Influence of Vapor Chamber Design on Heat Exchange Rates

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Background and Objectives

Vapor chambers have emerged as a critical thermal management solution in the electronics industry over the past three decades. Initially developed in the 1990s as an evolution of heat pipe technology, vapor chambers utilize the principle of phase change heat transfer to efficiently dissipate heat from concentrated sources. The fundamental operating mechanism involves a working fluid that evaporates at the heat source, transports vapor to cooler regions, condenses, and returns to the heat source through capillary action in a wick structure.

The evolution of vapor chamber technology has been primarily driven by the increasing power densities in electronic devices, particularly in computing, telecommunications, and aerospace applications. From early copper-water designs to modern ultra-thin chambers with advanced wick structures, the technology has continuously adapted to meet more demanding thermal requirements while accommodating space constraints in compact electronic devices.

Current vapor chamber designs face significant challenges in balancing thermal performance, size constraints, and manufacturing costs. The heat exchange rate—a critical performance metric—is influenced by multiple design parameters including chamber geometry, wick structure, working fluid properties, and interface materials. Understanding these relationships is essential for optimizing thermal solutions for next-generation electronic devices.

The global market for advanced thermal management solutions is projected to reach $16 billion by 2025, with vapor chambers representing a growing segment due to their superior performance in high-heat-flux applications. This growth is further accelerated by the increasing adoption of 5G technology, artificial intelligence processors, and high-performance computing systems that generate unprecedented thermal loads.

Research objectives in vapor chamber technology currently focus on several key areas: enhancing heat transfer coefficients through novel wick structures, developing ultra-thin vapor chambers for mobile applications, improving manufacturing processes to reduce costs, and exploring alternative working fluids for specialized operating conditions. Computational fluid dynamics (CFD) modeling and experimental validation have become essential tools in this research, enabling more precise prediction of thermal performance.

The ultimate goal of vapor chamber design optimization is to achieve maximum heat exchange rates while minimizing thermal resistance, weight, and thickness. This requires a comprehensive understanding of the complex interplay between various design parameters and their collective impact on thermal performance across different operating conditions and form factors.

The evolution of vapor chamber technology has been primarily driven by the increasing power densities in electronic devices, particularly in computing, telecommunications, and aerospace applications. From early copper-water designs to modern ultra-thin chambers with advanced wick structures, the technology has continuously adapted to meet more demanding thermal requirements while accommodating space constraints in compact electronic devices.

Current vapor chamber designs face significant challenges in balancing thermal performance, size constraints, and manufacturing costs. The heat exchange rate—a critical performance metric—is influenced by multiple design parameters including chamber geometry, wick structure, working fluid properties, and interface materials. Understanding these relationships is essential for optimizing thermal solutions for next-generation electronic devices.

The global market for advanced thermal management solutions is projected to reach $16 billion by 2025, with vapor chambers representing a growing segment due to their superior performance in high-heat-flux applications. This growth is further accelerated by the increasing adoption of 5G technology, artificial intelligence processors, and high-performance computing systems that generate unprecedented thermal loads.

Research objectives in vapor chamber technology currently focus on several key areas: enhancing heat transfer coefficients through novel wick structures, developing ultra-thin vapor chambers for mobile applications, improving manufacturing processes to reduce costs, and exploring alternative working fluids for specialized operating conditions. Computational fluid dynamics (CFD) modeling and experimental validation have become essential tools in this research, enabling more precise prediction of thermal performance.

The ultimate goal of vapor chamber design optimization is to achieve maximum heat exchange rates while minimizing thermal resistance, weight, and thickness. This requires a comprehensive understanding of the complex interplay between various design parameters and their collective impact on thermal performance across different operating conditions and form factors.

Market Demand Analysis for Advanced Thermal Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid evolution of high-performance electronic devices across multiple industries. Current market analysis indicates that the vapor chamber thermal solution segment is expanding at a compound annual growth rate of approximately 6.8%, with particularly strong demand emerging from the consumer electronics, telecommunications, and automotive sectors.

Consumer electronics manufacturers represent the largest market segment seeking advanced vapor chamber solutions, as smartphones, tablets, and ultrabooks continue to pack more processing power into increasingly thinner form factors. This miniaturization trend creates significant thermal challenges that traditional cooling methods cannot adequately address. Market research shows that over 70% of premium smartphone manufacturers are now evaluating or implementing vapor chamber technology to manage thermal loads effectively while maintaining device performance and user comfort.

