Interfacial Mechanics In Metal Matrix Composites Fabricated By Laser Powder Bed Fusion

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LPBF MMC Interface Mechanics Background and Objectives

Metal Matrix Composites (MMCs) have emerged as a significant advancement in materials science, offering enhanced mechanical properties compared to traditional metals. The integration of MMCs with Laser Powder Bed Fusion (LPBF) technology represents a convergence of advanced manufacturing and materials engineering that has evolved considerably over the past two decades. Initially, MMCs were primarily fabricated through conventional methods such as casting and powder metallurgy, limiting their geometric complexity and widespread industrial adoption.

The evolution of LPBF technology has revolutionized the manufacturing landscape by enabling the production of complex geometries with unprecedented design freedom. This additive manufacturing technique has progressed from producing simple prototypes to creating functional end-use parts across various industries including aerospace, automotive, and medical sectors. The application of LPBF to MMCs began gaining traction around 2010, with significant acceleration in research and development activities observed from 2015 onwards.

Understanding interfacial mechanics in LPBF-fabricated MMCs is crucial as these interfaces fundamentally determine the composite's overall performance. The interface between the metal matrix and reinforcement phases acts as the critical zone for load transfer, crack propagation resistance, and thermal stability. Historical challenges in this domain have included poor wettability between matrix and reinforcement materials, formation of detrimental interfacial reactions, and thermal expansion mismatch leading to residual stresses.

Current technological trends indicate a growing focus on tailoring these interfaces through surface modification of reinforcement particles, matrix alloy design, and process parameter optimization. The rapid thermal cycles characteristic of LPBF processing create unique interfacial conditions that differ significantly from those in conventionally manufactured MMCs, necessitating specialized research approaches and analytical techniques.

The primary technical objectives in this field include developing predictive models for interfacial behavior under LPBF processing conditions, establishing process-structure-property relationships specific to interfaces in LPBF-MMCs, and designing novel material combinations with optimized interfacial characteristics. Additionally, there is a pressing need to develop in-situ monitoring techniques capable of tracking interfacial evolution during the LPBF process.

Future technological trajectories point toward multi-material LPBF systems capable of creating functionally graded interfaces, computational tools for interface engineering, and high-throughput methodologies for rapid screening of matrix-reinforcement compatibility. The ultimate goal remains the development of LPBF-MMCs with interfaces that enable superior mechanical properties, thermal stability, and long-term reliability for demanding applications in extreme environments.

The evolution of LPBF technology has revolutionized the manufacturing landscape by enabling the production of complex geometries with unprecedented design freedom. This additive manufacturing technique has progressed from producing simple prototypes to creating functional end-use parts across various industries including aerospace, automotive, and medical sectors. The application of LPBF to MMCs began gaining traction around 2010, with significant acceleration in research and development activities observed from 2015 onwards.

Understanding interfacial mechanics in LPBF-fabricated MMCs is crucial as these interfaces fundamentally determine the composite's overall performance. The interface between the metal matrix and reinforcement phases acts as the critical zone for load transfer, crack propagation resistance, and thermal stability. Historical challenges in this domain have included poor wettability between matrix and reinforcement materials, formation of detrimental interfacial reactions, and thermal expansion mismatch leading to residual stresses.

Current technological trends indicate a growing focus on tailoring these interfaces through surface modification of reinforcement particles, matrix alloy design, and process parameter optimization. The rapid thermal cycles characteristic of LPBF processing create unique interfacial conditions that differ significantly from those in conventionally manufactured MMCs, necessitating specialized research approaches and analytical techniques.

The primary technical objectives in this field include developing predictive models for interfacial behavior under LPBF processing conditions, establishing process-structure-property relationships specific to interfaces in LPBF-MMCs, and designing novel material combinations with optimized interfacial characteristics. Additionally, there is a pressing need to develop in-situ monitoring techniques capable of tracking interfacial evolution during the LPBF process.

