should also take into account the specific characteristics of the flue gas, such as temperature, acidity, and particulate composition. Matching the material properties to the operating conditions can prevent premature failure and extend the cyclone's lifespan, ultimately reducing long-term costs.

In conclusion, while high-performance materials for cyclones may require a larger initial investment, their superior durability, resistance to corrosion and wear, and potential for improved operational efficiency often result in lower total costs over the cyclone's lifetime. A thorough cost-benefit analysis, considering both immediate expenses and long-term savings, is essential for making informed decisions in cyclone material selection for high-temperature flue gas applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!