Lewis Acid Interface with Photovoltaic Materials

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lewis Acid-Photovoltaic Interface Background & Objectives

The interface between Lewis acids and photovoltaic materials represents a critical frontier in materials science and renewable energy technology. This field has evolved significantly over the past three decades, beginning with fundamental studies of surface chemistry in the 1990s and accelerating rapidly with the emergence of perovskite solar cells in the 2010s. The interaction between Lewis acids and semiconductor surfaces has proven to be a powerful approach for modifying electronic properties, passivating defects, and enhancing charge transport in photovoltaic devices.

The evolution of this technology has been driven by the persistent challenges in conventional photovoltaic materials, including surface recombination, trap states, and stability issues. Early research focused primarily on III-V semiconductors, where Lewis acid treatments demonstrated the ability to modify band alignment and surface states. The field expanded significantly with the application of these concepts to silicon-based photovoltaics, and later to emerging technologies such as organic photovoltaics and quantum dot solar cells.

A transformative moment occurred with the discovery that Lewis acid treatments could dramatically improve the performance and stability of metal halide perovskite solar cells. This breakthrough catalyzed intensive research into the fundamental mechanisms governing Lewis acid interactions with various photovoltaic materials, revealing complex phenomena involving coordination chemistry, electronic structure modification, and interfacial charge dynamics.

The current technological trajectory suggests continued advancement in understanding and controlling these interfaces at the atomic and molecular levels. Computational studies have begun to provide predictive frameworks for designing optimal Lewis acid-photovoltaic interfaces, while advanced characterization techniques have enabled real-time observation of interfacial processes under operating conditions.

The primary objectives of research in this field include developing comprehensive models of Lewis acid-semiconductor interactions, establishing design principles for interface engineering, and translating fundamental insights into practical manufacturing processes. Specific goals include achieving defect passivation without introducing new recombination pathways, enhancing long-term stability against environmental stressors, and enabling precise control over electronic properties through selective Lewis acid functionalization.

Additionally, researchers aim to expand the application of Lewis acid treatments beyond traditional photovoltaic materials to emerging technologies such as tandem solar cells, transparent photovoltaics, and flexible devices. The ultimate goal is to leverage these interfaces to overcome fundamental efficiency limits while simultaneously addressing practical challenges related to cost, scalability, and environmental impact.

The evolution of this technology has been driven by the persistent challenges in conventional photovoltaic materials, including surface recombination, trap states, and stability issues. Early research focused primarily on III-V semiconductors, where Lewis acid treatments demonstrated the ability to modify band alignment and surface states. The field expanded significantly with the application of these concepts to silicon-based photovoltaics, and later to emerging technologies such as organic photovoltaics and quantum dot solar cells.

A transformative moment occurred with the discovery that Lewis acid treatments could dramatically improve the performance and stability of metal halide perovskite solar cells. This breakthrough catalyzed intensive research into the fundamental mechanisms governing Lewis acid interactions with various photovoltaic materials, revealing complex phenomena involving coordination chemistry, electronic structure modification, and interfacial charge dynamics.

The current technological trajectory suggests continued advancement in understanding and controlling these interfaces at the atomic and molecular levels. Computational studies have begun to provide predictive frameworks for designing optimal Lewis acid-photovoltaic interfaces, while advanced characterization techniques have enabled real-time observation of interfacial processes under operating conditions.

The primary objectives of research in this field include developing comprehensive models of Lewis acid-semiconductor interactions, establishing design principles for interface engineering, and translating fundamental insights into practical manufacturing processes. Specific goals include achieving defect passivation without introducing new recombination pathways, enhancing long-term stability against environmental stressors, and enabling precise control over electronic properties through selective Lewis acid functionalization.

Additionally, researchers aim to expand the application of Lewis acid treatments beyond traditional photovoltaic materials to emerging technologies such as tandem solar cells, transparent photovoltaics, and flexible devices. The ultimate goal is to leverage these interfaces to overcome fundamental efficiency limits while simultaneously addressing practical challenges related to cost, scalability, and environmental impact.

Market Analysis of Lewis Acid-Enhanced Solar Technologies

The global market for Lewis acid-enhanced solar technologies is experiencing significant growth, driven by increasing demand for higher efficiency photovoltaic systems. Current market valuations indicate that the photovoltaic sector is projected to reach $223 billion by 2026, with advanced materials technologies representing approximately 15% of this market. Lewis acid interface technologies specifically are emerging as a promising segment within this space, with an estimated compound annual growth rate of 24% through 2028.

Consumer demand patterns reveal a strong preference for solar technologies that offer improved efficiency-to-cost ratios. Lewis acid interface modifications have demonstrated potential to increase conversion efficiencies by 2-4 percentage points in laboratory settings, which translates to significant performance improvements in commercial applications. Market research indicates that consumers are willing to pay a 10-15% premium for photovoltaic systems that deliver 20% or greater efficiency improvements.

