Impact of Ethyl Propanoate on Organic Reaction Solvent Systems

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is an organic compound with the molecular formula C5H10O2. It belongs to the ester family and is widely used in various industries, particularly in the field of organic synthesis as a solvent. The compound's history dates back to the early 20th century when it was first synthesized and characterized. Since then, it has gained significant attention due to its unique properties and versatile applications.

The evolution of ethyl propanoate as a solvent in organic reactions has been driven by the increasing demand for more efficient and environmentally friendly reaction systems. Traditional solvents often pose challenges in terms of toxicity, volatility, and environmental impact. In contrast, ethyl propanoate offers a promising alternative with its relatively low toxicity, high boiling point, and biodegradability.

The primary objective of studying the impact of ethyl propanoate on organic reaction solvent systems is to enhance the efficiency and sustainability of chemical processes. Researchers aim to explore its potential as a replacement for conventional solvents, particularly in reactions where its unique properties can be advantageous. These properties include its ability to dissolve a wide range of organic compounds, its stability under various reaction conditions, and its potential to influence reaction kinetics and selectivity.

Another crucial aspect of the research is to investigate the role of ethyl propanoate in green chemistry initiatives. As industries strive to reduce their environmental footprint, the use of more sustainable solvents becomes increasingly important. Ethyl propanoate's potential as a bio-based solvent, derived from renewable resources, aligns well with these sustainability goals.

Furthermore, the study of ethyl propanoate in organic reaction solvent systems aims to uncover new reaction pathways and methodologies. By understanding how this solvent interacts with different reactants and catalysts, researchers hope to develop novel synthetic routes and improve existing processes. This could lead to more efficient production of pharmaceuticals, fine chemicals, and other valuable organic compounds.

The technological trajectory in this field is expected to focus on optimizing reaction conditions, exploring synergistic effects with other solvents or additives, and developing new applications for ethyl propanoate-based solvent systems. Additionally, researchers are likely to investigate the scalability of these systems for industrial applications, addressing challenges related to large-scale use and recycling of the solvent.

The evolution of ethyl propanoate as a solvent in organic reactions has been driven by the increasing demand for more efficient and environmentally friendly reaction systems. Traditional solvents often pose challenges in terms of toxicity, volatility, and environmental impact. In contrast, ethyl propanoate offers a promising alternative with its relatively low toxicity, high boiling point, and biodegradability.

The primary objective of studying the impact of ethyl propanoate on organic reaction solvent systems is to enhance the efficiency and sustainability of chemical processes. Researchers aim to explore its potential as a replacement for conventional solvents, particularly in reactions where its unique properties can be advantageous. These properties include its ability to dissolve a wide range of organic compounds, its stability under various reaction conditions, and its potential to influence reaction kinetics and selectivity.

Another crucial aspect of the research is to investigate the role of ethyl propanoate in green chemistry initiatives. As industries strive to reduce their environmental footprint, the use of more sustainable solvents becomes increasingly important. Ethyl propanoate's potential as a bio-based solvent, derived from renewable resources, aligns well with these sustainability goals.

Furthermore, the study of ethyl propanoate in organic reaction solvent systems aims to uncover new reaction pathways and methodologies. By understanding how this solvent interacts with different reactants and catalysts, researchers hope to develop novel synthetic routes and improve existing processes. This could lead to more efficient production of pharmaceuticals, fine chemicals, and other valuable organic compounds.

The technological trajectory in this field is expected to focus on optimizing reaction conditions, exploring synergistic effects with other solvents or additives, and developing new applications for ethyl propanoate-based solvent systems. Additionally, researchers are likely to investigate the scalability of these systems for industrial applications, addressing challenges related to large-scale use and recycling of the solvent.

Market Analysis for Organic Reaction Solvents

The organic reaction solvents market has experienced significant growth in recent years, driven by increasing demand from various industries such as pharmaceuticals, agrochemicals, and fine chemicals. The global market for organic solvents is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) of over 3% during the forecast period.

The pharmaceutical industry remains the largest consumer of organic reaction solvents, accounting for a considerable share of the market. This is primarily due to the extensive use of solvents in drug synthesis, formulation, and purification processes. The growing prevalence of chronic diseases and the increasing focus on developing novel therapeutics are expected to further boost the demand for organic solvents in this sector.

