How to Use Hydrochloric Acid Safely in Chemical Labs?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Safety Background and Objectives

Hydrochloric acid (HCl) has been a cornerstone in chemical laboratories for centuries, playing a crucial role in various analytical and synthetic processes. Its widespread use stems from its unique properties as a strong mineral acid, capable of dissolving many metals and minerals. The history of HCl in laboratories dates back to the alchemists of the Middle Ages, who referred to it as "spirit of salt." Since then, its applications have expanded significantly, encompassing fields such as materials science, pharmaceuticals, and environmental analysis.

Despite its utility, the corrosive nature of HCl presents significant safety challenges in laboratory settings. Improper handling can lead to severe chemical burns, respiratory issues, and equipment damage. The primary objective of this technical research report is to comprehensively explore safe handling practices for hydrochloric acid in chemical laboratories, addressing both current standards and emerging technologies that enhance safety protocols.

The evolution of safety measures for HCl usage has been driven by a combination of regulatory requirements, technological advancements, and a growing emphasis on workplace safety. Early safety measures were often rudimentary, relying primarily on personal protective equipment (PPE) and basic ventilation systems. However, as understanding of chemical hazards improved, more sophisticated approaches emerged, including advanced fume hood designs, spill containment systems, and automated handling equipment.

Current safety objectives focus on minimizing exposure risks through engineering controls, administrative procedures, and enhanced PPE. Key areas of concern include proper storage to prevent container degradation, efficient ventilation systems to manage vapors, and robust emergency response protocols for spills or accidental exposures. Additionally, there is a growing emphasis on training and education to ensure all laboratory personnel are well-versed in HCl handling procedures.

Looking forward, the trajectory of HCl safety in laboratories is likely to be influenced by several factors. Emerging technologies, such as smart sensors for real-time monitoring of acid vapors and advanced materials for more resistant protective gear, promise to further enhance safety measures. There is also a trend towards minimizing the use of concentrated HCl through dilution systems and exploring less hazardous alternatives where possible.

This report aims to provide a comprehensive overview of the current state of HCl safety in chemical laboratories, analyze the challenges faced, and explore innovative solutions on the horizon. By examining both historical context and future trends, we seek to offer insights that will contribute to the ongoing improvement of safety practices in handling this essential yet hazardous chemical.

Despite its utility, the corrosive nature of HCl presents significant safety challenges in laboratory settings. Improper handling can lead to severe chemical burns, respiratory issues, and equipment damage. The primary objective of this technical research report is to comprehensively explore safe handling practices for hydrochloric acid in chemical laboratories, addressing both current standards and emerging technologies that enhance safety protocols.

The evolution of safety measures for HCl usage has been driven by a combination of regulatory requirements, technological advancements, and a growing emphasis on workplace safety. Early safety measures were often rudimentary, relying primarily on personal protective equipment (PPE) and basic ventilation systems. However, as understanding of chemical hazards improved, more sophisticated approaches emerged, including advanced fume hood designs, spill containment systems, and automated handling equipment.

Current safety objectives focus on minimizing exposure risks through engineering controls, administrative procedures, and enhanced PPE. Key areas of concern include proper storage to prevent container degradation, efficient ventilation systems to manage vapors, and robust emergency response protocols for spills or accidental exposures. Additionally, there is a growing emphasis on training and education to ensure all laboratory personnel are well-versed in HCl handling procedures.

Looking forward, the trajectory of HCl safety in laboratories is likely to be influenced by several factors. Emerging technologies, such as smart sensors for real-time monitoring of acid vapors and advanced materials for more resistant protective gear, promise to further enhance safety measures. There is also a trend towards minimizing the use of concentrated HCl through dilution systems and exploring less hazardous alternatives where possible.

This report aims to provide a comprehensive overview of the current state of HCl safety in chemical laboratories, analyze the challenges faced, and explore innovative solutions on the horizon. By examining both historical context and future trends, we seek to offer insights that will contribute to the ongoing improvement of safety practices in handling this essential yet hazardous chemical.