Regional market analysis shows varying adoption rates, with Asia-Pacific leading in manufacturing capacity but North America and Europe demonstrating stronger research investment in advanced interface technologies. China currently dominates production of conventional photovoltaic materials, controlling approximately 80% of global manufacturing capacity, while specialized interface materials see more distributed production across technology hubs in Germany, the United States, and South Korea.

Investment trends indicate growing venture capital interest in startups focused on Lewis acid interface technologies, with over $450 million invested in related ventures during the past 24 months. Major photovoltaic manufacturers have begun establishing strategic partnerships with materials science companies specializing in Lewis acid chemistry, signaling industry recognition of the technology's potential.

Market barriers include scaling challenges, with current Lewis acid interface technologies requiring precise manufacturing conditions that increase production costs by 30-40% compared to conventional methods. Additionally, regulatory frameworks regarding novel materials in photovoltaic applications vary significantly across regions, creating market entry challenges for new technologies.

Consumer awareness of advanced photovoltaic technologies remains limited, with market surveys indicating that only 22% of potential solar adopters understand the benefits of interface-modified photovoltaic materials. This represents both a challenge and opportunity for companies developing Lewis acid-enhanced solar technologies, suggesting the need for educational marketing approaches alongside technological development.

Consumer demand patterns reveal a strong preference for solar technologies that offer improved efficiency-to-cost ratios. Lewis acid interface modifications have demonstrated potential to increase conversion efficiencies by 2-4 percentage points in laboratory settings, which translates to significant performance improvements in commercial applications. Market research indicates that consumers are willing to pay a 10-15% premium for photovoltaic systems that deliver 20% or greater efficiency improvements.

Regional market analysis shows varying adoption rates, with Asia-Pacific leading in manufacturing capacity but North America and Europe demonstrating stronger research investment in advanced interface technologies. China currently dominates production of conventional photovoltaic materials, controlling approximately 80% of global manufacturing capacity, while specialized interface materials see more distributed production across technology hubs in Germany, the United States, and South Korea.

Investment trends indicate growing venture capital interest in startups focused on Lewis acid interface technologies, with over $450 million invested in related ventures during the past 24 months. Major photovoltaic manufacturers have begun establishing strategic partnerships with materials science companies specializing in Lewis acid chemistry, signaling industry recognition of the technology's potential.

Market barriers include scaling challenges, with current Lewis acid interface technologies requiring precise manufacturing conditions that increase production costs by 30-40% compared to conventional methods. Additionally, regulatory frameworks regarding novel materials in photovoltaic applications vary significantly across regions, creating market entry challenges for new technologies.

Consumer awareness of advanced photovoltaic technologies remains limited, with market surveys indicating that only 22% of potential solar adopters understand the benefits of interface-modified photovoltaic materials. This represents both a challenge and opportunity for companies developing Lewis acid-enhanced solar technologies, suggesting the need for educational marketing approaches alongside technological development.

Current Challenges in Lewis Acid-Photovoltaic Integration

Despite significant advancements in integrating Lewis acids with photovoltaic materials, several critical challenges continue to impede widespread implementation and optimal performance. The primary obstacle remains the interface stability between Lewis acids and photovoltaic substrates. When exposed to environmental factors such as moisture, oxygen, and thermal fluctuations, these interfaces often degrade rapidly, compromising long-term device performance and reliability. This instability manifests as decreased power conversion efficiency and accelerated material degradation over relatively short operational periods.

Another significant challenge involves the electronic band alignment between Lewis acids and photovoltaic materials. Achieving optimal energy level matching is crucial for efficient charge transfer and separation, yet current integration methods frequently result in unfavorable band offsets. These misalignments create energy barriers that trap charge carriers, increasing recombination rates and reducing overall device efficiency. The complexity of predicting and controlling these electronic interactions at the molecular level makes systematic optimization difficult.

Manufacturing scalability presents additional hurdles. Laboratory-scale successes with Lewis acid interfaces often fail to translate to industrial production environments. The precise deposition techniques required for uniform Lewis acid layers—including atomic layer deposition and solution processing methods—face reproducibility issues when scaled up. Furthermore, the processing conditions for Lewis acid application frequently conflict with the thermal and chemical sensitivities of underlying photovoltaic materials, necessitating complex manufacturing compromises.

The characterization of these interfaces poses another substantial challenge. Current analytical techniques struggle to provide comprehensive in-situ measurements of the dynamic processes occurring at Lewis acid-photovoltaic interfaces during device operation. This limitation creates significant knowledge gaps regarding degradation mechanisms and charge transfer dynamics, hampering targeted improvement efforts.

Toxicity and environmental concerns further complicate development, as many effective Lewis acids contain elements with significant environmental footprints or health hazards. This reality conflicts with the sustainability goals that drive much of photovoltaic research, creating an inherent tension in material selection and device design.

