How Vapor Chambers Enhance Thermal Management in Aerospace

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution in Aerospace

Vapor chamber technology in aerospace thermal management has undergone significant evolution since its initial conceptualization in the 1960s. The fundamental design, consisting of a vacuum-sealed chamber with a working fluid and capillary wick structure, has remained consistent while manufacturing techniques and materials have advanced dramatically.

Early vapor chambers were primarily experimental, with limited aerospace applications due to manufacturing constraints and reliability concerns. The 1970s and 1980s saw the first practical implementations in satellite systems, where their passive operation provided reliable cooling for sensitive electronics without requiring power or moving parts.

The 1990s marked a turning point with the development of more sophisticated manufacturing techniques, allowing for thinner profiles and complex internal wick structures. This period saw increased adoption in military aircraft avionics cooling systems, where the high heat flux capabilities of vapor chambers proved advantageous for radar and communication systems.

By the early 2000s, advancements in sintering processes and material science enabled the creation of vapor chambers with significantly improved thermal performance. Aerospace manufacturers began incorporating these devices into commercial aircraft systems, particularly for cooling high-power electronics in increasingly electrified aircraft architectures.

The 2010s witnessed the miniaturization of vapor chamber technology, with ultra-thin designs becoming feasible for space-constrained applications. This development coincided with the rise of small satellites and unmanned aerial vehicles (UAVs), where thermal management in limited spaces presented unique challenges that vapor chambers could address effectively.

Recent innovations have focused on advanced materials, including copper-graphene composites and novel working fluids that extend operational temperature ranges. These developments have enabled vapor chambers to function reliably in the extreme conditions encountered in aerospace applications, from the vacuum of space to the high-g forces experienced during launch and maneuvers.

Current research directions include 3D-printed vapor chambers with optimized internal geometries, adaptive vapor chambers that can modify their thermal conductivity based on operating conditions, and integration with other thermal management technologies such as thermoelectric coolers and phase change materials to create comprehensive thermal solutions for next-generation aerospace systems.

The evolution trajectory suggests that future vapor chambers will likely become more specialized for specific aerospace applications, with customized designs optimized for particular thermal challenges rather than one-size-fits-all solutions.

Early vapor chambers were primarily experimental, with limited aerospace applications due to manufacturing constraints and reliability concerns. The 1970s and 1980s saw the first practical implementations in satellite systems, where their passive operation provided reliable cooling for sensitive electronics without requiring power or moving parts.

The 1990s marked a turning point with the development of more sophisticated manufacturing techniques, allowing for thinner profiles and complex internal wick structures. This period saw increased adoption in military aircraft avionics cooling systems, where the high heat flux capabilities of vapor chambers proved advantageous for radar and communication systems.

By the early 2000s, advancements in sintering processes and material science enabled the creation of vapor chambers with significantly improved thermal performance. Aerospace manufacturers began incorporating these devices into commercial aircraft systems, particularly for cooling high-power electronics in increasingly electrified aircraft architectures.

The 2010s witnessed the miniaturization of vapor chamber technology, with ultra-thin designs becoming feasible for space-constrained applications. This development coincided with the rise of small satellites and unmanned aerial vehicles (UAVs), where thermal management in limited spaces presented unique challenges that vapor chambers could address effectively.

Recent innovations have focused on advanced materials, including copper-graphene composites and novel working fluids that extend operational temperature ranges. These developments have enabled vapor chambers to function reliably in the extreme conditions encountered in aerospace applications, from the vacuum of space to the high-g forces experienced during launch and maneuvers.

Current research directions include 3D-printed vapor chambers with optimized internal geometries, adaptive vapor chambers that can modify their thermal conductivity based on operating conditions, and integration with other thermal management technologies such as thermoelectric coolers and phase change materials to create comprehensive thermal solutions for next-generation aerospace systems.