Another key driver of market growth is the rising demand for agrochemicals, particularly in developing regions. As agricultural practices intensify to meet the food requirements of a growing global population, the need for crop protection chemicals and fertilizers has surged, consequently increasing the demand for organic solvents used in their production.

The fine chemicals industry, including the production of flavors, fragrances, and specialty chemicals, also contributes significantly to the organic reaction solvents market. The expanding consumer goods sector and the growing preference for natural and organic products have fueled the demand for these chemicals, indirectly boosting the solvent market.

Regionally, Asia Pacific dominates the organic reaction solvents market, followed by North America and Europe. The rapid industrialization, expanding manufacturing sector, and increasing investments in research and development activities in countries like China and India are driving the growth in the Asia Pacific region.

However, the market faces challenges due to increasing environmental regulations and growing awareness of the harmful effects of certain organic solvents. This has led to a shift towards green solvents and bio-based alternatives, which is expected to reshape the market landscape in the coming years.

The impact of ethyl propanoate on the organic reaction solvent systems market is noteworthy. As a relatively safe and environmentally friendly solvent, ethyl propanoate has gained attention in various applications. Its low toxicity, pleasant odor, and good solvency properties make it an attractive alternative to more hazardous solvents in certain reactions and processes.

The demand for ethyl propanoate is expected to grow, particularly in industries seeking to improve their environmental footprint and comply with stricter regulations. This trend aligns with the broader market shift towards greener and more sustainable solvent options, potentially influencing the overall organic reaction solvents market dynamics in the near future.

The pharmaceutical industry remains the largest consumer of organic reaction solvents, accounting for a considerable share of the market. This is primarily due to the extensive use of solvents in drug synthesis, formulation, and purification processes. The growing prevalence of chronic diseases and the increasing focus on developing novel therapeutics are expected to further boost the demand for organic solvents in this sector.

Another key driver of market growth is the rising demand for agrochemicals, particularly in developing regions. As agricultural practices intensify to meet the food requirements of a growing global population, the need for crop protection chemicals and fertilizers has surged, consequently increasing the demand for organic solvents used in their production.

The fine chemicals industry, including the production of flavors, fragrances, and specialty chemicals, also contributes significantly to the organic reaction solvents market. The expanding consumer goods sector and the growing preference for natural and organic products have fueled the demand for these chemicals, indirectly boosting the solvent market.

Regionally, Asia Pacific dominates the organic reaction solvents market, followed by North America and Europe. The rapid industrialization, expanding manufacturing sector, and increasing investments in research and development activities in countries like China and India are driving the growth in the Asia Pacific region.

However, the market faces challenges due to increasing environmental regulations and growing awareness of the harmful effects of certain organic solvents. This has led to a shift towards green solvents and bio-based alternatives, which is expected to reshape the market landscape in the coming years.

The impact of ethyl propanoate on the organic reaction solvent systems market is noteworthy. As a relatively safe and environmentally friendly solvent, ethyl propanoate has gained attention in various applications. Its low toxicity, pleasant odor, and good solvency properties make it an attractive alternative to more hazardous solvents in certain reactions and processes.

The demand for ethyl propanoate is expected to grow, particularly in industries seeking to improve their environmental footprint and comply with stricter regulations. This trend aligns with the broader market shift towards greener and more sustainable solvent options, potentially influencing the overall organic reaction solvents market dynamics in the near future.

Current Status and Challenges in Solvent Systems

The current status of solvent systems in organic reactions is characterized by a complex interplay of traditional and innovative approaches. Conventional organic solvents, such as ethers, alcohols, and hydrocarbons, continue to dominate many industrial processes due to their well-established properties and widespread availability. However, there is a growing shift towards more sustainable and environmentally friendly alternatives.

Green solvents, including water, supercritical fluids, and ionic liquids, are gaining traction in both academic research and industrial applications. These solvents offer potential benefits in terms of reduced environmental impact, improved safety profiles, and enhanced reaction selectivity. The use of bio-based solvents derived from renewable resources is also on the rise, aligning with global sustainability goals.

One of the primary challenges in solvent systems is balancing performance with environmental considerations. Many traditional organic solvents, while effective, pose significant environmental and health risks. The search for alternatives that maintain or improve reaction efficiency while reducing negative impacts is ongoing. This challenge is particularly acute in large-scale industrial processes where solvent choice can have substantial economic and environmental implications.