Future technological trajectories point toward multi-material LPBF systems capable of creating functionally graded interfaces, computational tools for interface engineering, and high-throughput methodologies for rapid screening of matrix-reinforcement compatibility. The ultimate goal remains the development of LPBF-MMCs with interfaces that enable superior mechanical properties, thermal stability, and long-term reliability for demanding applications in extreme environments.

Market Analysis for LPBF-Fabricated Metal Matrix Composites

The global market for metal matrix composites (MMCs) fabricated through Laser Powder Bed Fusion (LPBF) is experiencing significant growth, driven by increasing demand for high-performance materials in aerospace, automotive, and defense sectors. Current market valuations indicate that the LPBF-fabricated MMC segment represents approximately 12% of the overall metal additive manufacturing market, with a compound annual growth rate exceeding the industry average.

Aerospace remains the dominant application sector, accounting for nearly 40% of the LPBF-MMC market. This dominance stems from the critical need for lightweight components with superior mechanical properties and thermal stability in extreme operating conditions. The automotive industry follows as the second-largest consumer, particularly in high-performance and electric vehicle segments where weight reduction and thermal management are paramount concerns.

Market research indicates a significant shift in customer requirements, with increasing emphasis on interfacial properties between matrix and reinforcement phases. End-users are specifically demanding MMCs with optimized interfaces that can withstand thermal cycling, mechanical loading, and corrosive environments without degradation or delamination. This trend is particularly evident in applications requiring long service life under variable operating conditions.

Regional analysis reveals North America as the current market leader, hosting major aerospace manufacturers and defense contractors who are early adopters of advanced MMC technologies. However, the Asia-Pacific region demonstrates the fastest growth rate, driven by rapid industrialization in China and significant R&D investments in Japan and South Korea focused on automotive and electronics applications.

The competitive landscape features both established metal powder suppliers expanding into MMC formulations and specialized startups developing proprietary interface engineering solutions. Material suppliers are increasingly offering pre-alloyed powders specifically designed to form optimized interfaces during the LPBF process, commanding premium pricing due to their performance advantages.

Economic analysis indicates that while LPBF-fabricated MMCs currently carry a cost premium of 30-50% compared to conventional manufacturing methods, this gap is narrowing as process optimization and economies of scale improve. The total cost of ownership calculations increasingly favor LPBF-MMCs when accounting for extended component lifespans, reduced maintenance requirements, and performance benefits derived from superior interfacial mechanics.

Market forecasts project continued strong growth, with particular expansion in medical device applications and renewable energy infrastructure where the unique properties of LPBF-fabricated MMCs with engineered interfaces provide compelling value propositions. The market is expected to further diversify as interfacial engineering techniques mature, enabling customization of MMC properties for specific application requirements.

Aerospace remains the dominant application sector, accounting for nearly 40% of the LPBF-MMC market. This dominance stems from the critical need for lightweight components with superior mechanical properties and thermal stability in extreme operating conditions. The automotive industry follows as the second-largest consumer, particularly in high-performance and electric vehicle segments where weight reduction and thermal management are paramount concerns.

Market research indicates a significant shift in customer requirements, with increasing emphasis on interfacial properties between matrix and reinforcement phases. End-users are specifically demanding MMCs with optimized interfaces that can withstand thermal cycling, mechanical loading, and corrosive environments without degradation or delamination. This trend is particularly evident in applications requiring long service life under variable operating conditions.

Regional analysis reveals North America as the current market leader, hosting major aerospace manufacturers and defense contractors who are early adopters of advanced MMC technologies. However, the Asia-Pacific region demonstrates the fastest growth rate, driven by rapid industrialization in China and significant R&D investments in Japan and South Korea focused on automotive and electronics applications.

The competitive landscape features both established metal powder suppliers expanding into MMC formulations and specialized startups developing proprietary interface engineering solutions. Material suppliers are increasingly offering pre-alloyed powders specifically designed to form optimized interfaces during the LPBF process, commanding premium pricing due to their performance advantages.