The evolution trajectory suggests that future vapor chambers will likely become more specialized for specific aerospace applications, with customized designs optimized for particular thermal challenges rather than one-size-fits-all solutions.

Market Demand Analysis for Advanced Thermal Solutions

The aerospace industry is witnessing unprecedented demand for advanced thermal management solutions, driven primarily by the increasing complexity and power density of modern aircraft and spacecraft systems. Market research indicates that the global aerospace thermal management market is projected to reach $9.4 billion by 2026, growing at a CAGR of approximately 4.3% from 2021. This growth trajectory is underpinned by the escalating thermal challenges in next-generation aerospace applications.

The shift toward more electric aircraft (MEA) architecture represents a significant market driver, as traditional hydraulic and pneumatic systems are being replaced with electrical alternatives that generate substantial heat. Military aircraft, particularly those with advanced avionics and radar systems, require thermal solutions capable of dissipating heat loads exceeding 50 kW in confined spaces, creating a specialized market segment for high-performance vapor chamber technologies.

Commercial aviation presents another substantial market opportunity, with major manufacturers like Boeing and Airbus incorporating increasingly sophisticated electronics that demand efficient cooling. The trend toward composite airframes further complicates thermal management, as these materials typically exhibit lower thermal conductivity compared to traditional aluminum structures, necessitating more effective heat spreading solutions like vapor chambers.

Satellite manufacturers represent a growing customer base for advanced thermal solutions, particularly as the small satellite market expands. CubeSats and other small spacecraft operate in extreme thermal environments with limited mass and volume allocations for thermal control systems, making lightweight vapor chambers an attractive option. Market analysis reveals that over 1,700 small satellites were launched in 2021 alone, with projections indicating continued growth in this sector.

The emerging urban air mobility (UAM) and electric vertical takeoff and landing (eVTOL) markets are creating new demand vectors for compact, lightweight thermal management systems. These vehicles face unique cooling challenges due to their electric propulsion systems and densely packed electronics, with thermal management representing approximately 8-12% of their total system development costs.

Regional analysis shows North America dominating the aerospace thermal management market with approximately 40% market share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in the Asia-Pacific region, where rapid expansion of aerospace manufacturing capabilities and increasing defense spending are creating new opportunities for thermal solution providers.

Customer requirements are increasingly focused on solutions that offer high thermal performance while minimizing weight penalties, with vapor chambers emerging as a technology capable of meeting these demanding specifications. Market surveys indicate that aerospace system integrators are willing to pay premium prices for thermal management technologies that deliver substantial improvements in heat spreading efficiency while maintaining reliability under extreme operating conditions.

The shift toward more electric aircraft (MEA) architecture represents a significant market driver, as traditional hydraulic and pneumatic systems are being replaced with electrical alternatives that generate substantial heat. Military aircraft, particularly those with advanced avionics and radar systems, require thermal solutions capable of dissipating heat loads exceeding 50 kW in confined spaces, creating a specialized market segment for high-performance vapor chamber technologies.

Commercial aviation presents another substantial market opportunity, with major manufacturers like Boeing and Airbus incorporating increasingly sophisticated electronics that demand efficient cooling. The trend toward composite airframes further complicates thermal management, as these materials typically exhibit lower thermal conductivity compared to traditional aluminum structures, necessitating more effective heat spreading solutions like vapor chambers.

Satellite manufacturers represent a growing customer base for advanced thermal solutions, particularly as the small satellite market expands. CubeSats and other small spacecraft operate in extreme thermal environments with limited mass and volume allocations for thermal control systems, making lightweight vapor chambers an attractive option. Market analysis reveals that over 1,700 small satellites were launched in 2021 alone, with projections indicating continued growth in this sector.

The emerging urban air mobility (UAM) and electric vertical takeoff and landing (eVTOL) markets are creating new demand vectors for compact, lightweight thermal management systems. These vehicles face unique cooling challenges due to their electric propulsion systems and densely packed electronics, with thermal management representing approximately 8-12% of their total system development costs.