Lab Demand for HCl Usage

The demand for hydrochloric acid (HCl) in chemical laboratories is driven by its versatile applications across various scientific disciplines. As a strong mineral acid, HCl plays a crucial role in numerous analytical and synthetic processes, making it an indispensable reagent in modern laboratory settings.

In analytical chemistry, HCl is widely used for pH adjustments, sample preparation, and as a component in various analytical methods. Its ability to dissolve many metals and metal oxides makes it valuable for sample digestion in elemental analysis. Furthermore, HCl is essential in titrations, particularly in acid-base chemistry, where it serves as a standard solution for determining the concentration of bases.

Organic chemistry laboratories rely heavily on HCl for various reactions and processes. It is used in the synthesis of organic compounds, such as in the preparation of acid chlorides and in hydrolysis reactions. HCl also finds applications in the purification of organic compounds through acid-base extractions and in the formation of hydrochloride salts of organic bases.

In biochemistry and molecular biology labs, HCl is utilized in protein studies, including protein denaturation and hydrolysis. It is also employed in the preparation of buffers and in the adjustment of pH for optimal enzyme activity. Additionally, HCl plays a role in nucleic acid extraction protocols and in the maintenance of certain cell culture media.

The demand for HCl in materials science and engineering laboratories stems from its use in etching and cleaning processes. It is particularly valuable in the preparation and treatment of metal surfaces, as well as in the fabrication of electronic components and semiconductors.

Environmental science laboratories require HCl for various analytical procedures, including the determination of water quality parameters and the analysis of soil samples. It is also used in the preparation of environmental samples for further analysis, such as in the extraction of heavy metals from sediments.

The pharmaceutical industry, which often conducts research in laboratory settings, uses HCl in drug synthesis, quality control, and stability testing. It is crucial in the preparation of certain drug formulations and in the analysis of pharmaceutical compounds.

Given its widespread use, the demand for HCl in chemical laboratories is substantial and consistent. However, this demand is tempered by safety considerations and regulatory requirements, which necessitate proper handling, storage, and disposal protocols. As a result, many laboratories are exploring safer alternatives or developing methods that minimize HCl usage without compromising research quality.

In analytical chemistry, HCl is widely used for pH adjustments, sample preparation, and as a component in various analytical methods. Its ability to dissolve many metals and metal oxides makes it valuable for sample digestion in elemental analysis. Furthermore, HCl is essential in titrations, particularly in acid-base chemistry, where it serves as a standard solution for determining the concentration of bases.

Organic chemistry laboratories rely heavily on HCl for various reactions and processes. It is used in the synthesis of organic compounds, such as in the preparation of acid chlorides and in hydrolysis reactions. HCl also finds applications in the purification of organic compounds through acid-base extractions and in the formation of hydrochloride salts of organic bases.

In biochemistry and molecular biology labs, HCl is utilized in protein studies, including protein denaturation and hydrolysis. It is also employed in the preparation of buffers and in the adjustment of pH for optimal enzyme activity. Additionally, HCl plays a role in nucleic acid extraction protocols and in the maintenance of certain cell culture media.

The demand for HCl in materials science and engineering laboratories stems from its use in etching and cleaning processes. It is particularly valuable in the preparation and treatment of metal surfaces, as well as in the fabrication of electronic components and semiconductors.

Environmental science laboratories require HCl for various analytical procedures, including the determination of water quality parameters and the analysis of soil samples. It is also used in the preparation of environmental samples for further analysis, such as in the extraction of heavy metals from sediments.

The pharmaceutical industry, which often conducts research in laboratory settings, uses HCl in drug synthesis, quality control, and stability testing. It is crucial in the preparation of certain drug formulations and in the analysis of pharmaceutical compounds.

