Joining And Fastening Solutions For Integrating CMCs Into Metal Housings

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC-Metal Integration Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that combine the high-temperature capabilities of ceramics with improved fracture toughness and damage tolerance. The integration of CMCs with metal housings has emerged as a critical technological frontier, particularly in aerospace, energy, and automotive sectors where extreme operating conditions demand materials that can withstand high temperatures while maintaining structural integrity.

The evolution of CMC technology dates back to the 1970s, with significant advancements occurring in the 1990s and 2000s. Initially developed for specialized aerospace applications, CMCs have gradually expanded into broader industrial uses. The trajectory of CMC development has been characterized by continuous improvements in manufacturing processes, material compositions, and integration techniques, leading to enhanced performance characteristics and wider applicability.

Current technological trends in CMC-metal integration focus on overcoming the fundamental challenges of joining dissimilar materials with vastly different thermal, mechanical, and chemical properties. The coefficient of thermal expansion (CTE) mismatch between ceramics and metals represents one of the most significant hurdles, often resulting in residual stresses and potential joint failure during thermal cycling.

The primary objective of CMC-metal integration research is to develop robust joining and fastening solutions that can maintain structural integrity across extreme temperature gradients while withstanding mechanical loads. These solutions must accommodate the brittle nature of ceramics while leveraging the ductility and toughness of metals to create reliable structural components.

Secondary objectives include reducing manufacturing complexity and costs, extending component lifespans, enabling field repairability, and ensuring consistent quality across production scales. The development of standardized testing methodologies and design guidelines represents another critical goal, as the industry currently lacks unified approaches to evaluating joint performance under complex loading conditions.

From a strategic perspective, mastering CMC-metal integration technologies offers significant competitive advantages in high-value markets. Companies that develop proprietary joining solutions can secure leadership positions in emerging applications such as hypersonic vehicles, next-generation turbine engines, and advanced nuclear systems.

The technical goals extend beyond mere functional integration to include predictive modeling capabilities that can accurately forecast joint behavior throughout the component lifecycle. This includes understanding degradation mechanisms, predicting failure modes, and developing accelerated testing protocols that correlate with real-world performance.

The evolution of CMC technology dates back to the 1970s, with significant advancements occurring in the 1990s and 2000s. Initially developed for specialized aerospace applications, CMCs have gradually expanded into broader industrial uses. The trajectory of CMC development has been characterized by continuous improvements in manufacturing processes, material compositions, and integration techniques, leading to enhanced performance characteristics and wider applicability.

Current technological trends in CMC-metal integration focus on overcoming the fundamental challenges of joining dissimilar materials with vastly different thermal, mechanical, and chemical properties. The coefficient of thermal expansion (CTE) mismatch between ceramics and metals represents one of the most significant hurdles, often resulting in residual stresses and potential joint failure during thermal cycling.

The primary objective of CMC-metal integration research is to develop robust joining and fastening solutions that can maintain structural integrity across extreme temperature gradients while withstanding mechanical loads. These solutions must accommodate the brittle nature of ceramics while leveraging the ductility and toughness of metals to create reliable structural components.

Secondary objectives include reducing manufacturing complexity and costs, extending component lifespans, enabling field repairability, and ensuring consistent quality across production scales. The development of standardized testing methodologies and design guidelines represents another critical goal, as the industry currently lacks unified approaches to evaluating joint performance under complex loading conditions.

From a strategic perspective, mastering CMC-metal integration technologies offers significant competitive advantages in high-value markets. Companies that develop proprietary joining solutions can secure leadership positions in emerging applications such as hypersonic vehicles, next-generation turbine engines, and advanced nuclear systems.

The technical goals extend beyond mere functional integration to include predictive modeling capabilities that can accurately forecast joint behavior throughout the component lifecycle. This includes understanding degradation mechanisms, predicting failure modes, and developing accelerated testing protocols that correlate with real-world performance.

Market Analysis for CMC-Metal Joining Applications

The market for CMC-metal joining solutions is experiencing significant growth, driven primarily by the aerospace and defense sectors where high-temperature applications demand materials that can withstand extreme conditions. The global CMC market was valued at approximately $4.5 billion in 2022 and is projected to grow at a compound annual growth rate of 9.8% through 2030, with joining technologies representing a critical enabling segment of this market.

Aerospace applications currently dominate the demand landscape, accounting for roughly 60% of the market for CMC-metal joining solutions. This is primarily due to the increasing use of CMCs in aircraft engine components, where their integration with metallic housings can reduce weight by up to 30% while maintaining structural integrity at temperatures exceeding 1200°C. Commercial aviation's push toward more fuel-efficient engines has accelerated adoption, with major manufacturers like GE Aviation and Rolls-Royce investing heavily in these integration technologies.

The power generation sector represents the second-largest market segment at approximately 20%, particularly in gas turbines where CMC components can significantly improve operational efficiency. Industrial applications, including chemical processing and oil and gas, constitute about 15% of the market, with automotive applications (particularly in high-performance vehicles) making up the remaining 5%.