Economic analysis indicates that while LPBF-fabricated MMCs currently carry a cost premium of 30-50% compared to conventional manufacturing methods, this gap is narrowing as process optimization and economies of scale improve. The total cost of ownership calculations increasingly favor LPBF-MMCs when accounting for extended component lifespans, reduced maintenance requirements, and performance benefits derived from superior interfacial mechanics.

Market forecasts project continued strong growth, with particular expansion in medical device applications and renewable energy infrastructure where the unique properties of LPBF-fabricated MMCs with engineered interfaces provide compelling value propositions. The market is expected to further diversify as interfacial engineering techniques mature, enabling customization of MMC properties for specific application requirements.

Current Challenges in MMC Interfacial Mechanics

The interfacial mechanics in Metal Matrix Composites (MMCs) fabricated by Laser Powder Bed Fusion (LPBF) presents several significant challenges that impede the widespread industrial adoption of these advanced materials. One of the primary obstacles is the thermal mismatch between the metallic matrix and reinforcement materials. During the rapid heating and cooling cycles characteristic of LPBF processes, differential thermal expansion coefficients generate substantial residual stresses at the interfaces, leading to microcracking, delamination, and premature component failure.

Another critical challenge is the chemical reactivity at high temperatures during laser processing. The extreme thermal conditions in the melt pool can trigger undesired interfacial reactions, forming brittle intermetallic compounds that compromise the mechanical integrity of the interface. These reactions are particularly problematic with carbon-based reinforcements like graphene and carbon nanotubes, where excessive carbide formation can deplete alloying elements from the matrix and create weak interfacial zones.

Wettability issues between the molten metal matrix and reinforcement particles represent another significant hurdle. Poor wettability results in inadequate bonding, void formation, and reinforcement clustering, all of which severely impact load transfer efficiency across the interface. This challenge is exacerbated by the ultrafast solidification rates in LPBF, which limit the time available for proper interfacial bonding to develop.

The non-uniform distribution of reinforcement particles within the metal matrix further complicates interfacial mechanics. Agglomeration tendencies, particularly with nano-scale reinforcements, create localized stress concentrations and heterogeneous mechanical properties. Current powder feeding and mixing techniques struggle to achieve homogeneous reinforcement distribution, resulting in inconsistent interfacial characteristics throughout the component.

Interface degradation mechanisms during service conditions also remain poorly understood. The dynamic behavior of MMC interfaces under cyclic loading, elevated temperatures, and corrosive environments requires further investigation. Current accelerated testing protocols fail to accurately predict long-term interfacial stability, creating uncertainty in lifetime predictions for critical applications.

From a characterization perspective, the multi-scale nature of interfacial phenomena presents significant analytical challenges. Conventional techniques struggle to provide comprehensive information across the relevant length scales, from atomic-level bonding characteristics to mesoscale stress distributions. Advanced in-situ characterization methods capable of monitoring interfacial evolution during LPBF processing are still in their infancy, limiting our fundamental understanding of interface formation mechanisms.

Another critical challenge is the chemical reactivity at high temperatures during laser processing. The extreme thermal conditions in the melt pool can trigger undesired interfacial reactions, forming brittle intermetallic compounds that compromise the mechanical integrity of the interface. These reactions are particularly problematic with carbon-based reinforcements like graphene and carbon nanotubes, where excessive carbide formation can deplete alloying elements from the matrix and create weak interfacial zones.

Wettability issues between the molten metal matrix and reinforcement particles represent another significant hurdle. Poor wettability results in inadequate bonding, void formation, and reinforcement clustering, all of which severely impact load transfer efficiency across the interface. This challenge is exacerbated by the ultrafast solidification rates in LPBF, which limit the time available for proper interfacial bonding to develop.