Given its widespread use, the demand for HCl in chemical laboratories is substantial and consistent. However, this demand is tempered by safety considerations and regulatory requirements, which necessitate proper handling, storage, and disposal protocols. As a result, many laboratories are exploring safer alternatives or developing methods that minimize HCl usage without compromising research quality.

HCl Handling Challenges

Handling hydrochloric acid (HCl) in chemical laboratories presents several significant challenges due to its corrosive and hazardous nature. One of the primary concerns is the risk of chemical burns and tissue damage upon contact with skin or eyes. Even brief exposure can cause severe irritation, while prolonged contact may result in permanent injury. Inhalation of HCl vapors poses another critical challenge, as it can lead to respiratory distress, coughing, and potential lung damage.

The storage and transportation of HCl require careful consideration. The acid's corrosive properties necessitate the use of specialized containers and handling equipment resistant to chemical degradation. Improper storage can lead to container failure, resulting in dangerous spills and potential environmental contamination. Additionally, the risk of accidental mixing with incompatible substances during storage or use can lead to violent reactions or the release of toxic gases.

Proper disposal of HCl and its waste products presents another significant challenge. Neutralization and dilution procedures must be carefully followed to ensure safe disposal without harming the environment or wastewater treatment systems. The acid's ability to react with various materials also complicates cleanup procedures in case of spills or accidents.

The concentration of HCl used in laboratories varies widely, ranging from dilute solutions to highly concentrated forms. Each concentration level presents unique handling challenges, requiring different safety protocols and personal protective equipment (PPE). Ensuring that laboratory personnel are adequately trained to handle various concentrations safely is an ongoing challenge for many institutions.

Temperature control during HCl handling is crucial, as the acid's volatility increases with temperature. This can lead to increased vapor emissions and heightened risk of exposure. Maintaining proper ventilation and temperature control in storage and work areas is essential but can be challenging in diverse laboratory environments.

The potential for HCl to react with metals, releasing hydrogen gas, presents an additional safety concern. This reaction can create explosive conditions if hydrogen accumulates in confined spaces. Preventing such accumulations requires careful attention to ventilation and the selection of appropriate materials for storage and handling equipment.

Lastly, the long-term health effects of chronic low-level exposure to HCl vapors pose a challenge in ensuring the safety of laboratory personnel. Implementing effective monitoring systems and maintaining stringent safety protocols over extended periods are essential but can be difficult to consistently enforce in busy laboratory settings.

The storage and transportation of HCl require careful consideration. The acid's corrosive properties necessitate the use of specialized containers and handling equipment resistant to chemical degradation. Improper storage can lead to container failure, resulting in dangerous spills and potential environmental contamination. Additionally, the risk of accidental mixing with incompatible substances during storage or use can lead to violent reactions or the release of toxic gases.

Proper disposal of HCl and its waste products presents another significant challenge. Neutralization and dilution procedures must be carefully followed to ensure safe disposal without harming the environment or wastewater treatment systems. The acid's ability to react with various materials also complicates cleanup procedures in case of spills or accidents.

The concentration of HCl used in laboratories varies widely, ranging from dilute solutions to highly concentrated forms. Each concentration level presents unique handling challenges, requiring different safety protocols and personal protective equipment (PPE). Ensuring that laboratory personnel are adequately trained to handle various concentrations safely is an ongoing challenge for many institutions.

Temperature control during HCl handling is crucial, as the acid's volatility increases with temperature. This can lead to increased vapor emissions and heightened risk of exposure. Maintaining proper ventilation and temperature control in storage and work areas is essential but can be challenging in diverse laboratory environments.

The potential for HCl to react with metals, releasing hydrogen gas, presents an additional safety concern. This reaction can create explosive conditions if hydrogen accumulates in confined spaces. Preventing such accumulations requires careful attention to ventilation and the selection of appropriate materials for storage and handling equipment.

