Hybrid Supercapacitors in Aerospace Energy Systems

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Hybrid Supercapacitors Background and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries for specialized applications. In aerospace systems, where weight, reliability, and performance under extreme conditions are critical factors, hybrid supercapacitors have emerged as a promising solution to address the unique energy demands of modern aircraft and spacecraft.

The aerospace industry has witnessed a paradigm shift from purely mechanical systems to more electrified platforms, driving the need for advanced energy storage solutions. Traditional batteries often fall short in providing the rapid charge-discharge cycles required for aerospace applications, while conventional supercapacitors lack sufficient energy density for sustained operations. Hybrid supercapacitors aim to bridge this gap by leveraging the strengths of both technologies.

Recent technological advancements have accelerated the development of hybrid supercapacitors specifically tailored for aerospace applications. These include innovations in electrode materials, electrolyte compositions, and cell designs that enhance performance under the extreme temperature variations, pressure changes, and vibration conditions encountered in aerospace environments. Notable milestones include the development of carbon-based nanomaterials, metal oxides, and conductive polymers that significantly improve energy and power densities while maintaining structural integrity.

The primary technical objectives for aerospace hybrid supercapacitors focus on several key parameters: increasing energy density beyond 20 Wh/kg while maintaining power densities above 10 kW/kg; extending operational temperature ranges from -60°C to +85°C; enhancing cycle life to exceed 500,000 cycles; and reducing weight by at least 30% compared to current solutions. Additionally, these systems must demonstrate resilience to radiation exposure, vacuum conditions, and rapid pressure changes.

Looking forward, the technology trajectory suggests continued refinement of hybrid architectures that optimize the interface between battery-type and capacitor-type electrodes. Research is increasingly focused on developing multifunctional energy storage systems that can be integrated into aircraft structures, thereby reducing overall weight while providing supplementary functions such as thermal management or electromagnetic shielding.

The successful development and implementation of hybrid supercapacitors in aerospace energy systems could revolutionize multiple aspects of aircraft and spacecraft design, enabling more efficient power management for critical systems, supporting the electrification of propulsion systems, and facilitating the deployment of advanced avionics and autonomous capabilities that require reliable, high-performance energy storage solutions.

The aerospace industry has witnessed a paradigm shift from purely mechanical systems to more electrified platforms, driving the need for advanced energy storage solutions. Traditional batteries often fall short in providing the rapid charge-discharge cycles required for aerospace applications, while conventional supercapacitors lack sufficient energy density for sustained operations. Hybrid supercapacitors aim to bridge this gap by leveraging the strengths of both technologies.

Recent technological advancements have accelerated the development of hybrid supercapacitors specifically tailored for aerospace applications. These include innovations in electrode materials, electrolyte compositions, and cell designs that enhance performance under the extreme temperature variations, pressure changes, and vibration conditions encountered in aerospace environments. Notable milestones include the development of carbon-based nanomaterials, metal oxides, and conductive polymers that significantly improve energy and power densities while maintaining structural integrity.

The primary technical objectives for aerospace hybrid supercapacitors focus on several key parameters: increasing energy density beyond 20 Wh/kg while maintaining power densities above 10 kW/kg; extending operational temperature ranges from -60°C to +85°C; enhancing cycle life to exceed 500,000 cycles; and reducing weight by at least 30% compared to current solutions. Additionally, these systems must demonstrate resilience to radiation exposure, vacuum conditions, and rapid pressure changes.

Looking forward, the technology trajectory suggests continued refinement of hybrid architectures that optimize the interface between battery-type and capacitor-type electrodes. Research is increasingly focused on developing multifunctional energy storage systems that can be integrated into aircraft structures, thereby reducing overall weight while providing supplementary functions such as thermal management or electromagnetic shielding.

The successful development and implementation of hybrid supercapacitors in aerospace energy systems could revolutionize multiple aspects of aircraft and spacecraft design, enabling more efficient power management for critical systems, supporting the electrification of propulsion systems, and facilitating the deployment of advanced avionics and autonomous capabilities that require reliable, high-performance energy storage solutions.

Market Analysis for Aerospace Energy Storage Solutions

The aerospace energy storage market is experiencing significant growth, projected to reach $7.6 billion by 2027, with a compound annual growth rate of 7.2% from 2022. This expansion is primarily driven by increasing satellite deployments, growing space exploration missions, and the rising adoption of electric propulsion systems in aircraft. Hybrid supercapacitors represent a particularly promising segment within this market, addressing the critical need for high power density, rapid charge-discharge capabilities, and reliable performance under extreme aerospace conditions.

Commercial aviation represents the largest market segment, accounting for approximately 42% of the total aerospace energy storage demand. Airlines and aircraft manufacturers are increasingly seeking energy solutions that reduce weight while maintaining or improving performance metrics. Military and defense applications follow closely at 35%, where the emphasis on mission-critical reliability and performance under extreme conditions makes hybrid supercapacitors especially valuable.