The non-uniform distribution of reinforcement particles within the metal matrix further complicates interfacial mechanics. Agglomeration tendencies, particularly with nano-scale reinforcements, create localized stress concentrations and heterogeneous mechanical properties. Current powder feeding and mixing techniques struggle to achieve homogeneous reinforcement distribution, resulting in inconsistent interfacial characteristics throughout the component.

Interface degradation mechanisms during service conditions also remain poorly understood. The dynamic behavior of MMC interfaces under cyclic loading, elevated temperatures, and corrosive environments requires further investigation. Current accelerated testing protocols fail to accurately predict long-term interfacial stability, creating uncertainty in lifetime predictions for critical applications.

From a characterization perspective, the multi-scale nature of interfacial phenomena presents significant analytical challenges. Conventional techniques struggle to provide comprehensive information across the relevant length scales, from atomic-level bonding characteristics to mesoscale stress distributions. Advanced in-situ characterization methods capable of monitoring interfacial evolution during LPBF processing are still in their infancy, limiting our fundamental understanding of interface formation mechanisms.

Current Interface Control Strategies in LPBF MMCs

01 Interface bonding mechanisms in LPBF-fabricated MMCs

The interfacial mechanics between the metal matrix and reinforcement particles in LPBF-fabricated MMCs are critical for determining the composite's mechanical properties. Various bonding mechanisms occur at these interfaces, including mechanical interlocking, chemical bonding, and diffusion zones. The high-temperature gradients and rapid solidification during the LPBF process create unique interfacial characteristics that differ from conventionally manufactured MMCs. Understanding these bonding mechanisms is essential for predicting and optimizing the mechanical performance of the composite materials.- Interfacial bonding mechanisms in MMCs fabricated by LPBF: The interfacial bonding between matrix and reinforcement phases in Metal Matrix Composites (MMCs) produced by Laser Powder Bed Fusion (LPBF) is critical for mechanical properties. Various mechanisms contribute to this bonding, including diffusion bonding, mechanical interlocking, and chemical reactions at the interfaces. The rapid heating and cooling rates in LPBF create unique interfacial structures that influence the overall performance of the composite. Understanding these mechanisms helps in designing MMCs with enhanced interfacial strength and improved load transfer capabilities.

- Reinforcement distribution and interface quality control in LPBF-MMCs: Achieving uniform distribution of reinforcement particles and controlling the quality of interfaces in MMCs fabricated by LPBF presents significant challenges. Process parameters such as laser power, scanning speed, and hatch spacing directly affect the interfacial characteristics. Advanced techniques for powder preparation and mixing, along with optimized processing strategies, can improve reinforcement distribution and interface quality. These approaches help minimize clustering, agglomeration, and unwanted interfacial reactions that could otherwise compromise the mechanical properties of the composite.

- Thermal behavior and residual stress at MMC interfaces during LPBF: The thermal behavior at matrix-reinforcement interfaces during LPBF processing significantly impacts the formation of residual stresses and potential defects. The mismatch in thermal expansion coefficients between matrix and reinforcement materials creates localized stress concentrations at interfaces. These thermal gradients can lead to microcracking, delamination, or formation of brittle intermetallic phases. Managing these thermal effects through process parameter optimization and material selection is essential for producing MMCs with strong interfacial bonding and minimal residual stresses.

- Novel reinforcement materials and surface treatments for enhanced interfacial mechanics: Innovative reinforcement materials and surface modification techniques are being developed to enhance the interfacial mechanics in LPBF-fabricated MMCs. These include functionalized nanoparticles, coated reinforcements, and in-situ formed reinforcements that promote stronger bonding with the metal matrix. Surface treatments of reinforcement particles prior to LPBF processing can improve wettability and chemical compatibility with the matrix material. These approaches lead to stronger interfaces, reduced porosity at boundaries, and improved mechanical properties of the resulting composites.

