Microinjection Molding and the Development of Smart Polymers

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Technology Evolution and Objectives

Microinjection molding technology emerged in the late 1980s as a specialized adaptation of conventional injection molding, designed to produce miniaturized plastic components with high precision. The evolution of this technology has been driven by increasing demands from industries such as medical devices, electronics, and microfluidics, where components with microscale features and tight tolerances are essential.

The initial development phase (1985-1995) focused primarily on adapting existing injection molding equipment to handle smaller shot weights and achieve higher precision. During this period, the technology was limited by material options and equipment capabilities, with most applications restricted to simple geometries in conventional thermoplastics.

The second evolutionary phase (1995-2005) saw significant advancements in dedicated microinjection molding machines, featuring specialized plasticizing units, improved control systems, and enhanced precision. This period marked the transition from adapted conventional equipment to purpose-built systems designed specifically for micro-scale production.

From 2005 to 2015, the technology experienced rapid growth in capabilities, with the integration of advanced process monitoring, quality control systems, and automation. Material science developments expanded the range of processable polymers to include high-performance engineering plastics, biocompatible materials, and the first generation of smart polymers with responsive properties.

The current phase (2015-present) represents a convergence of microinjection molding with smart polymer technology. Smart polymers—materials that respond to environmental stimuli such as temperature, pH, light, or electrical fields—have opened new frontiers for microinjection applications. This integration enables the production of components with programmable behaviors, self-healing capabilities, and adaptive responses to external conditions.

The technological trajectory is now moving toward multi-material microinjection molding, allowing the creation of complex components with integrated functionality through the combination of different smart polymers in a single part. Concurrently, advancements in process simulation and digital twin technology are enhancing predictability and control over the molding process at the micro scale.

The primary objectives for future development include: expanding the processability of novel smart polymers with enhanced responsive properties; improving part precision to sub-micron levels; developing in-mold sensing technologies for real-time process control; reducing cycle times to enhance economic viability; and establishing standardized design methodologies specific to smart polymer microcomponents.

As miniaturization continues across industries, microinjection molding of smart polymers aims to enable a new generation of intelligent microsystems with applications ranging from implantable medical devices and drug delivery systems to microelectromechanical systems (MEMS) and advanced sensors for the Internet of Things (IoT).

The initial development phase (1985-1995) focused primarily on adapting existing injection molding equipment to handle smaller shot weights and achieve higher precision. During this period, the technology was limited by material options and equipment capabilities, with most applications restricted to simple geometries in conventional thermoplastics.

The second evolutionary phase (1995-2005) saw significant advancements in dedicated microinjection molding machines, featuring specialized plasticizing units, improved control systems, and enhanced precision. This period marked the transition from adapted conventional equipment to purpose-built systems designed specifically for micro-scale production.

From 2005 to 2015, the technology experienced rapid growth in capabilities, with the integration of advanced process monitoring, quality control systems, and automation. Material science developments expanded the range of processable polymers to include high-performance engineering plastics, biocompatible materials, and the first generation of smart polymers with responsive properties.

The current phase (2015-present) represents a convergence of microinjection molding with smart polymer technology. Smart polymers—materials that respond to environmental stimuli such as temperature, pH, light, or electrical fields—have opened new frontiers for microinjection applications. This integration enables the production of components with programmable behaviors, self-healing capabilities, and adaptive responses to external conditions.

The technological trajectory is now moving toward multi-material microinjection molding, allowing the creation of complex components with integrated functionality through the combination of different smart polymers in a single part. Concurrently, advancements in process simulation and digital twin technology are enhancing predictability and control over the molding process at the micro scale.

The primary objectives for future development include: expanding the processability of novel smart polymers with enhanced responsive properties; improving part precision to sub-micron levels; developing in-mold sensing technologies for real-time process control; reducing cycle times to enhance economic viability; and establishing standardized design methodologies specific to smart polymer microcomponents.

As miniaturization continues across industries, microinjection molding of smart polymers aims to enable a new generation of intelligent microsystems with applications ranging from implantable medical devices and drug delivery systems to microelectromechanical systems (MEMS) and advanced sensors for the Internet of Things (IoT).