Lastly, the long-term health effects of chronic low-level exposure to HCl vapors pose a challenge in ensuring the safety of laboratory personnel. Implementing effective monitoring systems and maintaining stringent safety protocols over extended periods are essential but can be difficult to consistently enforce in busy laboratory settings.

Current HCl Safety Practices

01 Personal protective equipment for handling hydrochloric acid

Proper personal protective equipment (PPE) is crucial when handling hydrochloric acid. This includes acid-resistant gloves, goggles or face shields, and protective clothing. Specialized safety equipment such as acid-resistant suits and respiratory protection may be necessary for certain applications or in case of potential exposure to acid fumes.- Personal protective equipment for handling hydrochloric acid: Proper personal protective equipment (PPE) is crucial when handling hydrochloric acid. This includes acid-resistant gloves, goggles or face shields, and protective clothing. Respiratory protection may also be necessary in certain situations. Using appropriate PPE helps prevent skin contact, inhalation, and eye exposure to the corrosive acid.

- Storage and containment systems for hydrochloric acid: Safe storage of hydrochloric acid requires specialized containment systems. These may include corrosion-resistant tanks, secondary containment measures, and proper ventilation. Implementing appropriate storage solutions helps prevent leaks, spills, and potential chemical reactions, thereby reducing the risk of accidents and environmental contamination.

- Neutralization and disposal methods for hydrochloric acid: Proper neutralization and disposal of hydrochloric acid are essential for safety and environmental protection. This may involve using alkaline substances to neutralize the acid before disposal, or implementing specialized treatment processes. Correct disposal methods help prevent environmental contamination and ensure compliance with regulations.

- Emergency response and spill management: Effective emergency response and spill management procedures are crucial for hydrochloric acid safety. This includes having readily available safety showers, eyewash stations, and spill containment kits. Training personnel in proper emergency response techniques and implementing clear protocols for handling acid spills can minimize the potential for injuries and environmental damage.

- Monitoring and detection systems for hydrochloric acid: Implementing monitoring and detection systems can enhance safety when working with hydrochloric acid. This may include pH sensors, gas detectors, and automated alarm systems. These technologies help identify leaks, spills, or dangerous vapor concentrations quickly, allowing for prompt corrective actions and reducing the risk of exposure to personnel.

02 Storage and containment of hydrochloric acid

Safe storage of hydrochloric acid involves using corrosion-resistant containers and storage systems. This includes specialized tanks, piping, and secondary containment measures to prevent leaks and spills. Proper labeling and segregation from incompatible materials are essential for safe storage practices.Expand Specific Solutions03 Neutralization and disposal methods

Proper neutralization and disposal of hydrochloric acid are critical for safety and environmental protection. This may involve using alkaline substances to neutralize the acid before disposal or implementing specialized waste treatment processes. Safe disposal methods must comply with local regulations and environmental standards.Expand Specific Solutions04 Emergency response and first aid procedures

Establishing emergency response protocols and first aid procedures is essential for handling hydrochloric acid incidents. This includes having readily available safety showers, eyewash stations, and spill control equipment. Training personnel in proper emergency response techniques and providing immediate medical attention in case of exposure are crucial aspects of acid safety management.Expand Specific Solutions05 Ventilation and fume control systems

Proper ventilation and fume control systems are necessary when working with hydrochloric acid to prevent the accumulation of harmful vapors. This may include the use of fume hoods, local exhaust ventilation, and air scrubbing systems to remove acid fumes from the work environment and maintain safe air quality.Expand Specific Solutions

Key HCl Suppliers and Equipment Manufacturers

The safe use of hydrochloric acid in chemical labs is a mature field with established protocols and technologies. The market for lab safety equipment and chemicals is substantial, driven by stringent regulations and increasing awareness of workplace safety. Companies like Fluid Energy Group Ltd., Covestro Deutschland AG, and Praxair Technology, Inc. are key players in developing safer handling solutions for hydrochloric acid. The industry is in a growth phase, with ongoing innovations in containment systems, personal protective equipment, and neutralization techniques. Emerging technologies from firms such as Annihilare Medical Systems, Inc. and Enlighten Innovations, Inc. are focusing on improving safety measures and reducing environmental impact. The global market for lab safety products continues to expand, driven by the growing emphasis on research and development across various sectors.