- Characterization and modeling of interfacial properties in LPBF-MMCs: Advanced characterization techniques and computational modeling approaches are essential for understanding and predicting interfacial behavior in MMCs produced by LPBF. High-resolution imaging, spectroscopy, and mechanical testing methods provide insights into the microstructure and properties of interfaces. Multiscale modeling approaches, including finite element analysis and molecular dynamics simulations, help predict interfacial mechanics under various loading conditions. These tools enable the design of optimized processing parameters and material combinations for MMCs with superior interfacial properties and overall performance.

02 Reinforcement distribution and interfacial strength optimization

The distribution of reinforcement particles within the metal matrix significantly affects the interfacial mechanics of LPBF-fabricated MMCs. Techniques to achieve uniform distribution include powder pre-treatment, process parameter optimization, and post-processing methods. The interfacial strength can be enhanced by controlling the wetting behavior between the matrix and reinforcement, modifying particle surface characteristics, and optimizing laser parameters to create strong metallurgical bonds. These approaches help minimize interfacial defects such as pores, cracks, and weak bonding zones that can compromise the mechanical integrity of the composite.Expand Specific Solutions03 Thermal behavior and residual stress at MMC interfaces

The thermal behavior at the interfaces between the metal matrix and reinforcement particles during LPBF processing significantly impacts the mechanical properties of the resulting composite. Differences in thermal expansion coefficients between matrix and reinforcement materials create residual stresses at the interfaces, which can lead to microcracking or delamination. Managing these thermal mismatches through process parameter optimization, preheating strategies, or material selection is crucial for enhancing interfacial integrity. The rapid heating and cooling cycles characteristic of LPBF processing create unique thermal conditions that affect phase formation and interfacial reaction layers.Expand Specific Solutions04 Novel reinforcement materials and interface engineering

Advanced reinforcement materials and interface engineering approaches are being developed to enhance the performance of LPBF-fabricated MMCs. These include nano-reinforcements, functionally graded interfaces, and in-situ formed reinforcements that create stronger interfacial bonds. Surface modification of reinforcement particles prior to LPBF processing can improve wettability and bonding with the metal matrix. Coating technologies and chemical treatments are employed to create tailored interfaces that optimize load transfer between the matrix and reinforcement while minimizing detrimental interfacial reactions.Expand Specific Solutions05 Characterization and modeling of MMC interfacial mechanics

Advanced characterization techniques and computational modeling approaches are essential for understanding the interfacial mechanics in LPBF-fabricated MMCs. High-resolution microscopy, spectroscopy, and mechanical testing methods provide insights into the interfacial structure, composition, and properties. Finite element modeling, molecular dynamics simulations, and multi-scale modeling approaches help predict interfacial behavior under various loading conditions. These tools enable the optimization of processing parameters and material combinations to achieve desired interfacial characteristics and overall composite performance, facilitating the design of MMCs with enhanced mechanical properties for specific applications.Expand Specific Solutions

Leading Research Groups and Industrial Players

The interfacial mechanics in metal matrix composites fabricated by laser powder bed fusion (LPBF) represents an emerging field at the intersection of advanced manufacturing and materials science. This technology is currently in its growth phase, with the market expanding rapidly due to increasing industrial applications in aerospace, automotive, and medical sectors. Companies like VulcanForms, Nikon SLM Solutions, and Renishaw are leading commercial development, while research institutions such as Northwestern Polytechnical University and Central South University are advancing fundamental understanding of interface phenomena. The technology has reached moderate maturity for certain applications, but challenges remain in controlling interfacial properties at the microscale. Major industrial players including ArcelorMittal, Northrop Grumman, and Spirit AeroSystems are driving adoption through integration into high-performance component manufacturing.

VulcanForms, Inc.