Market Demand Analysis for Smart Polymer Applications

The global market for smart polymers is experiencing significant growth, driven by increasing demand across multiple industries. Current market valuations indicate that the smart polymers sector is expanding at a compound annual growth rate of 12.5% and is projected to reach $9.9 billion by 2025. This remarkable growth trajectory is fueled by the convergence of microinjection molding technologies with advanced polymer science, creating unprecedented opportunities for miniaturized components with responsive functionalities.

Healthcare and medical devices represent the largest application segment, accounting for approximately 38% of the total market share. The demand is particularly strong for drug delivery systems, tissue engineering scaffolds, and minimally invasive surgical tools that utilize smart polymers processed through microinjection molding. These applications benefit from the precise dimensional control and material property manipulation that microinjection molding enables at the microscale.

Consumer electronics constitutes the second-largest market segment, with manufacturers increasingly incorporating smart polymer microcomponents in wearable devices, smartphones, and other portable electronics. The ability to produce complex geometries with functional properties such as shape memory, self-healing capabilities, or stimuli-responsiveness has created new design possibilities that were previously unattainable with conventional materials and manufacturing methods.

Automotive and aerospace industries are rapidly adopting smart polymer microcomponents for sensor applications, lightweight structural elements, and smart surfaces. Market research indicates that these sectors will experience the fastest growth rate in smart polymer adoption over the next five years, with particular emphasis on components that can respond to environmental changes or self-diagnose potential failures.

Regional market analysis reveals that North America currently leads in smart polymer applications, holding approximately 35% of the global market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, driven by expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing investment in advanced materials research.

End-user surveys indicate that key market drivers include the growing demand for miniaturization, increased functionality in smaller footprints, and the push toward sustainable and recyclable materials. Customers are willing to pay premium prices for smart polymer components that offer multifunctionality, reduced assembly requirements, and enhanced performance characteristics compared to conventional alternatives.

Market barriers include the relatively high cost of specialized smart polymers, technical challenges in scaling microinjection molding processes for mass production, and regulatory hurdles for novel materials, particularly in medical applications. Despite these challenges, the market trajectory remains strongly positive as technological advancements continue to address these limitations.

Healthcare and medical devices represent the largest application segment, accounting for approximately 38% of the total market share. The demand is particularly strong for drug delivery systems, tissue engineering scaffolds, and minimally invasive surgical tools that utilize smart polymers processed through microinjection molding. These applications benefit from the precise dimensional control and material property manipulation that microinjection molding enables at the microscale.

Consumer electronics constitutes the second-largest market segment, with manufacturers increasingly incorporating smart polymer microcomponents in wearable devices, smartphones, and other portable electronics. The ability to produce complex geometries with functional properties such as shape memory, self-healing capabilities, or stimuli-responsiveness has created new design possibilities that were previously unattainable with conventional materials and manufacturing methods.

Automotive and aerospace industries are rapidly adopting smart polymer microcomponents for sensor applications, lightweight structural elements, and smart surfaces. Market research indicates that these sectors will experience the fastest growth rate in smart polymer adoption over the next five years, with particular emphasis on components that can respond to environmental changes or self-diagnose potential failures.

Regional market analysis reveals that North America currently leads in smart polymer applications, holding approximately 35% of the global market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, driven by expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing investment in advanced materials research.

End-user surveys indicate that key market drivers include the growing demand for miniaturization, increased functionality in smaller footprints, and the push toward sustainable and recyclable materials. Customers are willing to pay premium prices for smart polymer components that offer multifunctionality, reduced assembly requirements, and enhanced performance characteristics compared to conventional alternatives.

Market barriers include the relatively high cost of specialized smart polymers, technical challenges in scaling microinjection molding processes for mass production, and regulatory hurdles for novel materials, particularly in medical applications. Despite these challenges, the market trajectory remains strongly positive as technological advancements continue to address these limitations.

Current Technological Landscape and Challenges in Microinjection Molding

Microinjection molding technology has evolved significantly over the past two decades, establishing itself as a critical manufacturing process for producing miniaturized polymer components with high precision. Currently, the global landscape shows that Europe, particularly Germany and Switzerland, leads in equipment development, while Japan dominates in process refinement and automation. The United States excels in material innovation, especially in smart polymer development for medical applications.