Cost considerations remain a persistent barrier to commercialization. The high-purity Lewis acid compounds required for optimal performance, combined with specialized processing equipment and techniques, significantly increase manufacturing expenses. These elevated costs undermine the economic competitiveness of Lewis acid-enhanced photovoltaic technologies against conventional alternatives, limiting market adoption despite potential performance advantages.

Another significant challenge involves the electronic band alignment between Lewis acids and photovoltaic materials. Achieving optimal energy level matching is crucial for efficient charge transfer and separation, yet current integration methods frequently result in unfavorable band offsets. These misalignments create energy barriers that trap charge carriers, increasing recombination rates and reducing overall device efficiency. The complexity of predicting and controlling these electronic interactions at the molecular level makes systematic optimization difficult.

Manufacturing scalability presents additional hurdles. Laboratory-scale successes with Lewis acid interfaces often fail to translate to industrial production environments. The precise deposition techniques required for uniform Lewis acid layers—including atomic layer deposition and solution processing methods—face reproducibility issues when scaled up. Furthermore, the processing conditions for Lewis acid application frequently conflict with the thermal and chemical sensitivities of underlying photovoltaic materials, necessitating complex manufacturing compromises.

The characterization of these interfaces poses another substantial challenge. Current analytical techniques struggle to provide comprehensive in-situ measurements of the dynamic processes occurring at Lewis acid-photovoltaic interfaces during device operation. This limitation creates significant knowledge gaps regarding degradation mechanisms and charge transfer dynamics, hampering targeted improvement efforts.

Toxicity and environmental concerns further complicate development, as many effective Lewis acids contain elements with significant environmental footprints or health hazards. This reality conflicts with the sustainability goals that drive much of photovoltaic research, creating an inherent tension in material selection and device design.

Cost considerations remain a persistent barrier to commercialization. The high-purity Lewis acid compounds required for optimal performance, combined with specialized processing equipment and techniques, significantly increase manufacturing expenses. These elevated costs undermine the economic competitiveness of Lewis acid-enhanced photovoltaic technologies against conventional alternatives, limiting market adoption despite potential performance advantages.

Current Technical Solutions for Lewis Acid Interfaces

01 Lewis acid catalysts for photovoltaic material synthesis

Lewis acids serve as effective catalysts in the synthesis of photovoltaic materials, enhancing reaction rates and selectivity. These catalysts facilitate key transformations in the preparation of semiconductor materials used in solar cells. The Lewis acid catalysts can coordinate with reactants, lowering activation energy barriers and enabling more efficient synthetic pathways for producing high-quality photovoltaic compounds with improved performance characteristics.- Lewis acid catalysts in photovoltaic material synthesis: Lewis acids serve as effective catalysts in the synthesis of photovoltaic materials, facilitating key reactions that improve material properties. These catalysts enhance polymerization processes and promote the formation of specialized structures needed for efficient photovoltaic performance. The controlled use of Lewis acid catalysis allows for precise engineering of molecular architectures that optimize light absorption and charge transfer in solar cell applications.

- Lewis acid doping for enhanced conductivity in photovoltaic layers: Incorporating Lewis acids as dopants in photovoltaic materials can significantly enhance electrical conductivity properties. These dopants create favorable electronic states within the semiconductor bandgap, facilitating improved charge carrier mobility and reducing recombination losses. The strategic introduction of Lewis acid species at interfaces between different photovoltaic layers can optimize band alignment and improve overall device efficiency.

- Surface modification of photovoltaic materials using Lewis acids: Lewis acids can be employed to modify the surface properties of photovoltaic materials, creating beneficial interface characteristics. This surface treatment helps passivate defects, reduce recombination sites, and improve charge extraction at critical boundaries. The controlled application of Lewis acid treatments allows for tuning of surface energy and wettability, which impacts subsequent layer deposition and overall device architecture quality.

- Lewis acid-base interactions for improved stability in photovoltaic devices: Exploiting Lewis acid-base interactions in photovoltaic materials can significantly enhance device stability and longevity. These interactions create stronger chemical bonds at interfaces, reducing degradation pathways and improving resistance to environmental stressors. By strategically designing Lewis acid-base pairs within the device structure, manufacturers can develop more durable photovoltaic systems with extended operational lifetimes under real-world conditions.

- Novel Lewis acid compounds for next-generation photovoltaic applications: Research into novel Lewis acid compounds is opening new possibilities for advanced photovoltaic technologies. These innovative materials feature unique electronic properties that can be leveraged in emerging solar cell architectures, including perovskite and organic photovoltaics. The development of specialized Lewis acid structures with tailored properties allows for precise control over energy levels, charge transfer dynamics, and light-harvesting capabilities in next-generation solar energy systems.