Regional analysis shows North America dominating the aerospace thermal management market with approximately 40% market share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in the Asia-Pacific region, where rapid expansion of aerospace manufacturing capabilities and increasing defense spending are creating new opportunities for thermal solution providers.

Customer requirements are increasingly focused on solutions that offer high thermal performance while minimizing weight penalties, with vapor chambers emerging as a technology capable of meeting these demanding specifications. Market surveys indicate that aerospace system integrators are willing to pay premium prices for thermal management technologies that deliver substantial improvements in heat spreading efficiency while maintaining reliability under extreme operating conditions.

Current Challenges in Aerospace Thermal Management

Aerospace thermal management faces unprecedented challenges as modern aircraft and spacecraft systems become increasingly complex and powerful. The integration of advanced electronics, propulsion systems, and high-performance materials generates significant heat loads that must be efficiently dissipated to maintain operational integrity and safety. Traditional cooling methods such as forced air convection and liquid cooling systems are reaching their practical limits in addressing these thermal challenges.

One of the primary challenges is the extreme operating environments encountered in aerospace applications. Aircraft and spacecraft must function across dramatic temperature gradients, from the intense heat of hypersonic flight to the extreme cold of high-altitude or space environments. These conditions place extraordinary demands on thermal management systems, requiring solutions that can operate reliably across wide temperature ranges while maintaining precise thermal control.

Weight and space constraints represent another critical challenge. Every gram added to an aerospace vehicle impacts fuel efficiency, payload capacity, and overall performance. Conventional thermal management systems often involve bulky components such as heat sinks, fans, and liquid cooling infrastructure that consume valuable space and add significant weight. The aerospace industry urgently needs compact, lightweight thermal solutions that deliver superior performance without compromising the vehicle's structural efficiency.

Power limitations further complicate thermal management in aerospace applications. Many aircraft and spacecraft operate with strict power budgets, particularly in unmanned or satellite systems where energy resources are finite. Thermal management solutions that require substantial power for pumps, fans, or other active components may not be viable in these contexts, necessitating more energy-efficient approaches.

Reliability requirements pose additional challenges. Aerospace systems demand exceptional reliability, often needing to function flawlessly for years without maintenance in harsh conditions. Thermal management solutions must demonstrate extraordinary durability, with minimal moving parts and failure points to ensure consistent performance throughout the system's operational life.

The increasing power density of modern aerospace electronics presents perhaps the most pressing thermal challenge. Advanced avionics, radar systems, and communication equipment generate concentrated heat loads that can create dangerous hotspots if not properly managed. These localized thermal issues can lead to component failure, reduced performance, or even catastrophic system breakdown if not effectively addressed.

Finally, the aerospace industry faces growing pressure to develop more environmentally sustainable technologies. Traditional thermal management approaches often rely on materials or refrigerants with significant environmental impacts. Future solutions must balance thermal performance with environmental considerations, driving innovation toward greener technologies and materials.

One of the primary challenges is the extreme operating environments encountered in aerospace applications. Aircraft and spacecraft must function across dramatic temperature gradients, from the intense heat of hypersonic flight to the extreme cold of high-altitude or space environments. These conditions place extraordinary demands on thermal management systems, requiring solutions that can operate reliably across wide temperature ranges while maintaining precise thermal control.

Weight and space constraints represent another critical challenge. Every gram added to an aerospace vehicle impacts fuel efficiency, payload capacity, and overall performance. Conventional thermal management systems often involve bulky components such as heat sinks, fans, and liquid cooling infrastructure that consume valuable space and add significant weight. The aerospace industry urgently needs compact, lightweight thermal solutions that deliver superior performance without compromising the vehicle's structural efficiency.