Regionally, North America leads the market with approximately 45% share, followed by Europe (30%) and Asia-Pacific (20%). The dominance of North America is attributed to the concentration of aerospace manufacturers and substantial defense spending. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% annually, driven by China's and India's expanding aerospace industries and increasing industrial applications.

Market barriers include the high cost of joining technologies, with specialized brazing alloys for CMC-metal joints costing up to 20 times more than conventional alternatives. Technical challenges in creating reliable joints that maintain integrity across thermal cycles also limit wider adoption. Additionally, the specialized nature of these joining solutions requires significant expertise, creating a skills gap that constrains market expansion.

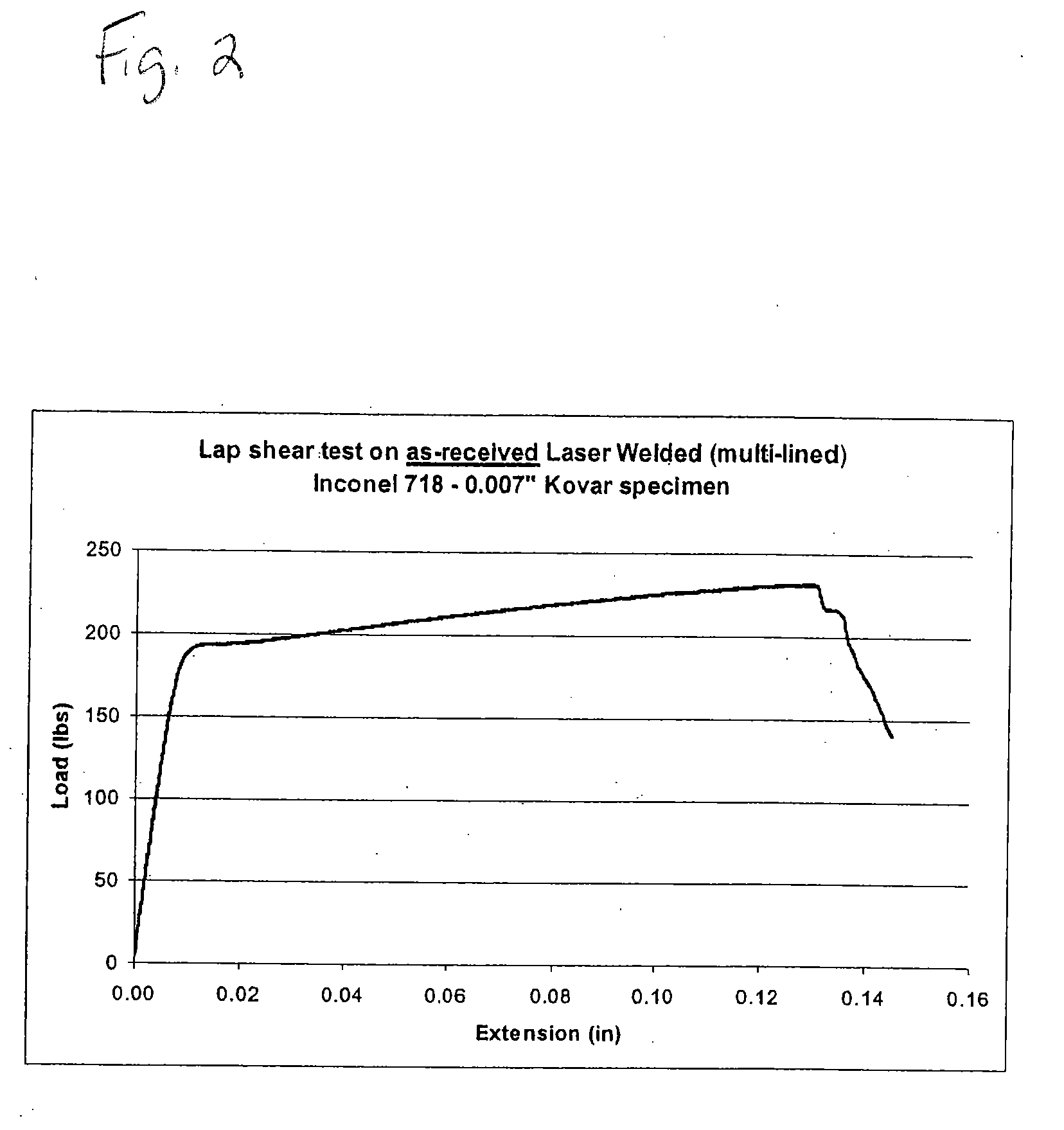

Customer requirements are evolving toward solutions that can withstand higher operating temperatures (beyond 1400°C) while maintaining joint strength above 200 MPa. There is also increasing demand for joining technologies that can accommodate complex geometries and reduce assembly time by at least 30%, particularly in high-volume applications like next-generation turbine components.