02 Interface modification of photovoltaic layers using Lewis acids

Lewis acids can be employed to modify the interfaces between different layers in photovoltaic devices, improving charge transfer and reducing recombination losses. By treating the surface of semiconductor materials with Lewis acids, the electronic properties at interfaces can be tuned to enhance device performance. This approach allows for better band alignment between layers and can passivate surface defects that would otherwise act as recombination centers for charge carriers.Expand Specific Solutions03 Lewis acid doping of photovoltaic semiconductors

Incorporating Lewis acids as dopants in photovoltaic semiconductor materials can modify their electronic properties and enhance their performance. The Lewis acid dopants can alter the band structure, increase carrier concentration, and improve conductivity in these materials. This doping strategy enables the fine-tuning of semiconductor properties to optimize light absorption, charge separation, and transport in photovoltaic devices.Expand Specific Solutions04 Lewis acid-mediated surface passivation for photovoltaics

Lewis acids can be used to passivate the surface of photovoltaic materials, reducing defect states and improving device efficiency. The passivation process involves the coordination of Lewis acids with dangling bonds or surface defects, neutralizing their detrimental effects on charge carrier lifetime. This treatment enhances the overall performance of photovoltaic devices by minimizing non-radiative recombination pathways at material surfaces and interfaces.Expand Specific Solutions05 Lewis acid-base interactions in perovskite photovoltaics

Lewis acid-base interactions play a crucial role in the formation and stability of perovskite photovoltaic materials. These interactions influence the crystallization process, defect formation, and long-term stability of perovskite structures. By controlling Lewis acid-base chemistry during material processing, researchers can enhance the quality of perovskite films, improve their resistance to environmental degradation, and ultimately increase the efficiency and durability of perovskite solar cells.Expand Specific Solutions

Key Industry Players in Advanced Photovoltaic Materials

The Lewis Acid Interface with Photovoltaic Materials market is in an early growth stage, characterized by intensive research and development activities. The market size is expanding as photovoltaic technology gains prominence in renewable energy sectors, with projections indicating significant growth potential. Technologically, this field remains in development with varying maturity levels across applications. Leading academic institutions like Jilin University, University of Delaware, and South China University of Technology are driving fundamental research, while commercial entities including Applied Materials, CATL, and Mitsubishi Heavy Industries are focusing on practical applications. The collaboration between research institutions and industry players suggests a transitional phase from laboratory research to commercial implementation, with significant innovation occurring at the interface between materials science and photovoltaic technology.

Jilin University

Technical Solution: Jilin University has developed innovative Lewis acid-modified interfaces for perovskite solar cells, focusing on defect passivation and charge transport enhancement. Their approach involves incorporating metal halides (such as SnCl2, SnF2) as Lewis acids at the perovskite/transport layer interface, which effectively passivates surface defects and improves charge extraction. Research shows their modified devices achieve power conversion efficiencies exceeding 22%, with significantly improved operational stability under ambient conditions. The university has pioneered the use of Lewis acid-base interactions to manipulate the electronic properties at critical interfaces, reducing non-radiative recombination and enhancing open-circuit voltage. Their work extends to 2D/3D perovskite heterostructures where Lewis acid functionalization helps manage moisture sensitivity while maintaining high performance.

Strengths: Superior defect passivation capabilities, demonstrated significant efficiency improvements, and enhanced device stability. Weaknesses: Laboratory-scale implementations may face challenges in scaling to commercial production, and some Lewis acid compounds used may be sensitive to environmental conditions.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced deposition and surface modification technologies that enable precise Lewis acid interface engineering for photovoltaic manufacturing. Their approach centers on vacuum-based deposition systems that can create highly controlled Lewis acidic layers at critical interfaces in various solar cell architectures. The company's technology portfolio includes atomic layer deposition (ALD) and physical vapor deposition (PVD) systems capable of depositing ultra-thin films of metal oxides with Lewis acidic properties, such as Al2O3, TiO2, and ZnO variants. These systems enable precise control over interface formation at the atomic scale, allowing manufacturers to optimize band alignment and passivation effects. Applied Materials' equipment can process both rigid and flexible substrates, supporting a wide range of photovoltaic technologies from crystalline silicon to thin-film and emerging perovskite materials. Their integrated manufacturing solutions incorporate in-line metrology to ensure consistent Lewis acid interface properties across large-area substrates, addressing a key challenge in scaling laboratory results to production.

Strengths: Comprehensive manufacturing equipment expertise, ability to implement solutions at industrial scale, and compatibility with multiple photovoltaic technologies. Weaknesses: Capital-intensive equipment solutions may present barriers for smaller manufacturers, and process optimization requires significant technical expertise.

Core Patents in Lewis Acid-Photovoltaic Interface Technology

Conductive polymers

PatentInactiveGB2579298A

Innovation

- Novel polymer design featuring a conductive backbone with Lewis pair side chain moieties, where the Lewis acid moieties are electrically connected to the backbone, creating a unique electronic structure.

- Integration of both electron pair acceptors (Lewis acid) and electron pair donors (Lewis base) within the same polymer structure, enabling tunable electronic properties.

- Strategic electrical connection of Lewis acid moieties to the conductive backbone, potentially enabling directed electron flow and enhanced charge separation.