Power limitations further complicate thermal management in aerospace applications. Many aircraft and spacecraft operate with strict power budgets, particularly in unmanned or satellite systems where energy resources are finite. Thermal management solutions that require substantial power for pumps, fans, or other active components may not be viable in these contexts, necessitating more energy-efficient approaches.

Reliability requirements pose additional challenges. Aerospace systems demand exceptional reliability, often needing to function flawlessly for years without maintenance in harsh conditions. Thermal management solutions must demonstrate extraordinary durability, with minimal moving parts and failure points to ensure consistent performance throughout the system's operational life.

The increasing power density of modern aerospace electronics presents perhaps the most pressing thermal challenge. Advanced avionics, radar systems, and communication equipment generate concentrated heat loads that can create dangerous hotspots if not properly managed. These localized thermal issues can lead to component failure, reduced performance, or even catastrophic system breakdown if not effectively addressed.

Finally, the aerospace industry faces growing pressure to develop more environmentally sustainable technologies. Traditional thermal management approaches often rely on materials or refrigerants with significant environmental impacts. Future solutions must balance thermal performance with environmental considerations, driving innovation toward greener technologies and materials.

Current Vapor Chamber Implementation Strategies

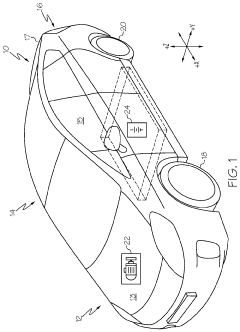

01 Vapor chamber design for electronic devices

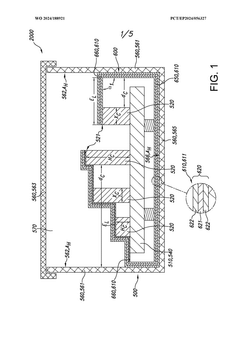

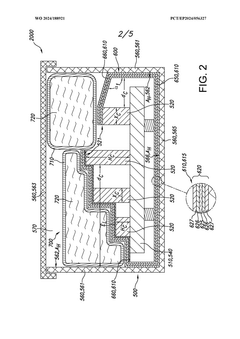

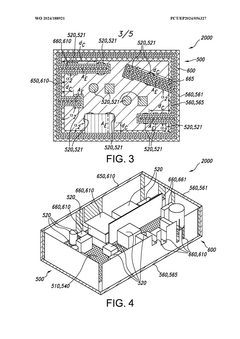

Vapor chambers are designed specifically for electronic devices to manage thermal issues. These designs incorporate specialized structures that efficiently transfer heat away from critical components, preventing overheating and maintaining optimal performance. The chambers utilize phase change principles where a working fluid evaporates at the heat source and condenses at cooler regions, effectively distributing thermal energy across the device.- Vapor chamber design for electronic devices: Vapor chambers are designed specifically for electronic devices to manage thermal issues. These designs incorporate specialized structures that efficiently transfer heat away from critical components. The chambers utilize phase change materials and optimized internal structures to maximize heat dissipation in compact electronic devices such as smartphones, tablets, and computers.

- Integration with cooling systems: Vapor chambers can be integrated with other cooling systems to create comprehensive thermal management solutions. These integrated systems may combine vapor chambers with heat sinks, fans, liquid cooling, or thermoelectric coolers to enhance overall thermal performance. The combined approach allows for more efficient heat transfer and distribution across various components and operating conditions.

- Advanced materials for vapor chambers: The development of advanced materials has significantly improved vapor chamber performance. These materials include high thermal conductivity metals, specialized wicking structures, and novel working fluids. The selection of appropriate materials enhances heat transfer efficiency, reduces thermal resistance, and improves the overall reliability and lifespan of vapor chamber thermal management systems.

- Vapor chambers for telecommunications equipment: Telecommunications equipment often generates significant heat during operation, requiring specialized thermal management solutions. Vapor chambers designed for telecommunications applications address the unique cooling challenges of network infrastructure, base stations, and data transmission equipment. These systems help maintain optimal operating temperatures for critical communication components while ensuring reliability in various environmental conditions.

