Life Cycle Assessment Of Nanocellulose Composites Versus Traditional Composites

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Composites Development Background and Objectives

Nanocellulose composites represent a revolutionary advancement in materials science, emerging from the convergence of nanotechnology and sustainable biomaterials research. The development of these innovative materials can be traced back to the early 2000s, when researchers began exploring cellulose at the nanoscale, discovering its exceptional mechanical properties and potential applications. This technological evolution was driven by growing environmental concerns and the need for sustainable alternatives to petroleum-based composites.

The trajectory of nanocellulose composite development has been characterized by significant breakthroughs in extraction methods, surface modification techniques, and composite manufacturing processes. Initially, research focused primarily on understanding the fundamental properties of nanocellulose, including its crystallinity, aspect ratio, and surface chemistry. As knowledge expanded, attention shifted toward practical applications and scalable production methods.

Recent technological trends indicate a rapid acceleration in nanocellulose composite innovation, with particular emphasis on improving compatibility between hydrophilic nanocellulose and hydrophobic polymer matrices. This has led to the development of various surface modification strategies and processing techniques that enhance interfacial adhesion and dispersion quality, resulting in superior mechanical and barrier properties.

The global push toward circular economy principles and carbon neutrality has further catalyzed interest in nanocellulose composites. These materials offer potential solutions to multiple sustainability challenges by utilizing renewable resources, reducing carbon footprints, and providing end-of-life biodegradability options that traditional composites cannot match.

The primary technical objectives in nanocellulose composite development include achieving cost-effective production at industrial scale, optimizing mechanical performance to match or exceed traditional composites, enhancing durability under various environmental conditions, and ensuring consistent quality across production batches. Additionally, researchers aim to develop standardized life cycle assessment methodologies specifically tailored to nanocellulose composites to accurately quantify their environmental benefits compared to conventional materials.

Another critical objective is to bridge the gap between laboratory success and commercial viability by addressing challenges in scalability, processing compatibility with existing manufacturing infrastructure, and long-term performance stability. This includes developing nanocellulose composites that can be processed using conventional equipment without significant modifications, thereby lowering barriers to industrial adoption.

The ultimate goal of nanocellulose composite development is to create a new generation of materials that combine exceptional performance with minimal environmental impact, providing sustainable alternatives across multiple industries including packaging, automotive, construction, and consumer goods.

The trajectory of nanocellulose composite development has been characterized by significant breakthroughs in extraction methods, surface modification techniques, and composite manufacturing processes. Initially, research focused primarily on understanding the fundamental properties of nanocellulose, including its crystallinity, aspect ratio, and surface chemistry. As knowledge expanded, attention shifted toward practical applications and scalable production methods.

Recent technological trends indicate a rapid acceleration in nanocellulose composite innovation, with particular emphasis on improving compatibility between hydrophilic nanocellulose and hydrophobic polymer matrices. This has led to the development of various surface modification strategies and processing techniques that enhance interfacial adhesion and dispersion quality, resulting in superior mechanical and barrier properties.

The global push toward circular economy principles and carbon neutrality has further catalyzed interest in nanocellulose composites. These materials offer potential solutions to multiple sustainability challenges by utilizing renewable resources, reducing carbon footprints, and providing end-of-life biodegradability options that traditional composites cannot match.

The primary technical objectives in nanocellulose composite development include achieving cost-effective production at industrial scale, optimizing mechanical performance to match or exceed traditional composites, enhancing durability under various environmental conditions, and ensuring consistent quality across production batches. Additionally, researchers aim to develop standardized life cycle assessment methodologies specifically tailored to nanocellulose composites to accurately quantify their environmental benefits compared to conventional materials.

Another critical objective is to bridge the gap between laboratory success and commercial viability by addressing challenges in scalability, processing compatibility with existing manufacturing infrastructure, and long-term performance stability. This includes developing nanocellulose composites that can be processed using conventional equipment without significant modifications, thereby lowering barriers to industrial adoption.

The ultimate goal of nanocellulose composite development is to create a new generation of materials that combine exceptional performance with minimal environmental impact, providing sustainable alternatives across multiple industries including packaging, automotive, construction, and consumer goods.

Market Demand Analysis for Sustainable Composite Materials

The global market for sustainable composite materials is experiencing unprecedented growth, driven by increasing environmental awareness and stringent regulations across industries. Current market analysis indicates that the demand for eco-friendly alternatives to traditional petroleum-based composites has surged by approximately 15-20% annually over the past five years. This growth trajectory is particularly evident in sectors such as automotive, construction, packaging, and consumer goods, where sustainability has become a core business imperative rather than a mere marketing advantage.

Nanocellulose composites represent a significant segment within this expanding market. Their appeal stems from the combination of renewable sourcing, biodegradability, and competitive mechanical properties compared to conventional composites. Market research suggests that industries are increasingly willing to invest in these materials despite potentially higher initial costs, recognizing the long-term economic benefits and regulatory compliance advantages they offer.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys indicating that over 70% of consumers across major markets express willingness to pay premium prices for sustainable alternatives. This consumer-driven demand has created substantial market pull for nanocellulose-based solutions, particularly in visible consumer applications where sustainability credentials provide tangible marketing advantages.