The current technological capabilities allow for the production of components with wall thicknesses down to 20 micrometers and structural details as small as 5 micrometers. Cycle times have been reduced to as little as 4-6 seconds for basic components, representing a 40% improvement compared to a decade ago. However, when working with smart polymers that incorporate functional additives, cycle times typically increase by 30-50% due to more complex processing requirements.

Despite these advancements, significant challenges persist in the microinjection molding of smart polymers. Material flow behavior at the micro-scale remains difficult to predict accurately, with conventional simulation models showing up to 25% deviation from actual results when dealing with highly filled smart polymers. This unpredictability increases production costs and limits design freedom.

Temperature control presents another major challenge, as smart polymers often have narrower processing windows than conventional materials. Variations as small as 3-5°C can significantly impact part quality and functional properties. Current heating systems struggle to maintain the required precision across the entire mold cavity, resulting in inconsistent material properties throughout the molded part.

Tool design and fabrication represent a substantial bottleneck, with micro-features requiring specialized manufacturing techniques such as laser ablation or micro-EDM. These processes increase tooling costs by 200-300% compared to conventional molds and extend lead times to 8-12 weeks. Additionally, tool wear occurs more rapidly when processing smart polymers containing functional fillers, reducing tool life by up to 40%.

Quality control and inspection present unique challenges at the micro-scale. Current vision systems can detect surface defects down to 2 micrometers, but internal defect detection remains limited. For smart polymers with embedded functionality, conventional testing methods often prove inadequate for verifying performance characteristics without damaging the components.

The integration of Industry 4.0 principles into microinjection molding is progressing unevenly across regions. While approximately 65% of new equipment installations in Europe and Japan incorporate advanced monitoring and control systems, adoption rates in other regions remain below 30%. This technological gap creates disparities in production capability and quality consistency across the global manufacturing landscape.

The current technological capabilities allow for the production of components with wall thicknesses down to 20 micrometers and structural details as small as 5 micrometers. Cycle times have been reduced to as little as 4-6 seconds for basic components, representing a 40% improvement compared to a decade ago. However, when working with smart polymers that incorporate functional additives, cycle times typically increase by 30-50% due to more complex processing requirements.

Despite these advancements, significant challenges persist in the microinjection molding of smart polymers. Material flow behavior at the micro-scale remains difficult to predict accurately, with conventional simulation models showing up to 25% deviation from actual results when dealing with highly filled smart polymers. This unpredictability increases production costs and limits design freedom.

Temperature control presents another major challenge, as smart polymers often have narrower processing windows than conventional materials. Variations as small as 3-5°C can significantly impact part quality and functional properties. Current heating systems struggle to maintain the required precision across the entire mold cavity, resulting in inconsistent material properties throughout the molded part.

Tool design and fabrication represent a substantial bottleneck, with micro-features requiring specialized manufacturing techniques such as laser ablation or micro-EDM. These processes increase tooling costs by 200-300% compared to conventional molds and extend lead times to 8-12 weeks. Additionally, tool wear occurs more rapidly when processing smart polymers containing functional fillers, reducing tool life by up to 40%.

Quality control and inspection present unique challenges at the micro-scale. Current vision systems can detect surface defects down to 2 micrometers, but internal defect detection remains limited. For smart polymers with embedded functionality, conventional testing methods often prove inadequate for verifying performance characteristics without damaging the components.

The integration of Industry 4.0 principles into microinjection molding is progressing unevenly across regions. While approximately 65% of new equipment installations in Europe and Japan incorporate advanced monitoring and control systems, adoption rates in other regions remain below 30%. This technological gap creates disparities in production capability and quality consistency across the global manufacturing landscape.

Current Technical Solutions for Microinjection Molding of Smart Polymers

01 Microinjection molding techniques for smart polymers

Microinjection molding is a specialized manufacturing process for producing small, high-precision polymer components. When applied to smart polymers, this technique enables the creation of micro-scale components with responsive properties. The process typically involves heating the smart polymer material to its flow temperature, injecting it into a micro-mold cavity under high pressure, and then cooling to solidify. This approach allows for the production of complex microstructures with functional properties that can respond to environmental stimuli.- Microinjection molding techniques for smart polymers: Microinjection molding is a specialized manufacturing process used for producing small, high-precision polymer components. When applied to smart polymers, this technique enables the production of micro-scale components with responsive properties. The process typically involves heating the smart polymer material to its flow temperature, injecting it into a micro-mold cavity under high pressure, and then cooling to solidify the part. This approach allows for the creation of complex microstructures with functional properties that can respond to environmental stimuli.