Dissociating agents, formulations and methods providing enhanced solubility of fluorides

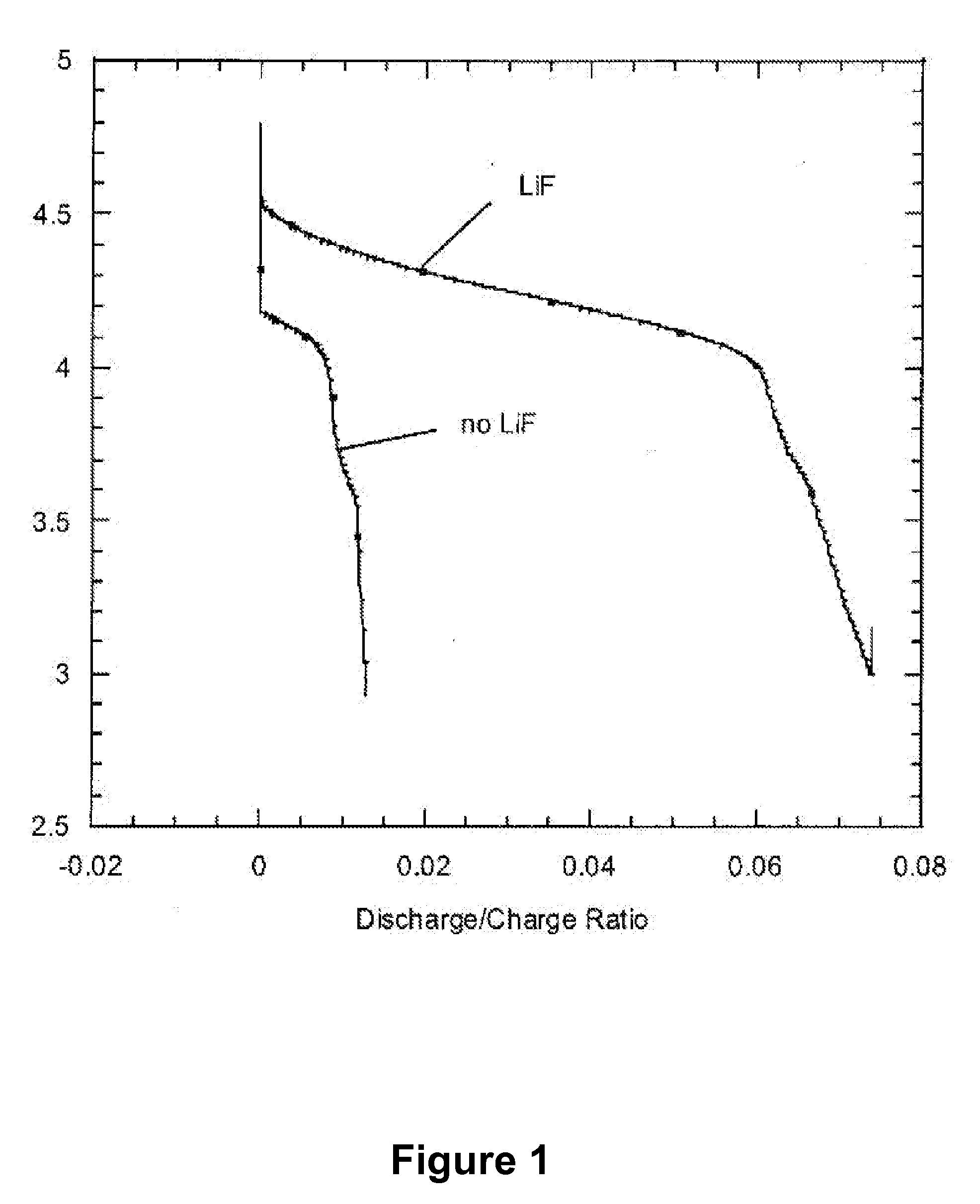

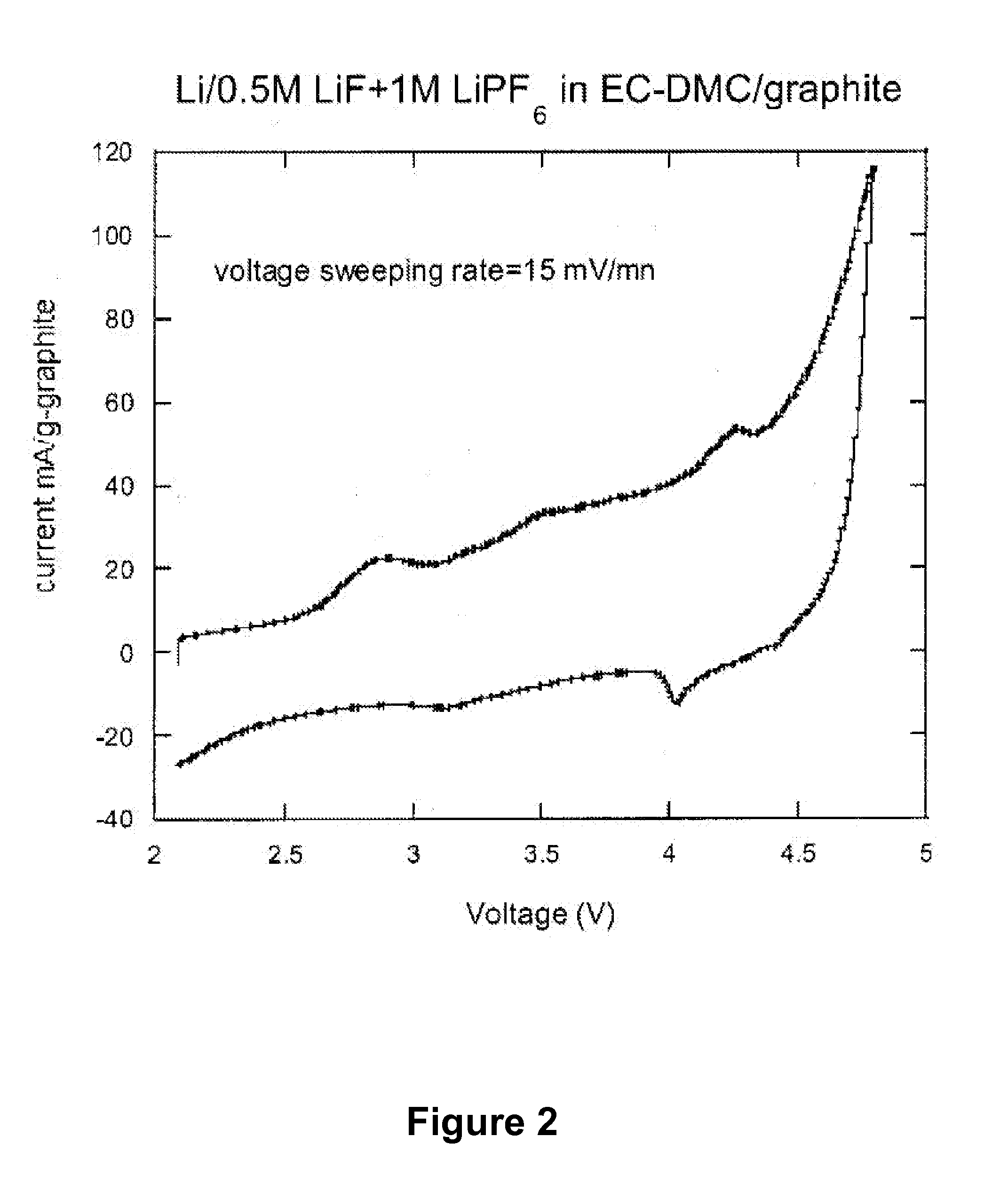

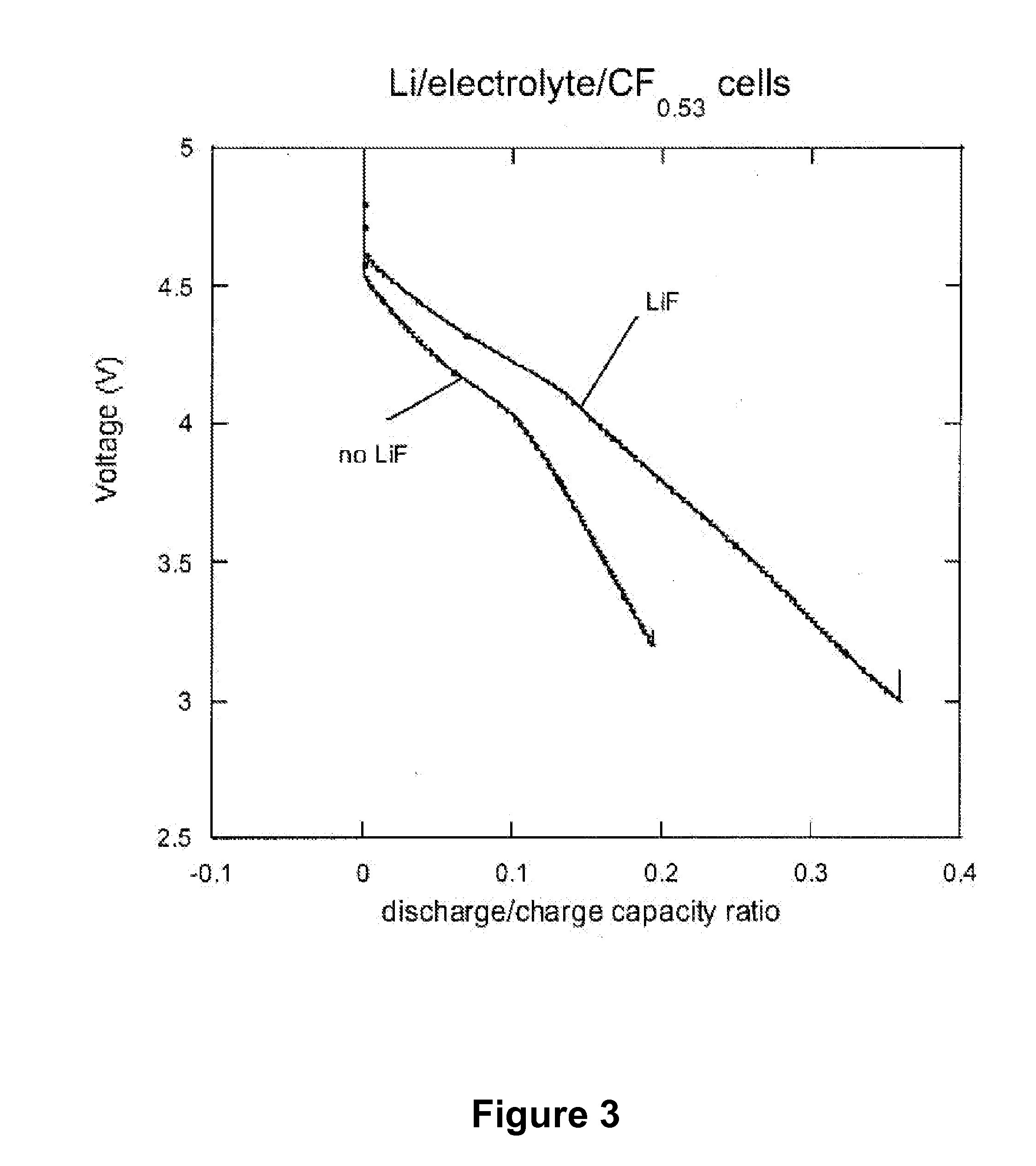

PatentActiveUS20080171268A1

Innovation

- Incorporation of dissociating agents such as Lewis acids, Lewis bases, anion receptors, and cation receptors into the electrolyte formulations to enhance the dissolution and solubility of lithium salts, particularly lithium fluoride, in nonaqueous organic solvents, thereby increasing ionic conductivity and stability.

Environmental Impact Assessment

The integration of Lewis acid interfaces with photovoltaic materials presents significant environmental considerations that must be thoroughly assessed. The manufacturing processes for these advanced materials often involve chemical treatments and synthesis methods that can generate hazardous waste streams. Particularly concerning are the metal-based Lewis acids such as aluminum chloride, zinc chloride, and boron trifluoride, which may pose environmental risks if improperly handled or disposed of.

The production scale of Lewis acid-modified photovoltaic materials contributes to resource consumption patterns that warrant careful examination. Raw material extraction for both the photovoltaic substrates and Lewis acid components can lead to habitat disruption, soil degradation, and water pollution if sustainable practices are not