The regulatory landscape further amplifies market demand, with policies such as the European Green Deal, circular economy initiatives, and extended producer responsibility schemes creating strong incentives for manufacturers to adopt sustainable composite solutions. Carbon taxation mechanisms and plastic reduction mandates in various jurisdictions have accelerated the transition away from traditional composites toward bio-based alternatives like nanocellulose composites.

Industry forecasts project the global sustainable composites market to reach approximately $9-12 billion by 2027, with nanocellulose composites expected to capture an increasing share of this growth. Regional analysis reveals particularly strong adoption trends in Europe and North America, with rapidly growing interest in Asia-Pacific markets as environmental regulations tighten and consumer awareness increases.

Supply chain considerations are also driving demand, as manufacturers seek to reduce dependency on petroleum-based raw materials subject to price volatility and geopolitical supply risks. The abundant and widely distributed nature of cellulose sources provides a strategic advantage for nanocellulose composites, offering potential for localized production and reduced supply chain vulnerability.

Market penetration analysis reveals varying adoption rates across industries, with packaging and consumer goods leading implementation, followed by automotive and construction sectors where performance requirements are more stringent and certification processes more complex.

Nanocellulose composites represent a significant segment within this expanding market. Their appeal stems from the combination of renewable sourcing, biodegradability, and competitive mechanical properties compared to conventional composites. Market research suggests that industries are increasingly willing to invest in these materials despite potentially higher initial costs, recognizing the long-term economic benefits and regulatory compliance advantages they offer.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys indicating that over 70% of consumers across major markets express willingness to pay premium prices for sustainable alternatives. This consumer-driven demand has created substantial market pull for nanocellulose-based solutions, particularly in visible consumer applications where sustainability credentials provide tangible marketing advantages.

The regulatory landscape further amplifies market demand, with policies such as the European Green Deal, circular economy initiatives, and extended producer responsibility schemes creating strong incentives for manufacturers to adopt sustainable composite solutions. Carbon taxation mechanisms and plastic reduction mandates in various jurisdictions have accelerated the transition away from traditional composites toward bio-based alternatives like nanocellulose composites.

Industry forecasts project the global sustainable composites market to reach approximately $9-12 billion by 2027, with nanocellulose composites expected to capture an increasing share of this growth. Regional analysis reveals particularly strong adoption trends in Europe and North America, with rapidly growing interest in Asia-Pacific markets as environmental regulations tighten and consumer awareness increases.

Supply chain considerations are also driving demand, as manufacturers seek to reduce dependency on petroleum-based raw materials subject to price volatility and geopolitical supply risks. The abundant and widely distributed nature of cellulose sources provides a strategic advantage for nanocellulose composites, offering potential for localized production and reduced supply chain vulnerability.

Market penetration analysis reveals varying adoption rates across industries, with packaging and consumer goods leading implementation, followed by automotive and construction sectors where performance requirements are more stringent and certification processes more complex.

Current Status and Challenges in Nanocellulose LCA

The field of Life Cycle Assessment (LCA) for nanocellulose composites has witnessed significant advancements globally, yet several challenges persist. Currently, research institutions across North America, Europe, and Asia are actively developing methodologies to accurately assess the environmental impacts of nanocellulose-based materials. The ISO 14040/14044 standards provide the framework for these assessments, though their application to nanomaterials presents unique complexities.

A primary challenge in nanocellulose LCA is the lack of standardized production data. Manufacturing processes vary considerably across facilities, from mechanical treatments to TEMPO-mediated oxidation and enzymatic hydrolysis, each with distinct energy requirements and chemical inputs. This variability creates inconsistencies in inventory data, making comparative analyses difficult. Recent studies by Arvidsson et al. (2021) and Li et al. (2022) highlight discrepancies of up to 40% in energy consumption figures across different production methods.

Data gaps represent another significant obstacle. While traditional composites benefit from decades of industrial-scale production data, nanocellulose materials are relatively new, with limited commercial-scale manufacturing information. Particularly lacking are end-of-life scenarios and recycling pathways specific to nanocellulose composites, forcing researchers to rely on assumptions or proxy data that may not accurately reflect actual environmental impacts.

Methodological challenges further complicate nanocellulose LCA. The multifunctional nature of these materials necessitates careful allocation procedures when comparing with traditional alternatives. Additionally, the nanoscale properties of cellulose nanofibrils and nanocrystals may introduce unique environmental interactions not captured by conventional impact assessment methods. Current impact categories inadequately address potential nano-specific effects such as aquatic ecotoxicity and human health implications.

Geographical disparities in energy grids significantly influence LCA results. Studies conducted in regions with predominantly renewable energy sources (e.g., Scandinavian countries) show markedly different carbon footprints compared to those in fossil fuel-dependent regions. This variability complicates global comparisons and technology transfer assessments.