- Smart polymer applications in microfluidic devices: Smart polymers are increasingly being used in microfluidic devices manufactured through microinjection molding. These materials enable the creation of responsive microchannels, valves, and pumps that can change their properties in response to external stimuli such as temperature, pH, or light. The integration of smart polymers in microfluidic systems allows for controlled fluid manipulation, targeted drug delivery, and the development of lab-on-a-chip devices with enhanced functionality and automation capabilities.

- Temperature-responsive smart polymers for micro-components: Temperature-responsive smart polymers, particularly those exhibiting lower critical solution temperature (LCST) or upper critical solution temperature (UCST) behavior, are being utilized in microinjection molding to create components that can change their properties with temperature variations. These materials can undergo reversible phase transitions, altering their volume, permeability, or mechanical properties in response to temperature changes. This behavior is particularly valuable for creating self-regulating microvalves, temperature sensors, and drug delivery systems that can respond to body temperature or external thermal stimuli.

- Biodegradable smart polymers for medical microdevices: Biodegradable smart polymers are being microinjection molded to create implantable medical microdevices that can perform specific functions and then safely degrade within the body. These materials combine responsive behavior with controlled degradation profiles, enabling applications such as time-released drug delivery systems, temporary tissue scaffolds, and dissolvable microsensors. The microinjection molding process allows for precise control over the microstructure and degradation characteristics of these devices, optimizing their performance for specific medical applications.

- Multi-material microinjection molding with smart polymers: Advanced microinjection molding techniques enable the combination of different smart polymers or smart polymers with conventional materials in a single micro-component. This multi-material approach allows for the creation of complex microdevices with spatially controlled responsive properties. By precisely positioning different materials within a microstructure, engineers can develop components with region-specific responses to stimuli, creating sophisticated functionalities such as selective permeability, directional actuation, or localized sensing capabilities.

02 Smart polymers with shape memory and self-healing properties

Smart polymers can be engineered to exhibit shape memory and self-healing capabilities. These materials can return to their original shape after deformation when exposed to specific stimuli such as temperature changes, light, or electrical current. Self-healing smart polymers can repair damage autonomously through various mechanisms including reversible bonds or encapsulated healing agents. When processed through microinjection molding, these functional polymers maintain their responsive properties while achieving complex geometries at the micro scale.Expand Specific Solutions03 Stimuli-responsive smart polymers for microfluidic applications

Smart polymers that respond to environmental stimuli such as pH, temperature, or light can be microinjection molded to create responsive microfluidic devices. These materials change their properties (such as permeability, volume, or hydrophilicity) in response to specific triggers, enabling controlled fluid flow, valve functions, or selective filtration within microfluidic channels. The precision of microinjection molding allows for the creation of intricate channel networks with integrated responsive elements for lab-on-a-chip applications.Expand Specific Solutions04 Composite and nanocomposite smart polymers for enhanced functionality

Incorporating nanoparticles or other functional materials into smart polymers creates composite systems with enhanced or novel properties. These composites can be processed via microinjection molding to produce micro-components with combined functionalities such as electrical conductivity, magnetic responsiveness, or improved mechanical properties while maintaining their smart characteristics. The microinjection molding process must be carefully controlled to ensure proper dispersion of the additives and to preserve the responsive nature of the smart polymer matrix.Expand Specific Solutions05 Process optimization for microinjection molding of smart polymers

Successful microinjection molding of smart polymers requires careful optimization of processing parameters including melt temperature, injection pressure, cooling rate, and mold design. These parameters must be tailored to preserve the functional properties of smart polymers while achieving complete mold filling and dimensional accuracy at the micro scale. Advanced techniques such as variothermal processing, vacuum-assisted molding, or specialized surface treatments may be employed to overcome challenges specific to smart polymers, such as degradation of responsive components or poor flow behavior.Expand Specific Solutions

Key Industry Players and Competitive Landscape Analysis

Microinjection Molding and Smart Polymers market is currently in a growth phase, with increasing adoption across medical, automotive, and electronics industries. The global market size is estimated to reach $1.5 billion by 2025, driven by demand for miniaturized components with complex geometries. Technologically, the field is advancing rapidly with companies like BASF, Intel, and Boeing investing in R&D for high-performance applications. Leading academic institutions including Georgia Tech Research Corp. and University of Washington are collaborating with industry players such as Stratasys and Covestro to develop smart polymers with self-healing, shape-memory, and stimuli-responsive properties. Kaneka and Total Petrochemicals are focusing on sustainable smart polymer solutions, while Medtronic and LEGO are exploring specialized applications in medical devices and consumer products respectively.

