How V8 Engines Shape Global Automotive Technological Trends?

JUL 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception, shaping global automotive technological trends throughout its history. Initially developed in the early 20th century, V8 engines quickly became synonymous with power and performance in the automotive industry.

In the 1950s and 1960s, V8 engines reached their golden age, particularly in American muscle cars. This era saw rapid advancements in engine design, with manufacturers competing to produce more powerful and efficient V8s. The introduction of overhead valve (OHV) designs and higher compression ratios marked significant milestones in V8 technology.

The 1970s brought new challenges for V8 engines, as stricter emissions regulations and fuel economy standards forced manufacturers to adapt. This period saw the development of electronic fuel injection systems and catalytic converters, which helped V8 engines meet new environmental requirements while maintaining performance.

The 1980s and 1990s witnessed a shift towards more compact and fuel-efficient engines, leading to a temporary decline in V8 popularity. However, advancements in materials science and computer-aided design allowed engineers to create more efficient and powerful V8 engines, sparking a renaissance in the late 1990s and early 2000s.

Recent years have seen a focus on improving V8 efficiency through technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. These innovations have allowed V8 engines to remain competitive in an era of increasing environmental consciousness and stringent fuel economy standards.

The advent of hybrid and electric powertrains has presented both challenges and opportunities for V8 technology. Some manufacturers have begun integrating electric motors with V8 engines to create high-performance hybrid systems, combining the traditional appeal of V8 power with improved efficiency and reduced emissions.

Looking forward, the future of V8 engines in the automotive industry remains uncertain. While some manufacturers are phasing out V8 engines in favor of smaller, turbocharged alternatives or electric powertrains, others continue to invest in V8 technology, particularly for high-performance and luxury vehicles. The ongoing evolution of V8 engines will likely focus on further improvements in efficiency, emissions reduction, and integration with electrification technologies to meet future automotive demands.

In the 1950s and 1960s, V8 engines reached their golden age, particularly in American muscle cars. This era saw rapid advancements in engine design, with manufacturers competing to produce more powerful and efficient V8s. The introduction of overhead valve (OHV) designs and higher compression ratios marked significant milestones in V8 technology.

The 1970s brought new challenges for V8 engines, as stricter emissions regulations and fuel economy standards forced manufacturers to adapt. This period saw the development of electronic fuel injection systems and catalytic converters, which helped V8 engines meet new environmental requirements while maintaining performance.

The 1980s and 1990s witnessed a shift towards more compact and fuel-efficient engines, leading to a temporary decline in V8 popularity. However, advancements in materials science and computer-aided design allowed engineers to create more efficient and powerful V8 engines, sparking a renaissance in the late 1990s and early 2000s.

Recent years have seen a focus on improving V8 efficiency through technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. These innovations have allowed V8 engines to remain competitive in an era of increasing environmental consciousness and stringent fuel economy standards.

The advent of hybrid and electric powertrains has presented both challenges and opportunities for V8 technology. Some manufacturers have begun integrating electric motors with V8 engines to create high-performance hybrid systems, combining the traditional appeal of V8 power with improved efficiency and reduced emissions.

Looking forward, the future of V8 engines in the automotive industry remains uncertain. While some manufacturers are phasing out V8 engines in favor of smaller, turbocharged alternatives or electric powertrains, others continue to invest in V8 technology, particularly for high-performance and luxury vehicles. The ongoing evolution of V8 engines will likely focus on further improvements in efficiency, emissions reduction, and integration with electrification technologies to meet future automotive demands.

Market Demand Analysis

The global automotive industry has witnessed a significant shift in market demand for V8 engines in recent years. While traditionally associated with high-performance vehicles and luxury segments, V8 engines have faced increasing pressure from environmental regulations and changing consumer preferences. However, they continue to play a crucial role in shaping automotive technological trends.

In the luxury and performance vehicle segments, V8 engines remain highly sought after due to their power, smoothness, and prestige. Premium automakers such as BMW, Mercedes-Benz, and Audi continue to offer V8 options in their flagship models, catering to customers who prioritize performance and driving experience. The demand for V8-powered sports cars and supercars from brands like Ferrari, Lamborghini, and Porsche also remains strong, particularly in markets where fuel efficiency is not the primary concern.

The pickup truck market, especially in North America, continues to be a stronghold for V8 engines. Full-size trucks from manufacturers like Ford, Chevrolet, and Ram often feature V8 options, as these engines provide the necessary power and torque for towing and hauling. This segment has shown resilience in V8 demand, driven by both commercial and personal use requirements.

