Nanocellulose As A Lightweight Reinforcement In Sporting Goods

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Technology Evolution and Objectives

Nanocellulose has emerged as a revolutionary material in the field of sustainable reinforcement technologies over the past two decades. Initially discovered in the early 1980s, this naturally occurring nanomaterial has undergone significant evolution from laboratory curiosity to commercially viable reinforcement option. The fundamental structure of nanocellulose, derived from plant cell walls, consists of crystalline regions with exceptional mechanical properties, including high tensile strength (up to 10 GPa) and stiffness comparable to Kevlar, while maintaining a density approximately five times lower than steel.

The technological evolution of nanocellulose has progressed through several distinct phases. The first generation (1980-2000) focused primarily on extraction methods and basic characterization. The second generation (2000-2010) saw advancements in production scalability and initial applications in paper products. The current third generation (2010-present) has witnessed breakthrough developments in surface modification techniques and integration with polymer matrices specifically designed for high-performance applications, including sporting goods.

The primary objective in utilizing nanocellulose as a lightweight reinforcement in sporting equipment is to achieve superior strength-to-weight ratios that enhance athletic performance while maintaining or improving durability. This aligns with the growing consumer demand for high-performance, sustainable sporting goods that minimize environmental impact without compromising functionality.

Technical objectives specifically related to sporting goods applications include developing processing methods that ensure uniform dispersion of nanocellulose within polymer matrices, preventing agglomeration that would compromise mechanical properties. Additionally, researchers aim to optimize interfacial bonding between nanocellulose and various polymer systems commonly used in sporting equipment manufacturing, such as epoxy resins, polyurethanes, and thermoplastic composites.

Another critical objective is addressing moisture sensitivity, as nanocellulose's hydrophilic nature can lead to performance degradation in humid conditions—a significant concern for outdoor sporting equipment. Current research focuses on developing effective surface treatments and encapsulation methods to enhance hydrophobicity without diminishing reinforcement capabilities.

The long-term technological trajectory points toward fully customizable nanocellulose-reinforced composites with programmable mechanical properties tailored to specific sporting applications—from tennis rackets requiring precise flex patterns to golf clubs needing optimized energy transfer. This customization potential represents a paradigm shift from traditional "one-material-fits-all" approaches to sporting equipment design.

Industry projections suggest that nanocellulose technology will reach technological maturity for widespread sporting goods applications within the next 5-7 years, contingent upon overcoming current challenges in cost-effective mass production and standardization of material specifications across the supply chain.

The technological evolution of nanocellulose has progressed through several distinct phases. The first generation (1980-2000) focused primarily on extraction methods and basic characterization. The second generation (2000-2010) saw advancements in production scalability and initial applications in paper products. The current third generation (2010-present) has witnessed breakthrough developments in surface modification techniques and integration with polymer matrices specifically designed for high-performance applications, including sporting goods.

The primary objective in utilizing nanocellulose as a lightweight reinforcement in sporting equipment is to achieve superior strength-to-weight ratios that enhance athletic performance while maintaining or improving durability. This aligns with the growing consumer demand for high-performance, sustainable sporting goods that minimize environmental impact without compromising functionality.

Technical objectives specifically related to sporting goods applications include developing processing methods that ensure uniform dispersion of nanocellulose within polymer matrices, preventing agglomeration that would compromise mechanical properties. Additionally, researchers aim to optimize interfacial bonding between nanocellulose and various polymer systems commonly used in sporting equipment manufacturing, such as epoxy resins, polyurethanes, and thermoplastic composites.

Another critical objective is addressing moisture sensitivity, as nanocellulose's hydrophilic nature can lead to performance degradation in humid conditions—a significant concern for outdoor sporting equipment. Current research focuses on developing effective surface treatments and encapsulation methods to enhance hydrophobicity without diminishing reinforcement capabilities.

The long-term technological trajectory points toward fully customizable nanocellulose-reinforced composites with programmable mechanical properties tailored to specific sporting applications—from tennis rackets requiring precise flex patterns to golf clubs needing optimized energy transfer. This customization potential represents a paradigm shift from traditional "one-material-fits-all" approaches to sporting equipment design.

Industry projections suggest that nanocellulose technology will reach technological maturity for widespread sporting goods applications within the next 5-7 years, contingent upon overcoming current challenges in cost-effective mass production and standardization of material specifications across the supply chain.

Market Analysis for Sustainable Sporting Goods Materials

The global sporting goods market has witnessed a significant shift towards sustainable materials in recent years, driven by increasing environmental awareness among consumers and regulatory pressures on manufacturers. The market for eco-friendly sporting equipment is projected to grow at a compound annual growth rate of 5.7% through 2030, outpacing the overall sporting goods market growth of 4.2%. This trend represents a substantial opportunity for nanocellulose-reinforced products to capture market share.

