How to Strike New Chemical Pathways Using Fluoroantimonic Acid?

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid: Background and Objectives

Fluoroantimonic acid, a superacid composed of a mixture of hydrogen fluoride (HF) and antimony pentafluoride (SbF5), has emerged as a powerful tool in chemical synthesis and catalysis. This compound, with its extraordinary acidity, surpasses the strength of conventional acids by several orders of magnitude, opening up new possibilities in chemical transformations.

The development of fluoroantimonic acid can be traced back to the early 20th century, with significant advancements made in the 1960s and 1970s. Its unique properties stem from the formation of hexafluoroantimonate anions (SbF6-) and protonated solvent species, resulting in an exceptionally strong proton-donating ability.

The primary objective in exploring new chemical pathways using fluoroantimonic acid is to harness its extreme acidity for facilitating reactions that are otherwise challenging or impossible with conventional acids. This includes activating typically unreactive compounds, enabling novel carbon-carbon bond formations, and catalyzing isomerization reactions under milder conditions.

One of the key trends in this field is the application of fluoroantimonic acid in petrochemical processes, particularly in the isomerization of alkanes and the cracking of hydrocarbons. These applications have significant implications for the production of high-octane fuels and valuable chemical intermediates.

Another emerging trend is the use of fluoroantimonic acid in organic synthesis, where it can promote reactions such as Friedel-Crafts alkylations and acylations with unprecedented efficiency. Researchers are also exploring its potential in the activation of small molecules like methane, which could lead to more efficient natural gas utilization.

The extreme reactivity of fluoroantimonic acid presents both opportunities and challenges. While it enables unique transformations, it also necessitates specialized handling techniques and equipment due to its corrosive nature and sensitivity to moisture. This has led to a parallel focus on developing safer handling protocols and containment systems.

Looking ahead, the field is moving towards understanding the fundamental mechanisms of superacid-mediated reactions at the molecular level. This knowledge is crucial for designing more selective and efficient processes. Additionally, there is growing interest in developing supported or immobilized forms of fluoroantimonic acid to enhance its practicality in industrial applications.

As research progresses, the goal is to expand the repertoire of reactions that can be catalyzed by fluoroantimonic acid, potentially revolutionizing certain areas of chemical synthesis and processing. This includes exploring its application in the activation of greenhouse gases, the synthesis of novel materials, and the development of more environmentally friendly chemical processes.

The development of fluoroantimonic acid can be traced back to the early 20th century, with significant advancements made in the 1960s and 1970s. Its unique properties stem from the formation of hexafluoroantimonate anions (SbF6-) and protonated solvent species, resulting in an exceptionally strong proton-donating ability.

The primary objective in exploring new chemical pathways using fluoroantimonic acid is to harness its extreme acidity for facilitating reactions that are otherwise challenging or impossible with conventional acids. This includes activating typically unreactive compounds, enabling novel carbon-carbon bond formations, and catalyzing isomerization reactions under milder conditions.

One of the key trends in this field is the application of fluoroantimonic acid in petrochemical processes, particularly in the isomerization of alkanes and the cracking of hydrocarbons. These applications have significant implications for the production of high-octane fuels and valuable chemical intermediates.

Another emerging trend is the use of fluoroantimonic acid in organic synthesis, where it can promote reactions such as Friedel-Crafts alkylations and acylations with unprecedented efficiency. Researchers are also exploring its potential in the activation of small molecules like methane, which could lead to more efficient natural gas utilization.

The extreme reactivity of fluoroantimonic acid presents both opportunities and challenges. While it enables unique transformations, it also necessitates specialized handling techniques and equipment due to its corrosive nature and sensitivity to moisture. This has led to a parallel focus on developing safer handling protocols and containment systems.

Looking ahead, the field is moving towards understanding the fundamental mechanisms of superacid-mediated reactions at the molecular level. This knowledge is crucial for designing more selective and efficient processes. Additionally, there is growing interest in developing supported or immobilized forms of fluoroantimonic acid to enhance its practicality in industrial applications.

As research progresses, the goal is to expand the repertoire of reactions that can be catalyzed by fluoroantimonic acid, potentially revolutionizing certain areas of chemical synthesis and processing. This includes exploring its application in the activation of greenhouse gases, the synthesis of novel materials, and the development of more environmentally friendly chemical processes.