Technical Solution: VulcanForms has developed a revolutionary approach to interfacial mechanics in metal matrix composites through their proprietary high-powered, multi-laser LPBF technology. Their system utilizes an array of precisely controlled lasers that can be individually programmed to create optimized thermal conditions at matrix-reinforcement interfaces. This enables unprecedented control over interfacial reaction kinetics and resulting microstructures. VulcanForms' technology incorporates advanced computational fluid dynamics modeling that predicts melt pool behavior specifically at heterogeneous interfaces, allowing for pre-build optimization of processing parameters. Their "Adaptive Interface Control" system continuously monitors and adjusts laser parameters in real-time based on material-specific thermal models, ensuring consistent interfacial properties throughout complex geometries. VulcanForms has demonstrated particular success with aluminum matrix composites reinforced with ceramic particles, achieving superior interfacial bonding without excessive formation of brittle intermetallic phases that typically plague these material systems.

Strengths: Industry-leading multi-laser technology enables precise control of thermal conditions at interfaces; sophisticated real-time monitoring and adjustment capabilities. Weaknesses: Relatively new technology with limited long-term performance data; high capital equipment costs may limit accessibility for smaller manufacturers.

Nikon SLM Solutions AG

Technical Solution: Nikon SLM Solutions AG has developed advanced laser powder bed fusion (LPBF) systems specifically designed for metal matrix composites (MMCs). Their technology focuses on precise control of interfacial mechanics through proprietary laser parameter optimization. Their NXG XII 600 system utilizes 12 lasers with 1kW power each to achieve optimal melt pool dynamics at the matrix-reinforcement interface. The company has pioneered a multi-scale simulation approach that predicts interfacial reactions during the LPBF process, allowing for pre-process optimization of parameters to control interfacial layer thickness and composition. Their patented "Controlled Reactivity" process manages the thermal gradient at the interface zone, resulting in tailored interfacial properties without compromising the overall mechanical integrity of MMCs. Recent developments include in-situ monitoring systems that provide real-time feedback on interfacial formation during the build process.

Strengths: Superior multi-laser technology enables precise control of thermal conditions at interfaces; advanced monitoring systems provide real-time data on interfacial formation. Weaknesses: High equipment costs limit accessibility; complex parameter optimization requires significant expertise and development time.

Key Interfacial Phenomena and Characterization Techniques

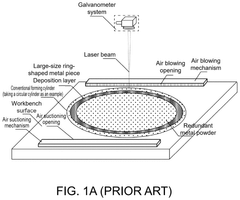

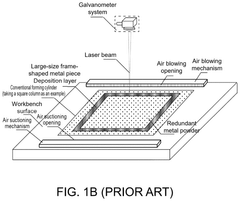

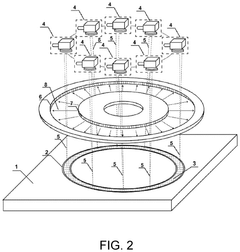

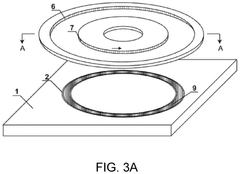

Laser powder bed fusion forming device and method for large-size ring/frame-shaped metal piece

PatentActiveUS12390857B2

Innovation

- A laser powder bed fusion forming device with a ring/frame-shaped forming cylinder and substrate, combined with a dust removal module that creates a radial or circumferential air flow field using air suctioning and blowing mechanisms, ensuring efficient smoke and dust removal and reduced powder usage.

Material Selection and Compatibility Assessment

Material selection and compatibility assessment are critical factors in determining the performance and reliability of metal matrix composites (MMCs) fabricated through Laser Powder Bed Fusion (LPBF). The interfacial mechanics between matrix and reinforcement materials significantly influence the overall mechanical properties, thermal stability, and long-term durability of the composite structure.

When selecting materials for LPBF-fabricated MMCs, several key considerations must be evaluated. The thermal expansion coefficient mismatch between matrix and reinforcement materials can generate residual stresses at interfaces during the rapid heating and cooling cycles characteristic of LPBF processes. Materials with substantial differences in thermal expansion behavior often develop microcracks or delamination at interfaces, compromising structural integrity.