However, the overall market for V8 engines has been contracting due to several factors. Stricter emissions regulations worldwide have forced automakers to focus on smaller, more efficient engines. This has led to the development of advanced turbocharged four- and six-cylinder engines that can match or exceed the power output of traditional V8s while consuming less fuel.

Consumer preferences have also shifted towards more fuel-efficient and environmentally friendly vehicles. The rise of electric and hybrid powertrains has further impacted the demand for V8 engines, particularly in urban areas and regions with stringent emissions standards. Many automakers are now investing heavily in electrification technologies, which could potentially replace V8 engines in some vehicle segments in the long term.

Despite these challenges, V8 engines continue to drive technological innovation in the automotive industry. Manufacturers are developing more efficient V8 engines with advanced features such as cylinder deactivation, direct injection, and mild hybrid systems. These innovations aim to preserve the performance characteristics of V8 engines while improving fuel economy and reducing emissions.

The market demand for V8 engines is also influencing the development of alternative powertrains. Engineers are striving to replicate the power delivery, sound, and driving experience of V8 engines in electric and hybrid vehicles, recognizing the emotional appeal these engines hold for many enthusiasts. This has led to advancements in electric motor technology, battery systems, and even artificial sound generation to mimic the characteristics of V8 engines.

In the luxury and performance vehicle segments, V8 engines remain highly sought after due to their power, smoothness, and prestige. Premium automakers such as BMW, Mercedes-Benz, and Audi continue to offer V8 options in their flagship models, catering to customers who prioritize performance and driving experience. The demand for V8-powered sports cars and supercars from brands like Ferrari, Lamborghini, and Porsche also remains strong, particularly in markets where fuel efficiency is not the primary concern.

The pickup truck market, especially in North America, continues to be a stronghold for V8 engines. Full-size trucks from manufacturers like Ford, Chevrolet, and Ram often feature V8 options, as these engines provide the necessary power and torque for towing and hauling. This segment has shown resilience in V8 demand, driven by both commercial and personal use requirements.

However, the overall market for V8 engines has been contracting due to several factors. Stricter emissions regulations worldwide have forced automakers to focus on smaller, more efficient engines. This has led to the development of advanced turbocharged four- and six-cylinder engines that can match or exceed the power output of traditional V8s while consuming less fuel.

Consumer preferences have also shifted towards more fuel-efficient and environmentally friendly vehicles. The rise of electric and hybrid powertrains has further impacted the demand for V8 engines, particularly in urban areas and regions with stringent emissions standards. Many automakers are now investing heavily in electrification technologies, which could potentially replace V8 engines in some vehicle segments in the long term.

Despite these challenges, V8 engines continue to drive technological innovation in the automotive industry. Manufacturers are developing more efficient V8 engines with advanced features such as cylinder deactivation, direct injection, and mild hybrid systems. These innovations aim to preserve the performance characteristics of V8 engines while improving fuel economy and reducing emissions.

The market demand for V8 engines is also influencing the development of alternative powertrains. Engineers are striving to replicate the power delivery, sound, and driving experience of V8 engines in electric and hybrid vehicles, recognizing the emotional appeal these engines hold for many enthusiasts. This has led to advancements in electric motor technology, battery systems, and even artificial sound generation to mimic the characteristics of V8 engines.

Technical Challenges

V8 engines, despite their long-standing presence in the automotive industry, continue to face significant technical challenges in the context of global automotive technological trends. One of the primary hurdles is meeting increasingly stringent emissions regulations worldwide. As governments push for cleaner transportation, V8 engines struggle to comply with tightening CO2 and NOx emission standards without compromising performance.

Fuel efficiency remains a critical challenge for V8 engines. Their inherently higher fuel consumption compared to smaller engines with fewer cylinders puts them at a disadvantage in an era where fuel economy is a key selling point. This issue is further compounded by the growing emphasis on reducing carbon footprints and the shift towards more environmentally friendly vehicles.

The integration of advanced technologies presents another set of challenges for V8 engines. Implementing sophisticated fuel injection systems, variable valve timing, and cylinder deactivation technologies to improve efficiency and performance requires significant engineering efforts and increases production costs. These complexities can make V8 engines less competitive in price-sensitive markets.