Scale-up considerations present perhaps the most pressing challenge. Laboratory and pilot-scale production data dominate current literature, but these rarely translate directly to industrial-scale operations. Efficiency improvements, waste recovery systems, and process optimizations typical of mature manufacturing are not yet fully realized or documented for nanocellulose production, potentially overestimating environmental impacts in current assessments.

A primary challenge in nanocellulose LCA is the lack of standardized production data. Manufacturing processes vary considerably across facilities, from mechanical treatments to TEMPO-mediated oxidation and enzymatic hydrolysis, each with distinct energy requirements and chemical inputs. This variability creates inconsistencies in inventory data, making comparative analyses difficult. Recent studies by Arvidsson et al. (2021) and Li et al. (2022) highlight discrepancies of up to 40% in energy consumption figures across different production methods.

Data gaps represent another significant obstacle. While traditional composites benefit from decades of industrial-scale production data, nanocellulose materials are relatively new, with limited commercial-scale manufacturing information. Particularly lacking are end-of-life scenarios and recycling pathways specific to nanocellulose composites, forcing researchers to rely on assumptions or proxy data that may not accurately reflect actual environmental impacts.

Methodological challenges further complicate nanocellulose LCA. The multifunctional nature of these materials necessitates careful allocation procedures when comparing with traditional alternatives. Additionally, the nanoscale properties of cellulose nanofibrils and nanocrystals may introduce unique environmental interactions not captured by conventional impact assessment methods. Current impact categories inadequately address potential nano-specific effects such as aquatic ecotoxicity and human health implications.

Geographical disparities in energy grids significantly influence LCA results. Studies conducted in regions with predominantly renewable energy sources (e.g., Scandinavian countries) show markedly different carbon footprints compared to those in fossil fuel-dependent regions. This variability complicates global comparisons and technology transfer assessments.

Scale-up considerations present perhaps the most pressing challenge. Laboratory and pilot-scale production data dominate current literature, but these rarely translate directly to industrial-scale operations. Efficiency improvements, waste recovery systems, and process optimizations typical of mature manufacturing are not yet fully realized or documented for nanocellulose production, potentially overestimating environmental impacts in current assessments.

Current LCA Methodologies for Nanocellulose Composites

01 Environmental impact assessment of nanocellulose composites

Life cycle assessment methodologies are applied to evaluate the environmental impacts of nanocellulose composite materials throughout their entire lifecycle. These assessments consider factors such as raw material extraction, processing energy requirements, manufacturing emissions, use phase performance, and end-of-life disposal options. The analysis helps quantify carbon footprint, resource depletion, and other environmental indicators to determine the sustainability advantages of nanocellulose composites compared to conventional materials.- Environmental impact assessment of nanocellulose composites: Life cycle assessment methodologies are applied to evaluate the environmental impacts of nanocellulose composite materials throughout their entire lifecycle. These assessments consider factors such as raw material extraction, processing energy requirements, manufacturing emissions, use phase performance, and end-of-life disposal or recycling options. The analysis helps quantify carbon footprint, resource depletion, and other environmental indicators to determine the sustainability advantages of nanocellulose compared to conventional materials.

- Production methods and energy efficiency in nanocellulose composite manufacturing: Various production techniques for nanocellulose composites are evaluated from a life cycle perspective, focusing on energy consumption and efficiency. The assessment examines different extraction and processing methods, including mechanical, chemical, and enzymatic approaches, to determine which techniques minimize environmental impact while maintaining desired material properties. Energy-efficient manufacturing processes are identified as critical factors in reducing the overall environmental footprint of nanocellulose composite materials.

- Biodegradability and end-of-life scenarios for nanocellulose composites: The biodegradability and end-of-life management of nanocellulose composites are assessed through life cycle methodologies. These evaluations examine how nanocellulose-based materials decompose under various environmental conditions and waste management systems. The analysis includes composting, recycling potential, and waste-to-energy conversion options, providing insights into the circular economy benefits of these bio-based materials compared to petroleum-derived alternatives.

- Data management systems for nanocellulose composite life cycle assessment: Specialized data management systems and computational tools are developed to facilitate comprehensive life cycle assessments of nanocellulose composites. These systems collect, organize, and analyze complex datasets related to material flows, energy consumption, and environmental impacts throughout the product lifecycle. Advanced algorithms and modeling techniques help identify optimization opportunities and support decision-making processes for sustainable nanocellulose composite development.

- Application-specific life cycle benefits of nanocellulose composites: Life cycle assessments are conducted for specific applications of nanocellulose composites across various industries. These evaluations compare the environmental performance of nanocellulose-based solutions against conventional materials in sectors such as packaging, construction, automotive, and consumer goods. The assessments quantify benefits such as weight reduction, improved durability, enhanced recyclability, and reduced toxicity, demonstrating how application-specific advantages contribute to overall sustainability improvements.