Market Demand Analysis for Novel Chemical Pathways

The market demand for novel chemical pathways using fluoroantimonic acid is driven by several key factors in the chemical industry. Fluoroantimonic acid, known as the world's strongest superacid, has unique properties that make it valuable for various applications. Its extreme acidity and ability to protonate even weak bases create opportunities for new chemical reactions and processes.

In the petrochemical sector, there is a growing interest in using fluoroantimonic acid for catalytic cracking and isomerization of hydrocarbons. This could lead to more efficient production of high-value fuels and petrochemicals. The pharmaceutical industry is also exploring its potential in synthesizing complex drug molecules, particularly those with challenging structures that are difficult to produce using conventional methods.

The electronics industry shows significant demand for fluoroantimonic acid in the production of advanced materials for semiconductors and display technologies. Its ability to etch and modify surfaces at the nanoscale makes it valuable for creating high-performance electronic components.

In materials science, researchers are investigating the use of fluoroantimonic acid to develop new polymers and composite materials with enhanced properties. This could open up opportunities in aerospace, automotive, and consumer goods industries for lighter, stronger, and more durable materials.

The fine chemicals industry is another area where novel chemical pathways using fluoroantimonic acid could find substantial applications. Its potential to facilitate challenging organic transformations could lead to more efficient and cost-effective production of specialty chemicals and intermediates.

However, the market demand is tempered by several challenges. The extreme corrosiveness and reactivity of fluoroantimonic acid require specialized handling and equipment, which can increase production costs. Safety and environmental concerns also pose significant hurdles to widespread adoption, necessitating the development of robust containment and disposal protocols.

Despite these challenges, the potential benefits of novel chemical pathways using fluoroantimonic acid continue to drive research and development efforts. As new applications are discovered and safety protocols are improved, the market demand is expected to grow, particularly in high-value, specialized chemical production sectors.

In the petrochemical sector, there is a growing interest in using fluoroantimonic acid for catalytic cracking and isomerization of hydrocarbons. This could lead to more efficient production of high-value fuels and petrochemicals. The pharmaceutical industry is also exploring its potential in synthesizing complex drug molecules, particularly those with challenging structures that are difficult to produce using conventional methods.

The electronics industry shows significant demand for fluoroantimonic acid in the production of advanced materials for semiconductors and display technologies. Its ability to etch and modify surfaces at the nanoscale makes it valuable for creating high-performance electronic components.

In materials science, researchers are investigating the use of fluoroantimonic acid to develop new polymers and composite materials with enhanced properties. This could open up opportunities in aerospace, automotive, and consumer goods industries for lighter, stronger, and more durable materials.

The fine chemicals industry is another area where novel chemical pathways using fluoroantimonic acid could find substantial applications. Its potential to facilitate challenging organic transformations could lead to more efficient and cost-effective production of specialty chemicals and intermediates.

However, the market demand is tempered by several challenges. The extreme corrosiveness and reactivity of fluoroantimonic acid require specialized handling and equipment, which can increase production costs. Safety and environmental concerns also pose significant hurdles to widespread adoption, necessitating the development of robust containment and disposal protocols.

Despite these challenges, the potential benefits of novel chemical pathways using fluoroantimonic acid continue to drive research and development efforts. As new applications are discovered and safety protocols are improved, the market demand is expected to grow, particularly in high-value, specialized chemical production sectors.

Current State and Challenges in Superacid Chemistry

Superacid chemistry has witnessed significant advancements in recent years, with fluoroantimonic acid (HSbF6) emerging as one of the most potent superacids known to date. The current state of superacid research is characterized by intense exploration of novel applications and the development of more stable and efficient superacid systems.

One of the primary challenges in superacid chemistry is the extreme reactivity of these compounds, which makes handling and storage difficult. Researchers are actively working on developing containment systems and protocols to safely manipulate superacids in laboratory and industrial settings. Additionally, the corrosive nature of superacids poses significant material compatibility issues, necessitating the development of specialized equipment and reaction vessels.

The synthesis and characterization of new superacid systems remain at the forefront of current research. Scientists are exploring combinations of strong Lewis acids and Brønsted acids to create even more powerful superacid mixtures. These efforts aim to push the boundaries of acidity and unlock new chemical transformations that were previously unattainable.

In the realm of catalysis, superacids have shown tremendous potential. However, challenges persist in controlling selectivity and minimizing side reactions in complex organic transformations. Researchers are investigating ways to fine-tune the acidity and reactivity of superacid catalysts to achieve higher yields and better stereoselectivity in various chemical processes.