- Miniaturized vapor chambers for compact devices: As electronic devices become smaller and more powerful, miniaturized vapor chambers have been developed to address thermal management in limited spaces. These compact thermal solutions maintain efficient heat dissipation despite size constraints. The miniaturized designs incorporate innovative internal structures, optimized fluid channels, and specialized manufacturing techniques to achieve effective cooling in ultra-thin and compact electronic devices.

02 Integration with cooling systems

Vapor chambers can be integrated with other cooling systems to enhance thermal management efficiency. These integrated solutions combine vapor chambers with heat sinks, fans, or liquid cooling systems to create comprehensive thermal management solutions. The synergistic effect of these combined systems provides superior cooling performance for high-power electronic components and systems operating under demanding conditions.Expand Specific Solutions03 Advanced materials for vapor chambers

The development of advanced materials has significantly improved vapor chamber performance. These materials enhance thermal conductivity, reduce weight, and improve durability of vapor chambers. Innovations include specialized wicking structures, composite materials, and nano-enhanced surfaces that optimize the phase change process and heat transfer efficiency, allowing for more effective thermal management in compact electronic devices.Expand Specific Solutions04 Vapor chambers for telecommunications equipment

Vapor chambers are specifically designed for telecommunications equipment to address the unique thermal challenges in this sector. These solutions manage heat in network infrastructure, base stations, and data transmission equipment. The specialized designs ensure reliable operation of telecommunications systems under varying environmental conditions and high data processing loads, preventing signal degradation and equipment failure due to thermal issues.Expand Specific Solutions05 Miniaturized vapor chambers for portable devices

Miniaturized vapor chambers have been developed for portable electronic devices where space is limited but thermal management remains critical. These compact thermal solutions maintain efficient heat dissipation despite size constraints, enabling powerful processing capabilities in smartphones, tablets, and wearable technology. The designs incorporate ultra-thin profiles and flexible structures that can conform to the limited space available in modern portable electronics.Expand Specific Solutions

Key Aerospace and Thermal Solution Providers

The vapor chamber thermal management market in aerospace is in a growth phase, characterized by increasing demand for advanced cooling solutions in high-performance aerospace applications. The market is expanding as aerospace systems become more compact and powerful, requiring efficient thermal management. Key players include established aerospace suppliers like Hamilton Sundstrand and Commercial Aircraft Corporation of China alongside thermal technology specialists such as Furukawa Electric and Murata Manufacturing. These companies are advancing vapor chamber technology from early adoption to mainstream implementation, with varying levels of technical maturity. General Electric and Thales represent diversified conglomerates with significant aerospace divisions investing in this technology, while research institutions like Purdue Research Foundation and Sabanci University contribute to fundamental innovation, creating a competitive landscape balanced between established players and specialized entrants.

General Electric Company

Technical Solution: General Electric has developed advanced vapor chamber thermal management solutions specifically for aerospace applications. Their technology utilizes a flattened heat pipe design with a vacuum-sealed chamber containing a working fluid that undergoes phase change to efficiently transfer heat. GE's aerospace vapor chambers incorporate proprietary wick structures that enable operation against gravity and in variable g-force environments. The company has implemented these systems in aircraft engines, avionics cooling, and satellite thermal control systems, achieving up to 40% improvement in heat dissipation compared to traditional cooling methods. GE's vapor chambers are designed to withstand the extreme temperature fluctuations (-65°C to +150°C) encountered in aerospace environments while maintaining structural integrity. Their latest generation incorporates composite materials to reduce weight by approximately 30% compared to conventional aluminum heat sinks, a critical factor for aerospace applications.

Strengths: Superior thermal performance in variable gravity conditions; lightweight composite construction reduces aircraft weight; proven reliability in extreme aerospace environments. Weaknesses: Higher manufacturing costs compared to traditional cooling solutions; requires specialized design expertise; potential for working fluid leakage in case of physical damage.