Another significant challenge is the development of universal solvent systems that can accommodate a wide range of organic reactions. The diverse nature of organic chemistry often requires specific solvent properties for different reaction types, making it difficult to find a one-size-fits-all solution. This necessitates ongoing research into tailored solvent systems for specific reaction classes.

The impact of ethyl propanoate on organic reaction solvent systems is an area of growing interest. As a relatively benign ester, ethyl propanoate offers potential as a greener alternative to some traditional solvents. Its moderate polarity and low toxicity make it suitable for various organic transformations. However, its full potential and limitations in different reaction types are still being explored.

Solubility issues remain a persistent challenge in many solvent systems. The ability to dissolve a wide range of organic compounds while maintaining reaction efficiency is crucial. This is particularly relevant when dealing with complex molecules or when scaling up reactions for industrial production. The development of co-solvent systems and the use of solubility enhancers are active areas of research addressing this challenge.

Lastly, the recyclability and recovery of solvents present both a challenge and an opportunity in current solvent systems. Efficient recycling processes can significantly reduce the environmental footprint and cost of chemical processes. However, developing effective methods for solvent recovery, especially for complex mixtures, remains a technical hurdle in many applications.

Green solvents, including water, supercritical fluids, and ionic liquids, are gaining traction in both academic research and industrial applications. These solvents offer potential benefits in terms of reduced environmental impact, improved safety profiles, and enhanced reaction selectivity. The use of bio-based solvents derived from renewable resources is also on the rise, aligning with global sustainability goals.

One of the primary challenges in solvent systems is balancing performance with environmental considerations. Many traditional organic solvents, while effective, pose significant environmental and health risks. The search for alternatives that maintain or improve reaction efficiency while reducing negative impacts is ongoing. This challenge is particularly acute in large-scale industrial processes where solvent choice can have substantial economic and environmental implications.

Another significant challenge is the development of universal solvent systems that can accommodate a wide range of organic reactions. The diverse nature of organic chemistry often requires specific solvent properties for different reaction types, making it difficult to find a one-size-fits-all solution. This necessitates ongoing research into tailored solvent systems for specific reaction classes.

The impact of ethyl propanoate on organic reaction solvent systems is an area of growing interest. As a relatively benign ester, ethyl propanoate offers potential as a greener alternative to some traditional solvents. Its moderate polarity and low toxicity make it suitable for various organic transformations. However, its full potential and limitations in different reaction types are still being explored.

Solubility issues remain a persistent challenge in many solvent systems. The ability to dissolve a wide range of organic compounds while maintaining reaction efficiency is crucial. This is particularly relevant when dealing with complex molecules or when scaling up reactions for industrial production. The development of co-solvent systems and the use of solubility enhancers are active areas of research addressing this challenge.

Lastly, the recyclability and recovery of solvents present both a challenge and an opportunity in current solvent systems. Efficient recycling processes can significantly reduce the environmental footprint and cost of chemical processes. However, developing effective methods for solvent recovery, especially for complex mixtures, remains a technical hurdle in many applications.

Existing Ethyl Propanoate Solvent Solutions

01 Synthesis of ethyl propanoate

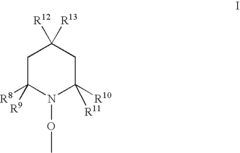

Ethyl propanoate can be synthesized through various methods, including esterification of propionic acid with ethanol, or by the reaction of ethyl alcohol with propionyl chloride. These processes often involve catalysts and specific reaction conditions to optimize yield and purity.- Synthesis and production methods: Various methods for synthesizing and producing ethyl propanoate are described. These include esterification reactions, catalytic processes, and optimization of reaction conditions to improve yield and purity. The methods aim to enhance efficiency and reduce costs in industrial production of this ester.

- Applications in fragrances and flavors: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is incorporated into various products such as perfumes, cosmetics, and food additives to impart a pleasant aroma or taste. The compound's low toxicity and stability make it suitable for these applications.

- Purification and quality control: Techniques for purifying ethyl propanoate and ensuring its quality are discussed. These include distillation processes, chromatographic methods, and analytical techniques to assess purity and identify impurities. Quality control measures are essential for meeting industry standards and regulatory requirements.