02 Production methods and energy efficiency in nanocellulose composite manufacturing

Various production techniques for nanocellulose composites are evaluated from a life cycle perspective, focusing on energy consumption and efficiency. The assessment examines different extraction and processing methods, including mechanical, chemical, and enzymatic approaches, to determine which techniques minimize environmental impact while maintaining desired material properties. Energy optimization strategies and renewable energy integration in manufacturing processes are analyzed to improve the overall sustainability profile of nanocellulose composite production.Expand Specific Solutions03 Biodegradability and end-of-life scenarios for nanocellulose composites

Life cycle assessments of nanocellulose composites focus on their biodegradability and various end-of-life scenarios. Studies evaluate how these materials decompose in different environments and compare disposal options including composting, recycling, incineration, and landfilling. The assessments quantify environmental benefits of biodegradable nanocellulose composites in reducing waste accumulation and microplastic pollution compared to conventional petroleum-based materials, while also identifying optimal waste management strategies to maximize environmental benefits.Expand Specific Solutions04 Data management systems for nanocellulose composite life cycle assessment

Specialized data management systems and software tools are developed to facilitate comprehensive life cycle assessments of nanocellulose composites. These systems collect, organize, and analyze complex datasets related to material flows, energy consumption, emissions, and other environmental parameters throughout the product lifecycle. Advanced algorithms and computational methods enable more accurate modeling of environmental impacts, helping researchers and manufacturers optimize nanocellulose composite formulations and processing techniques for improved sustainability performance.Expand Specific Solutions05 Application-specific sustainability analysis of nanocellulose composites

Life cycle assessments are conducted for nanocellulose composites in specific application domains to evaluate their environmental performance compared to conventional materials. These analyses consider the unique requirements and lifecycle characteristics of applications in packaging, construction, automotive, electronics, and medical fields. The assessments quantify potential environmental benefits such as weight reduction, improved durability, enhanced recyclability, and reduced toxicity, while also identifying application-specific challenges and optimization opportunities to maximize sustainability advantages in each sector.Expand Specific Solutions

Key Industry Players in Nanocellulose Composite Development

The life cycle assessment (LCA) of nanocellulose composites versus traditional composites is in an emerging growth phase, with the global market for sustainable composites expanding rapidly due to environmental regulations and consumer demand. The technology is approaching commercial maturity, with key players demonstrating significant advancements. FPInnovations leads in forestry-based nanocellulose research, while VTT and Kyoto University have pioneered fundamental processing technologies. Universities like Washington State, UBC, and Zhejiang are advancing applications research, while companies including DIC Corp., Asahi Kasei, and Kao Corp. are commercializing products. The competitive landscape shows a balanced ecosystem of academic institutions developing foundational knowledge and industrial players scaling production, with increasing focus on sustainability metrics and performance optimization.

FPInnovations

Technical Solution: FPInnovations has developed a comprehensive life cycle assessment framework specifically for nanocellulose composites production. Their technical approach involves a cradle-to-gate analysis methodology that quantifies environmental impacts across the entire value chain, from raw material extraction to final product manufacturing. The company has pioneered a process that reduces energy consumption in nanocellulose production by up to 30% compared to conventional methods through their patented mechanical pre-treatment and enzymatic hydrolysis combination. Their LCA studies demonstrate that their nanocellulose composites can achieve carbon footprint reductions of 35-45% versus traditional petroleum-based composites when accounting for biogenic carbon sequestration. FPInnovations has also developed specialized software tools that enable manufacturers to model environmental impacts across different production scenarios and end-of-life options for nanocellulose-based materials.

Strengths: Industry-leading expertise in forestry-based biomaterials with established commercial-scale production capabilities; comprehensive LCA methodology specifically tailored for cellulosic nanomaterials. Weaknesses: Their assessment models may overestimate carbon sequestration benefits in certain applications; limited data on end-of-life scenarios for nanocellulose composites in different disposal environments.

University of Tokyo

Technical Solution: The University of Tokyo has developed a comprehensive life cycle assessment methodology for nanocellulose composites that emphasizes precision in impact allocation and uncertainty analysis. Their technical approach incorporates advanced statistical methods to quantify uncertainty in LCA results, providing confidence intervals for comparative assertions between nanocellulose and traditional composites. Tokyo researchers have pioneered the integration of material flow analysis with LCA, tracking nanomaterial releases throughout the product lifecycle and quantifying potential environmental risks with greater precision than conventional assessments. Their studies demonstrate that nanocellulose-reinforced bioplastics can achieve 50-70% lower global warming potential compared to glass fiber composites when accounting for end-of-life scenarios. The University has also developed specialized characterization methods for assessing biodegradation rates in various environmental compartments, showing that their nanocellulose composites can achieve complete biodegradation in industrial composting facilities within 6-12 months compared to centuries for traditional petroleum-based composites. Their assessment framework includes detailed analysis of land use impacts, demonstrating that sustainable forestry practices for nanocellulose production can actually enhance carbon sequestration compared to baseline scenarios.

Strengths: Methodological rigor with strong emphasis on uncertainty analysis and statistical validity; detailed consideration of nanomaterial-specific environmental fate and transport. Weaknesses: Assessment framework requires extensive data inputs that may not be readily available for all production scenarios; limited consideration of economic factors in sustainability assessment.