Hamilton Sundstrand Corp.

Technical Solution: Hamilton Sundstrand has pioneered vapor chamber technology for aerospace thermal management through their Advanced Thermal Solutions division. Their vapor chambers utilize a proprietary sintered powder metal wick structure that maximizes capillary action and fluid distribution, enabling effective heat transfer even in zero-gravity environments. The company's aerospace vapor chambers incorporate specialized working fluids that remain stable under extreme temperature cycling and radiation exposure encountered in space applications. Hamilton Sundstrand's systems have been deployed in multiple satellite platforms and aircraft environmental control systems, demonstrating a thermal conductivity approximately 5-10 times higher than solid aluminum heat spreaders of equivalent dimensions. Their vapor chamber technology has been integrated into critical avionics cooling systems for both military and commercial aircraft, where they've achieved a 25-30% reduction in component operating temperatures while reducing overall thermal management system weight.

Strengths: Exceptional performance in zero-gravity environments; highly reliable wick structures prevent dry-out; extensive flight heritage and proven durability in aerospace applications. Weaknesses: Complex manufacturing process increases production costs; limited flexibility for retrofitting into existing systems; requires careful integration with other thermal management components.

Critical Patents and Research in Aerospace Cooling

Cooling fingers as a sustainable and reliable solution for LED drivers

PatentWO2024188921A1

Innovation

- A thermally conductive element with a sheet-like structure and extensions configured at specific angles for improved thermal contact with electrical components, providing higher thermal conductivity and ease of application and removal, thus offering a sustainable and reliable cooling solution.

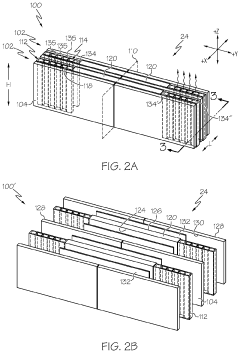

Thermal management systems including vapor chambers and phase change materials and vehicles including the same

PatentActiveUS11387506B2

Innovation

- A thermal management system incorporating a vapor chamber with an evaporator and condenser surface connected by a wick, combined with a phase change material (PCM) shell, where the evaporator surface is thermally coupled to the battery cell to absorb waste heat, and the condenser surface is coupled to the PCM to reject heat, enhancing heat transfer efficiency.

Material Science Advancements for Vapor Chambers

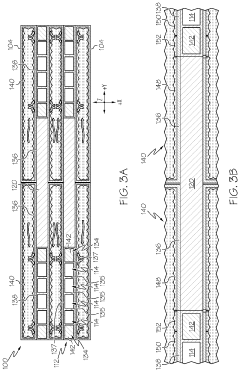

Material science innovations have significantly propelled vapor chamber technology forward, enabling more efficient thermal management solutions for aerospace applications. Recent advancements in wick structures have led to the development of multi-layer composite wicks that combine different materials and structures to optimize capillary action and thermal conductivity. These composite wicks typically feature a fine-pore layer for high capillary pressure and a coarse-pore layer for reduced flow resistance, resulting in enhanced heat transfer capabilities.

Copper has traditionally dominated vapor chamber construction due to its excellent thermal conductivity. However, aluminum and its alloys are gaining prominence for aerospace applications because of their lighter weight and adequate thermal performance. The weight reduction is crucial for aerospace systems where every gram matters. Additionally, researchers have developed copper-graphene composites that offer up to 25% improvement in thermal conductivity compared to pure copper while maintaining similar mechanical properties.

Surface treatments and coatings represent another frontier in vapor chamber material science. Hydrophilic coatings on wick structures enhance liquid spreading and capillary action, while hydrophobic coatings on vapor spaces reduce flow resistance. Nano-structured surfaces created through chemical etching or deposition processes can increase the effective surface area for heat transfer by up to 40%, significantly improving thermal performance.