Covestro Deutschland AG

Technical Solution: Covestro has developed advanced smart polymer solutions for microinjection molding that incorporate stimuli-responsive materials capable of changing properties in response to external triggers. Their proprietary technology combines polycarbonates and thermoplastic polyurethanes with functional additives to create polymers that exhibit shape memory effects, self-healing capabilities, and programmable mechanical properties. The company has pioneered a process called "Intelligent Molding" that optimizes the microinjection parameters specifically for smart polymers, ensuring precise control over crystallinity and molecular orientation during the molding process. Their materials feature multi-responsive capabilities, reacting to temperature, pH, light, or electrical stimuli, making them suitable for applications in medical devices, automotive components, and consumer electronics. Covestro's approach integrates digitalization through embedded sensors within the polymer matrix that can communicate with external systems for real-time monitoring and adaptive responses.

Strengths: Superior material engineering expertise with extensive polymer chemistry knowledge; established manufacturing infrastructure allowing rapid scaling; comprehensive quality control systems ensuring consistent performance of smart polymers. Weaknesses: Higher production costs compared to conventional polymers; some smart polymer formulations have limited temperature resistance; complex processing parameters require specialized equipment and expertise.

Stratasys Ltd.

Technical Solution: Stratasys has developed an innovative hybrid approach combining microinjection molding with additive manufacturing for smart polymer applications. Their "Digital Polymer" platform integrates traditional microinjection techniques with their proprietary PolyJet technology to create multi-material, multi-property components with embedded smart functionalities. This approach allows for the precise deposition of different polymer types within a single component, creating structures with regionally-specific responsive behaviors. Stratasys has pioneered materials that combine rigid and flexible segments within a single polymer chain, enabling components that exhibit programmable mechanical responses to external stimuli. Their technology facilitates the creation of microfluidic devices with integrated valves and pumps that respond to thermal or electrical inputs without additional assembly steps. The company has developed specialized software tools that optimize the design of smart polymer components for their hybrid manufacturing process, accounting for material transitions, shrinkage compensation, and functional requirements. Stratasys's approach is particularly valuable for producing small-batch, customized smart polymer components with complex geometries that would be challenging to manufacture using conventional microinjection molding alone.

Strengths: Unique capability to combine multiple materials with different properties in a single component; flexibility in design iterations without tooling changes; ability to create complex internal structures not possible with traditional molding. Weaknesses: Lower production throughput compared to dedicated microinjection molding; size limitations for certain applications; higher unit costs for large-volume production compared to traditional microinjection molding.

Core Patents and Innovations in Smart Polymer Processing

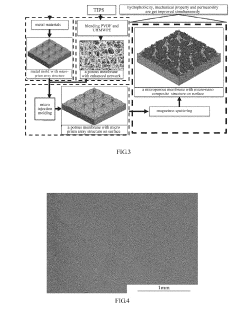

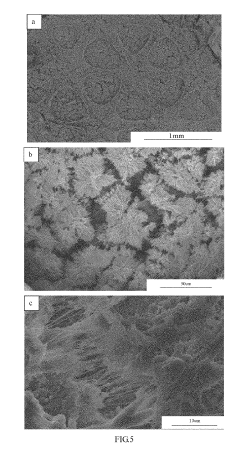

Polyvinylidene Fluoride/Ultra-high Molecular Weight Polyethylene Blend Microporous Membrane and Preparation Method Thereof

PatentActiveUS20190105611A1

Innovation

- A polyvinylidene fluoride/ultra-high molecular weight polyethylene blend microporous membrane is prepared using a combination of thermally induced phase separation and micro-injection molding, with a micro-prism array structure and surface modification by magnetron sputtering, to achieve improved hydrophobicity, mechanical strength, and permeability.