Critical Technical Innovations in Nanocellulose Processing

Nanocellulose composite, and method for manufacturing same

PatentWO2018190645A1

Innovation

- A method involving the preparation of cellulose nanofibers with a silica coating or silica particles attached to their surface, which are then mixed with a polymer to form a composite, enhancing dispersibility and heat resistance through surface vitrification and uneven silica coating.

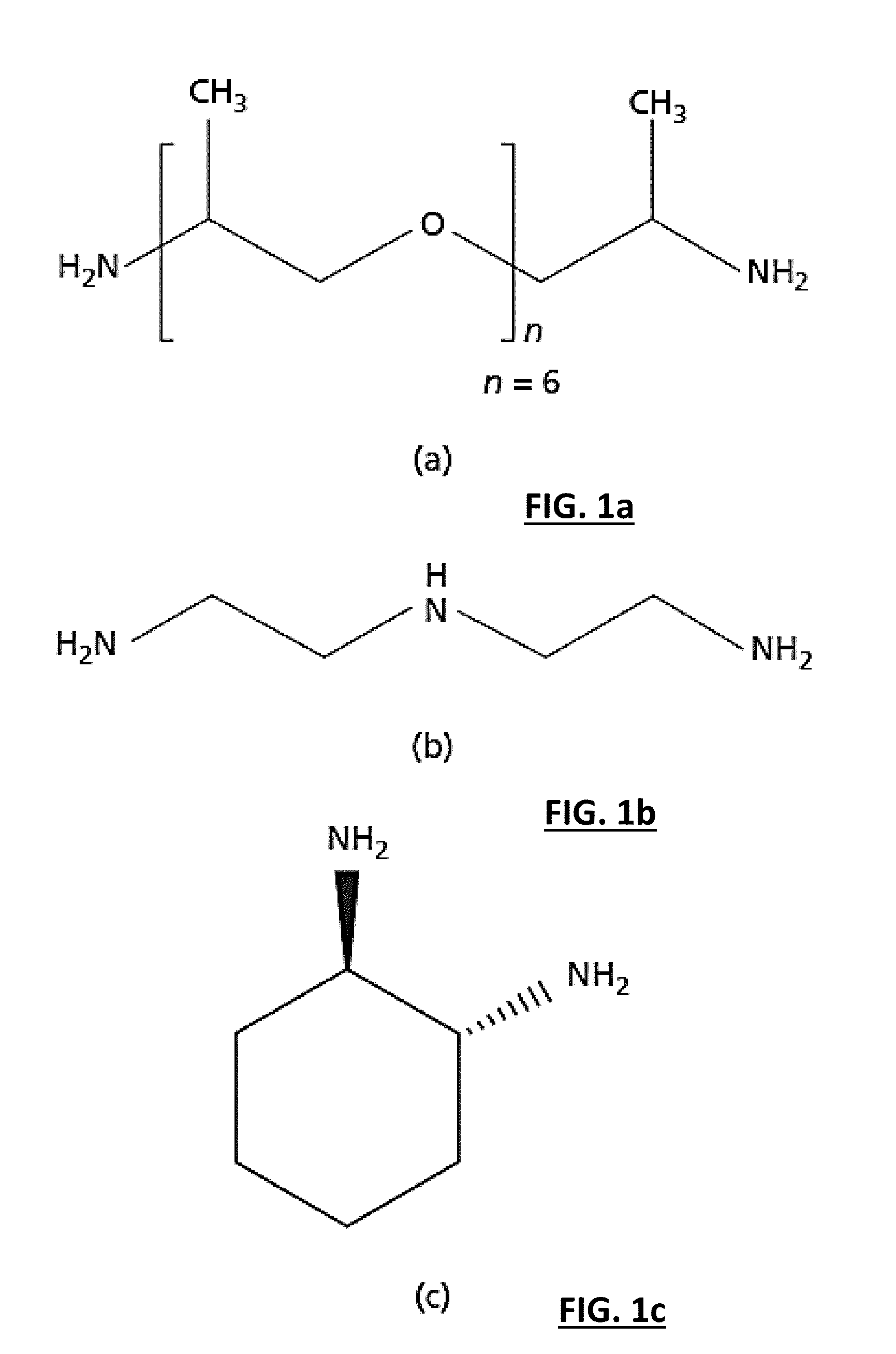

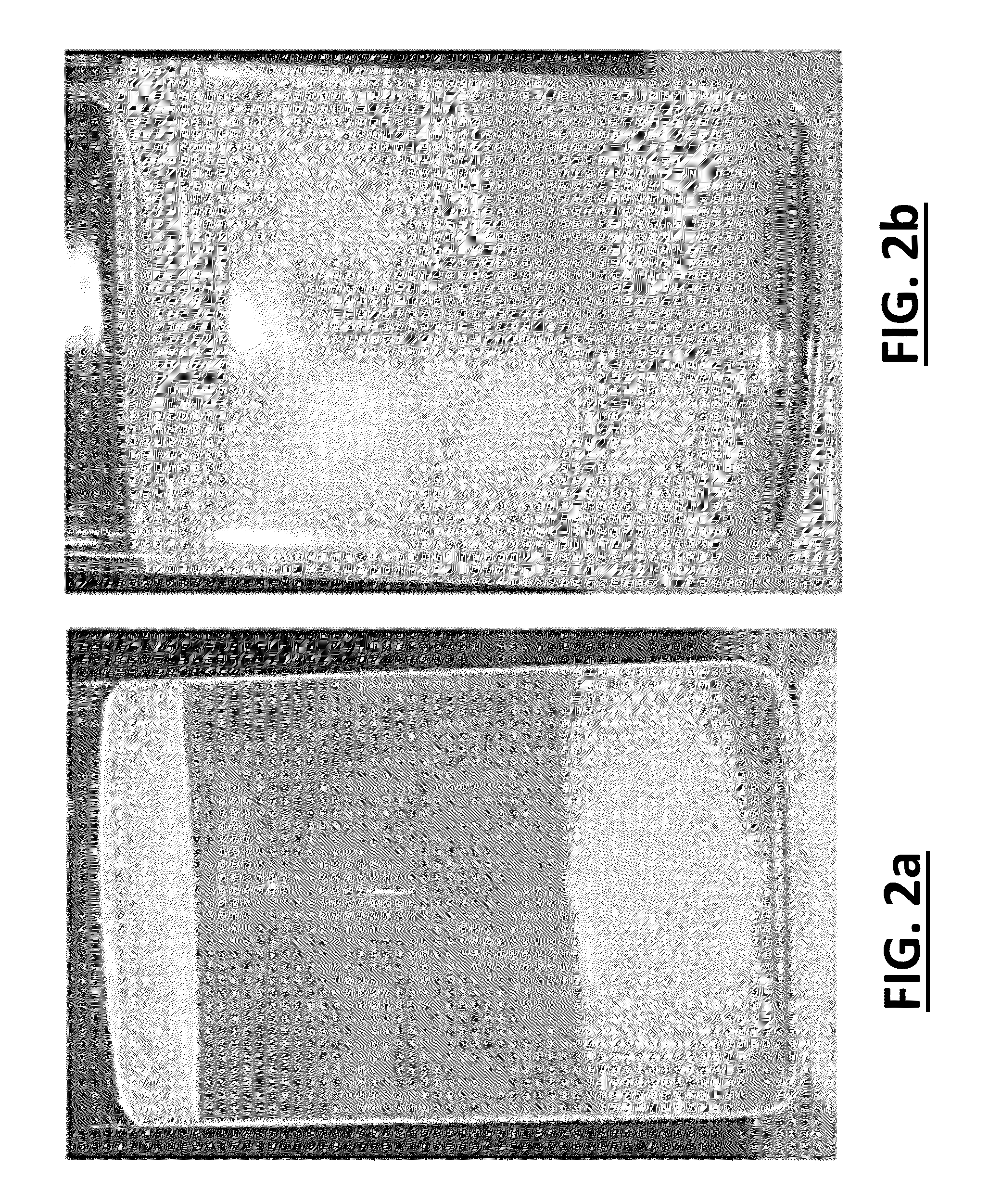

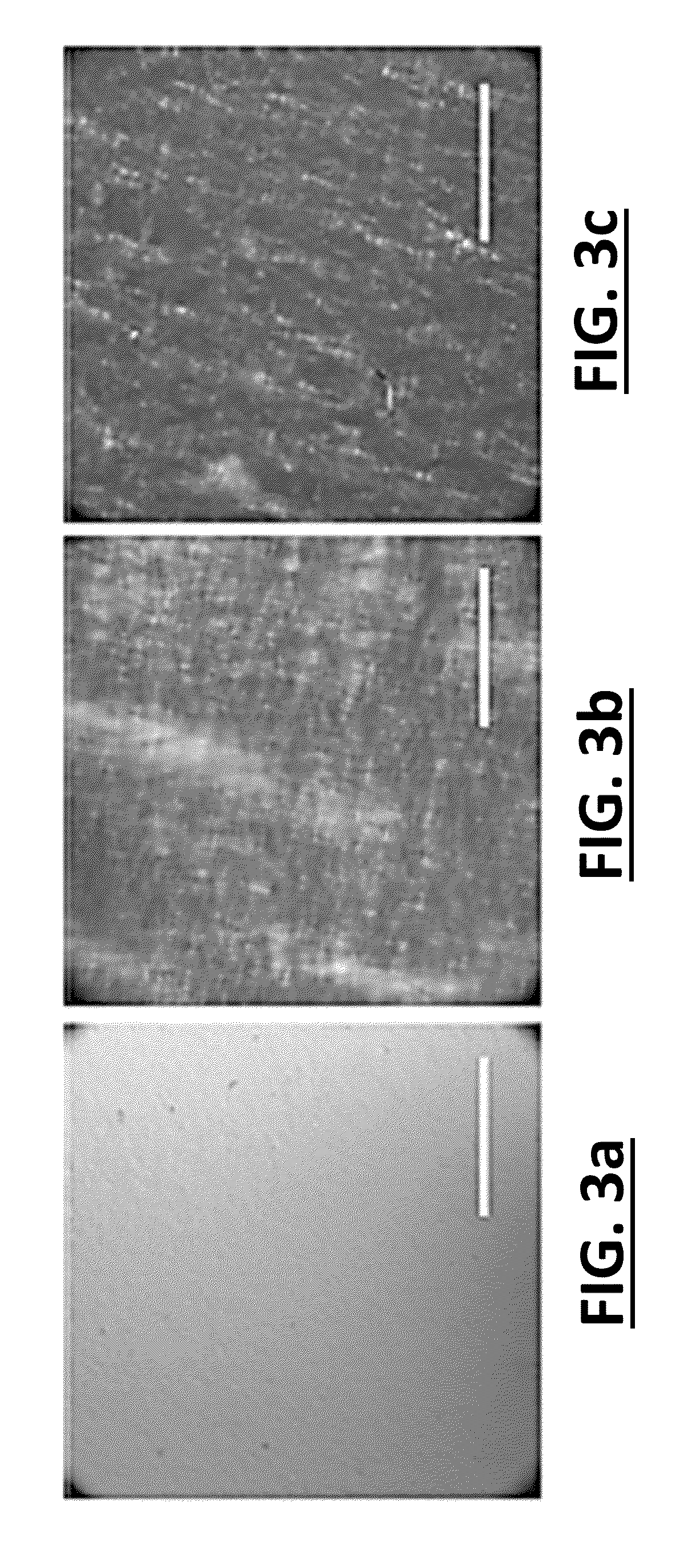

Reinforced Epoxy Nanocomposites and Methods for Preparation Thereof

PatentInactiveUS20160152820A1

Innovation

- A method involving a CNC/hardener/solvent suspension is created, where CNCs are dispersed in water to form an organogel, solvent is removed, and then a hardener is added, followed by mixing with epoxy and curing to form a CNC/epoxy nanocomposite, improving CNC dispersion and mechanical properties.

Environmental Impact Comparison Framework

To effectively compare the environmental impacts of nanocellulose composites and traditional composites, a comprehensive framework must be established that accounts for multiple dimensions of sustainability. This framework should incorporate standardized methodologies for quantifying environmental burdens throughout the entire life cycle of both material types.

The Environmental Impact Comparison Framework begins with boundary definition, clearly delineating system parameters for both nanocellulose and traditional composites. This includes raw material extraction, processing, manufacturing, use phase, and