Advanced manufacturing techniques have enabled the production of increasingly complex internal structures. Additive manufacturing allows for the creation of optimized wick geometries that would be impossible with traditional manufacturing methods. Sintering processes have evolved to create porous structures with precisely controlled pore size distributions, enhancing capillary performance while maintaining structural integrity under the harsh conditions experienced in aerospace applications.

High-temperature materials research has expanded the operational range of vapor chambers. Silicon carbide, titanium alloys, and ceramic composites are being integrated into vapor chamber designs for applications requiring operation above 200°C. These materials maintain their structural and thermal properties at elevated temperatures, making them suitable for use in engine compartments and other high-temperature aerospace environments.

Environmentally friendly working fluids are replacing traditional refrigerants with high global warming potential. Water remains the preferred working fluid for many applications, but researchers are developing specialized fluids with lower freezing points and higher boiling points to address the extreme temperature ranges encountered in aerospace environments. These advancements collectively push the boundaries of vapor chamber performance, enabling more efficient thermal management solutions for increasingly demanding aerospace applications.

Copper has traditionally dominated vapor chamber construction due to its excellent thermal conductivity. However, aluminum and its alloys are gaining prominence for aerospace applications because of their lighter weight and adequate thermal performance. The weight reduction is crucial for aerospace systems where every gram matters. Additionally, researchers have developed copper-graphene composites that offer up to 25% improvement in thermal conductivity compared to pure copper while maintaining similar mechanical properties.

Surface treatments and coatings represent another frontier in vapor chamber material science. Hydrophilic coatings on wick structures enhance liquid spreading and capillary action, while hydrophobic coatings on vapor spaces reduce flow resistance. Nano-structured surfaces created through chemical etching or deposition processes can increase the effective surface area for heat transfer by up to 40%, significantly improving thermal performance.

Advanced manufacturing techniques have enabled the production of increasingly complex internal structures. Additive manufacturing allows for the creation of optimized wick geometries that would be impossible with traditional manufacturing methods. Sintering processes have evolved to create porous structures with precisely controlled pore size distributions, enhancing capillary performance while maintaining structural integrity under the harsh conditions experienced in aerospace applications.

High-temperature materials research has expanded the operational range of vapor chambers. Silicon carbide, titanium alloys, and ceramic composites are being integrated into vapor chamber designs for applications requiring operation above 200°C. These materials maintain their structural and thermal properties at elevated temperatures, making them suitable for use in engine compartments and other high-temperature aerospace environments.

Environmentally friendly working fluids are replacing traditional refrigerants with high global warming potential. Water remains the preferred working fluid for many applications, but researchers are developing specialized fluids with lower freezing points and higher boiling points to address the extreme temperature ranges encountered in aerospace environments. These advancements collectively push the boundaries of vapor chamber performance, enabling more efficient thermal management solutions for increasingly demanding aerospace applications.

Weight-to-Performance Optimization Strategies

In aerospace applications, the weight-to-performance ratio represents a critical design parameter that directly impacts fuel efficiency, operational costs, and mission capabilities. Vapor chamber thermal management systems must be optimized to deliver maximum cooling performance while minimizing mass contribution to the overall aerospace structure.

Advanced material selection forms the cornerstone of weight optimization strategies. Lightweight metals such as aluminum-silicon carbide composites and copper-graphene hybrids offer superior thermal conductivity while reducing overall mass by up to 30% compared to traditional copper-based vapor chambers. These materials maintain structural integrity under extreme aerospace conditions while significantly decreasing weight penalties.

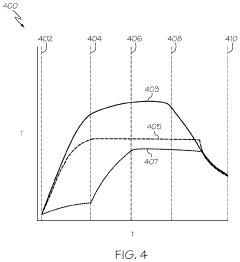

Geometric optimization techniques further enhance weight-to-performance ratios through computational fluid dynamics (CFD) modeling. By implementing variable wick structures with graduated porosity, engineers can create vapor chambers that concentrate cooling capacity precisely where thermal loads are highest. This targeted approach eliminates unnecessary material in low-heat regions, reducing weight while maintaining or improving thermal performance.