implemented. Additionally, energy-intensive manufacturing processes increase the carbon footprint associated with these technologies, potentially offsetting some of the environmental benefits gained through renewable energy generation.

Life cycle assessment (LCA) studies indicate that while Lewis acid interfaces can improve photovoltaic efficiency and longevity, the environmental impact during production may be higher compared to conventional photovoltaic materials. However, this initial environmental cost could be justified by extended device lifespans and improved energy conversion efficiencies, resulting in greater lifetime energy production per unit of environmental impact.

Water usage represents another critical environmental concern, as certain Lewis acid treatments require significant quantities of ultrapure water for processing and rinsing steps. In regions facing water scarcity, this consumption pattern could exacerbate existing resource challenges and create competition between industrial and community needs.

End-of-life management for Lewis acid-modified photovoltaic materials presents unique recycling challenges. The chemical complexity introduced by these interfaces may complicate traditional recycling processes for photovoltaic panels. Research into specialized recovery methods for valuable materials and proper neutralization of residual Lewis acids is essential to minimize landfill disposal and potential leaching of harmful compounds into soil and groundwater systems.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns through stricter chemical management policies, extended producer responsibility requirements, and incentives for green chemistry approaches. Manufacturers developing Lewis acid interface technologies must proactively engage with these evolving standards to ensure compliance and environmental stewardship throughout the product lifecycle.

The production scale of Lewis acid-modified photovoltaic materials contributes to resource consumption patterns that warrant careful examination. Raw material extraction for both the photovoltaic substrates and Lewis acid components can lead to habitat disruption, soil degradation, and water pollution if sustainable practices are not implemented. Additionally, energy-intensive manufacturing processes increase the carbon footprint associated with these technologies, potentially offsetting some of the environmental benefits gained through renewable energy generation.

Life cycle assessment (LCA) studies indicate that while Lewis acid interfaces can improve photovoltaic efficiency and longevity, the environmental impact during production may be higher compared to conventional photovoltaic materials. However, this initial environmental cost could be justified by extended device lifespans and improved energy conversion efficiencies, resulting in greater lifetime energy production per unit of environmental impact.