Synthon BV

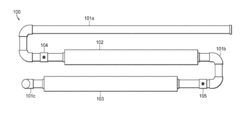

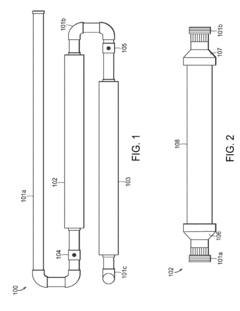

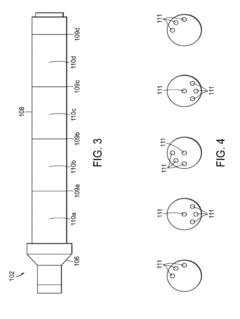

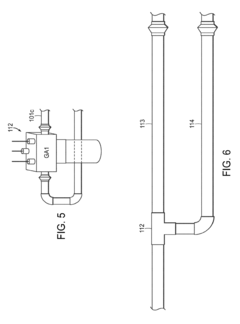

Technical Solution: Synthon BV has developed a comprehensive safety protocol for handling hydrochloric acid in pharmaceutical research laboratories. Their approach includes the implementation of a centralized acid distribution system that pipes diluted hydrochloric acid directly to workstations, reducing the need for manual handling and transport[13]. Synthon has also designed a series of fail-safe valves and emergency shut-off mechanisms throughout the distribution system to quickly contain potential leaks. The company has implemented a state-of-the-art air quality monitoring system that continuously measures acid vapor levels and adjusts ventilation accordingly[14]. Additionally, Synthon has developed a specialized training program that incorporates both theoretical knowledge and practical skills assessment, ensuring all laboratory personnel are proficient in acid handling procedures and emergency response protocols[15].

Strengths: Centralized distribution system, advanced monitoring and containment measures, comprehensive training program. Weaknesses: Potential limitations in flexibility for small-scale or varied acid concentration needs, high initial infrastructure costs.

Covestro Deutschland AG

Technical Solution: Covestro Deutschland AG has implemented a multi-faceted approach to ensure the safe use of hydrochloric acid in chemical laboratories. Their strategy includes the development of a proprietary acid-resistant polymer coating for laboratory surfaces and equipment, significantly reducing the risk of corrosion and contamination[10]. Covestro has also designed an intelligent acid dilution system that automatically prepares solutions to the desired concentration, minimizing human exposure during the dilution process[11]. The company has implemented a comprehensive waste management system that includes on-site neutralization facilities and a closed-loop recycling process for recovering and purifying used hydrochloric acid[12]. Furthermore, Covestro has developed an augmented reality (AR) system for laboratory safety inspections, allowing for remote expert guidance and real-time hazard identification during acid handling procedures.

Strengths: Innovative material solutions, automated dilution processes, and advanced waste management. Weaknesses: Potential high costs associated with implementing proprietary technologies and maintaining specialized systems.

Innovative HCl Handling Technologies

Synthetic acid and associated methods

PatentActiveAU2021200047A1

Innovation

- A synthetic acid, hydrogen glycine, is created by mixing glycine with hydrogen chloride gas, offering a safer, non-corrosive, and environmentally friendly alternative for various applications, including surface cleaning, well fracturing, and pH adjustment, with a pH level similar to hydrochloric acid but without fuming or significant corrosion.

Mixing device

PatentActiveUS20180147548A1

Innovation

- A mixing device that produces fluidic vortices within a chamber with strategically placed apertures to stabilize HOCl, allowing for its production without electrolysis or chlorine gas, and using a weaker acid like acetic acid to control pH and proton concentration, enabling stable storage for several months.