Weight reduction is a persistent challenge for vehicles equipped with V8 engines. The larger size and higher number of components in V8 engines contribute to increased vehicle weight, which negatively impacts fuel efficiency and handling. Engineers must constantly innovate to reduce engine weight without compromising durability or performance.

The rise of electric and hybrid powertrains poses an existential threat to V8 engines. As automotive manufacturers invest heavily in electrification, the development resources allocated to traditional internal combustion engines, including V8s, are diminishing. This shift in focus challenges the long-term viability of V8 engines in mainstream vehicles.

Noise, vibration, and harshness (NVH) management presents ongoing challenges for V8 engines, particularly in luxury vehicles where refinement is paramount. Balancing the desire for a powerful engine note with the need for a quiet, comfortable ride requires sophisticated engineering solutions and adds to production costs.

Thermal management is another critical area of concern. V8 engines generate significant heat, necessitating advanced cooling systems to maintain optimal operating temperatures and prevent performance degradation. This challenge becomes more pronounced as manufacturers strive to package V8 engines in smaller engine bays for improved aerodynamics and design aesthetics.

Lastly, the complexity of V8 engines poses challenges in terms of maintenance and reliability. With more moving parts and sophisticated systems, V8 engines can be more prone to mechanical issues and require more frequent servicing, potentially increasing the total cost of ownership for consumers.

Fuel efficiency remains a critical challenge for V8 engines. Their inherently higher fuel consumption compared to smaller engines with fewer cylinders puts them at a disadvantage in an era where fuel economy is a key selling point. This issue is further compounded by the growing emphasis on reducing carbon footprints and the shift towards more environmentally friendly vehicles.

The integration of advanced technologies presents another set of challenges for V8 engines. Implementing sophisticated fuel injection systems, variable valve timing, and cylinder deactivation technologies to improve efficiency and performance requires significant engineering efforts and increases production costs. These complexities can make V8 engines less competitive in price-sensitive markets.

Weight reduction is a persistent challenge for vehicles equipped with V8 engines. The larger size and higher number of components in V8 engines contribute to increased vehicle weight, which negatively impacts fuel efficiency and handling. Engineers must constantly innovate to reduce engine weight without compromising durability or performance.

The rise of electric and hybrid powertrains poses an existential threat to V8 engines. As automotive manufacturers invest heavily in electrification, the development resources allocated to traditional internal combustion engines, including V8s, are diminishing. This shift in focus challenges the long-term viability of V8 engines in mainstream vehicles.

Noise, vibration, and harshness (NVH) management presents ongoing challenges for V8 engines, particularly in luxury vehicles where refinement is paramount. Balancing the desire for a powerful engine note with the need for a quiet, comfortable ride requires sophisticated engineering solutions and adds to production costs.

Thermal management is another critical area of concern. V8 engines generate significant heat, necessitating advanced cooling systems to maintain optimal operating temperatures and prevent performance degradation. This challenge becomes more pronounced as manufacturers strive to package V8 engines in smaller engine bays for improved aerodynamics and design aesthetics.

Lastly, the complexity of V8 engines poses challenges in terms of maintenance and reliability. With more moving parts and sophisticated systems, V8 engines can be more prone to mechanical issues and require more frequent servicing, potentially increasing the total cost of ownership for consumers.

Current V8 Solutions

01 V8 Engine Design and Configuration

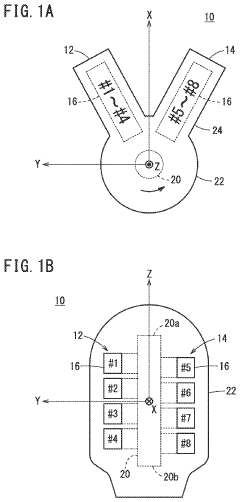

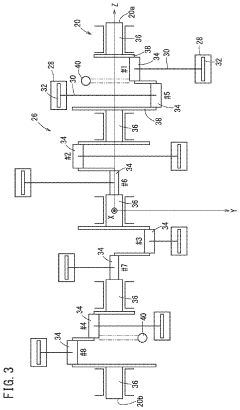

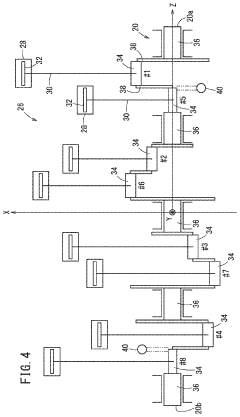

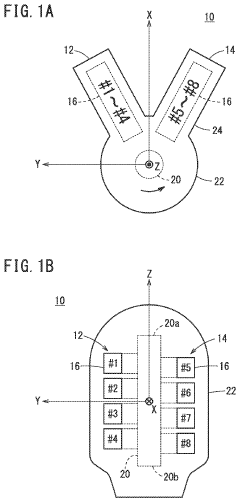

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. The design often includes features for improved performance, fuel efficiency, and reduced emissions.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. The design often includes features for improved performance, fuel efficiency, and reduced emissions.