The satellite industry constitutes about 18% of the market, with particular growth in small satellite constellations requiring efficient power management systems. The remaining 5% encompasses specialized applications including unmanned aerial vehicles, high-altitude platforms, and experimental aircraft.

Geographically, North America dominates with 38% market share, benefiting from substantial aerospace R&D investments and the presence of major industry players. Europe follows at 29%, with significant contributions from countries with strong aerospace sectors like France, Germany, and the UK. The Asia-Pacific region represents 24% and is experiencing the fastest growth rate at 9.1% annually, driven by expanding aerospace programs in China, Japan, and India.

Customer requirements in this market emphasize several key performance indicators: energy density (targeting >200 Wh/kg), cycle life (>10,000 cycles), temperature tolerance (-50°C to +80°C), and radiation resistance. Hybrid supercapacitors are increasingly preferred over traditional batteries due to their superior performance in rapid charge-discharge scenarios, extended operational lifetime in space environments, and better thermal management characteristics.

Market barriers include high initial costs compared to conventional energy storage solutions, with hybrid supercapacitor systems typically commanding a 30-40% premium. Technical challenges in system integration and the conservative adoption cycle of the aerospace industry also constrain market penetration. However, these barriers are gradually diminishing as manufacturing scales up and successful implementation cases demonstrate the technology's value proposition in mission-critical aerospace applications.

Commercial aviation represents the largest market segment, accounting for approximately 42% of the total aerospace energy storage demand. Airlines and aircraft manufacturers are increasingly seeking energy solutions that reduce weight while maintaining or improving performance metrics. Military and defense applications follow closely at 35%, where the emphasis on mission-critical reliability and performance under extreme conditions makes hybrid supercapacitors especially valuable.

The satellite industry constitutes about 18% of the market, with particular growth in small satellite constellations requiring efficient power management systems. The remaining 5% encompasses specialized applications including unmanned aerial vehicles, high-altitude platforms, and experimental aircraft.

Geographically, North America dominates with 38% market share, benefiting from substantial aerospace R&D investments and the presence of major industry players. Europe follows at 29%, with significant contributions from countries with strong aerospace sectors like France, Germany, and the UK. The Asia-Pacific region represents 24% and is experiencing the fastest growth rate at 9.1% annually, driven by expanding aerospace programs in China, Japan, and India.

Customer requirements in this market emphasize several key performance indicators: energy density (targeting >200 Wh/kg), cycle life (>10,000 cycles), temperature tolerance (-50°C to +80°C), and radiation resistance. Hybrid supercapacitors are increasingly preferred over traditional batteries due to their superior performance in rapid charge-discharge scenarios, extended operational lifetime in space environments, and better thermal management characteristics.

Market barriers include high initial costs compared to conventional energy storage solutions, with hybrid supercapacitor systems typically commanding a 30-40% premium. Technical challenges in system integration and the conservative adoption cycle of the aerospace industry also constrain market penetration. However, these barriers are gradually diminishing as manufacturing scales up and successful implementation cases demonstrate the technology's value proposition in mission-critical aerospace applications.

Current State and Challenges in Hybrid Supercapacitor Technology

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. In the aerospace sector, the current state of hybrid supercapacitor technology shows promising developments but faces several critical challenges. Globally, research institutions and aerospace companies have achieved notable progress in developing hybrid supercapacitors with improved energy density, cycle life, and operational stability under extreme conditions.

The current technological landscape reveals that hybrid supercapacitors have reached energy densities of 10-50 Wh/kg, significantly higher than conventional supercapacitors (5-10 Wh/kg) but still lower than lithium-ion batteries (100-265 Wh/kg). This intermediate position makes them particularly suitable for specific aerospace applications requiring rapid power delivery and moderate energy storage.