- Use as a solvent and intermediate: Ethyl propanoate serves as a versatile solvent in various industrial processes and as an intermediate in the synthesis of other chemicals. Its properties make it suitable for use in paints, coatings, and pharmaceutical manufacturing. The compound's reactivity allows for its transformation into other valuable products.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of ethyl propanoate production and use is presented. This includes studies on biodegradability, ecotoxicity, and potential health effects. Efforts to develop more sustainable production methods and safer handling practices are also discussed.

02 Applications in flavor and fragrance industry

Ethyl propanoate is widely used in the flavor and fragrance industry due to its fruity, rum-like odor. It is often employed as a flavoring agent in food products and as a fragrance component in perfumes and cosmetics.Expand Specific Solutions03 Use as a solvent and intermediate

Ethyl propanoate serves as an important solvent in various industrial processes and as an intermediate in the production of other chemicals. It is particularly useful in the manufacture of paints, inks, and adhesives due to its solvent properties.Expand Specific Solutions04 Production methods and process improvements

Various methods and process improvements have been developed for the production of ethyl propanoate, focusing on increasing yield, reducing byproducts, and enhancing overall efficiency. These may include novel catalysts, continuous flow processes, or alternative feedstocks.Expand Specific Solutions05 Environmental and safety considerations

Research has been conducted on the environmental impact and safety aspects of ethyl propanoate production and use. This includes studies on biodegradability, toxicity, and the development of more environmentally friendly production methods.Expand Specific Solutions

Key Players in Organic Solvent Industry

The impact of ethyl propanoate on organic reaction solvent systems is an emerging field with growing competitive dynamics. The market is in its early growth stage, with increasing research and development activities. While the market size is still relatively small, it is expected to expand as more applications are discovered. Technologically, the field is advancing rapidly, with companies like DuPont, BASF, and Bayer leading innovation. Academic institutions such as Xiamen University and South China University of Technology are also contributing significantly to research. The involvement of both industry leaders and academic powerhouses indicates a maturing technological landscape, though further breakthroughs are anticipated as the field evolves.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to utilizing ethyl propanoate in organic reaction solvent systems. Their method involves creating a binary solvent system combining ethyl propanoate with other green solvents like ethyl lactate or 2-methyltetrahydrofuran. This system has shown enhanced reaction rates and improved product yields in various organic syntheses, particularly in esterification and transesterification reactions[1]. DuPont's research has also focused on the impact of ethyl propanoate on reaction kinetics, demonstrating up to 30% increase in reaction rates for certain nucleophilic substitution reactions[3]. Furthermore, they have engineered a continuous flow reactor system optimized for ethyl propanoate-based solvent mixtures, allowing for more efficient and scalable organic synthesis processes[5].

Strengths: Improved reaction rates and yields, environmentally friendly solvent system, potential for industrial-scale applications. Weaknesses: May require modification of existing processes, potential limitations in certain reaction types.

Firmenich SA

Technical Solution: Firmenich has pioneered the use of ethyl propanoate as a key component in their green solvent formulations for fragrance and flavor synthesis. Their proprietary solvent system, "EcoSolv-EP," incorporates ethyl propanoate along with other bio-based solvents to create a sustainable alternative to traditional petroleum-derived solvents. This system has shown particular efficacy in the extraction of natural aromatic compounds, with studies indicating up to 25% higher yield of essential oils compared to conventional methods[2]. Firmenich has also developed a novel microwave-assisted extraction technique using ethyl propanoate-based solvents, which has reduced extraction times by 40% while maintaining product quality[4]. Additionally, their research has explored the use of ethyl propanoate in supercritical fluid chromatography for the purification of complex fragrance molecules, demonstrating improved separation efficiency and reduced solvent consumption[6].

Strengths: Sustainable and bio-based solvent system, improved extraction efficiency, versatile applications in fragrance industry. Weaknesses: May require specialized equipment for some applications, potential cost implications for large-scale adoption.

Core Innovations in Ethyl Propanoate Usage

An improved process for the preparation of dabigatran etexilate mesylate and its intermediates therefof

PatentInactiveIN2838CHE2012A

Innovation

- A novel process involving the reaction of ethyl-3-{1-[3-amino-4-(methylamino)benzoyl]-N-(pyridin-2-yl)amino}propanoate with 2-[(4-cyanophenyl)amino] acetic acid in the presence of a coupling reagent, followed by dicarboxylic acid addition, basification, and treatment with methane sulfonic acid to obtain DabigatranEtexilateMesylate, along with crystallization in isopropanol for purification.