The application of superacids in materials science is another area of active research. Scientists are exploring the use of superacids in the synthesis of novel materials, such as advanced polymers and nanostructures. However, challenges remain in controlling the reaction conditions and preventing degradation of sensitive materials under extreme acidic conditions.

Environmental concerns associated with superacid chemistry pose significant challenges. The disposal and neutralization of superacids require careful consideration and specialized techniques to minimize environmental impact. Researchers are working on developing more environmentally friendly superacid systems and improved methods for their neutralization and recycling.

Computational studies have become increasingly important in understanding the behavior of superacids at the molecular level. However, accurately modeling these highly reactive systems remains challenging due to the complex electronic structures and dynamic nature of superacid-substrate interactions. Advancements in computational methods and increased computing power are gradually overcoming these limitations, providing valuable insights into superacid chemistry.

One of the primary challenges in superacid chemistry is the extreme reactivity of these compounds, which makes handling and storage difficult. Researchers are actively working on developing containment systems and protocols to safely manipulate superacids in laboratory and industrial settings. Additionally, the corrosive nature of superacids poses significant material compatibility issues, necessitating the development of specialized equipment and reaction vessels.

The synthesis and characterization of new superacid systems remain at the forefront of current research. Scientists are exploring combinations of strong Lewis acids and Brønsted acids to create even more powerful superacid mixtures. These efforts aim to push the boundaries of acidity and unlock new chemical transformations that were previously unattainable.

In the realm of catalysis, superacids have shown tremendous potential. However, challenges persist in controlling selectivity and minimizing side reactions in complex organic transformations. Researchers are investigating ways to fine-tune the acidity and reactivity of superacid catalysts to achieve higher yields and better stereoselectivity in various chemical processes.

The application of superacids in materials science is another area of active research. Scientists are exploring the use of superacids in the synthesis of novel materials, such as advanced polymers and nanostructures. However, challenges remain in controlling the reaction conditions and preventing degradation of sensitive materials under extreme acidic conditions.

Environmental concerns associated with superacid chemistry pose significant challenges. The disposal and neutralization of superacids require careful consideration and specialized techniques to minimize environmental impact. Researchers are working on developing more environmentally friendly superacid systems and improved methods for their neutralization and recycling.

Computational studies have become increasingly important in understanding the behavior of superacids at the molecular level. However, accurately modeling these highly reactive systems remains challenging due to the complex electronic structures and dynamic nature of superacid-substrate interactions. Advancements in computational methods and increased computing power are gradually overcoming these limitations, providing valuable insights into superacid chemistry.

Existing Methodologies for Fluoroantimonic Acid Utilization

01 Synthesis and production of fluoroantimonic acid

Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.- Synthesis and production of fluoroantimonic acid: Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.

- Applications in organic synthesis and catalysis: Fluoroantimonic acid is utilized as a powerful superacid catalyst in various organic synthesis reactions. It facilitates alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are challenging or impossible with conventional acid catalysts, making it valuable in the production of specialty chemicals and advanced materials.

- Use in materials science and surface treatment: Fluoroantimonic acid finds applications in materials science, particularly in surface treatment and modification of various substrates. It is used for etching, cleaning, and activating surfaces of metals, semiconductors, and other materials. The acid's unique properties allow for precise control of surface characteristics, enhancing material performance in specific applications.

- Safety and handling considerations: Due to its extreme corrosiveness and reactivity, handling fluoroantimonic acid requires stringent safety measures. Specialized equipment, containment systems, and personal protective gear are essential when working with this superacid. Proper storage, transportation, and disposal protocols have been developed to minimize risks associated with its use in industrial and research settings.

- Analytical and characterization techniques: Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its interactions with other substances. These methods include spectroscopic analysis, electrochemical measurements, and computational modeling. Such techniques are crucial for understanding the acid's behavior, optimizing its use in different applications, and developing new superacid systems.

02 Applications in catalysis and chemical reactions

Fluoroantimonic acid is utilized as a powerful superacid catalyst in various chemical reactions. It is particularly effective in promoting alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acid catalysts.Expand Specific Solutions03 Use in materials science and surface treatments

Fluoroantimonic acid finds applications in materials science, particularly in surface treatments and modifications. It can be used to etch or modify surfaces of various materials, including metals and semiconductors. The acid's strong protonating ability allows for unique surface chemistry and the creation of specialized coatings or films.Expand Specific Solutions04 Safety and handling considerations