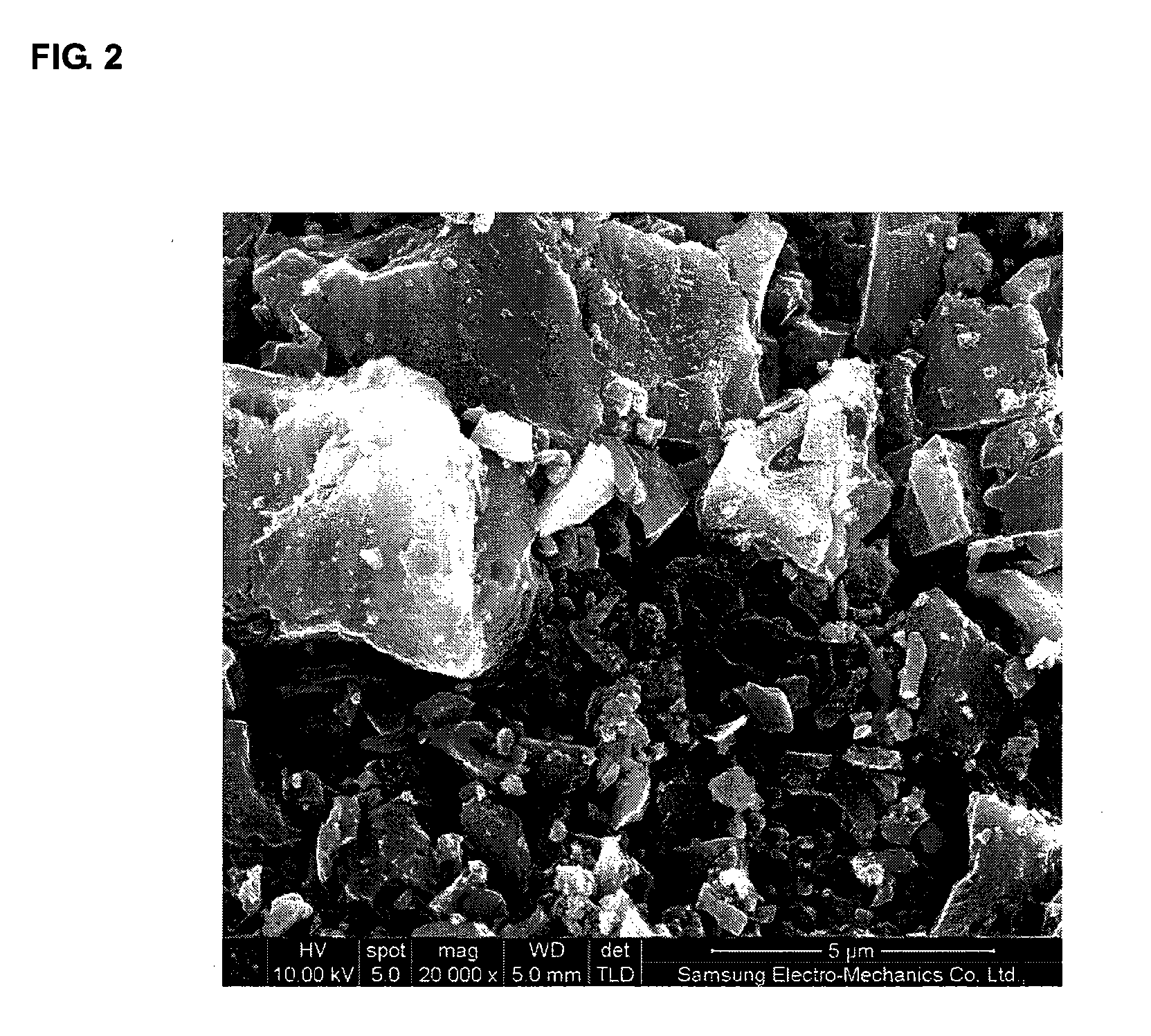

Material science innovations represent a key area of advancement, with researchers developing novel electrode materials including metal oxides, conductive polymers, and carbon-based nanomaterials. These materials demonstrate enhanced electrochemical properties, contributing to improved performance metrics. However, the integration of these advanced materials into practical, scalable devices remains challenging.

Temperature sensitivity presents a significant technical hurdle for aerospace applications. Current hybrid supercapacitors experience performance degradation at the extreme temperatures encountered in aerospace environments (-65°C to +125°C). Research indicates that electrolyte stability and electrode material integrity are particularly vulnerable to these temperature variations.

Weight and volume constraints pose another critical challenge. Despite improvements, the power-to-weight and energy-to-volume ratios of hybrid supercapacitors still require optimization for aerospace applications where every gram and cubic centimeter matters. Current designs struggle to meet the stringent requirements of modern aerospace systems.

Safety and reliability concerns persist, particularly regarding thermal runaway risks and long-term stability. While hybrid supercapacitors generally offer better safety profiles than lithium-ion batteries, their behavior under failure conditions in aerospace environments requires further investigation and standardization.

Manufacturing scalability represents another significant barrier. Current production methods for high-performance hybrid supercapacitors often involve complex processes that are difficult to scale economically. The aerospace industry requires consistent, high-quality components produced at reasonable costs, a standard that current manufacturing capabilities struggle to meet.

Regulatory and certification frameworks for hybrid supercapacitors in aerospace applications remain underdeveloped. The lack of standardized testing protocols and certification pathways creates uncertainty for technology developers and potential adopters, slowing implementation despite technological readiness.

The current technological landscape reveals that hybrid supercapacitors have reached energy densities of 10-50 Wh/kg, significantly higher than conventional supercapacitors (5-10 Wh/kg) but still lower than lithium-ion batteries (100-265 Wh/kg). This intermediate position makes them particularly suitable for specific aerospace applications requiring rapid power delivery and moderate energy storage.

Material science innovations represent a key area of advancement, with researchers developing novel electrode materials including metal oxides, conductive polymers, and carbon-based nanomaterials. These materials demonstrate enhanced electrochemical properties, contributing to improved performance metrics. However, the integration of these advanced materials into practical, scalable devices remains challenging.

Temperature sensitivity presents a significant technical hurdle for aerospace applications. Current hybrid supercapacitors experience performance degradation at the extreme temperatures encountered in aerospace environments (-65°C to +125°C). Research indicates that electrolyte stability and electrode material integrity are particularly vulnerable to these temperature variations.