- Fuel Injection Systems for V8 Engines: Advanced fuel injection systems are crucial for optimizing V8 engine performance. These systems may include direct injection, multi-point injection, or a combination of both to improve fuel atomization, combustion efficiency, and power output while reducing emissions.

- Valve Train and Camshaft Innovations: Innovations in valve train and camshaft designs for V8 engines focus on improving engine breathing, reducing friction, and enhancing overall efficiency. This may include variable valve timing, lift systems, and advanced materials for camshaft construction.

- Turbocharging and Supercharging V8 Engines: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher power output from a smaller displacement engine.

- Cooling and Lubrication Systems for V8 Engines: Effective cooling and lubrication systems are essential for V8 engine performance and longevity. Advanced designs may include precision oil cooling, improved coolant flow management, and innovative materials to enhance heat dissipation and reduce friction throughout the engine.

02 Fuel Injection Systems for V8 Engines

Advanced fuel injection systems are developed for V8 engines to optimize fuel delivery and combustion. These systems may include direct injection, multi-port injection, or a combination of both, aiming to improve engine efficiency and reduce fuel consumption while maintaining high performance.Expand Specific Solutions03 Valve Train and Camshaft Innovations

Innovations in valve train and camshaft designs for V8 engines focus on improving engine breathing and overall efficiency. This may include variable valve timing, cylinder deactivation systems, and advanced camshaft profiles to enhance performance across different engine speeds and loads.Expand Specific Solutions04 Turbocharging and Supercharging V8 Engines

Forced induction systems, such as turbochargers and superchargers, are increasingly used in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased power from a smaller displacement engine.Expand Specific Solutions05 Cooling and Lubrication Systems for V8 Engines

Advanced cooling and lubrication systems are crucial for maintaining optimal performance and longevity of V8 engines. These may include improved oil circulation methods, advanced coolant formulations, and innovative heat management techniques to ensure efficient operation under various conditions.Expand Specific Solutions

Key Manufacturers

The V8 engine market is in a mature stage, with established players like GM, Honda, Toyota, and BMW dominating the landscape. However, the industry is experiencing a shift towards more fuel-efficient and environmentally friendly technologies. The global V8 engine market size is estimated to be in the billions, driven by demand in luxury vehicles and high-performance applications. Technologically, V8 engines are well-developed, but companies like Nissan, Chery, and Geely are investing in innovations to improve efficiency and reduce emissions. Emerging players such as TAE Technologies are exploring alternative power sources, potentially disrupting the traditional V8 market in the long term.

GM Global Technology Operations LLC

Technical Solution: GM's V8 engine technology focuses on Dynamic Fuel Management (DFM) system, which can deactivate cylinders in 17 different patterns to optimize fuel efficiency and performance. Their latest 6.2L V8 engine with DFM can operate on anything from two to eight cylinders, depending on demand[1]. GM is also developing a new generation of small block V8 engines, codenamed the 6th-generation small block, which aims to improve fuel efficiency while maintaining power output[2]. These engines are expected to incorporate advanced technologies such as variable valve timing, direct injection, and possibly mild hybrid systems to meet stringent emission standards[3].

Strengths: Advanced cylinder deactivation technology, high power output, and ongoing development for future emission standards. Weaknesses: Relatively high fuel consumption compared to smaller engines, potential complexity in maintenance due to advanced technologies.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V8 engines focuses on balancing power and efficiency. Their latest 5.7L V8 engine, found in vehicles like the Tundra and Land Cruiser, utilizes Dual VVT-i (Variable Valve Timing with intelligence) and an Acoustic Control Induction System (ACIS) to optimize performance across a wide range of driving conditions[4]. Toyota is also developing a new twin-turbo V8 engine, rumored to be around 4.0L in displacement, which aims to provide V8 power with improved fuel efficiency[5]. This engine is expected to feature direct injection, a high compression ratio, and possibly a mild hybrid system to meet future emission regulations while maintaining the characteristic V8 performance[6].