Consumer surveys indicate that approximately 68% of sporting goods purchasers now consider environmental impact when making buying decisions, with this percentage rising to 78% among millennials and Generation Z consumers. This demographic shift is particularly relevant as these younger consumers represent the largest segment of sporting goods purchasers, accounting for over 60% of total market spending.

The premium segment of sustainable sporting goods has shown remarkable resilience even during economic downturns, with consumers willing to pay 15-20% more for products with verifiable environmental benefits. This price premium potential makes nanocellulose reinforcement commercially attractive despite higher initial production costs compared to conventional materials.

Regional market analysis reveals varying adoption rates of sustainable sporting goods. Europe leads with a 42% market share of eco-friendly sporting equipment, followed by North America at 31%, Asia-Pacific at 18%, and the rest of the world accounting for 9%. However, the Asia-Pacific region demonstrates the fastest growth rate, suggesting significant future expansion opportunities for nanocellulose-reinforced products.

By product category, sustainable materials have gained the most traction in outdoor equipment (hiking, camping, water sports), racquet sports, and winter sports equipment. These segments prioritize lightweight yet durable materials—precisely the benefits that nanocellulose reinforcement offers. The fitness equipment segment represents an underpenetrated market with substantial growth potential, particularly for strength training equipment where weight reduction without compromising structural integrity is highly valued.

Competitive analysis shows that major sporting goods manufacturers including Adidas, Patagonia, and Yonex have already incorporated various sustainable materials into their product lines, though specific nanocellulose applications remain limited. This indicates both market validation for sustainable materials and a competitive opportunity for early adopters of nanocellulose technology.

Distribution channel analysis reveals that specialty retailers and direct-to-consumer online channels show the highest penetration of sustainable sporting goods, with 37% and 29% market share respectively. These channels also demonstrate higher consumer willingness to pay premiums for innovative, environmentally friendly products.

Consumer surveys indicate that approximately 68% of sporting goods purchasers now consider environmental impact when making buying decisions, with this percentage rising to 78% among millennials and Generation Z consumers. This demographic shift is particularly relevant as these younger consumers represent the largest segment of sporting goods purchasers, accounting for over 60% of total market spending.

The premium segment of sustainable sporting goods has shown remarkable resilience even during economic downturns, with consumers willing to pay 15-20% more for products with verifiable environmental benefits. This price premium potential makes nanocellulose reinforcement commercially attractive despite higher initial production costs compared to conventional materials.

Regional market analysis reveals varying adoption rates of sustainable sporting goods. Europe leads with a 42% market share of eco-friendly sporting equipment, followed by North America at 31%, Asia-Pacific at 18%, and the rest of the world accounting for 9%. However, the Asia-Pacific region demonstrates the fastest growth rate, suggesting significant future expansion opportunities for nanocellulose-reinforced products.

By product category, sustainable materials have gained the most traction in outdoor equipment (hiking, camping, water sports), racquet sports, and winter sports equipment. These segments prioritize lightweight yet durable materials—precisely the benefits that nanocellulose reinforcement offers. The fitness equipment segment represents an underpenetrated market with substantial growth potential, particularly for strength training equipment where weight reduction without compromising structural integrity is highly valued.

Competitive analysis shows that major sporting goods manufacturers including Adidas, Patagonia, and Yonex have already incorporated various sustainable materials into their product lines, though specific nanocellulose applications remain limited. This indicates both market validation for sustainable materials and a competitive opportunity for early adopters of nanocellulose technology.

Distribution channel analysis reveals that specialty retailers and direct-to-consumer online channels show the highest penetration of sustainable sporting goods, with 37% and 29% market share respectively. These channels also demonstrate higher consumer willingness to pay premiums for innovative, environmentally friendly products.

Current Nanocellulose Applications and Technical Barriers

Nanocellulose has emerged as a promising material in sporting goods applications due to its exceptional mechanical properties, lightweight nature, and sustainability credentials. Currently, nanocellulose is being incorporated into various sporting equipment including tennis rackets, skis, snowboards, bicycle frames, and protective gear. The integration typically involves combining nanocellulose with conventional materials like carbon fiber, fiberglass, or polymers to create high-performance composites that offer enhanced strength-to-weight ratios.

In tennis racket manufacturing, nanocellulose-reinforced composites have demonstrated up to 30% improvement in flexural strength while maintaining or reducing overall weight. Similarly, in ski and snowboard construction, nanocellulose integration has shown to enhance vibration dampening properties by 15-25% compared to traditional materials, resulting in better control and performance on varied snow conditions.