Additive manufacturing processes have revolutionized vapor chamber design by enabling complex internal geometries impossible to achieve with traditional manufacturing methods. 3D-printed vapor chambers featuring lattice structures and optimized vapor channels can reduce weight by up to 25% while improving thermal performance by 15-20% compared to conventional designs. These manufacturing advances allow for part consolidation, further reducing system weight.

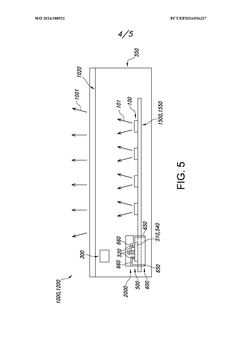

Integration strategies that combine vapor chambers with structural elements represent another frontier in optimization. Multi-functional designs where vapor chambers simultaneously serve as heat spreaders and load-bearing components eliminate redundant structures. For example, satellite panels incorporating vapor chambers within their structural framework have demonstrated 40% weight savings compared to conventional thermal management approaches.

Miniaturization techniques have yielded ultra-thin vapor chambers (less than 0.5mm thickness) that maintain effective thermal performance while dramatically reducing weight. These micro vapor chambers utilize advanced capillary structures and working fluids specifically engineered for aerospace applications, delivering thermal conductivities exceeding 5000 W/m·K with minimal mass penalties.

Performance validation through accelerated life testing under simulated aerospace conditions ensures that weight optimization does not compromise reliability. Thermal cycling between extreme temperatures (-65°C to +150°C), vibration testing, and radiation exposure assessments validate the durability of lightweight vapor chamber designs before implementation in mission-critical aerospace systems.

Advanced material selection forms the cornerstone of weight optimization strategies. Lightweight metals such as aluminum-silicon carbide composites and copper-graphene hybrids offer superior thermal conductivity while reducing overall mass by up to 30% compared to traditional copper-based vapor chambers. These materials maintain structural integrity under extreme aerospace conditions while significantly decreasing weight penalties.

Geometric optimization techniques further enhance weight-to-performance ratios through computational fluid dynamics (CFD) modeling. By implementing variable wick structures with graduated porosity, engineers can create vapor chambers that concentrate cooling capacity precisely where thermal loads are highest. This targeted approach eliminates unnecessary material in low-heat regions, reducing weight while maintaining or improving thermal performance.

Additive manufacturing processes have revolutionized vapor chamber design by enabling complex internal geometries impossible to achieve with traditional manufacturing methods. 3D-printed vapor chambers featuring lattice structures and optimized vapor channels can reduce weight by up to 25% while improving thermal performance by 15-20% compared to conventional designs. These manufacturing advances allow for part consolidation, further reducing system weight.

Integration strategies that combine vapor chambers with structural elements represent another frontier in optimization. Multi-functional designs where vapor chambers simultaneously serve as heat spreaders and load-bearing components eliminate redundant structures. For example, satellite panels incorporating vapor chambers within their structural framework have demonstrated 40% weight savings compared to conventional thermal management approaches.

Miniaturization techniques have yielded ultra-thin vapor chambers (less than 0.5mm thickness) that maintain effective thermal performance while dramatically reducing weight. These micro vapor chambers utilize advanced capillary structures and working fluids specifically engineered for aerospace applications, delivering thermal conductivities exceeding 5000 W/m·K with minimal mass penalties.

Performance validation through accelerated life testing under simulated aerospace conditions ensures that weight optimization does not compromise reliability. Thermal cycling between extreme temperatures (-65°C to +150°C), vibration testing, and radiation exposure assessments validate the durability of lightweight vapor chamber designs before implementation in mission-critical aerospace systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!