Regulatory Framework for HCl in Labs

The regulatory framework for hydrochloric acid (HCl) in laboratories is a critical aspect of ensuring safe handling and usage of this corrosive substance. Governments and regulatory bodies worldwide have established comprehensive guidelines and standards to minimize risks associated with HCl exposure and accidents.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a pivotal role in regulating HCl use in laboratories. OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandates proper labeling, safety data sheets, and employee training for hazardous chemicals, including HCl. Additionally, the OSHA Laboratory Standard (29 CFR 1910.1450) outlines specific requirements for chemical hygiene plans and exposure controls in laboratory settings.

The Environmental Protection Agency (EPA) also contributes to the regulatory framework through the Resource Conservation and Recovery Act (RCRA), which governs the disposal of hazardous waste, including spent HCl solutions. Laboratories must adhere to strict protocols for waste management and disposal to comply with EPA regulations.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard communication. Many countries have adopted GHS principles, ensuring consistency in the classification and labeling of HCl across borders.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation and the Classification, Labelling, and Packaging (CLP) regulation form the backbone of chemical safety legislation. These regulations impose stringent requirements on the registration, assessment, and communication of chemical hazards, including those associated with HCl.

Specific to laboratory environments, many countries have adopted standards similar to those set by the National Research Council's "Prudent Practices in the Laboratory." These guidelines provide comprehensive recommendations for the safe handling, storage, and disposal of hazardous chemicals, including HCl.

Professional organizations, such as the American Chemical Society (ACS) and the Royal Society of Chemistry (RSC), also contribute to the regulatory landscape by developing best practices and safety guidelines for laboratory operations. These organizations often work in conjunction with regulatory bodies to enhance and refine safety protocols.

Compliance with these regulations typically requires laboratories to implement robust safety management systems, including regular risk assessments, standard operating procedures, emergency response plans, and ongoing training programs. Proper documentation and record-keeping are essential components of regulatory compliance, ensuring traceability and accountability in HCl handling and usage.

As the scientific community continues to evolve, regulatory frameworks for HCl in laboratories are subject to periodic reviews and updates. This dynamic process ensures that safety standards keep pace with technological advancements and emerging best practices in chemical safety management.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a pivotal role in regulating HCl use in laboratories. OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandates proper labeling, safety data sheets, and employee training for hazardous chemicals, including HCl. Additionally, the OSHA Laboratory Standard (29 CFR 1910.1450) outlines specific requirements for chemical hygiene plans and exposure controls in laboratory settings.

The Environmental Protection Agency (EPA) also contributes to the regulatory framework through the Resource Conservation and Recovery Act (RCRA), which governs the disposal of hazardous waste, including spent HCl solutions. Laboratories must adhere to strict protocols for waste management and disposal to comply with EPA regulations.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard communication. Many countries have adopted GHS principles, ensuring consistency in the classification and labeling of HCl across borders.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation and the Classification, Labelling, and Packaging (CLP) regulation form the backbone of chemical safety legislation. These regulations impose stringent requirements on the registration, assessment, and communication of chemical hazards, including those associated with HCl.

Specific to laboratory environments, many countries have adopted standards similar to those set by the National Research Council's "Prudent Practices in the Laboratory." These guidelines provide comprehensive recommendations for the safe handling, storage, and disposal of hazardous chemicals, including HCl.

Professional organizations, such as the American Chemical Society (ACS) and the Royal Society of Chemistry (RSC), also contribute to the regulatory landscape by developing best practices and safety guidelines for laboratory operations. These organizations often work in conjunction with regulatory bodies to enhance and refine safety protocols.

Compliance with these regulations typically requires laboratories to implement robust safety management systems, including regular risk assessments, standard operating procedures, emergency response plans, and ongoing training programs. Proper documentation and record-keeping are essential components of regulatory compliance, ensuring traceability and accountability in HCl handling and usage.