Sustainability Aspects of Smart Polymer Manufacturing

The sustainability of smart polymer manufacturing through microinjection molding represents a critical intersection of advanced materials science and environmental responsibility. As industries increasingly adopt these innovative materials, the environmental footprint of their production processes demands thorough examination. Current smart polymer manufacturing processes often involve energy-intensive operations and potentially hazardous chemical additives, presenting significant sustainability challenges.

Life cycle assessment (LCA) studies reveal that microinjection molding of smart polymers can reduce material waste by up to 30% compared to conventional molding techniques. This reduction stems from the precision inherent in microinjection systems, which minimize excess material usage and scrap generation. Additionally, the miniaturization of components leads to decreased transportation emissions throughout the supply chain, further enhancing the environmental profile of these materials.

Energy consumption remains a primary concern in smart polymer production. The specialized processing conditions required for stimuli-responsive polymers typically demand precise temperature control and extended processing times. Recent technological innovations have introduced energy-efficient microinjection systems that incorporate regenerative braking in hydraulic components, reducing energy requirements by approximately 15-20% compared to first-generation equipment.

Water usage presents another sustainability dimension, particularly for hydrogel-based smart polymers. Closed-loop water recycling systems have emerged as promising solutions, potentially recovering up to 85% of process water. These systems employ advanced filtration technologies to remove contaminants while preserving the necessary purity levels for subsequent production cycles.

Raw material sourcing constitutes a fundamental sustainability consideration. The development of bio-based smart polymers derived from renewable resources has gained significant momentum, with several commercially viable options now available. These materials offer comparable performance characteristics while reducing dependence on petroleum-based feedstocks. Research indicates that certain bio-derived smart polymers can achieve carbon footprint reductions of 40-60% compared to their conventional counterparts.

End-of-life management for smart polymer products presents unique challenges due to their complex compositions. Emerging technologies for selective degradation of responsive elements show promise for improving recyclability. Additionally, design-for-disassembly approaches are being integrated into product development workflows, facilitating more effective material recovery and reuse pathways.

Regulatory frameworks worldwide are increasingly addressing the sustainability aspects of advanced polymer manufacturing. The European Union's Circular Economy Action Plan specifically targets improved recyclability of complex polymer systems, while similar initiatives are emerging in North America and Asia. These regulatory developments are driving industry innovation toward more sustainable smart polymer production methodologies.

Life cycle assessment (LCA) studies reveal that microinjection molding of smart polymers can reduce material waste by up to 30% compared to conventional molding techniques. This reduction stems from the precision inherent in microinjection systems, which minimize excess material usage and scrap generation. Additionally, the miniaturization of components leads to decreased transportation emissions throughout the supply chain, further enhancing the environmental profile of these materials.

Energy consumption remains a primary concern in smart polymer production. The specialized processing conditions required for stimuli-responsive polymers typically demand precise temperature control and extended processing times. Recent technological innovations have introduced energy-efficient microinjection systems that incorporate regenerative braking in hydraulic components, reducing energy requirements by approximately 15-20% compared to first-generation equipment.

Water usage presents another sustainability dimension, particularly for hydrogel-based smart polymers. Closed-loop water recycling systems have emerged as promising solutions, potentially recovering up to 85% of process water. These systems employ advanced filtration technologies to remove contaminants while preserving the necessary purity levels for subsequent production cycles.

Raw material sourcing constitutes a fundamental sustainability consideration. The development of bio-based smart polymers derived from renewable resources has gained significant momentum, with several commercially viable options now available. These materials offer comparable performance characteristics while reducing dependence on petroleum-based feedstocks. Research indicates that certain bio-derived smart polymers can achieve carbon footprint reductions of 40-60% compared to their conventional counterparts.

End-of-life management for smart polymer products presents unique challenges due to their complex compositions. Emerging technologies for selective degradation of responsive elements show promise for improving recyclability. Additionally, design-for-disassembly approaches are being integrated into product development workflows, facilitating more effective material recovery and reuse pathways.