Weight and volume constraints pose another critical challenge. Despite improvements, the power-to-weight and energy-to-volume ratios of hybrid supercapacitors still require optimization for aerospace applications where every gram and cubic centimeter matters. Current designs struggle to meet the stringent requirements of modern aerospace systems.

Safety and reliability concerns persist, particularly regarding thermal runaway risks and long-term stability. While hybrid supercapacitors generally offer better safety profiles than lithium-ion batteries, their behavior under failure conditions in aerospace environments requires further investigation and standardization.

Manufacturing scalability represents another significant barrier. Current production methods for high-performance hybrid supercapacitors often involve complex processes that are difficult to scale economically. The aerospace industry requires consistent, high-quality components produced at reasonable costs, a standard that current manufacturing capabilities struggle to meet.

Regulatory and certification frameworks for hybrid supercapacitors in aerospace applications remain underdeveloped. The lack of standardized testing protocols and certification pathways creates uncertainty for technology developers and potential adopters, slowing implementation despite technological readiness.

Current Hybrid Supercapacitor Implementation in Aerospace

01 Electrode materials for hybrid supercapacitors

Hybrid supercapacitors utilize specialized electrode materials to combine the high energy density of batteries with the high power density of traditional supercapacitors. These materials often include carbon-based structures (like graphene or carbon nanotubes) combined with metal oxides or conductive polymers. The electrode composition significantly affects the performance characteristics, including energy storage capacity, charge-discharge rates, and cycle life of the hybrid supercapacitor.- Electrode materials for hybrid supercapacitors: Various materials can be used as electrodes in hybrid supercapacitors to enhance energy density and performance. These include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for both faradaic and non-faradaic energy storage mechanisms, resulting in devices with higher energy density than conventional supercapacitors while maintaining good power density. The selection and optimization of these electrode materials significantly impact the overall performance of hybrid supercapacitors.

- Electrolyte compositions for hybrid supercapacitors: The electrolyte plays a crucial role in hybrid supercapacitor performance, affecting ionic conductivity, operating voltage window, and overall device stability. Various electrolyte compositions, including aqueous, organic, and ionic liquid-based formulations, can be tailored to specific applications. Advanced electrolyte designs incorporate additives to enhance stability, prevent electrode degradation, and improve the temperature range of operation. The interface between the electrolyte and electrode materials is critical for optimizing charge transfer and energy storage capabilities.

- Fabrication methods and device structures: Innovative fabrication techniques and device architectures are essential for developing high-performance hybrid supercapacitors. These include layer-by-layer assembly, 3D electrode structures, and integrated device designs that minimize internal resistance. Advanced manufacturing processes such as roll-to-roll production, spray coating, and electrodeposition enable scalable and cost-effective production. The physical configuration of components, including electrode thickness, separator design, and packaging, significantly impacts the device's energy density, power capability, and cycle life.

- Energy management systems for hybrid supercapacitors: Energy management systems are designed to optimize the performance of hybrid supercapacitors in various applications. These systems include charge controllers, voltage regulators, and monitoring circuits that ensure safe and efficient operation. Advanced management systems incorporate algorithms for balancing charge distribution, preventing overcharging, and maximizing energy recovery during discharge cycles. Integration with other energy storage technologies, such as batteries, allows for complementary operation that leverages the high power density of supercapacitors with the high energy density of batteries.

- Applications of hybrid supercapacitors: Hybrid supercapacitors find applications across various sectors due to their unique combination of high energy and power density. In automotive applications, they provide peak power for acceleration and regenerative braking in electric and hybrid vehicles. For renewable energy systems, they help stabilize power output from intermittent sources like solar and wind. In consumer electronics, they enable rapid charging capabilities and extended device lifetimes. Industrial applications include backup power systems, grid stabilization, and heavy machinery where high power bursts are required with minimal maintenance.

02 Electrolyte formulations for hybrid supercapacitors

The electrolyte is a critical component in hybrid supercapacitors, affecting ionic conductivity, operating voltage window, and overall device performance. Advanced electrolyte formulations may include organic, aqueous, or ionic liquid-based solutions, each offering different advantages in terms of conductivity, stability, and safety. Specialized additives can enhance the electrolyte properties, improving the energy density and extending the operational temperature range of hybrid supercapacitors.Expand Specific Solutions03 Energy management systems incorporating hybrid supercapacitors

Hybrid supercapacitors can be integrated into sophisticated energy management systems that optimize power distribution, storage, and utilization. These systems often include control algorithms that manage the charge-discharge cycles, monitor performance parameters, and protect against overcharging or deep discharging. Applications range from renewable energy storage to electric vehicles, where the rapid charge-discharge capabilities of hybrid supercapacitors complement traditional battery systems.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitors

Advanced manufacturing techniques are essential for producing high-performance hybrid supercapacitors. These processes may include specialized coating methods, electrode assembly techniques, and encapsulation procedures that ensure optimal electrical contact and structural integrity. Innovations in manufacturing focus on improving consistency, reducing costs, and scaling production while maintaining the performance characteristics of laboratory prototypes.Expand Specific Solutions05 Novel hybrid supercapacitor architectures

Innovative architectural designs for hybrid supercapacitors aim to overcome traditional limitations in energy and power density. These designs may include asymmetric configurations, where different materials are used for positive and negative electrodes, or multi-layer structures that optimize ion transport pathways. Novel architectures often focus on maximizing the surface area available for charge storage while maintaining efficient electron and ion transport throughout the device.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The hybrid supercapacitor market in aerospace energy systems is currently in its growth phase, with increasing adoption driven by demands for more efficient and lightweight power solutions. The global market is projected to expand significantly as aerospace manufacturers seek alternatives to traditional energy storage systems. Technologically, major players demonstrate varying levels of maturity: established industrial giants like Robert Bosch GmbH and Samsung Electro Mechanics offer commercially viable solutions, while research institutions such as Tsinghua University and the Chinese Academy of Sciences lead fundamental innovation. Aerospace specialists including Airbus Operations and Safran Electrical & Power are integrating these technologies into practical applications, while energy companies like Shell and automotive manufacturers such as General Motors and SAIC Motor are exploring crossover applications. This diverse ecosystem indicates a technology approaching mainstream adoption but still undergoing significant refinement.

Commissariat à l´énergie atomique et aux énergies Alternatives

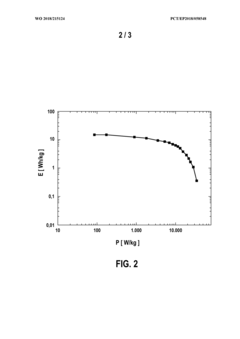

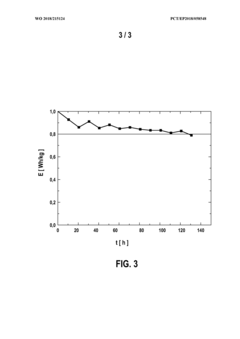

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed advanced hybrid supercapacitor technology specifically tailored for aerospace applications. Their research focuses on nano-structured carbon-based electrodes combined with lithium-ion intercalation materials to create devices that bridge the gap between traditional supercapacitors and batteries. CEA's proprietary electrode fabrication process utilizes hierarchical porous carbon structures derived from sustainable biomass sources, which are then functionalized with nitrogen and oxygen groups to enhance capacitance. Their hybrid systems achieve energy densities of 15-20 Wh/kg while maintaining power densities of 5-7 kW/kg. A key innovation in CEA's approach is their development of solid-state electrolytes that eliminate leakage risks in aerospace environments while extending the operating temperature range from -60°C to +100°C. The organization has demonstrated these technologies in collaboration with European aerospace manufacturers, showing particular promise for satellite applications where their systems provide efficient power management for orbital maneuvers and eclipse transitions. CEA's hybrid supercapacitors have demonstrated exceptional cycle stability, maintaining over 80% capacity after 100,000 charge-discharge cycles.

Strengths: Cutting-edge research capabilities; solid-state electrolyte technology eliminates leakage concerns; excellent cycle stability and calendar life. Weaknesses: Technology still in transition from research to commercial scale; higher costs compared to conventional solutions; integration complexity with existing aerospace power systems.

Safran Electrical & Power SA

Technical Solution: Safran has developed advanced hybrid supercapacitor systems specifically designed for aerospace applications, focusing on power management during critical flight phases. Their technology integrates lithium-ion capacitors with traditional batteries to create a hybrid energy storage system that can deliver high power during takeoff and landing while maintaining energy density for cruise operations. The system employs proprietary electrode materials combining activated carbon with lithium-doped materials to achieve energy densities approaching 15 Wh/kg while maintaining power densities above 5 kW/kg. Safran's aerospace-certified systems include thermal management solutions that prevent thermal runaway in the harsh conditions of flight, with operating temperature ranges from -40°C to +70°C. Their modular architecture allows for scalability across different aircraft platforms, from business jets to commercial airliners.

Strengths: Aerospace-specific certification and compliance with stringent aviation safety standards; excellent thermal management capabilities; proven integration with existing aircraft electrical systems. Weaknesses: Higher cost compared to conventional systems; weight still remains a challenge for smaller aircraft applications; limited cycle life at extreme temperature conditions.