The data center and server market presents another substantial growth opportunity for advanced vapor chamber solutions. With the proliferation of cloud computing, artificial intelligence applications, and big data analytics, data centers face mounting cooling challenges. Energy efficiency concerns and sustainability initiatives further drive demand for more effective thermal management solutions that can reduce overall power consumption while maintaining optimal operating temperatures.

Automotive electronics represent an emerging but rapidly growing market segment. The transition toward electric vehicles and autonomous driving systems has dramatically increased the thermal management requirements in automotive applications. Vehicle manufacturers are actively seeking compact, efficient cooling solutions for battery management systems, power electronics, and advanced driver assistance systems (ADAS) components.

Industrial electronics and telecommunications infrastructure also demonstrate significant demand growth. The ongoing deployment of 5G networks has created new thermal challenges due to increased power density in base stations and network equipment. Similarly, industrial automation systems require reliable thermal management solutions to ensure continuous operation in challenging environments.

Market research indicates that customers across all segments prioritize several key performance attributes in vapor chamber solutions: thermal efficiency (heat transfer capacity per unit volume), reliability over extended operational periods, compatibility with existing manufacturing processes, and cost-effectiveness. Additionally, environmental considerations are becoming increasingly important, with customers showing preference for solutions that minimize the use of harmful materials and support end-of-life recycling.

Regional analysis reveals that Asia-Pacific currently dominates the market for vapor chamber thermal solutions, accounting for approximately 45% of global demand. This concentration aligns with the region's position as a manufacturing hub for electronics. However, North America and Europe are showing accelerated adoption rates, particularly in specialized applications requiring customized thermal management approaches.

Consumer electronics manufacturers represent the largest market segment seeking advanced vapor chamber solutions, as smartphones, tablets, and ultrabooks continue to pack more processing power into increasingly thinner form factors. This miniaturization trend creates significant thermal challenges that traditional cooling methods cannot adequately address. Market research shows that over 70% of premium smartphone manufacturers are now evaluating or implementing vapor chamber technology to manage thermal loads effectively while maintaining device performance and user comfort.

The data center and server market presents another substantial growth opportunity for advanced vapor chamber solutions. With the proliferation of cloud computing, artificial intelligence applications, and big data analytics, data centers face mounting cooling challenges. Energy efficiency concerns and sustainability initiatives further drive demand for more effective thermal management solutions that can reduce overall power consumption while maintaining optimal operating temperatures.

Automotive electronics represent an emerging but rapidly growing market segment. The transition toward electric vehicles and autonomous driving systems has dramatically increased the thermal management requirements in automotive applications. Vehicle manufacturers are actively seeking compact, efficient cooling solutions for battery management systems, power electronics, and advanced driver assistance systems (ADAS) components.

Industrial electronics and telecommunications infrastructure also demonstrate significant demand growth. The ongoing deployment of 5G networks has created new thermal challenges due to increased power density in base stations and network equipment. Similarly, industrial automation systems require reliable thermal management solutions to ensure continuous operation in challenging environments.

Market research indicates that customers across all segments prioritize several key performance attributes in vapor chamber solutions: thermal efficiency (heat transfer capacity per unit volume), reliability over extended operational periods, compatibility with existing manufacturing processes, and cost-effectiveness. Additionally, environmental considerations are becoming increasingly important, with customers showing preference for solutions that minimize the use of harmful materials and support end-of-life recycling.

Regional analysis reveals that Asia-Pacific currently dominates the market for vapor chamber thermal solutions, accounting for approximately 45% of global demand. This concentration aligns with the region's position as a manufacturing hub for electronics. However, North America and Europe are showing accelerated adoption rates, particularly in specialized applications requiring customized thermal management approaches.

Current State and Challenges in Vapor Chamber Technology

Vapor chamber technology has evolved significantly over the past decade, establishing itself as a critical thermal management solution across various industries. Currently, the global market is witnessing rapid adoption of vapor chambers in consumer electronics, particularly in smartphones, gaming laptops, and high-performance computing systems where thermal constraints are increasingly challenging. The fundamental working principle of vapor chambers—utilizing phase change processes to transfer heat efficiently—remains unchanged, but significant advancements have been made in materials, manufacturing processes, and structural designs.