Due to its extreme corrosiveness and reactivity, fluoroantimonic acid requires specialized handling and storage procedures. Safety measures include the use of specialized containment materials, personal protective equipment, and strict protocols for handling and disposal. Research has been conducted to develop safer handling methods and to mitigate the risks associated with its use.Expand Specific Solutions05 Analytical and characterization techniques

Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its reactions. These include spectroscopic methods, electrochemical analyses, and computational modeling. Such techniques are crucial for understanding the acid's properties, reaction mechanisms, and potential applications in different fields of chemistry and materials science.Expand Specific Solutions

Key Players in Superacid Research and Development

The development of new chemical pathways using fluoroantimonic acid is in an early stage, with significant potential for growth. The market size is relatively small but expanding as researchers explore novel applications in organic synthesis and catalysis. Technologically, it's still evolving, with varying levels of maturity across different institutions. Universities like The University of Texas System, Cornell University, and The University of California are at the forefront of academic research. Companies such as Mitsubishi Gas Chemical Co., Inc. and 3M Innovative Properties Co. are advancing industrial applications. The competitive landscape is diverse, with academic institutions, chemical companies, and research organizations collaborating and competing to unlock the full potential of this powerful superacid in creating new chemical pathways.

Mitsubishi Gas Chemical Co., Inc.

Technical Solution: Mitsubishi Gas Chemical has developed a groundbreaking approach to using fluoroantimonic acid in chemical synthesis. Their method involves a novel containment system that allows for the safe handling and precise application of fluoroantimonic acid in various reactions. This system enables the company to explore new chemical pathways, particularly in the synthesis of complex organic compounds. They have also developed a unique neutralization process that allows for the safe disposal of the acid after use, addressing one of the major challenges in working with such a potent substance.

Strengths: Advanced safety measures; Potential for novel compound synthesis. Weaknesses: High cost of specialized equipment; Limited scalability for large-scale production.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN INDUSTRIES has pioneered a method for using fluoroantimonic acid in the production of advanced fluoropolymers. Their approach involves using the superacidic properties of fluoroantimonic acid to catalyze the polymerization of fluorine-containing monomers under carefully controlled conditions. This allows for the creation of new types of fluoropolymers with unique properties, such as enhanced chemical resistance and thermal stability. DAIKIN has also developed a specialized reactor design that can withstand the extreme corrosiveness of fluoroantimonic acid, enabling safer and more efficient production processes.

Strengths: Enables production of novel fluoropolymers; Highly efficient catalytic process. Weaknesses: High energy requirements; Potential environmental concerns due to fluorine-containing products.

Innovative Approaches in Fluoroantimonic Acid Chemistry

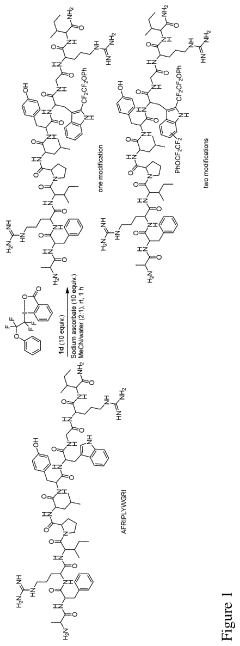

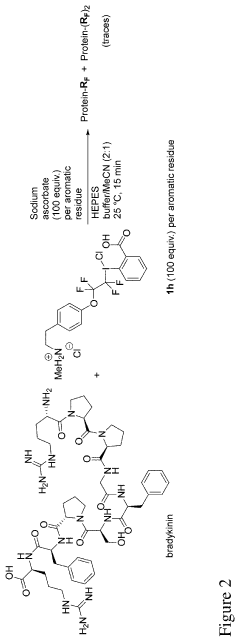

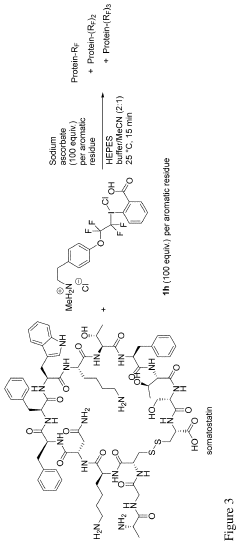

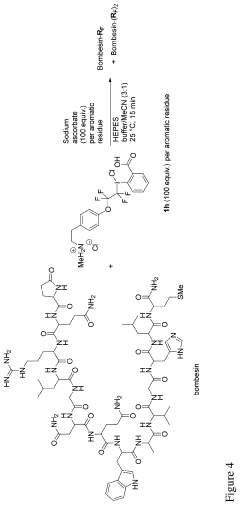

A method for functionalization of an aromatic amino acid or a nucleobase

PatentActiveUS20220177514A1

Innovation

- A transition metal-free method using hypervalent iodine fluoroalkyl reagents with reductants to rapidly functionalize aromatic amino acids and nucleobases, forming fluoroalkylating radicals that selectively react with target residues, enabling fast and versatile bioconjugation.