Key Technical Innovations in Aerospace-Grade Supercapacitors

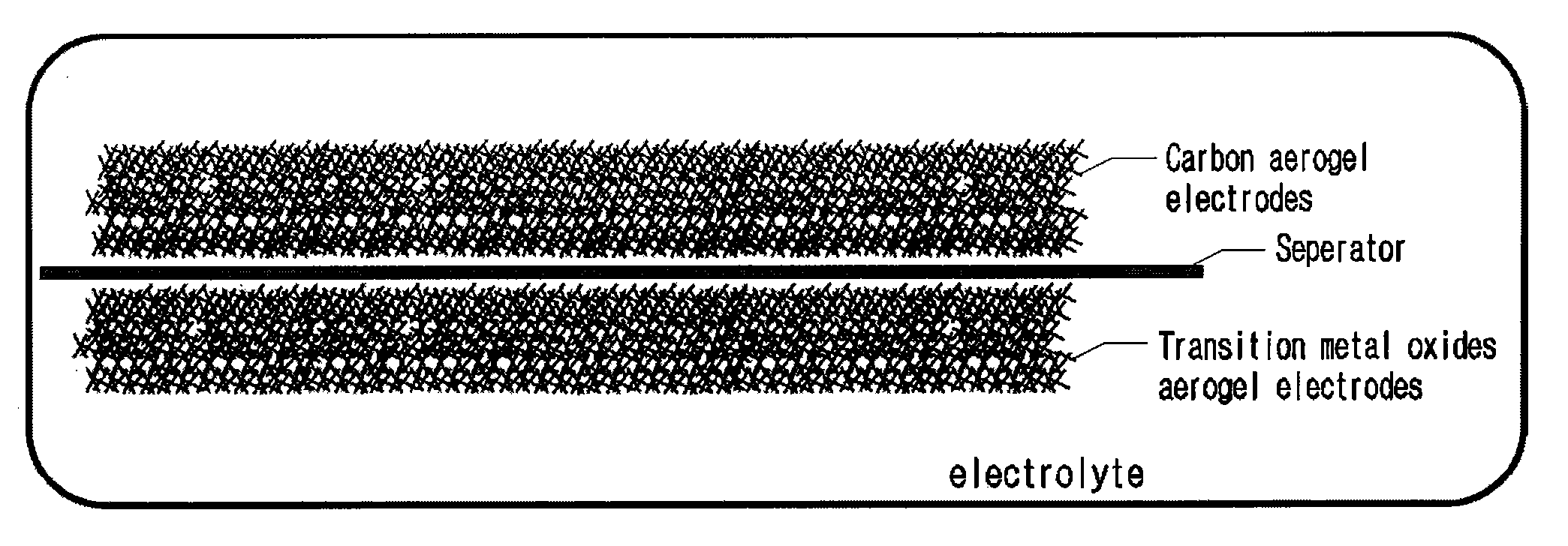

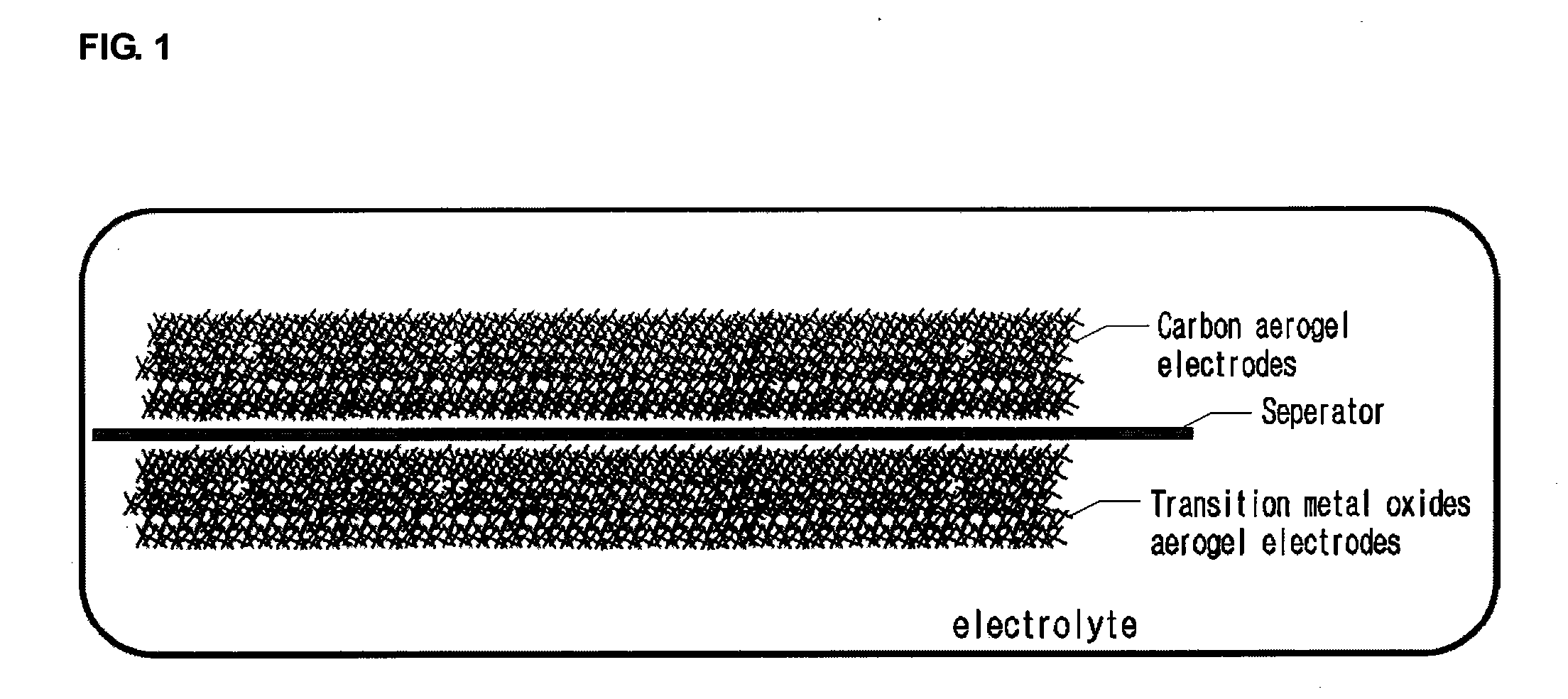

Hybrid supercapacitor using transition metal oxide aerogel

PatentInactiveUS20100195268A1

Innovation

- A hybrid supercapacitor design utilizing a monolithic carbon aerogel cathode and transition metal oxide aerogel anode, eliminating the need for a current collector and binder, thereby optimizing the contact area and reducing internal resistance, and employing a sol-gel process to control pore size and enhance capacitance.

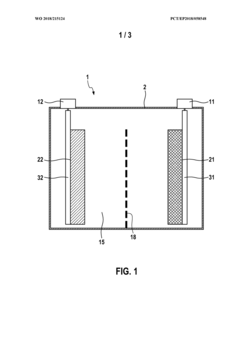

Hybrid supercapacitor for high-temperature applications

PatentWO2018215124A1

Innovation

- A hybrid supercapacitor design featuring a negative electrode with static capacitive active material, a positive electrode with electrochemical redox active material, and an electrolyte composition including an ionic liquid and lithium-containing conductive additive, allowing for high power and energy density along with extended lifespan at elevated temperatures.

Safety and Reliability Standards for Aerospace Power Systems

The aerospace industry imposes exceptionally stringent safety and reliability requirements on all components, with power systems being particularly critical. Hybrid supercapacitors deployed in aerospace applications must adhere to comprehensive standards that exceed those of terrestrial applications. The primary aerospace standards governing energy storage systems include DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment), MIL-STD-810 (Environmental Engineering Considerations), and MIL-STD-704 (Aircraft Electric Power Characteristics).

Safety certification for hybrid supercapacitors requires extensive testing for thermal runaway prevention, with temperature tolerance ranges typically between -65°C to +150°C for military aerospace applications. These systems must demonstrate resilience against rapid decompression scenarios, where traditional battery technologies might experience catastrophic failure. The FAA and EASA mandate that energy storage systems maintain operational integrity during extreme vibration conditions (20-2000 Hz frequency range) and withstand shock loads up to 20G.

Reliability standards for aerospace power systems emphasize redundancy architectures and fault tolerance. Hybrid supercapacitors must demonstrate a minimum operational lifetime of 10,000 charge-discharge cycles while maintaining at least 80% of initial capacity. Mean Time Between Failures (MTBF) requirements typically exceed 50,000 hours for critical systems, necessitating advanced prognostic health monitoring capabilities integrated within the supercapacitor management systems.