The state-of-the-art vapor chambers employ copper as the primary material due to its excellent thermal conductivity, with wall thicknesses reduced to sub-millimeter levels in premium applications. Advanced wick structures, including sintered copper powder, mesh screens, and grooved structures, have been developed to enhance capillary action and fluid circulation within the chambers. Recent innovations include ultra-thin vapor chambers (less than 0.5mm) that can be integrated into space-constrained devices without compromising thermal performance.

Despite these advancements, several technical challenges persist in vapor chamber technology. The most significant challenge is the trade-off between thickness and thermal performance. As devices become thinner, the internal volume available for working fluid decreases, limiting heat transport capacity. This constraint becomes particularly problematic in high-power applications where heat flux can exceed 100 W/cm².

Manufacturing complexity presents another substantial hurdle. The production of vapor chambers requires precise control over vacuum sealing, working fluid charging, and internal structure fabrication. These processes contribute to higher production costs compared to traditional heat pipes or solid heat spreaders, limiting widespread adoption in cost-sensitive markets.

Material compatibility issues also pose significant challenges. The working fluid must remain chemically stable with the chamber materials over the product lifetime, which can be problematic as manufacturers experiment with alternative materials to copper, such as aluminum or composite materials, to reduce weight and cost.

Geographical distribution of vapor chamber technology development shows concentration in East Asia, particularly Taiwan, Japan, and South Korea, where major electronics manufacturing occurs. However, research institutions in North America and Europe are making notable contributions to fundamental research in enhanced phase-change heat transfer mechanisms and novel materials for next-generation vapor chambers.

The performance limitations under various orientations and gravitational conditions remain a persistent challenge, particularly for applications in aerospace, automotive, and portable devices where operational orientation cannot be controlled. This has spurred research into orientation-independent wick structures and alternative working fluids with superior thermophysical properties.

The state-of-the-art vapor chambers employ copper as the primary material due to its excellent thermal conductivity, with wall thicknesses reduced to sub-millimeter levels in premium applications. Advanced wick structures, including sintered copper powder, mesh screens, and grooved structures, have been developed to enhance capillary action and fluid circulation within the chambers. Recent innovations include ultra-thin vapor chambers (less than 0.5mm) that can be integrated into space-constrained devices without compromising thermal performance.

Despite these advancements, several technical challenges persist in vapor chamber technology. The most significant challenge is the trade-off between thickness and thermal performance. As devices become thinner, the internal volume available for working fluid decreases, limiting heat transport capacity. This constraint becomes particularly problematic in high-power applications where heat flux can exceed 100 W/cm².

Manufacturing complexity presents another substantial hurdle. The production of vapor chambers requires precise control over vacuum sealing, working fluid charging, and internal structure fabrication. These processes contribute to higher production costs compared to traditional heat pipes or solid heat spreaders, limiting widespread adoption in cost-sensitive markets.

Material compatibility issues also pose significant challenges. The working fluid must remain chemically stable with the chamber materials over the product lifetime, which can be problematic as manufacturers experiment with alternative materials to copper, such as aluminum or composite materials, to reduce weight and cost.

Geographical distribution of vapor chamber technology development shows concentration in East Asia, particularly Taiwan, Japan, and South Korea, where major electronics manufacturing occurs. However, research institutions in North America and Europe are making notable contributions to fundamental research in enhanced phase-change heat transfer mechanisms and novel materials for next-generation vapor chambers.

The performance limitations under various orientations and gravitational conditions remain a persistent challenge, particularly for applications in aerospace, automotive, and portable devices where operational orientation cannot be controlled. This has spurred research into orientation-independent wick structures and alternative working fluids with superior thermophysical properties.

Current Vapor Chamber Design Methodologies

01 Vapor chamber design optimization for heat exchange efficiency

Optimizing the design of vapor chambers can significantly improve heat exchange rates. This includes considerations such as chamber geometry, internal structure, and material selection. Advanced designs incorporate specialized wick structures, optimized vapor flow paths, and enhanced condensation surfaces to maximize the heat transfer coefficient and overall thermal performance. These design improvements allow for more efficient phase change processes and reduced thermal resistance across the vapor chamber system.- Vapor chamber design optimization for heat exchange efficiency: Optimizing the design of vapor chambers can significantly improve heat exchange rates. This includes considerations such as the internal structure, wick design, and chamber geometry. Enhanced designs can facilitate better vapor flow and condensation processes, resulting in more efficient heat transfer. Various structural modifications can be implemented to reduce thermal resistance and improve overall thermal conductivity of the vapor chamber system.