Chemical compatibility represents another crucial aspect of material selection. The high-temperature environment during laser processing can trigger undesirable chemical reactions between matrix and reinforcement materials. These reactions may form brittle intermetallic compounds or other detrimental phases at interfaces, potentially creating weak points in the composite structure. Comprehensive thermodynamic analysis of potential material combinations is essential to predict and mitigate such reactions.

Wettability characteristics between molten metal matrices and reinforcement materials directly impact interface quality. Poor wettability leads to inadequate bonding, void formation, and reduced load transfer efficiency across interfaces. Surface modification techniques, such as coating reinforcement particles or adjusting laser processing parameters, can enhance wettability and promote stronger interfacial bonding.

The particle size distribution and morphology of reinforcement materials must be carefully optimized for LPBF processing. Excessively fine particles may agglomerate and distribute unevenly, while overly large particles can disrupt the powder bed uniformity and laser absorption characteristics. The ideal reinforcement size typically ranges between 5-45 μm for most LPBF systems, balancing processability with interfacial area optimization.

Recent research has demonstrated promising results with titanium-based matrices reinforced with ceramic particles such as TiC and TiB2, aluminum matrices with SiC reinforcements, and nickel superalloys strengthened with oxide dispersions. These material combinations exhibit favorable interfacial characteristics when processed under optimized LPBF conditions, resulting in enhanced mechanical properties without significant interfacial degradation.

Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM), atom probe tomography (APT), and in-situ synchrotron X-ray diffraction have revolutionized our understanding of interfacial phenomena in LPBF-fabricated MMCs. These techniques enable precise analysis of chemical gradients, crystallographic relationships, and nanoscale defects at interfaces, providing crucial insights for material selection and process optimization.

When selecting materials for LPBF-fabricated MMCs, several key considerations must be evaluated. The thermal expansion coefficient mismatch between matrix and reinforcement materials can generate residual stresses at interfaces during the rapid heating and cooling cycles characteristic of LPBF processes. Materials with substantial differences in thermal expansion behavior often develop microcracks or delamination at interfaces, compromising structural integrity.

Chemical compatibility represents another crucial aspect of material selection. The high-temperature environment during laser processing can trigger undesirable chemical reactions between matrix and reinforcement materials. These reactions may form brittle intermetallic compounds or other detrimental phases at interfaces, potentially creating weak points in the composite structure. Comprehensive thermodynamic analysis of potential material combinations is essential to predict and mitigate such reactions.

Wettability characteristics between molten metal matrices and reinforcement materials directly impact interface quality. Poor wettability leads to inadequate bonding, void formation, and reduced load transfer efficiency across interfaces. Surface modification techniques, such as coating reinforcement particles or adjusting laser processing parameters, can enhance wettability and promote stronger interfacial bonding.

The particle size distribution and morphology of reinforcement materials must be carefully optimized for LPBF processing. Excessively fine particles may agglomerate and distribute unevenly, while overly large particles can disrupt the powder bed uniformity and laser absorption characteristics. The ideal reinforcement size typically ranges between 5-45 μm for most LPBF systems, balancing processability with interfacial area optimization.

Recent research has demonstrated promising results with titanium-based matrices reinforced with ceramic particles such as TiC and TiB2, aluminum matrices with SiC reinforcements, and nickel superalloys strengthened with oxide dispersions. These material combinations exhibit favorable interfacial characteristics when processed under optimized LPBF conditions, resulting in enhanced mechanical properties without significant interfacial degradation.

Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM), atom probe tomography (APT), and in-situ synchrotron X-ray diffraction have revolutionized our understanding of interfacial phenomena in LPBF-fabricated MMCs. These techniques enable precise analysis of chemical gradients, crystallographic relationships, and nanoscale defects at interfaces, providing crucial insights for material selection and process optimization.