Electromagnetic compatibility standards (MIL-STD-461) impose strict limitations on electromagnetic interference generation and susceptibility. Hybrid supercapacitors must operate without performance degradation in high-radiation environments, particularly for satellite applications where radiation hardening is essential. This requires specialized materials and shielding techniques not necessary in terrestrial applications.

Recent developments in aerospace standards have begun addressing the unique characteristics of hybrid supercapacitors, particularly their rapid charge-discharge capabilities and intermediate position between batteries and traditional capacitors. The SAE International Aerospace Standards AS6349 committee is currently developing specific guidelines for supercapacitor implementation in aircraft electrical systems, focusing on their integration with existing power architectures.

Compliance verification protocols for hybrid supercapacitors include accelerated life testing, environmental stress screening, and Hardware-in-the-Loop (HIL) simulation under various flight conditions. Manufacturers must provide comprehensive documentation of materials composition, particularly regarding fire-retardant properties and outgassing characteristics in low-pressure environments.

Safety certification for hybrid supercapacitors requires extensive testing for thermal runaway prevention, with temperature tolerance ranges typically between -65°C to +150°C for military aerospace applications. These systems must demonstrate resilience against rapid decompression scenarios, where traditional battery technologies might experience catastrophic failure. The FAA and EASA mandate that energy storage systems maintain operational integrity during extreme vibration conditions (20-2000 Hz frequency range) and withstand shock loads up to 20G.

Reliability standards for aerospace power systems emphasize redundancy architectures and fault tolerance. Hybrid supercapacitors must demonstrate a minimum operational lifetime of 10,000 charge-discharge cycles while maintaining at least 80% of initial capacity. Mean Time Between Failures (MTBF) requirements typically exceed 50,000 hours for critical systems, necessitating advanced prognostic health monitoring capabilities integrated within the supercapacitor management systems.