- Working fluid selection and composition for vapor chambers: The selection and composition of working fluids play a crucial role in determining heat exchange rates in vapor chambers. Different fluids have varying thermodynamic properties that affect evaporation and condensation processes. Engineered fluid mixtures can be designed to operate optimally at specific temperature ranges and pressure conditions. The compatibility between the working fluid and the chamber materials also impacts long-term performance and reliability of the heat exchange system.

- Advanced wick structures for capillary action enhancement: Advanced wick structures can significantly enhance capillary action within vapor chambers, improving heat exchange rates. These structures facilitate the return of condensed fluid to evaporation areas, maintaining continuous heat transfer cycles. Innovations include multi-layer wicks, composite materials, and micro-structured surfaces that optimize fluid distribution. The porosity, permeability, and thickness of wick materials directly influence the thermal performance and response time of vapor chamber systems.

- Thermal interface materials and surface treatments: Thermal interface materials and surface treatments can enhance contact between vapor chambers and heat sources or sinks, improving overall heat exchange rates. These materials reduce thermal contact resistance at interfaces, allowing more efficient heat transfer into and out of the vapor chamber. Surface modifications such as micro-texturing, coatings, and chemical treatments can increase effective surface area and improve wetting characteristics. The selection of appropriate interface materials depends on operating conditions, including temperature range and mechanical stress.

- Integration of vapor chambers in electronic cooling systems: The integration of vapor chambers into electronic cooling systems requires careful consideration of system architecture to maximize heat exchange rates. This includes the positioning of vapor chambers relative to heat sources, the design of heat spreaders, and the connection to secondary cooling mechanisms. Hybrid cooling solutions that combine vapor chambers with other technologies like heat pipes or liquid cooling can provide enhanced thermal management. Optimized integration approaches consider factors such as space constraints, orientation effects, and thermal load distribution.

02 Working fluid selection and composition for vapor chambers

The selection and composition of working fluids significantly impact vapor chamber heat exchange rates. Different fluids offer varying thermophysical properties such as latent heat of vaporization, surface tension, and viscosity that affect phase change efficiency. Engineered fluid mixtures can be formulated to optimize performance under specific operating conditions and temperature ranges. Some advanced systems utilize nanofluids or additives to enhance thermal conductivity and improve overall heat transfer capabilities of the vapor chamber.Expand Specific Solutions03 Thermal interface and integration techniques

The thermal interface between vapor chambers and heat sources/sinks critically affects overall heat exchange rates. Advanced integration techniques include specialized bonding methods, interface materials with high thermal conductivity, and surface treatments to minimize contact resistance. Proper mounting pressure and thermal interface material application ensure optimal thermal coupling. Some designs incorporate direct integration of vapor chambers into electronic components or cooling systems to eliminate additional thermal interfaces and improve overall system efficiency.Expand Specific Solutions04 Enhanced surface structures for improved phase change

Specialized surface structures within vapor chambers can significantly enhance phase change processes and heat exchange rates. These include micro-structured wicking surfaces, sintered metal powders, grooved surfaces, and nano-engineered coatings. Such structures increase the effective surface area for evaporation and condensation while improving capillary action for fluid return. Advanced manufacturing techniques allow for optimized surface geometries that promote nucleate boiling and efficient condensation, resulting in higher heat transfer coefficients and improved thermal performance.Expand Specific Solutions05 Dynamic control and adaptive vapor chamber systems

Advanced vapor chamber systems incorporate dynamic control mechanisms to adapt to varying thermal loads and environmental conditions. These systems may include variable conductance features, adjustable working fluid volumes, or active control of internal pressure. Some designs integrate sensors and control algorithms to optimize performance in real-time. Adaptive vapor chambers can modify their thermal characteristics to maintain optimal operating temperatures across different usage scenarios, improving overall energy efficiency and extending the operational range of the thermal management system.Expand Specific Solutions