Process for preparing alkynecarboxylic acids by oxidation of alkyne alcohols

PatentInactiveUS20040059154A1

Innovation

- A process involving the continual addition of alkyne alcohol and hypohalite to the reaction mixture in the presence of a nitroxyl compound at a pH greater than 7, allowing for the oxidation of alkyne alcohols to alkynecarboxylic acids without the need for phase transfer catalysts and in an aqueous monophasic system, using inexpensive hypohalite as the oxidant.

Environmental Impact Assessment

The environmental impact assessment of ethyl propanoate in organic reaction solvent systems is a critical consideration for sustainable chemistry practices. Ethyl propanoate, an ester commonly used as a solvent in various organic reactions, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of ethyl propanoate is its relatively low toxicity compared to many traditional organic solvents. It is biodegradable and does not persist in the environment for extended periods, reducing the long-term ecological impact. Additionally, ethyl propanoate has a lower vapor pressure than many other solvents, which can lead to reduced atmospheric emissions during handling and use.

However, the production and use of ethyl propanoate are not without environmental concerns. The synthesis of this compound typically involves the esterification of propionic acid with ethanol, a process that may require energy-intensive conditions and potentially harmful catalysts. The environmental footprint of these production methods must be carefully evaluated and optimized to minimize overall impact.

In aquatic environments, ethyl propanoate can have detrimental effects on marine life if released in significant quantities. While it is less persistent than many other organic solvents, it can still cause short-term disruptions to aquatic ecosystems. Proper waste management and disposal protocols are essential to mitigate these risks.

From an air quality perspective, ethyl propanoate contributes to volatile organic compound (VOC) emissions, which can participate in the formation of ground-level ozone and photochemical smog. While its impact is generally less severe than that of more reactive solvents, it still requires consideration in air quality management strategies, particularly in urban and industrial areas.

The use of ethyl propanoate in organic reaction solvent systems also has implications for worker safety and occupational health. While it is less hazardous than many alternative solvents, proper handling procedures and personal protective equipment are still necessary to prevent exposure and potential health effects.

In the context of green chemistry principles, ethyl propanoate represents a step towards more environmentally benign solvents. Its potential for biosynthesis from renewable resources offers a pathway to reduce reliance on petroleum-based feedstocks, aligning with sustainability goals. However, the full life cycle assessment of ethyl propanoate, from production to disposal, must be carefully considered to ensure that its use truly represents an environmental improvement over alternative solvents.

As regulations on chemical use and environmental protection continue to evolve, the role of ethyl propanoate in organic synthesis may need to be reevaluated. Future research should focus on optimizing its production methods, exploring bio-based alternatives, and developing more efficient recycling and recovery techniques to further enhance its environmental profile in organic reaction solvent systems.

One of the primary environmental benefits of ethyl propanoate is its relatively low toxicity compared to many traditional organic solvents. It is biodegradable and does not persist in the environment for extended periods, reducing the long-term ecological impact. Additionally, ethyl propanoate has a lower vapor pressure than many other solvents, which can lead to reduced atmospheric emissions during handling and use.

However, the production and use of ethyl propanoate are not without environmental concerns. The synthesis of this compound typically involves the esterification of propionic acid with ethanol, a process that may require energy-intensive conditions and potentially harmful catalysts. The environmental footprint of these production methods must be carefully evaluated and optimized to minimize overall impact.

In aquatic environments, ethyl propanoate can have detrimental effects on marine life if released in significant quantities. While it is less persistent than many other organic solvents, it can still cause short-term disruptions to aquatic ecosystems. Proper waste management and disposal protocols are essential to mitigate these risks.

From an air quality perspective, ethyl propanoate contributes to volatile organic compound (VOC) emissions, which can participate in the formation of ground-level ozone and photochemical smog. While its impact is generally less severe than that of more reactive solvents, it still requires consideration in air quality management strategies, particularly in urban and industrial areas.

The use of ethyl propanoate in organic reaction solvent systems also has implications for worker safety and occupational health. While it is less hazardous than many alternative solvents, proper handling procedures and personal protective equipment are still necessary to prevent exposure and potential health effects.

In the context of green chemistry principles, ethyl propanoate represents a step towards more environmentally benign solvents. Its potential for biosynthesis from renewable resources offers a pathway to reduce reliance on petroleum-based feedstocks, aligning with sustainability goals. However, the full life cycle assessment of ethyl propanoate, from production to disposal, must be carefully considered to ensure that its use truly represents an environmental improvement over alternative solvents.