Bismuth ferrite nanoparticles in functional nanochannels: a novel approach to enhance 4-aminophenol detection

PatentPendingIN202411014908A

Innovation

- The use of bismuth ferrite nanoparticles in functional nanochannels, specifically conical nanochannels modified with poly(allylamine hydrochloride) for immobilization, enhances the electrochemical detection of 4-aminophenol through adsorption mechanisms, leveraging cyclic voltammetry and differential pulse voltammetry for improved sensitivity.

Safety and Environmental Considerations

Fluoroantimonic acid, being one of the strongest known superacids, presents significant safety and environmental challenges that must be carefully addressed when considering its use in striking new chemical pathways. The extreme corrosiveness and reactivity of this compound necessitate stringent safety protocols and specialized handling equipment.

Personal protective equipment (PPE) is of paramount importance when working with fluoroantimonic acid. This includes chemical-resistant suits, gloves, and face shields, as well as respiratory protection to prevent inhalation of toxic fumes. All equipment must be fluorine-resistant, as standard materials may degrade rapidly upon contact.

Containment and storage of fluoroantimonic acid require specially designed vessels made from materials such as PTFE (Teflon) or certain alloys of monel. Standard glass or metal containers are unsuitable due to the acid's extreme reactivity. Proper ventilation systems equipped with scrubbers are essential to manage any potential fumes or vapors.

Environmental considerations are equally critical. Any release of fluoroantimonic acid into the environment could have severe consequences. It can react violently with water, producing highly toxic and corrosive hydrogen fluoride gas. Soil and water contamination must be prevented at all costs, as the acid can cause long-lasting ecological damage.

Waste management and disposal of fluoroantimonic acid and its byproducts require specialized procedures. Neutralization must be carried out carefully, often involving dilution with large quantities of cold water or ice, followed by treatment with appropriate bases. All waste must be treated as hazardous and disposed of according to strict regulatory guidelines.

Emergency response plans must be in place to deal with potential spills or accidents. This includes having appropriate spill kits, neutralizing agents, and trained personnel ready to respond immediately. Regular safety drills and training sessions should be conducted to ensure all staff are prepared for potential incidents.

Regulatory compliance is another crucial aspect. The use of fluoroantimonic acid is subject to strict regulations in many jurisdictions due to its hazardous nature. Proper documentation, permits, and adherence to safety standards are essential to maintain legal and ethical operations.

Personal protective equipment (PPE) is of paramount importance when working with fluoroantimonic acid. This includes chemical-resistant suits, gloves, and face shields, as well as respiratory protection to prevent inhalation of toxic fumes. All equipment must be fluorine-resistant, as standard materials may degrade rapidly upon contact.

Containment and storage of fluoroantimonic acid require specially designed vessels made from materials such as PTFE (Teflon) or certain alloys of monel. Standard glass or metal containers are unsuitable due to the acid's extreme reactivity. Proper ventilation systems equipped with scrubbers are essential to manage any potential fumes or vapors.

Environmental considerations are equally critical. Any release of fluoroantimonic acid into the environment could have severe consequences. It can react violently with water, producing highly toxic and corrosive hydrogen fluoride gas. Soil and water contamination must be prevented at all costs, as the acid can cause long-lasting ecological damage.

Waste management and disposal of fluoroantimonic acid and its byproducts require specialized procedures. Neutralization must be carried out carefully, often involving dilution with large quantities of cold water or ice, followed by treatment with appropriate bases. All waste must be treated as hazardous and disposed of according to strict regulatory guidelines.

Emergency response plans must be in place to deal with potential spills or accidents. This includes having appropriate spill kits, neutralizing agents, and trained personnel ready to respond immediately. Regular safety drills and training sessions should be conducted to ensure all staff are prepared for potential incidents.

Regulatory compliance is another crucial aspect. The use of fluoroantimonic acid is subject to strict regulations in many jurisdictions due to its hazardous nature. Proper documentation, permits, and adherence to safety standards are essential to maintain legal and ethical operations.