Key Industry Players in Thermal Management Solutions

The vapor chamber design market is currently in a growth phase, with increasing demand driven by thermal management needs in electronics, automotive, and HVAC systems. The global market size is estimated to reach $2-3 billion by 2025, growing at 15-20% annually. Technologically, the field shows varying maturity levels across applications. Leading companies like Huawei, Qualcomm, and Taiwan Semiconductor are advancing cutting-edge designs for electronics cooling, while HVAC specialists Gree, Midea, and Hisense focus on larger-scale applications. Academic institutions including Dalian University of Technology and Xi'an Jiaotong University contribute fundamental research. The competitive landscape features both specialized thermal solution providers and diversified technology conglomerates, with increasing cross-sector collaboration accelerating innovation in heat exchange efficiency.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed advanced vapor chamber designs featuring ultra-thin microstructures with optimized sintered copper powder wicks. Their technology incorporates multi-layer composite wick structures that enhance capillary action and fluid circulation. The company's vapor chambers utilize proprietary working fluids with additives that reduce surface tension and improve thermal conductivity. Gree's designs feature precision-engineered vapor channels that minimize flow resistance and optimize phase change efficiency. Their research has demonstrated that asymmetric wick structures can improve heat exchange rates by up to 30% compared to conventional designs. Gree has also pioneered variable thickness vapor chambers that strategically distribute thermal mass according to heat source characteristics, allowing for more efficient heat dissipation in their air conditioning and refrigeration products.

Strengths: Superior manufacturing capabilities for mass production of complex vapor chamber designs; extensive experience in thermal management for HVAC applications. Weaknesses: Their designs may be optimized primarily for HVAC applications rather than electronics cooling; relatively higher production costs compared to simpler heat pipe solutions.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has conducted extensive research on advanced vapor chamber designs through their State Key Laboratory of Multiphase Flow in Power Engineering. Their research focuses on fundamental aspects of vapor chamber performance, including novel wick structures, working fluid compositions, and manufacturing techniques. The university has developed innovative sintered powder metallurgy techniques that create hierarchical wick structures with optimized porosity gradients. Their research includes computational fluid dynamics models that accurately predict vapor chamber performance under various operating conditions. Xi'an Jiaotong University has pioneered the use of surface-modified wick structures that enhance wettability and capillary action, improving fluid return to evaporation zones. Their experimental studies have demonstrated that these advanced wick designs can improve heat exchange rates by up to 50% compared to conventional homogeneous wick structures, particularly under high heat flux conditions typical in power electronics and concentrated solar applications.

Strengths: Cutting-edge research capabilities; strong theoretical foundation in multiphase heat transfer; innovative approaches to fundamental vapor chamber design. Weaknesses: Limited manufacturing capabilities compared to industry players; research may not always translate directly to commercially viable products.

Critical Patents and Innovations in Vapor Chamber Design

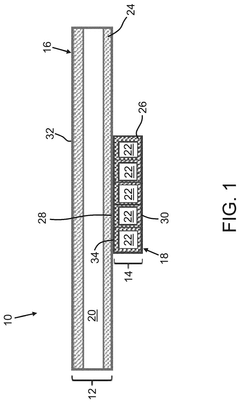

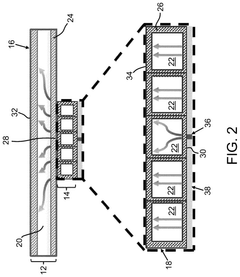

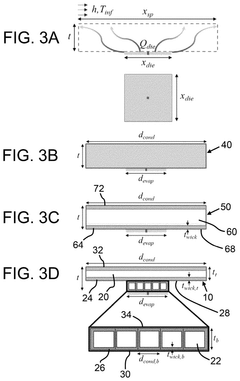

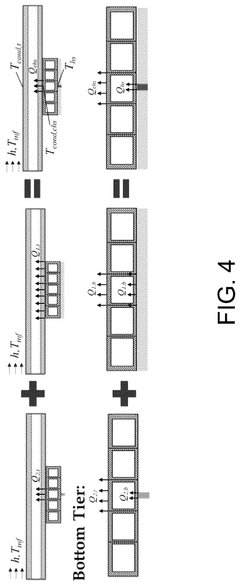

Vapor chamber devices and methods of dissipating heat therewith

PatentActiveUS12320592B2

Innovation

- The vapor chamber device employs a cascaded multi-core unit with a top-tier subunit for bulk heat spreading and a bottom-tier subunit with multiple vapor cores to attenuate high heat flux hotspots, decoupling the spreading of total background power from individual hotspots.