Simulation and Modeling Approaches for Interface Prediction

Simulation and modeling approaches have become indispensable tools for predicting interfacial behavior in metal matrix composites (MMCs) fabricated via Laser Powder Bed Fusion (LPBF). These computational methods enable researchers to understand the complex thermomechanical processes occurring at the matrix-reinforcement interfaces without extensive experimental trials.

Finite Element Analysis (FEA) represents the most widely adopted simulation approach for interface prediction in LPBF-fabricated MMCs. Multi-physics FEA models can simultaneously account for heat transfer, fluid dynamics, and mechanical stress development during the rapid melting and solidification processes characteristic of LPBF. These models typically incorporate temperature-dependent material properties and phase transformation kinetics to accurately predict interfacial reactions and residual stress distributions.

Molecular Dynamics (MD) simulations offer insights at the atomic scale, particularly valuable for understanding diffusion mechanisms and chemical reactions at the interfaces. MD simulations have successfully predicted the formation of intermetallic compounds and other reaction products at matrix-reinforcement interfaces in various MMC systems processed by LPBF, including Ti-SiC, Al-TiC, and Ni-TiB2 composites.

Phase-field modeling has emerged as a powerful approach for simulating microstructural evolution at interfaces during solidification. This method can predict the morphology of reaction layers and intermetallic phases formed at the interfaces, providing insights into how processing parameters influence interfacial characteristics. Recent advancements have enabled coupling phase-field models with thermal simulations to account for the unique thermal history experienced during LPBF processing.

Machine learning approaches are increasingly being integrated with traditional simulation methods to enhance predictive capabilities. Neural networks trained on experimental data can predict interfacial properties based on processing parameters and material combinations, significantly reducing computational costs compared to full-scale simulations. These hybrid modeling approaches show particular promise for optimizing LPBF parameters to achieve desired interfacial characteristics.

Computational thermodynamics, particularly CALPHAD (CALculation of PHAse Diagrams) methods, provide essential input data for other simulation approaches by predicting equilibrium phases and their properties. When coupled with kinetic models, these thermodynamic calculations can predict the sequence and rates of interfacial reactions during the rapid thermal cycles of LPBF processing.

Finite Element Analysis (FEA) represents the most widely adopted simulation approach for interface prediction in LPBF-fabricated MMCs. Multi-physics FEA models can simultaneously account for heat transfer, fluid dynamics, and mechanical stress development during the rapid melting and solidification processes characteristic of LPBF. These models typically incorporate temperature-dependent material properties and phase transformation kinetics to accurately predict interfacial reactions and residual stress distributions.

Molecular Dynamics (MD) simulations offer insights at the atomic scale, particularly valuable for understanding diffusion mechanisms and chemical reactions at the interfaces. MD simulations have successfully predicted the formation of intermetallic compounds and other reaction products at matrix-reinforcement interfaces in various MMC systems processed by LPBF, including Ti-SiC, Al-TiC, and Ni-TiB2 composites.

Phase-field modeling has emerged as a powerful approach for simulating microstructural evolution at interfaces during solidification. This method can predict the morphology of reaction layers and intermetallic phases formed at the interfaces, providing insights into how processing parameters influence interfacial characteristics. Recent advancements have enabled coupling phase-field models with thermal simulations to account for the unique thermal history experienced during LPBF processing.

Machine learning approaches are increasingly being integrated with traditional simulation methods to enhance predictive capabilities. Neural networks trained on experimental data can predict interfacial properties based on processing parameters and material combinations, significantly reducing computational costs compared to full-scale simulations. These hybrid modeling approaches show particular promise for optimizing LPBF parameters to achieve desired interfacial characteristics.

Computational thermodynamics, particularly CALPHAD (CALculation of PHAse Diagrams) methods, provide essential input data for other simulation approaches by predicting equilibrium phases and their properties. When coupled with kinetic models, these thermodynamic calculations can predict the sequence and rates of interfacial reactions during the rapid thermal cycles of LPBF processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!