Regulatory frameworks worldwide are increasingly addressing the sustainability aspects of advanced polymer manufacturing. The European Union's Circular Economy Action Plan specifically targets improved recyclability of complex polymer systems, while similar initiatives are emerging in North America and Asia. These regulatory developments are driving industry innovation toward more sustainable smart polymer production methodologies.

Quality Control and Precision Standards for Micro-Scale Production

Quality control in microinjection molding represents a critical challenge due to the microscopic scale of components and the complexity of smart polymer applications. Traditional quality inspection methods often prove inadequate when dealing with parts featuring dimensions in the micrometer range, necessitating specialized approaches tailored to micro-scale production environments.

The industry has established several key precision standards that govern microinjection molding processes. ISO 10360 and ISO 13485 provide frameworks specifically applicable to micro-scale manufacturing, with tolerances typically ranging from ±1 to ±5 micrometers depending on the application requirements. For smart polymers with embedded functionalities, these tolerances become even more stringent, often requiring precision within sub-micron ranges.

Advanced metrology systems have emerged as essential tools for quality assurance in this field. Optical measurement technologies, including confocal microscopy and white light interferometry, enable non-contact dimensional verification with resolution capabilities reaching nanometer scales. These systems can detect surface defects, dimensional variations, and structural inconsistencies that would be imperceptible through conventional inspection methods.

In-line monitoring represents another crucial aspect of quality control for microinjection molding. Real-time process parameter monitoring systems track critical variables such as injection pressure, melt temperature, and cooling rates with millisecond precision. Machine learning algorithms increasingly complement these systems by identifying patterns that precede quality deviations, enabling predictive maintenance and proactive quality management.

Statistical process control (SPC) methodologies have been adapted specifically for micro-scale production environments. These approaches employ specialized sampling techniques and modified control charts that account for the unique challenges of microinjection molding, including the significant impact of environmental factors like temperature fluctuations and particulate contamination.

For smart polymers with functional properties, additional quality parameters must be verified beyond dimensional accuracy. Electrical conductivity testing, mechanical response evaluation, and chemical composition analysis are frequently integrated into quality control protocols. These tests ensure that the polymer's smart functionalities—whether shape memory, self-healing, or stimulus-responsive behavior—meet design specifications.

Documentation and traceability systems have evolved to support the stringent requirements of industries utilizing microinjection molded smart polymer components, particularly in medical and aerospace applications. Digital twin technologies increasingly enable virtual modeling of production processes, allowing manufacturers to simulate and optimize quality control procedures before physical implementation.

The industry has established several key precision standards that govern microinjection molding processes. ISO 10360 and ISO 13485 provide frameworks specifically applicable to micro-scale manufacturing, with tolerances typically ranging from ±1 to ±5 micrometers depending on the application requirements. For smart polymers with embedded functionalities, these tolerances become even more stringent, often requiring precision within sub-micron ranges.

Advanced metrology systems have emerged as essential tools for quality assurance in this field. Optical measurement technologies, including confocal microscopy and white light interferometry, enable non-contact dimensional verification with resolution capabilities reaching nanometer scales. These systems can detect surface defects, dimensional variations, and structural inconsistencies that would be imperceptible through conventional inspection methods.

In-line monitoring represents another crucial aspect of quality control for microinjection molding. Real-time process parameter monitoring systems track critical variables such as injection pressure, melt temperature, and cooling rates with millisecond precision. Machine learning algorithms increasingly complement these systems by identifying patterns that precede quality deviations, enabling predictive maintenance and proactive quality management.

Statistical process control (SPC) methodologies have been adapted specifically for micro-scale production environments. These approaches employ specialized sampling techniques and modified control charts that account for the unique challenges of microinjection molding, including the significant impact of environmental factors like temperature fluctuations and particulate contamination.

For smart polymers with functional properties, additional quality parameters must be verified beyond dimensional accuracy. Electrical conductivity testing, mechanical response evaluation, and chemical composition analysis are frequently integrated into quality control protocols. These tests ensure that the polymer's smart functionalities—whether shape memory, self-healing, or stimulus-responsive behavior—meet design specifications.

Documentation and traceability systems have evolved to support the stringent requirements of industries utilizing microinjection molded smart polymer components, particularly in medical and aerospace applications. Digital twin technologies increasingly enable virtual modeling of production processes, allowing manufacturers to simulate and optimize quality control procedures before physical implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!