Aerospace applications currently dominate the demand landscape, accounting for roughly 60% of the market for CMC-metal joining solutions. This is primarily due to the increasing use of CMCs in aircraft engine components, where their integration with metallic housings can reduce weight by up to 30% while maintaining structural integrity at temperatures exceeding 1200°C. Commercial aviation's push toward more fuel-efficient engines has accelerated adoption, with major manufacturers like GE Aviation and Rolls-Royce investing heavily in these integration technologies.

The power generation sector represents the second-largest market segment at approximately 20%, particularly in gas turbines where CMC components can significantly improve operational efficiency. Industrial applications, including chemical processing and oil and gas, constitute about 15% of the market, with automotive applications (particularly in high-performance vehicles) making up the remaining 5%.

Regionally, North America leads the market with approximately 45% share, followed by Europe (30%) and Asia-Pacific (20%). The dominance of North America is attributed to the concentration of aerospace manufacturers and substantial defense spending. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% annually, driven by China's and India's expanding aerospace industries and increasing industrial applications.

Market barriers include the high cost of joining technologies, with specialized brazing alloys for CMC-metal joints costing up to 20 times more than conventional alternatives. Technical challenges in creating reliable joints that maintain integrity across thermal cycles also limit wider adoption. Additionally, the specialized nature of these joining solutions requires significant expertise, creating a skills gap that constrains market expansion.

Customer requirements are evolving toward solutions that can withstand higher operating temperatures (beyond 1400°C) while maintaining joint strength above 200 MPa. There is also increasing demand for joining technologies that can accommodate complex geometries and reduce assembly time by at least 30%, particularly in high-volume applications like next-generation turbine components.

Technical Challenges in CMC-Metal Interface Systems

The integration of Ceramic Matrix Composites (CMCs) with metal housings presents significant technical challenges due to the fundamental differences in material properties. The coefficient of thermal expansion (CTE) mismatch between CMCs and metals creates substantial stress concentrations at interface regions during thermal cycling, often leading to premature failure. CMCs typically exhibit CTE values of 2-5×10^-6/K, while common metals used in housings such as steel or aluminum have CTEs ranging from 11-23×10^-6/K, creating a critical design constraint.

Chemical incompatibility represents another major challenge, as high-temperature reactions between CMCs and metals can form brittle intermetallic compounds or cause degradation of the interface strength. Silicon-based CMCs are particularly susceptible to reaction with titanium alloys, forming titanium silicides that compromise structural integrity. Additionally, galvanic corrosion can occur when carbon-containing CMCs contact metals in the presence of an electrolyte, accelerating degradation.

Mechanical load transfer across the CMC-metal interface presents unique difficulties due to the brittle nature of ceramics compared to the ductile behavior of metals. Traditional joining methods like welding are generally unsuitable as they can damage the ceramic phase or create residual stresses that lead to microcracking. The interface must accommodate not only static loads but also dynamic and cyclic loading conditions typical in aerospace and energy applications.

Manufacturing challenges further complicate integration efforts. Conventional metal joining processes often involve temperatures exceeding the oxidation limits of many CMCs, while lower-temperature processes may not provide adequate bond strength. Surface preparation requirements differ significantly between metals and ceramics, with ceramics requiring specialized treatments to achieve adequate adhesion.

Environmental durability of the CMC-metal interface represents a persistent concern, particularly in applications involving extreme temperatures, oxidizing environments, or moisture exposure. Interface degradation mechanisms can be accelerated by environmental factors, reducing the effective service life of the component system.

Inspection and quality assurance of CMC-metal interfaces present additional technical hurdles. Non-destructive evaluation techniques must be adapted to detect defects at the interface between dissimilar materials with vastly different acoustic and electromagnetic properties. The complex geometry of many practical joints further complicates reliable inspection.

These technical challenges necessitate innovative approaches to joining and fastening solutions that can accommodate the fundamental material differences while maintaining structural integrity across diverse operating conditions. Addressing these challenges is essential for expanding the application of CMC-metal hybrid structures in advanced engineering systems.

Chemical incompatibility represents another major challenge, as high-temperature reactions between CMCs and metals can form brittle intermetallic compounds or cause degradation of the interface strength. Silicon-based CMCs are particularly susceptible to reaction with titanium alloys, forming titanium silicides that compromise structural integrity. Additionally, galvanic corrosion can occur when carbon-containing CMCs contact metals in the presence of an electrolyte, accelerating degradation.

Mechanical load transfer across the CMC-metal interface presents unique difficulties due to the brittle nature of ceramics compared to the ductile behavior of metals. Traditional joining methods like welding are generally unsuitable as they can damage the ceramic phase or create residual stresses that lead to microcracking. The interface must accommodate not only static loads but also dynamic and cyclic loading conditions typical in aerospace and energy applications.

Manufacturing challenges further complicate integration efforts. Conventional metal joining processes often involve temperatures exceeding the oxidation limits of many CMCs, while lower-temperature processes may not provide adequate bond strength. Surface preparation requirements differ significantly between metals and ceramics, with ceramics requiring specialized treatments to achieve adequate adhesion.