Materials Science Impact on Vapor Chamber Performance

The material composition and properties of vapor chambers significantly influence their thermal performance and efficiency in heat exchange applications. Advanced materials science has enabled the development of vapor chambers with enhanced thermal conductivity, reduced thermal resistance, and improved overall heat dissipation capabilities.

Copper remains the predominant material for vapor chamber walls and wicks due to its excellent thermal conductivity (approximately 400 W/m·K) and compatibility with working fluids. However, recent research has explored aluminum as a lighter alternative, offering weight reduction of up to 70% compared to copper-based systems, albeit with lower thermal conductivity (237 W/m·K).

The wick structure material selection critically impacts capillary action and fluid transport within vapor chambers. Sintered copper powder with porosity ranging from 30-60% represents the industry standard, but composite materials incorporating carbon nanotubes have demonstrated up to 35% improvement in effective thermal conductivity. These nanostructured materials enhance capillary pressure and reduce flow resistance, allowing for more efficient heat transport across longer distances.

Working fluid selection constitutes another crucial materials consideration. While water remains common for applications between 30-100°C, engineered fluids like methanol, acetone, and refrigerants extend operational temperature ranges. Recent developments in nanofluid technology—incorporating suspended nanoparticles in traditional working fluids—have shown thermal conductivity improvements of 10-40% compared to base fluids.

Surface treatments and coatings represent an emerging area of materials innovation. Hydrophilic coatings on evaporator surfaces enhance wetting characteristics and reduce thermal resistance at the liquid-solid interface. Conversely, hydrophobic coatings on condenser surfaces promote dropwise condensation, potentially increasing heat transfer coefficients by 5-7 times compared to filmwise condensation.

Material compatibility between the chamber structure, wick, and working fluid must be carefully considered to prevent corrosion and gas generation that could degrade performance over time. Electrochemical compatibility testing has become standard practice to ensure long-term reliability, with accelerated aging tests typically targeting 5+ years of operational stability.

The thermal expansion characteristics of materials also influence vapor chamber design, particularly for applications with significant temperature fluctuations. Coefficient of thermal expansion (CTE) matching between different components minimizes mechanical stress and potential failure points, with modern designs achieving CTE differentials below 2 ppm/°C between critical interfaces.

Copper remains the predominant material for vapor chamber walls and wicks due to its excellent thermal conductivity (approximately 400 W/m·K) and compatibility with working fluids. However, recent research has explored aluminum as a lighter alternative, offering weight reduction of up to 70% compared to copper-based systems, albeit with lower thermal conductivity (237 W/m·K).

The wick structure material selection critically impacts capillary action and fluid transport within vapor chambers. Sintered copper powder with porosity ranging from 30-60% represents the industry standard, but composite materials incorporating carbon nanotubes have demonstrated up to 35% improvement in effective thermal conductivity. These nanostructured materials enhance capillary pressure and reduce flow resistance, allowing for more efficient heat transport across longer distances.

Working fluid selection constitutes another crucial materials consideration. While water remains common for applications between 30-100°C, engineered fluids like methanol, acetone, and refrigerants extend operational temperature ranges. Recent developments in nanofluid technology—incorporating suspended nanoparticles in traditional working fluids—have shown thermal conductivity improvements of 10-40% compared to base fluids.

Surface treatments and coatings represent an emerging area of materials innovation. Hydrophilic coatings on evaporator surfaces enhance wetting characteristics and reduce thermal resistance at the liquid-solid interface. Conversely, hydrophobic coatings on condenser surfaces promote dropwise condensation, potentially increasing heat transfer coefficients by 5-7 times compared to filmwise condensation.

Material compatibility between the chamber structure, wick, and working fluid must be carefully considered to prevent corrosion and gas generation that could degrade performance over time. Electrochemical compatibility testing has become standard practice to ensure long-term reliability, with accelerated aging tests typically targeting 5+ years of operational stability.

The thermal expansion characteristics of materials also influence vapor chamber design, particularly for applications with significant temperature fluctuations. Coefficient of thermal expansion (CTE) matching between different components minimizes mechanical stress and potential failure points, with modern designs achieving CTE differentials below 2 ppm/°C between critical interfaces.