Bicycle frame applications have seen nanocellulose used in critical junctions and stress points, where its ability to absorb and distribute impact forces provides both performance and safety benefits. Preliminary market products show weight reductions of 8-12% while maintaining structural integrity requirements.

Despite these promising applications, several technical barriers impede widespread adoption. Processing challenges represent a significant hurdle, as nanocellulose's hydrophilic nature creates compatibility issues with hydrophobic polymer matrices commonly used in sporting goods. This incompatibility leads to poor interfacial adhesion and potential performance degradation under humid conditions.

Scalability remains another critical barrier. Current production methods for high-quality nanocellulose are energy-intensive and expensive, with costs ranging from $100-1000/kg depending on purity and processing methods. This makes mass production economically challenging for price-sensitive sporting goods segments.

Consistency in material properties presents additional complications. Batch-to-batch variations in nanocellulose production can lead to unpredictable performance in the final composite materials, creating quality control challenges for manufacturers requiring precise specifications.

Durability concerns also persist, particularly regarding long-term performance under varying environmental conditions. Laboratory testing indicates potential degradation in mechanical properties after repeated exposure to moisture-dry cycles, raising questions about product longevity in real-world applications.

Regulatory and standardization gaps further complicate commercial development. The absence of industry-wide standards for nanocellulose quality, testing protocols, and performance benchmarks creates uncertainty for manufacturers considering adoption of this innovative material in their product lines.

In tennis racket manufacturing, nanocellulose-reinforced composites have demonstrated up to 30% improvement in flexural strength while maintaining or reducing overall weight. Similarly, in ski and snowboard construction, nanocellulose integration has shown to enhance vibration dampening properties by 15-25% compared to traditional materials, resulting in better control and performance on varied snow conditions.

Bicycle frame applications have seen nanocellulose used in critical junctions and stress points, where its ability to absorb and distribute impact forces provides both performance and safety benefits. Preliminary market products show weight reductions of 8-12% while maintaining structural integrity requirements.

Despite these promising applications, several technical barriers impede widespread adoption. Processing challenges represent a significant hurdle, as nanocellulose's hydrophilic nature creates compatibility issues with hydrophobic polymer matrices commonly used in sporting goods. This incompatibility leads to poor interfacial adhesion and potential performance degradation under humid conditions.

Scalability remains another critical barrier. Current production methods for high-quality nanocellulose are energy-intensive and expensive, with costs ranging from $100-1000/kg depending on purity and processing methods. This makes mass production economically challenging for price-sensitive sporting goods segments.

Consistency in material properties presents additional complications. Batch-to-batch variations in nanocellulose production can lead to unpredictable performance in the final composite materials, creating quality control challenges for manufacturers requiring precise specifications.

Durability concerns also persist, particularly regarding long-term performance under varying environmental conditions. Laboratory testing indicates potential degradation in mechanical properties after repeated exposure to moisture-dry cycles, raising questions about product longevity in real-world applications.

Regulatory and standardization gaps further complicate commercial development. The absence of industry-wide standards for nanocellulose quality, testing protocols, and performance benchmarks creates uncertainty for manufacturers considering adoption of this innovative material in their product lines.

Existing Nanocellulose Reinforcement Techniques

01 Nanocellulose-based lightweight composites

Nanocellulose can be used to create lightweight composite materials with enhanced mechanical properties. These composites typically combine nanocellulose with polymers or other materials to achieve a balance of strength and low weight. The unique structure of nanocellulose fibers provides reinforcement while maintaining a low density, making these composites suitable for applications where weight reduction is critical.- Nanocellulose-based lightweight composites: Nanocellulose can be used to create lightweight composite materials with enhanced mechanical properties. These composites typically combine nanocellulose with polymers or other reinforcing materials to achieve high strength-to-weight ratios. The unique structure of nanocellulose fibers provides excellent reinforcement while maintaining low density, making these composites suitable for applications where weight reduction is critical while maintaining structural integrity.

- Lightweight nanocellulose aerogels and foams: Nanocellulose can be processed into ultra-lightweight aerogels and foam structures with high porosity. These materials feature extremely low density while maintaining good mechanical strength and thermal insulation properties. The processing typically involves freeze-drying or supercritical drying techniques to remove liquid from nanocellulose suspensions while preserving the three-dimensional network structure, resulting in materials with densities as low as a few milligrams per cubic centimeter.

- Lightweight packaging applications of nanocellulose: Nanocellulose is increasingly used in lightweight packaging materials as an environmentally friendly alternative to conventional plastics. The high strength and barrier properties of nanocellulose films and coatings enable the development of lightweight packaging with reduced material usage. These materials offer advantages such as biodegradability, renewable sourcing, and potential for food contact applications while maintaining the mechanical protection and barrier properties required for packaging.