Environmental durability of the CMC-metal interface represents a persistent concern, particularly in applications involving extreme temperatures, oxidizing environments, or moisture exposure. Interface degradation mechanisms can be accelerated by environmental factors, reducing the effective service life of the component system.

Inspection and quality assurance of CMC-metal interfaces present additional technical hurdles. Non-destructive evaluation techniques must be adapted to detect defects at the interface between dissimilar materials with vastly different acoustic and electromagnetic properties. The complex geometry of many practical joints further complicates reliable inspection.

These technical challenges necessitate innovative approaches to joining and fastening solutions that can accommodate the fundamental material differences while maintaining structural integrity across diverse operating conditions. Addressing these challenges is essential for expanding the application of CMC-metal hybrid structures in advanced engineering systems.

Current CMC-Metal Joining Methodologies

01 Mechanical fastening systems for CMC components

Various mechanical fastening systems have been developed specifically for ceramic matrix composite (CMC) components. These systems include specialized bolts, pins, and clamps designed to accommodate the unique properties of CMCs, such as their brittleness and thermal expansion characteristics. These fastening solutions allow for secure attachment while minimizing stress concentration points that could lead to component failure. The designs often incorporate features that allow for thermal expansion and contraction without damaging the CMC parts.- Mechanical fastening systems for CMC components: Various mechanical fastening systems have been developed specifically for ceramic matrix composites (CMCs) to address their unique properties. These systems include specialized bolts, pins, and clamps designed to accommodate the thermal expansion characteristics and brittleness of CMCs. The fastening solutions often incorporate features to distribute load evenly and prevent stress concentration points that could lead to component failure during high-temperature applications.

- Joining techniques for CMC-to-metal interfaces: Specialized joining methods have been developed to create reliable connections between ceramic matrix composites and metallic components. These techniques address the challenges of joining dissimilar materials with different thermal expansion coefficients and mechanical properties. Solutions include brazing with specialized filler materials, diffusion bonding under controlled conditions, and the use of transition layers or graded interfaces to mitigate stress concentrations at the joint.

- High-temperature resistant joining solutions: Advanced joining solutions have been developed specifically for high-temperature applications where CMCs are commonly used. These include specialized ceramic adhesives, refractory metal brazes, and composite interlayers that maintain their integrity at elevated temperatures. The joining methods are designed to withstand thermal cycling while maintaining structural integrity and gas-tightness in extreme environments such as gas turbine engines and aerospace applications.

- Integrated design approaches for CMC assemblies: Innovative design approaches focus on integrating CMC components into larger assemblies through careful consideration of attachment points and load paths. These designs often incorporate features directly into the CMC components during manufacturing, such as integral flanges, attachment lugs, or reinforced regions. The integrated design approach minimizes the need for secondary machining operations and reduces stress concentrations that could lead to failure in service.

- Sealing solutions for CMC joints: Specialized sealing technologies have been developed to ensure gas-tight and fluid-tight joints between CMC components or between CMCs and other materials. These sealing solutions address the challenges of maintaining seal integrity at high temperatures and under thermal cycling conditions. Approaches include compliant ceramic seals, metal foil seals with specific geometries to accommodate differential thermal expansion, and hybrid sealing systems that combine multiple materials to achieve the required performance.

02 Adhesive bonding techniques for CMC integration

Adhesive bonding provides a non-mechanical method for joining CMC components. Specialized high-temperature adhesives have been formulated to withstand the extreme operating conditions where CMCs are typically used. These adhesives create strong bonds between CMC parts or between CMCs and other materials while distributing loads evenly across the bonded surface. The bonding techniques often involve surface preparation methods specific to ceramic materials to enhance adhesion strength and durability in high-temperature environments.Expand Specific Solutions03 Interlocking joint designs for CMC structures

Innovative interlocking joint designs have been created specifically for CMC structures. These joints utilize geometric features such as dovetails, tongue-and-groove configurations, and puzzle-like interfaces that allow components to lock together. The interlocking designs provide mechanical stability while accommodating the thermal expansion characteristics of ceramic materials. These joining solutions are particularly valuable in high-temperature applications where traditional fastening methods might fail.Expand Specific Solutions04 Hybrid joining methods combining multiple techniques

Hybrid joining approaches combine multiple fastening techniques to leverage the advantages of each method while mitigating their individual limitations. These solutions might integrate mechanical fasteners with adhesive bonding, or combine interlocking features with brazing techniques. The hybrid methods provide redundancy in the joining system, enhancing reliability in critical applications. These approaches are particularly valuable for joining CMCs to dissimilar materials where thermal expansion mismatches present significant challenges.Expand Specific Solutions05 Specialized fastening for turbine engine CMC applications