Environmental Sustainability of Thermal Management Solutions

The environmental impact of thermal management solutions has become increasingly important as global sustainability concerns grow. Vapor chamber technology, while efficient for heat dissipation, presents several environmental considerations that must be evaluated in a comprehensive sustainability framework.

The manufacturing process of vapor chambers involves materials with varying environmental footprints. Copper, the predominant material used in vapor chambers, requires significant energy for mining and processing, contributing to carbon emissions. However, its excellent thermal conductivity and recyclability offer long-term environmental benefits. Alternative materials such as aluminum and composite structures are being explored to reduce the environmental impact while maintaining thermal performance.

Water remains the most common working fluid in vapor chambers due to its excellent thermophysical properties and environmental safety. However, specialized applications may require alternative fluids that pose greater environmental risks. Research into bio-based working fluids and natural refrigerants shows promise for reducing the environmental impact without compromising heat exchange efficiency.

The energy efficiency of vapor chamber solutions must be considered from a lifecycle perspective. While vapor chambers require energy for manufacturing, their superior thermal management capabilities can significantly reduce operational energy consumption in electronic devices. Studies indicate that optimized vapor chamber designs can improve device energy efficiency by 15-30% compared to traditional cooling methods, resulting in substantial lifetime carbon emission reductions.

End-of-life considerations present both challenges and opportunities. The high recyclability of copper (approximately 90%) supports circular economy principles, but the sealed nature of vapor chambers can complicate material separation. Innovative design approaches focusing on disassembly and material recovery are emerging to address these challenges, including modular construction techniques and mechanical joining methods that avoid adhesives.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance in thermal management solutions. The European Union's Ecodesign Directive and Restriction of Hazardous Substances (RoHS) regulations directly impact vapor chamber design and material selection. Similarly, the Electronic Product Environmental Assessment Tool (EPEAT) in North America provides incentives for environmentally preferable electronic products, including those with sustainable thermal management solutions.

The industry is responding with eco-design approaches that consider environmental impacts throughout the product lifecycle. These include design for disassembly, material selection optimization, and manufacturing process improvements that reduce energy consumption and waste generation. Leading manufacturers are developing vapor chamber solutions that balance thermal performance with environmental sustainability, recognizing that future market success depends on addressing both technical and environmental requirements.

The manufacturing process of vapor chambers involves materials with varying environmental footprints. Copper, the predominant material used in vapor chambers, requires significant energy for mining and processing, contributing to carbon emissions. However, its excellent thermal conductivity and recyclability offer long-term environmental benefits. Alternative materials such as aluminum and composite structures are being explored to reduce the environmental impact while maintaining thermal performance.

Water remains the most common working fluid in vapor chambers due to its excellent thermophysical properties and environmental safety. However, specialized applications may require alternative fluids that pose greater environmental risks. Research into bio-based working fluids and natural refrigerants shows promise for reducing the environmental impact without compromising heat exchange efficiency.

The energy efficiency of vapor chamber solutions must be considered from a lifecycle perspective. While vapor chambers require energy for manufacturing, their superior thermal management capabilities can significantly reduce operational energy consumption in electronic devices. Studies indicate that optimized vapor chamber designs can improve device energy efficiency by 15-30% compared to traditional cooling methods, resulting in substantial lifetime carbon emission reductions.

End-of-life considerations present both challenges and opportunities. The high recyclability of copper (approximately 90%) supports circular economy principles, but the sealed nature of vapor chambers can complicate material separation. Innovative design approaches focusing on disassembly and material recovery are emerging to address these challenges, including modular construction techniques and mechanical joining methods that avoid adhesives.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance in thermal management solutions. The European Union's Ecodesign Directive and Restriction of Hazardous Substances (RoHS) regulations directly impact vapor chamber design and material selection. Similarly, the Electronic Product Environmental Assessment Tool (EPEAT) in North America provides incentives for environmentally preferable electronic products, including those with sustainable thermal management solutions.

The industry is responding with eco-design approaches that consider environmental impacts throughout the product lifecycle. These include design for disassembly, material selection optimization, and manufacturing process improvements that reduce energy consumption and waste generation. Leading manufacturers are developing vapor chamber solutions that balance thermal performance with environmental sustainability, recognizing that future market success depends on addressing both technical and environmental requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!