Electromagnetic compatibility standards (MIL-STD-461) impose strict limitations on electromagnetic interference generation and susceptibility. Hybrid supercapacitors must operate without performance degradation in high-radiation environments, particularly for satellite applications where radiation hardening is essential. This requires specialized materials and shielding techniques not necessary in terrestrial applications.

Recent developments in aerospace standards have begun addressing the unique characteristics of hybrid supercapacitors, particularly their rapid charge-discharge capabilities and intermediate position between batteries and traditional capacitors. The SAE International Aerospace Standards AS6349 committee is currently developing specific guidelines for supercapacitor implementation in aircraft electrical systems, focusing on their integration with existing power architectures.

Compliance verification protocols for hybrid supercapacitors include accelerated life testing, environmental stress screening, and Hardware-in-the-Loop (HIL) simulation under various flight conditions. Manufacturers must provide comprehensive documentation of materials composition, particularly regarding fire-retardant properties and outgassing characteristics in low-pressure environments.

Environmental Impact and Sustainability Considerations

The integration of hybrid supercapacitors in aerospace energy systems presents significant environmental advantages compared to traditional power solutions. These devices offer reduced environmental footprint through their extended lifecycle, with operational lifespans reaching up to 1 million charge-discharge cycles compared to conventional batteries' few thousand cycles. This dramatic increase in longevity directly translates to fewer replacement components and substantially reduced electronic waste generation in aerospace applications.

Material composition represents another critical environmental consideration. Unlike conventional lithium-ion batteries that rely heavily on rare earth elements and potentially toxic materials, hybrid supercapacitors increasingly utilize sustainable carbon-based materials such as graphene, activated carbon, and carbon nanotubes. Recent advancements have demonstrated promising results with bio-derived carbon sources, including agricultural waste products, further enhancing their sustainability profile.

Energy efficiency metrics also favor hybrid supercapacitors in aerospace contexts. With charge-discharge efficiencies exceeding 95% in optimal conditions, these systems minimize energy losses during operation. This efficiency translates to reduced overall energy consumption throughout the aerospace vehicle lifecycle, contributing to lower carbon emissions when considering the complete energy chain from generation to utilization.

Manufacturing processes for hybrid supercapacitors continue to evolve toward greater sustainability. Current production methods still involve energy-intensive processes, particularly in the synthesis of advanced electrode materials. However, emerging green manufacturing techniques, including aqueous processing and solvent-free electrode fabrication, demonstrate potential for reducing the environmental impact of production by up to 40% according to recent industry analyses.

End-of-life considerations represent a significant advantage for hybrid supercapacitor technology. The predominant carbon-based materials in these devices are inherently more recyclable than complex battery chemistries. Developing recycling protocols specifically for aerospace-grade supercapacitors could recover up to 80% of critical materials, creating a circular economy opportunity while reducing dependence on virgin resource extraction.

Regulatory frameworks increasingly recognize these environmental benefits, with aerospace sustainability certifications beginning to award preferential status to energy storage solutions with demonstrated lifecycle advantages. This regulatory trend is likely to accelerate adoption of hybrid supercapacitor technology in next-generation aerospace platforms seeking to minimize environmental impact while maintaining or enhancing performance parameters.

Material composition represents another critical environmental consideration. Unlike conventional lithium-ion batteries that rely heavily on rare earth elements and potentially toxic materials, hybrid supercapacitors increasingly utilize sustainable carbon-based materials such as graphene, activated carbon, and carbon nanotubes. Recent advancements have demonstrated promising results with bio-derived carbon sources, including agricultural waste products, further enhancing their sustainability profile.

Energy efficiency metrics also favor hybrid supercapacitors in aerospace contexts. With charge-discharge efficiencies exceeding 95% in optimal conditions, these systems minimize energy losses during operation. This efficiency translates to reduced overall energy consumption throughout the aerospace vehicle lifecycle, contributing to lower carbon emissions when considering the complete energy chain from generation to utilization.

Manufacturing processes for hybrid supercapacitors continue to evolve toward greater sustainability. Current production methods still involve energy-intensive processes, particularly in the synthesis of advanced electrode materials. However, emerging green manufacturing techniques, including aqueous processing and solvent-free electrode fabrication, demonstrate potential for reducing the environmental impact of production by up to 40% according to recent industry analyses.

End-of-life considerations represent a significant advantage for hybrid supercapacitor technology. The predominant carbon-based materials in these devices are inherently more recyclable than complex battery chemistries. Developing recycling protocols specifically for aerospace-grade supercapacitors could recover up to 80% of critical materials, creating a circular economy opportunity while reducing dependence on virgin resource extraction.

Regulatory frameworks increasingly recognize these environmental benefits, with aerospace sustainability certifications beginning to award preferential status to energy storage solutions with demonstrated lifecycle advantages. This regulatory trend is likely to accelerate adoption of hybrid supercapacitor technology in next-generation aerospace platforms seeking to minimize environmental impact while maintaining or enhancing performance parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!