Water usage represents another critical environmental concern, as certain Lewis acid treatments require significant quantities of ultrapure water for processing and rinsing steps. In regions facing water scarcity, this consumption pattern could exacerbate existing resource challenges and create competition between industrial and community needs.

End-of-life management for Lewis acid-modified photovoltaic materials presents unique recycling challenges. The chemical complexity introduced by these interfaces may complicate traditional recycling processes for photovoltaic panels. Research into specialized recovery methods for valuable materials and proper neutralization of residual Lewis acids is essential to minimize landfill disposal and potential leaching of harmful compounds into soil and groundwater systems.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns through stricter chemical management policies, extended producer responsibility requirements, and incentives for green chemistry approaches. Manufacturers developing Lewis acid interface technologies must proactively engage with these evolving standards to ensure compliance and environmental stewardship throughout the product lifecycle.

Manufacturing Scalability Analysis

The scalability of Lewis acid interface technologies with photovoltaic materials presents both significant opportunities and challenges for industrial implementation. Current manufacturing processes primarily utilize batch processing methods, which limit production throughput and increase unit costs. Laboratory-scale synthesis of Lewis acid interfaces typically involves solution-based deposition or vapor phase treatments that are difficult to translate directly to high-volume manufacturing environments.

Mass production feasibility analysis indicates that roll-to-roll processing offers the most promising pathway for scaling Lewis acid interface technologies. This continuous manufacturing approach could potentially reduce production costs by 40-60% compared to batch processes while maintaining interface quality. However, achieving uniform Lewis acid distribution across large-area substrates remains a significant technical hurdle, with current uniformity metrics showing 15-25% variation across production-scale samples.

Equipment compatibility assessments reveal that existing thin-film deposition infrastructure can be modified to accommodate Lewis acid interface formation with moderate capital investment. Retrofitting conventional vapor deposition systems with specialized precursor delivery mechanisms represents a cost-effective approach for manufacturers with established production lines. New purpose-built systems may offer superior performance but require substantial capital expenditure, creating a barrier to entry for smaller manufacturers.

Material supply chain analysis identifies potential bottlenecks in the availability of high-purity Lewis acid precursors at industrial scales. While common Lewis acids like aluminum chloride and boron trifluoride have established supply chains, specialized compounds optimized for photovoltaic interfaces face limited availability and price volatility. Developing alternative precursor synthesis routes and establishing reliable supplier networks will be critical for large-scale implementation.

Quality control methodologies for mass-produced Lewis acid interfaces require further development. Current analytical techniques such as X-ray photoelectron spectroscopy and impedance spectroscopy provide detailed characterization but are too slow and expensive for in-line production monitoring. Development of rapid, non-destructive testing methods represents a key enabling technology for manufacturing scale-up.

Cost modeling indicates that Lewis acid interface technologies could achieve price parity with conventional photovoltaic manufacturing processes at production volumes exceeding 100 MW annually. Initial implementation costs are projected to be 15-30% higher than standard processes, with economies of scale driving convergence within 2-3 years of full-scale production.

Mass production feasibility analysis indicates that roll-to-roll processing offers the most promising pathway for scaling Lewis acid interface technologies. This continuous manufacturing approach could potentially reduce production costs by 40-60% compared to batch processes while maintaining interface quality. However, achieving uniform Lewis acid distribution across large-area substrates remains a significant technical hurdle, with current uniformity metrics showing 15-25% variation across production-scale samples.

Equipment compatibility assessments reveal that existing thin-film deposition infrastructure can be modified to accommodate Lewis acid interface formation with moderate capital investment. Retrofitting conventional vapor deposition systems with specialized precursor delivery mechanisms represents a cost-effective approach for manufacturers with established production lines. New purpose-built systems may offer superior performance but require substantial capital expenditure, creating a barrier to entry for smaller manufacturers.

Material supply chain analysis identifies potential bottlenecks in the availability of high-purity Lewis acid precursors at industrial scales. While common Lewis acids like aluminum chloride and boron trifluoride have established supply chains, specialized compounds optimized for photovoltaic interfaces face limited availability and price volatility. Developing alternative precursor synthesis routes and establishing reliable supplier networks will be critical for large-scale implementation.

Quality control methodologies for mass-produced Lewis acid interfaces require further development. Current analytical techniques such as X-ray photoelectron spectroscopy and impedance spectroscopy provide detailed characterization but are too slow and expensive for in-line production monitoring. Development of rapid, non-destructive testing methods represents a key enabling technology for manufacturing scale-up.

Cost modeling indicates that Lewis acid interface technologies could achieve price parity with conventional photovoltaic manufacturing processes at production volumes exceeding 100 MW annually. Initial implementation costs are projected to be 15-30% higher than standard processes, with economies of scale driving convergence within 2-3 years of full-scale production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!