Turbine engines represent one of the most demanding applications for CMC components, requiring specialized fastening solutions. These include high-temperature capable attachment systems designed specifically for turbine blades, combustor liners, and other engine components made from CMCs. The fastening systems accommodate the extreme thermal cycling, vibration, and centrifugal forces present in turbine engines while maintaining the structural integrity of the ceramic components. These solutions often incorporate cooling features to protect the joining areas from the most extreme temperatures.Expand Specific Solutions

Leading Companies in CMC-Metal Integration Industry

The ceramic matrix composite (CMC) integration into metal housings market is currently in a growth phase, characterized by increasing adoption across aerospace, defense, and industrial sectors. The market size is expanding steadily, driven by demand for high-temperature applications where traditional materials fail. Technologically, the field is advancing from experimental to commercial implementation, with varying maturity levels across joining techniques. Leading players include aerospace giants Boeing, RTX Corp., and Rolls-Royce Corp., who are developing proprietary integration solutions, while specialized companies like XiAn Xinyao Ceramic Composite Materials and COI Ceramics focus on material development. Academic institutions such as Xi'an Jiaotong University and Harbin Institute of Technology contribute fundamental research, while industrial conglomerates like General Electric, Siemens AG, and NIPPON STEEL are advancing practical applications through their extensive manufacturing capabilities.

The Boeing Co.

Technical Solution: Boeing has pioneered advanced mechanical fastening systems for CMC-to-metal integration in aerospace structures. Their approach utilizes specialized ceramic-friendly fasteners with carefully engineered preload characteristics to prevent damage to the brittle ceramic components. Boeing's patented "floating attachment" system allows for differential thermal expansion between CMCs and metallic structures by incorporating controlled degrees of freedom at attachment points. This system has been implemented in high-temperature zones of hypersonic vehicles where traditional joining methods fail. Boeing has also developed hybrid joining techniques combining mechanical fastening with high-temperature adhesives, creating redundant load paths that enhance reliability in critical applications. Their testing has demonstrated joint integrity through thousands of thermal cycles between -65°F and 2000°F.

Strengths: Extensive experience with extreme operating environments; sophisticated design methodologies accounting for thermal and mechanical stresses; proven reliability in flight applications. Weaknesses: Solutions typically require complex and expensive manufacturing processes; limited scalability to mass production.

General Electric Company

Technical Solution: GE has developed proprietary brazing and mechanical fastening techniques specifically for integrating silicon carbide CMCs with metallic components in turbine engines. Their approach combines high-temperature brazing alloys with specialized surface preparation methods to create reliable ceramic-to-metal joints capable of withstanding temperatures exceeding 1200°C. GE's patented "compliant layer" technology addresses the thermal expansion mismatch between CMCs and metals by incorporating an intermediate layer that accommodates differential expansion during thermal cycling. This technology has been successfully implemented in LEAP engine components, where CMC shrouds are joined to metallic support structures, resulting in 20% weight reduction and significantly improved high-temperature performance.

Strengths: Industry-leading expertise in high-temperature applications; proven technology deployed in commercial aviation; comprehensive testing infrastructure. Weaknesses: Solutions are primarily optimized for aerospace applications and may require significant adaptation for other industries; high implementation costs compared to conventional materials.

Key Patents in CMC-Metal Fastening Technologies

CMC fastening system

PatentActiveEP1923578A3

Innovation

- A simple CMC fastening system featuring a detachable slotted bracket with flared end rivets or pins, optionally with sleeves and leaf springs, that securely connects CMCs to metallic components while accommodating thermal expansion differences and distributing loads effectively.