end-of-life scenarios. Particular attention must be paid to the unique aspects of nanocellulose production, such as mechanical or chemical processing of cellulose sources, versus the often petrochemical-based pathways of traditional composites.

Key environmental indicators within this framework include greenhouse gas emissions, energy consumption, water usage, land use changes, biodegradability, and toxicity profiles. For nanocellulose composites, the renewable nature of cellulose sources presents potential advantages in carbon sequestration and reduced fossil resource depletion compared to traditional composites. However, energy-intensive processing steps for nanocellulose extraction may offset some benefits.

The framework must also incorporate regional variations in environmental impacts. For instance, the environmental profile of nanocellulose production varies significantly depending on the source of cellulose (forestry products, agricultural residues, or dedicated crops) and local energy mix used in processing. Similarly, traditional composite manufacturing impacts differ based on regional industrial practices and regulations.

Temporal considerations are equally important within this framework. While traditional composites have well-established production systems with optimized efficiency, nanocellulose composites represent an emerging technology with potential for significant efficiency improvements as production scales. The framework should account for technology maturity and projected improvements in manufacturing processes.

End-of-life scenarios present particularly significant differences between these materials. The framework must evaluate biodegradability, recyclability, energy recovery potential, and landfill impacts. Nanocellulose composites generally offer superior biodegradability compared to traditional petroleum-based composites, potentially reducing waste accumulation and microplastic pollution.

Finally, the framework should incorporate uncertainty analysis and sensitivity testing to identify which parameters most significantly influence environmental outcomes. This allows for targeted improvement strategies and helps stakeholders understand the robustness of comparative assessments between these fundamentally different material systems.

The Environmental Impact Comparison Framework begins with boundary definition, clearly delineating system parameters for both nanocellulose and traditional composites. This includes raw material extraction, processing, manufacturing, use phase, and end-of-life scenarios. Particular attention must be paid to the unique aspects of nanocellulose production, such as mechanical or chemical processing of cellulose sources, versus the often petrochemical-based pathways of traditional composites.

Key environmental indicators within this framework include greenhouse gas emissions, energy consumption, water usage, land use changes, biodegradability, and toxicity profiles. For nanocellulose composites, the renewable nature of cellulose sources presents potential advantages in carbon sequestration and reduced fossil resource depletion compared to traditional composites. However, energy-intensive processing steps for nanocellulose extraction may offset some benefits.