Strengths: Reliable and durable V8 engines, ongoing development of more efficient turbo V8s. Weaknesses: Current V8 lineup is aging, relatively late in adopting turbocharging for V8s compared to some competitors.

Core V8 Innovations

V8 engine

PatentActiveUS11821359B2

Innovation

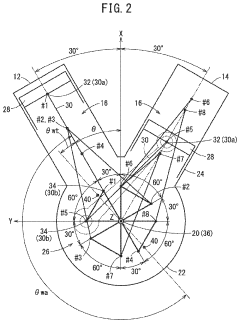

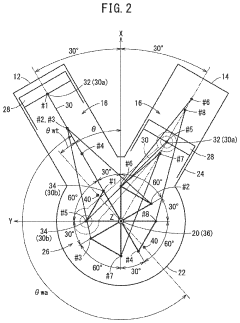

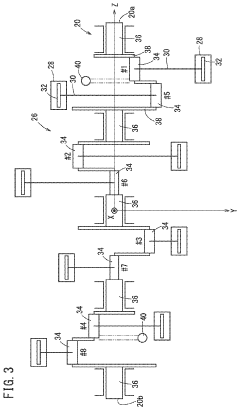

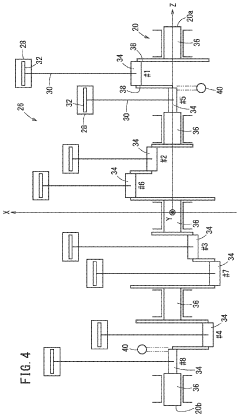

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Emissions Regulations

Emissions regulations have become a pivotal factor in shaping the development and deployment of V8 engines in the global automotive industry. As governments worldwide intensify their efforts to combat climate change and improve air quality, stringent emission standards have been implemented, significantly impacting the design and production of high-performance engines.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind the evolution of V8 engines. These regulations require automakers to achieve specific fleet-wide fuel efficiency targets, prompting manufacturers to develop more efficient V8 engines or reduce their production in favor of smaller, more fuel-efficient alternatives.

The European Union has introduced increasingly strict CO2 emission targets for new vehicles, with penalties for non-compliance. This has led to a decline in V8 engine offerings in the European market, as manufacturers focus on downsizing and electrification to meet these stringent requirements.

China, the world's largest automotive market, has also implemented rigorous emissions standards. The China 6 standard, equivalent to Euro 6, has forced automakers to adapt their V8 engines to meet these requirements or limit their availability in the Chinese market.

To comply with these regulations, manufacturers have employed various technologies in V8 engines. Variable valve timing, direct fuel injection, and cylinder deactivation have become common features, allowing V8 engines to operate more efficiently and reduce emissions without sacrificing performance.

Turbocharging and supercharging technologies have also gained prominence in V8 engine design. These forced induction methods enable manufacturers to extract more power from smaller displacement engines, meeting both performance demands and emissions requirements.

The integration of hybrid technology with V8 engines has emerged as another strategy to meet emissions regulations. By combining electric motors with traditional V8 powerplants, automakers can achieve improved fuel efficiency and reduced emissions while maintaining the characteristic power and sound of V8 engines.

Despite these advancements, the long-term viability of V8 engines in the face of increasingly stringent emissions regulations remains uncertain. As the automotive industry shifts towards electrification, the role of V8 engines may evolve, potentially becoming limited to niche markets or high-performance applications where their unique characteristics are still highly valued.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind the evolution of V8 engines. These regulations require automakers to achieve specific fleet-wide fuel efficiency targets, prompting manufacturers to develop more efficient V8 engines or reduce their production in favor of smaller, more fuel-efficient alternatives.

The European Union has introduced increasingly strict CO2 emission targets for new vehicles, with penalties for non-compliance. This has led to a decline in V8 engine offerings in the European market, as manufacturers focus on downsizing and electrification to meet these stringent requirements.

China, the world's largest automotive market, has also implemented rigorous emissions standards. The China 6 standard, equivalent to Euro 6, has forced automakers to adapt their V8 engines to meet these requirements or limit their availability in the Chinese market.

To comply with these regulations, manufacturers have employed various technologies in V8 engines. Variable valve timing, direct fuel injection, and cylinder deactivation have become common features, allowing V8 engines to operate more efficiently and reduce emissions without sacrificing performance.