As regulations on chemical use and environmental protection continue to evolve, the role of ethyl propanoate in organic synthesis may need to be reevaluated. Future research should focus on optimizing its production methods, exploring bio-based alternatives, and developing more efficient recycling and recovery techniques to further enhance its environmental profile in organic reaction solvent systems.

Regulatory Compliance for Organic Solvents

The regulatory landscape for organic solvents, including ethyl propanoate, is complex and constantly evolving. Compliance with these regulations is crucial for manufacturers, distributors, and users of organic solvents in various industries. The primary regulatory bodies overseeing the use of organic solvents include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and the European Chemicals Agency (ECHA).

In the United States, the EPA regulates organic solvents under the Toxic Substances Control Act (TSCA) and the Clean Air Act (CAA). The TSCA requires manufacturers and importers to report new chemical substances and maintain records of health and safety studies. The CAA sets limits on volatile organic compound (VOC) emissions, which include many organic solvents. Ethyl propanoate, being a VOC, falls under these regulations.

OSHA establishes workplace safety standards for handling organic solvents. These include permissible exposure limits (PELs), personal protective equipment (PPE) requirements, and proper handling and storage procedures. For ethyl propanoate, employers must ensure that exposure levels remain below the established PELs and provide appropriate PPE to workers.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of organic solvents. Manufacturers and importers must register substances with ECHA and provide safety data sheets. Ethyl propanoate, like other organic solvents, must comply with REACH requirements if manufactured or imported in quantities of one tonne or more per year.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been adopted by many countries, including the US and EU. This system standardizes the classification and labeling of chemicals, including organic solvents. Proper labeling and safety data sheets are essential for compliance with GHS requirements.

Specific to reaction solvent systems, additional regulations may apply depending on the intended use and industry. For pharmaceutical applications, Good Manufacturing Practice (GMP) guidelines must be followed. These guidelines, enforced by agencies like the FDA in the US and the EMA in Europe, ensure the quality and safety of drug products, including the solvents used in their production.

Environmental regulations also play a significant role in the use of organic solvents. Many jurisdictions have implemented solvent recycling and waste management regulations to minimize environmental impact. Companies using ethyl propanoate and other organic solvents must adhere to proper disposal and recycling practices.

As regulations continue to evolve, staying compliant requires ongoing vigilance and adaptation. Companies must regularly review and update their compliance strategies, conduct risk assessments, and implement robust management systems to ensure adherence to all applicable regulations governing organic solvents.

In the United States, the EPA regulates organic solvents under the Toxic Substances Control Act (TSCA) and the Clean Air Act (CAA). The TSCA requires manufacturers and importers to report new chemical substances and maintain records of health and safety studies. The CAA sets limits on volatile organic compound (VOC) emissions, which include many organic solvents. Ethyl propanoate, being a VOC, falls under these regulations.

OSHA establishes workplace safety standards for handling organic solvents. These include permissible exposure limits (PELs), personal protective equipment (PPE) requirements, and proper handling and storage procedures. For ethyl propanoate, employers must ensure that exposure levels remain below the established PELs and provide appropriate PPE to workers.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of organic solvents. Manufacturers and importers must register substances with ECHA and provide safety data sheets. Ethyl propanoate, like other organic solvents, must comply with REACH requirements if manufactured or imported in quantities of one tonne or more per year.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been adopted by many countries, including the US and EU. This system standardizes the classification and labeling of chemicals, including organic solvents. Proper labeling and safety data sheets are essential for compliance with GHS requirements.

Specific to reaction solvent systems, additional regulations may apply depending on the intended use and industry. For pharmaceutical applications, Good Manufacturing Practice (GMP) guidelines must be followed. These guidelines, enforced by agencies like the FDA in the US and the EMA in Europe, ensure the quality and safety of drug products, including the solvents used in their production.

Environmental regulations also play a significant role in the use of organic solvents. Many jurisdictions have implemented solvent recycling and waste management regulations to minimize environmental impact. Companies using ethyl propanoate and other organic solvents must adhere to proper disposal and recycling practices.

As regulations continue to evolve, staying compliant requires ongoing vigilance and adaptation. Companies must regularly review and update their compliance strategies, conduct risk assessments, and implement robust management systems to ensure adherence to all applicable regulations governing organic solvents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!