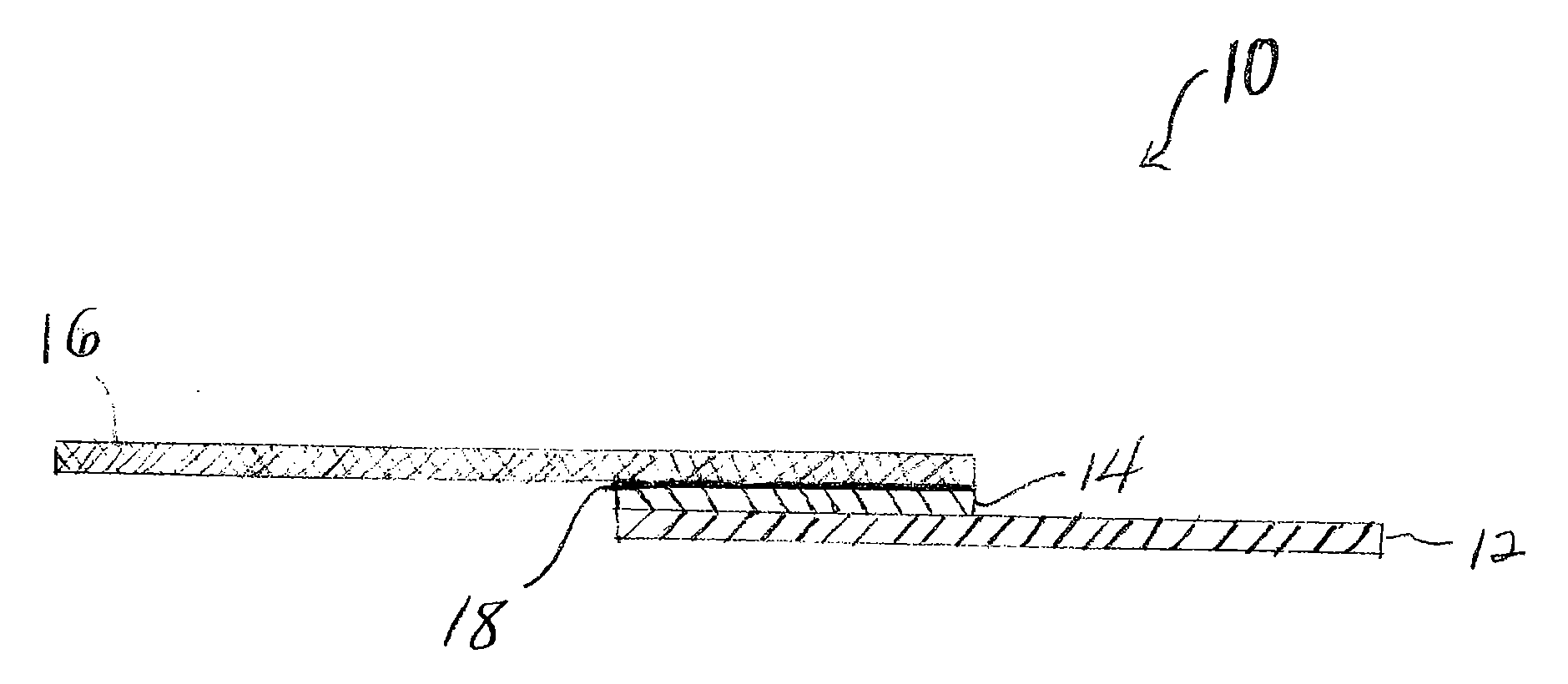

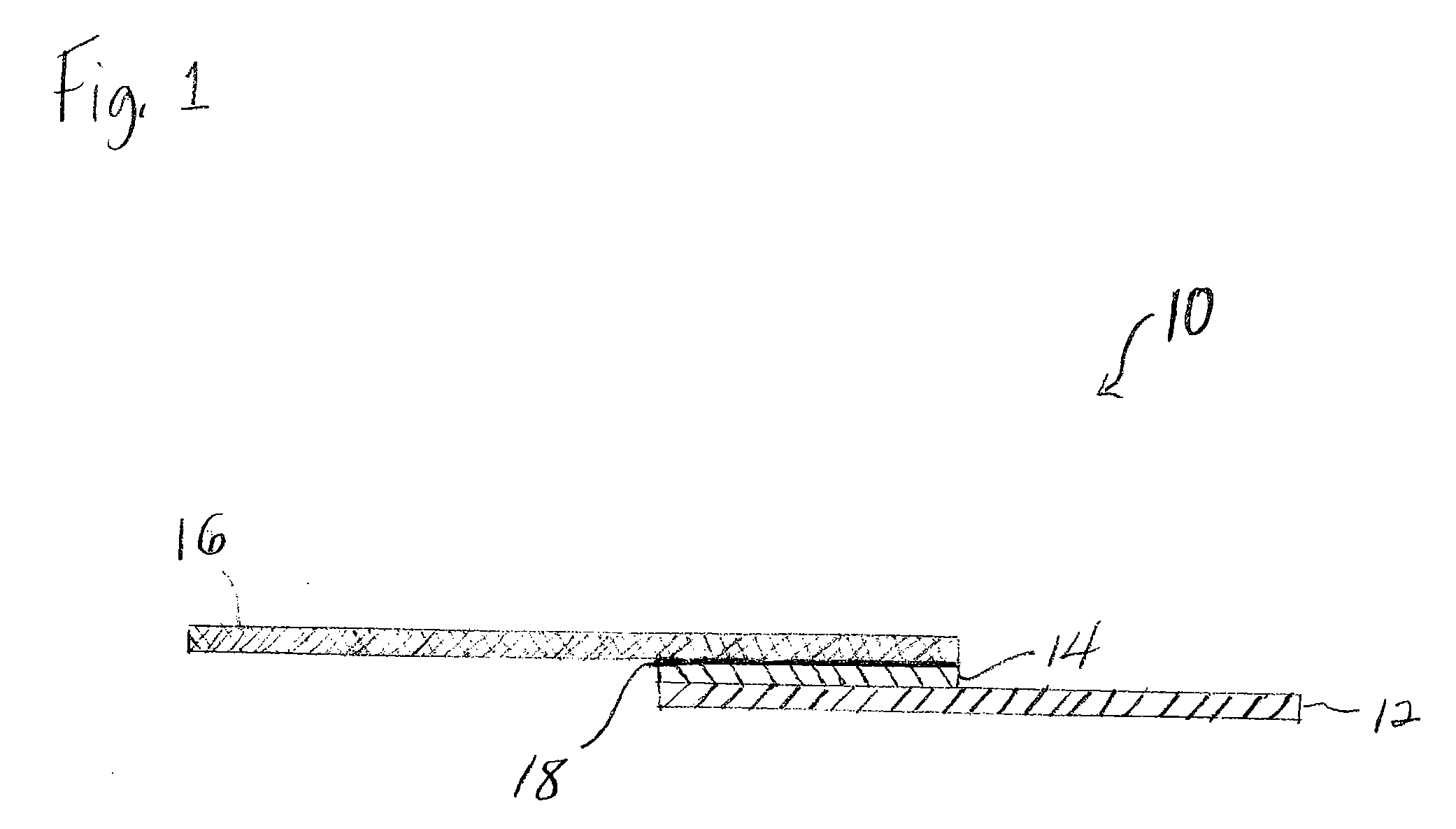

Method of joining metals to ceramic matrix composites

PatentActiveUS20080274362A1

Innovation

- A method involving a compliant interlayer with a thermal expansion coefficient between that of the metal and ceramic is used, allowing for bonding of the metal to the ceramic matrix composite through welding, metallizing, or brazing, enabling a high strength bond that can withstand higher operating temperatures.

Thermal Management Considerations for CMC-Metal Joints

Thermal management represents a critical challenge in CMC-metal integration systems due to the significant coefficient of thermal expansion (CTE) mismatch between ceramic matrix composites and metallic materials. When subjected to operational temperature fluctuations, these dissimilar materials expand and contract at different rates, generating substantial thermal stresses at joint interfaces that can lead to premature failure.

The thermal conductivity differential between CMCs (typically 10-40 W/m·K) and metals (50-400 W/m·K) creates thermal gradients that must be carefully managed. These gradients can induce localized hot spots and thermal fatigue, particularly in high-temperature applications such as aerospace propulsion systems where temperatures may exceed 1200°C.

Effective thermal management strategies include the implementation of compliant layers between CMC and metal components. Materials such as braided metallic fibers or specialized high-temperature alloys can serve as thermal buffers, accommodating differential expansion while maintaining structural integrity. These intermediate layers effectively distribute thermal stresses across a broader area rather than concentrating them at discrete points.

Thermal barrier coatings (TBCs) represent another viable approach, providing insulation that reduces heat transfer between components. Advanced zirconia-based TBCs can withstand temperatures up to 1500°C while significantly reducing thermal gradients across joint interfaces. Recent developments in functionally graded materials (FGMs) show particular promise, as they feature gradually changing composition and properties that minimize abrupt thermal discontinuities.

Active cooling techniques must also be considered for extreme thermal environments. Directed air or liquid cooling channels strategically positioned near joint interfaces can maintain temperatures within acceptable operational limits. Computational fluid dynamics (CFD) modeling has proven invaluable in optimizing these cooling systems to address specific thermal challenges in CMC-metal assemblies.