The framework must also incorporate regional variations in environmental impacts. For instance, the environmental profile of nanocellulose production varies significantly depending on the source of cellulose (forestry products, agricultural residues, or dedicated crops) and local energy mix used in processing. Similarly, traditional composite manufacturing impacts differ based on regional industrial practices and regulations.

Temporal considerations are equally important within this framework. While traditional composites have well-established production systems with optimized efficiency, nanocellulose composites represent an emerging technology with potential for significant efficiency improvements as production scales. The framework should account for technology maturity and projected improvements in manufacturing processes.

End-of-life scenarios present particularly significant differences between these materials. The framework must evaluate biodegradability, recyclability, energy recovery potential, and landfill impacts. Nanocellulose composites generally offer superior biodegradability compared to traditional petroleum-based composites, potentially reducing waste accumulation and microplastic pollution.

Finally, the framework should incorporate uncertainty analysis and sensitivity testing to identify which parameters most significantly influence environmental outcomes. This allows for targeted improvement strategies and helps stakeholders understand the robustness of comparative assessments between these fundamentally different material systems.

Circular Economy Integration Strategies

The integration of nanocellulose composites into circular economy frameworks represents a significant opportunity to enhance sustainability across product lifecycles. Traditional composites, often petroleum-based and difficult to recycle, create substantial end-of-life challenges. Nanocellulose composites, by contrast, offer inherent advantages for circular economy implementation due to their bio-based nature and potential biodegradability.

A primary circular economy strategy involves designing nanocellulose composites specifically for disassembly and material recovery. This approach requires consideration of binding agents and additives that maintain recyclability while delivering performance comparable to traditional composites. Companies pioneering this strategy have developed modular design approaches where nanocellulose components can be separated from other materials at end-of-life, facilitating material recovery and reprocessing.

Cascading use represents another promising integration pathway, where nanocellulose materials are systematically downcycled through multiple applications. For instance, high-performance nanocellulose composites initially used in automotive applications might later be repurposed for less demanding applications in construction or packaging. This maximizes material value before eventual biodegradation or energy recovery.

Biological cycle integration leverages the biodegradability potential of certain nanocellulose formulations. Research indicates that properly engineered nanocellulose composites can decompose under industrial composting conditions, returning valuable nutrients to biological systems. This contrasts sharply with traditional composites that persist in landfills or require energy-intensive recycling processes.

Industrial symbiosis networks are emerging where waste streams from one industry become feedstock for nanocellulose production. Paper and pulp industry byproducts, agricultural residues, and even food processing waste can serve as cellulose sources, creating closed-loop systems that minimize virgin material extraction while reducing waste.

Digital tracking technologies, including blockchain and RFID systems, are being deployed to monitor nanocellulose materials throughout their lifecycle. These technologies enable precise material passports that document composition, processing history, and recycling instructions, facilitating more efficient material recovery and quality assurance in secondary markets.

Policy frameworks supporting these circular economy strategies remain underdeveloped but are evolving rapidly. Extended Producer Responsibility schemes, landfill taxes, and recycled content mandates are creating economic incentives that favor nanocellulose composites over traditional alternatives. Companies integrating circular principles into their nanocellulose product development are positioning themselves advantageously for anticipated regulatory changes and consumer preferences for sustainable materials.

A primary circular economy strategy involves designing nanocellulose composites specifically for disassembly and material recovery. This approach requires consideration of binding agents and additives that maintain recyclability while delivering performance comparable to traditional composites. Companies pioneering this strategy have developed modular design approaches where nanocellulose components can be separated from other materials at end-of-life, facilitating material recovery and reprocessing.

Cascading use represents another promising integration pathway, where nanocellulose materials are systematically downcycled through multiple applications. For instance, high-performance nanocellulose composites initially used in automotive applications might later be repurposed for less demanding applications in construction or packaging. This maximizes material value before eventual biodegradation or energy recovery.

Biological cycle integration leverages the biodegradability potential of certain nanocellulose formulations. Research indicates that properly engineered nanocellulose composites can decompose under industrial composting conditions, returning valuable nutrients to biological systems. This contrasts sharply with traditional composites that persist in landfills or require energy-intensive recycling processes.

Industrial symbiosis networks are emerging where waste streams from one industry become feedstock for nanocellulose production. Paper and pulp industry byproducts, agricultural residues, and even food processing waste can serve as cellulose sources, creating closed-loop systems that minimize virgin material extraction while reducing waste.

Digital tracking technologies, including blockchain and RFID systems, are being deployed to monitor nanocellulose materials throughout their lifecycle. These technologies enable precise material passports that document composition, processing history, and recycling instructions, facilitating more efficient material recovery and quality assurance in secondary markets.

Policy frameworks supporting these circular economy strategies remain underdeveloped but are evolving rapidly. Extended Producer Responsibility schemes, landfill taxes, and recycled content mandates are creating economic incentives that favor nanocellulose composites over traditional alternatives. Companies integrating circular principles into their nanocellulose product development are positioning themselves advantageously for anticipated regulatory changes and consumer preferences for sustainable materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!