As the scientific community continues to evolve, regulatory frameworks for HCl in laboratories are subject to periodic reviews and updates. This dynamic process ensures that safety standards keep pace with technological advancements and emerging best practices in chemical safety management.

Environmental Impact of HCl Use

The use of hydrochloric acid (HCl) in chemical laboratories has significant environmental implications that must be carefully considered and managed. HCl is a strong acid that can cause severe damage to ecosystems if released into the environment without proper treatment. When HCl comes into contact with water bodies, it can drastically lower the pH, leading to acidification of aquatic environments. This acidification can have devastating effects on aquatic life, including fish kills, disruption of food chains, and alteration of ecosystem dynamics.

Furthermore, the release of HCl vapors into the atmosphere can contribute to acid rain formation. Acid rain has far-reaching consequences, affecting not only aquatic ecosystems but also terrestrial environments, including forests, soil quality, and agricultural productivity. It can also accelerate the deterioration of buildings and infrastructure, particularly those made of limestone or marble.

The production and transportation of HCl also have environmental impacts. The manufacturing process of HCl often involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the risk of accidental spills during transportation poses a threat to soil and groundwater contamination.

Proper disposal of HCl waste is crucial to minimize environmental impact. Neutralization is a common method used to treat HCl waste before disposal. However, this process generates salt solutions that, if not managed correctly, can still have negative effects on the environment, such as increasing the salinity of water bodies.

To mitigate these environmental risks, laboratories must implement strict protocols for HCl handling, storage, and disposal. This includes using appropriate containment systems, maintaining proper ventilation, and ensuring that all personnel are trained in safe handling procedures. Implementing recycling and recovery systems for HCl can also help reduce the overall environmental footprint of its use in laboratories.

Alternatives to HCl should be considered whenever possible. In some applications, less hazardous acids or non-acid alternatives may be suitable substitutes. Research into green chemistry principles and the development of more environmentally friendly reagents can contribute to reducing the reliance on HCl and other strong acids in laboratory settings.

Monitoring and reporting systems are essential to track HCl usage and any potential environmental releases. Regular environmental assessments and audits can help identify areas for improvement in HCl management practices. By adopting a comprehensive approach to environmental stewardship, laboratories can minimize the negative impacts of HCl use while still benefiting from its important applications in chemical research and analysis.

Furthermore, the release of HCl vapors into the atmosphere can contribute to acid rain formation. Acid rain has far-reaching consequences, affecting not only aquatic ecosystems but also terrestrial environments, including forests, soil quality, and agricultural productivity. It can also accelerate the deterioration of buildings and infrastructure, particularly those made of limestone or marble.

The production and transportation of HCl also have environmental impacts. The manufacturing process of HCl often involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the risk of accidental spills during transportation poses a threat to soil and groundwater contamination.

Proper disposal of HCl waste is crucial to minimize environmental impact. Neutralization is a common method used to treat HCl waste before disposal. However, this process generates salt solutions that, if not managed correctly, can still have negative effects on the environment, such as increasing the salinity of water bodies.

To mitigate these environmental risks, laboratories must implement strict protocols for HCl handling, storage, and disposal. This includes using appropriate containment systems, maintaining proper ventilation, and ensuring that all personnel are trained in safe handling procedures. Implementing recycling and recovery systems for HCl can also help reduce the overall environmental footprint of its use in laboratories.

Alternatives to HCl should be considered whenever possible. In some applications, less hazardous acids or non-acid alternatives may be suitable substitutes. Research into green chemistry principles and the development of more environmentally friendly reagents can contribute to reducing the reliance on HCl and other strong acids in laboratory settings.

Monitoring and reporting systems are essential to track HCl usage and any potential environmental releases. Regular environmental assessments and audits can help identify areas for improvement in HCl management practices. By adopting a comprehensive approach to environmental stewardship, laboratories can minimize the negative impacts of HCl use while still benefiting from its important applications in chemical research and analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!