Long-term thermal cycling represents a particular concern for joint durability. Research indicates that repeated thermal excursions can progressively degrade joint integrity through mechanisms such as oxidation, interdiffusion, and microstructural evolution. Testing protocols typically subject specimens to thousands of thermal cycles between ambient and maximum operating temperatures to validate joint performance under realistic service conditions.

Emerging technologies in this domain include phase-change materials that absorb thermal energy during temperature spikes and advanced ceramics with engineered thermal expansion properties that more closely match those of adjacent metallic components. These innovations promise to expand the operational envelope of integrated CMC-metal systems in next-generation high-temperature applications.

The thermal conductivity differential between CMCs (typically 10-40 W/m·K) and metals (50-400 W/m·K) creates thermal gradients that must be carefully managed. These gradients can induce localized hot spots and thermal fatigue, particularly in high-temperature applications such as aerospace propulsion systems where temperatures may exceed 1200°C.

Effective thermal management strategies include the implementation of compliant layers between CMC and metal components. Materials such as braided metallic fibers or specialized high-temperature alloys can serve as thermal buffers, accommodating differential expansion while maintaining structural integrity. These intermediate layers effectively distribute thermal stresses across a broader area rather than concentrating them at discrete points.

Thermal barrier coatings (TBCs) represent another viable approach, providing insulation that reduces heat transfer between components. Advanced zirconia-based TBCs can withstand temperatures up to 1500°C while significantly reducing thermal gradients across joint interfaces. Recent developments in functionally graded materials (FGMs) show particular promise, as they feature gradually changing composition and properties that minimize abrupt thermal discontinuities.

Active cooling techniques must also be considered for extreme thermal environments. Directed air or liquid cooling channels strategically positioned near joint interfaces can maintain temperatures within acceptable operational limits. Computational fluid dynamics (CFD) modeling has proven invaluable in optimizing these cooling systems to address specific thermal challenges in CMC-metal assemblies.