Turbocharging and supercharging technologies have also gained prominence in V8 engine design. These forced induction methods enable manufacturers to extract more power from smaller displacement engines, meeting both performance demands and emissions requirements.

The integration of hybrid technology with V8 engines has emerged as another strategy to meet emissions regulations. By combining electric motors with traditional V8 powerplants, automakers can achieve improved fuel efficiency and reduced emissions while maintaining the characteristic power and sound of V8 engines.

Despite these advancements, the long-term viability of V8 engines in the face of increasingly stringent emissions regulations remains uncertain. As the automotive industry shifts towards electrification, the role of V8 engines may evolve, potentially becoming limited to niche markets or high-performance applications where their unique characteristics are still highly valued.

Electrification Impact

The electrification of the automotive industry has significantly impacted the development and relevance of V8 engines in global technological trends. As governments worldwide implement stricter emissions regulations and push for cleaner transportation solutions, traditional V8 engines face increasing challenges in maintaining their market position.

Electric vehicles (EVs) have emerged as a major disruptor in the automotive sector, offering zero-emission alternatives to conventional internal combustion engines. This shift has forced manufacturers to reconsider their powertrain strategies, with many redirecting resources from V8 engine development to electric and hybrid technologies.

The rise of EVs has led to a decline in V8 engine production volumes, particularly in mass-market segments. However, V8 engines continue to maintain a presence in specific niches, such as high-performance vehicles, luxury cars, and certain truck applications. Manufacturers are adapting by developing hybrid V8 powertrains, combining the traditional appeal of V8 engines with improved fuel efficiency and reduced emissions.

Electrification has also influenced the design and engineering of V8 engines. To meet increasingly stringent emissions standards, manufacturers have implemented advanced technologies like cylinder deactivation, direct injection, and turbocharging. These innovations aim to improve fuel economy and reduce environmental impact while preserving the characteristic power and sound of V8 engines.

The shift towards electrification has accelerated research and development in battery technology, power electronics, and electric motor design. This focus on electric powertrains has led to advancements in energy density, charging speeds, and overall EV performance, further challenging the dominance of V8 engines in high-performance applications.

Despite the growing emphasis on electrification, V8 engines continue to play a role in shaping automotive technological trends. Their ongoing development drives innovation in areas such as materials science, thermal management, and combustion efficiency. These advancements often have broader applications beyond V8 engines, contributing to overall automotive engineering progress.

As the automotive industry transitions towards a more electrified future, the impact on V8 engines remains complex. While their market share may decrease, V8 engines are likely to persist in specialized applications, benefiting from ongoing technological improvements and integration with hybrid systems. The challenge for manufacturers lies in balancing the heritage and appeal of V8 engines with the increasing demand for sustainable mobility solutions.

Electric vehicles (EVs) have emerged as a major disruptor in the automotive sector, offering zero-emission alternatives to conventional internal combustion engines. This shift has forced manufacturers to reconsider their powertrain strategies, with many redirecting resources from V8 engine development to electric and hybrid technologies.

The rise of EVs has led to a decline in V8 engine production volumes, particularly in mass-market segments. However, V8 engines continue to maintain a presence in specific niches, such as high-performance vehicles, luxury cars, and certain truck applications. Manufacturers are adapting by developing hybrid V8 powertrains, combining the traditional appeal of V8 engines with improved fuel efficiency and reduced emissions.

Electrification has also influenced the design and engineering of V8 engines. To meet increasingly stringent emissions standards, manufacturers have implemented advanced technologies like cylinder deactivation, direct injection, and turbocharging. These innovations aim to improve fuel economy and reduce environmental impact while preserving the characteristic power and sound of V8 engines.

The shift towards electrification has accelerated research and development in battery technology, power electronics, and electric motor design. This focus on electric powertrains has led to advancements in energy density, charging speeds, and overall EV performance, further challenging the dominance of V8 engines in high-performance applications.

Despite the growing emphasis on electrification, V8 engines continue to play a role in shaping automotive technological trends. Their ongoing development drives innovation in areas such as materials science, thermal management, and combustion efficiency. These advancements often have broader applications beyond V8 engines, contributing to overall automotive engineering progress.

As the automotive industry transitions towards a more electrified future, the impact on V8 engines remains complex. While their market share may decrease, V8 engines are likely to persist in specialized applications, benefiting from ongoing technological improvements and integration with hybrid systems. The challenge for manufacturers lies in balancing the heritage and appeal of V8 engines with the increasing demand for sustainable mobility solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!