Scalability and Industrial Applications

Fluoroantimonic acid's potential for industrial applications and scalability is a critical aspect of its development as a superacid catalyst. The extreme reactivity of this compound presents both opportunities and challenges for large-scale implementation. In terms of scalability, the production of fluoroantimonic acid requires careful handling and specialized equipment due to its corrosive nature and sensitivity to moisture. Current industrial processes for its synthesis involve the reaction of hydrogen fluoride with antimony pentafluoride, which must be conducted under strictly controlled conditions.

The scalability of fluoroantimonic acid-based processes is largely dependent on the development of suitable containment materials and reaction vessels. Traditional materials such as glass and most metals are rapidly degraded by this superacid, necessitating the use of specialized fluoropolymers or exotic alloys. This requirement significantly impacts the cost and feasibility of scaling up reactions involving fluoroantimonic acid. However, recent advancements in materials science have led to the creation of more resistant composites, potentially enabling larger-scale applications.

Industrial applications of fluoroantimonic acid are primarily focused on its use as a catalyst in various organic transformations. Its extreme acidity allows for the activation of typically unreactive compounds, opening new synthetic pathways in the production of pharmaceuticals, agrochemicals, and specialty chemicals. The petroleum industry has shown particular interest in using fluoroantimonic acid for isomerization reactions in the refining process, potentially improving the octane rating of gasoline and the quality of other hydrocarbon products.

The scalability of fluoroantimonic acid-catalyzed reactions is also influenced by the need for precise control over reaction conditions. The high reactivity of the acid requires careful temperature management and precise reagent addition to prevent runaway reactions or unwanted side products. This necessitates the development of advanced process control systems and reactor designs capable of maintaining stable conditions at larger scales.

Environmental and safety considerations play a crucial role in the industrial adoption of fluoroantimonic acid-based processes. The acid's extreme corrosivity and potential for generating toxic fumes necessitate robust containment and handling protocols. Scaling up these processes requires significant investment in safety infrastructure, including specialized ventilation systems, neutralization facilities, and emergency response capabilities. These factors contribute to the overall cost and complexity of implementing fluoroantimonic acid technology on an industrial scale.

Despite these challenges, the unique reactivity of fluoroantimonic acid continues to drive research into its potential industrial applications. Efforts are ongoing to develop more efficient and safer methods for handling and utilizing this superacid at scale. As new chemical pathways are discovered and optimized, the industrial relevance of fluoroantimonic acid is likely to grow, particularly in sectors requiring highly selective and powerful catalysts for complex transformations.

The scalability of fluoroantimonic acid-based processes is largely dependent on the development of suitable containment materials and reaction vessels. Traditional materials such as glass and most metals are rapidly degraded by this superacid, necessitating the use of specialized fluoropolymers or exotic alloys. This requirement significantly impacts the cost and feasibility of scaling up reactions involving fluoroantimonic acid. However, recent advancements in materials science have led to the creation of more resistant composites, potentially enabling larger-scale applications.

Industrial applications of fluoroantimonic acid are primarily focused on its use as a catalyst in various organic transformations. Its extreme acidity allows for the activation of typically unreactive compounds, opening new synthetic pathways in the production of pharmaceuticals, agrochemicals, and specialty chemicals. The petroleum industry has shown particular interest in using fluoroantimonic acid for isomerization reactions in the refining process, potentially improving the octane rating of gasoline and the quality of other hydrocarbon products.

The scalability of fluoroantimonic acid-catalyzed reactions is also influenced by the need for precise control over reaction conditions. The high reactivity of the acid requires careful temperature management and precise reagent addition to prevent runaway reactions or unwanted side products. This necessitates the development of advanced process control systems and reactor designs capable of maintaining stable conditions at larger scales.

Environmental and safety considerations play a crucial role in the industrial adoption of fluoroantimonic acid-based processes. The acid's extreme corrosivity and potential for generating toxic fumes necessitate robust containment and handling protocols. Scaling up these processes requires significant investment in safety infrastructure, including specialized ventilation systems, neutralization facilities, and emergency response capabilities. These factors contribute to the overall cost and complexity of implementing fluoroantimonic acid technology on an industrial scale.

Despite these challenges, the unique reactivity of fluoroantimonic acid continues to drive research into its potential industrial applications. Efforts are ongoing to develop more efficient and safer methods for handling and utilizing this superacid at scale. As new chemical pathways are discovered and optimized, the industrial relevance of fluoroantimonic acid is likely to grow, particularly in sectors requiring highly selective and powerful catalysts for complex transformations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!