Long-term thermal cycling represents a particular concern for joint durability. Research indicates that repeated thermal excursions can progressively degrade joint integrity through mechanisms such as oxidation, interdiffusion, and microstructural evolution. Testing protocols typically subject specimens to thousands of thermal cycles between ambient and maximum operating temperatures to validate joint performance under realistic service conditions.

Emerging technologies in this domain include phase-change materials that absorb thermal energy during temperature spikes and advanced ceramics with engineered thermal expansion properties that more closely match those of adjacent metallic components. These innovations promise to expand the operational envelope of integrated CMC-metal systems in next-generation high-temperature applications.

Material Compatibility and Degradation Analysis

The integration of Ceramic Matrix Composites (CMCs) with metal housings presents significant material compatibility challenges that must be addressed to ensure structural integrity and longevity. The fundamental issue stems from the disparate physical and chemical properties between CMCs and metals, particularly their different coefficients of thermal expansion (CTE). CMCs typically exhibit CTEs ranging from 2-6 × 10^-6/K, while common metals used in housings such as steel, aluminum, and titanium alloys have CTEs between 8-24 × 10^-6/K. This mismatch creates substantial interfacial stresses during thermal cycling, potentially leading to joint failure.

Chemical interactions at the CMC-metal interface represent another critical concern. At elevated temperatures, diffusion processes accelerate, potentially forming brittle intermetallic compounds or causing degradation of the ceramic matrix. Silicon-based CMCs are particularly susceptible to reactions with transition metals, forming silicides that can compromise the joint integrity. Additionally, in oxidizing environments, preferential oxidation at the interface can create oxide scales with poor adhesion properties, further weakening the joint.

Galvanic corrosion presents a significant long-term degradation mechanism when joining dissimilar materials. The electrochemical potential difference between CMCs and metals, particularly in the presence of an electrolyte, can accelerate corrosion at the interface. This phenomenon is exacerbated in applications exposed to moisture, salt environments, or acidic conditions, necessitating careful material selection or the implementation of isolation strategies.

Environmental factors significantly impact the degradation kinetics of CMC-metal joints. Water vapor can accelerate the degradation of certain CMCs, particularly those with glass or oxide matrices, through stress corrosion cracking mechanisms. Similarly, salt environments can penetrate the interface region, creating localized corrosion cells and accelerating material degradation. High-temperature applications introduce additional concerns related to creep behavior differences between the joined materials.

The mechanical load distribution across the CMC-metal interface requires careful consideration to prevent stress concentrations that could initiate cracks. The inherent brittleness of CMCs compared to the ductility of metals means that under loading conditions, plastic deformation in the metal cannot be accommodated by the ceramic component, creating high localized stresses. These stress concentrations are particularly problematic under cyclic loading conditions, where they can lead to progressive damage accumulation and eventual failure.

Interfacial coating systems offer promising solutions to these compatibility challenges. Functionally graded materials (FGMs) that provide a gradual transition between the properties of CMCs and metals can effectively mitigate thermal expansion mismatches. Similarly, diffusion barrier coatings composed of refractory metals or stable compounds can prevent detrimental chemical interactions while maintaining mechanical integrity at the interface.

Chemical interactions at the CMC-metal interface represent another critical concern. At elevated temperatures, diffusion processes accelerate, potentially forming brittle intermetallic compounds or causing degradation of the ceramic matrix. Silicon-based CMCs are particularly susceptible to reactions with transition metals, forming silicides that can compromise the joint integrity. Additionally, in oxidizing environments, preferential oxidation at the interface can create oxide scales with poor adhesion properties, further weakening the joint.

Galvanic corrosion presents a significant long-term degradation mechanism when joining dissimilar materials. The electrochemical potential difference between CMCs and metals, particularly in the presence of an electrolyte, can accelerate corrosion at the interface. This phenomenon is exacerbated in applications exposed to moisture, salt environments, or acidic conditions, necessitating careful material selection or the implementation of isolation strategies.

Environmental factors significantly impact the degradation kinetics of CMC-metal joints. Water vapor can accelerate the degradation of certain CMCs, particularly those with glass or oxide matrices, through stress corrosion cracking mechanisms. Similarly, salt environments can penetrate the interface region, creating localized corrosion cells and accelerating material degradation. High-temperature applications introduce additional concerns related to creep behavior differences between the joined materials.

The mechanical load distribution across the CMC-metal interface requires careful consideration to prevent stress concentrations that could initiate cracks. The inherent brittleness of CMCs compared to the ductility of metals means that under loading conditions, plastic deformation in the metal cannot be accommodated by the ceramic component, creating high localized stresses. These stress concentrations are particularly problematic under cyclic loading conditions, where they can lead to progressive damage accumulation and eventual failure.

Interfacial coating systems offer promising solutions to these compatibility challenges. Functionally graded materials (FGMs) that provide a gradual transition between the properties of CMCs and metals can effectively mitigate thermal expansion mismatches. Similarly, diffusion barrier coatings composed of refractory metals or stable compounds can prevent detrimental chemical interactions while maintaining mechanical integrity at the interface.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!