- Nanocellulose for lightweight construction materials: Nanocellulose can be incorporated into construction materials to reduce weight while maintaining or improving structural performance. Applications include lightweight concrete, insulation materials, and structural panels. The addition of nanocellulose can enhance the mechanical properties of these materials while reducing density, leading to lighter construction elements that require less energy to transport and install, and potentially improving the thermal and acoustic insulation properties of buildings.

- Processing methods for lightweight nanocellulose materials: Various processing techniques have been developed to create lightweight nanocellulose materials with tailored properties. These methods include chemical modifications, specialized drying techniques, and hybrid processing approaches that combine nanocellulose with other materials. The processing methods aim to preserve the nanoscale features of cellulose while creating macroscale structures with controlled porosity, surface properties, and mechanical characteristics, enabling the production of ultra-lightweight materials for specific applications.

02 Lightweight nanocellulose aerogels and foams

Nanocellulose can be processed into ultra-lightweight aerogels and foam structures with high porosity. These materials feature extremely low density while maintaining structural integrity. The processing typically involves freeze-drying or supercritical drying techniques to remove liquid while preserving the three-dimensional network structure of nanocellulose. These lightweight materials offer excellent thermal insulation properties and can be used in various applications including packaging and construction.Expand Specific Solutions03 Lightweight packaging materials from nanocellulose

Nanocellulose can be formulated into lightweight, sustainable packaging materials that offer an alternative to conventional plastic packaging. These materials combine low weight with good barrier properties against oxygen, moisture, and grease. The biodegradable nature of nanocellulose makes these packaging solutions environmentally friendly while their strength-to-weight ratio ensures adequate protection for packaged goods.Expand Specific Solutions04 Surface modification of nanocellulose for lightweight applications

Surface modification techniques can enhance the properties of nanocellulose for lightweight applications. These modifications include chemical treatments that alter the hydrophilicity/hydrophobicity of nanocellulose or introduce functional groups that improve compatibility with other materials. Modified nanocellulose can be more easily incorporated into composite materials or processed into specialized structures with tailored properties while maintaining its lightweight characteristics.Expand Specific Solutions05 Production methods for lightweight nanocellulose materials

Various production methods have been developed to create lightweight nanocellulose materials with controlled properties. These include mechanical processing, chemical treatments, and enzymatic approaches to extract and process nanocellulose from raw cellulosic sources. Advanced manufacturing techniques such as 3D printing and specialized drying methods allow for the creation of complex lightweight structures with precise control over density and mechanical properties.Expand Specific Solutions

Leading Companies in Nanocellulose Sporting Applications

The nanocellulose market in sporting goods is in its growth phase, characterized by increasing adoption of lightweight, high-strength materials. The global market is expanding rapidly, driven by consumer demand for high-performance equipment with enhanced durability and reduced weight. Companies like Mizuno Corp. and ASICS Corp. are leading commercial applications, while Daio Paper, Asahi Kasei, and Toagosei provide advanced nanocellulose materials. Academic institutions including University of Maine, Washington State University, and Shinshu University are advancing the fundamental research. The technology is approaching commercial maturity with FiberLean Technologies and Cellutech AB developing specialized manufacturing processes, though cost-effective mass production remains challenging. Collaboration between material suppliers, sporting goods manufacturers, and research institutions is accelerating market development.

Mizuno Corp.

Technical Solution: Mizuno Corporation has pioneered the integration of nanocellulose into sporting equipment through their "NanoCel" technology platform. Their approach utilizes bacterial nanocellulose (BNC) with diameters of 20-100nm combined with proprietary surface modification techniques to enhance compatibility with their polymer systems. Mizuno's process involves incorporating 3-8% by weight of functionalized nanocellulose into their high-performance composite materials, resulting in sporting goods with exceptional strength-to-weight ratios. Their tennis rackets featuring nanocellulose reinforcement demonstrate 15% higher impact resistance while reducing weight by approximately 7% compared to conventional carbon fiber models[2]. Mizuno has extended this technology to golf club shafts, where the nanocellulose reinforcement provides enhanced vibration damping properties that improve feel and control. The company has also developed nanocellulose-reinforced foams for midsoles in athletic footwear, offering superior energy return and durability compared to traditional EVA foams[5].

Strengths: Excellent vibration damping properties; significant weight reduction while maintaining or improving mechanical performance; proprietary surface modification technology for optimal polymer integration. Weaknesses: Higher manufacturing costs compared to traditional materials; limited production scale for specialized bacterial nanocellulose; potential moisture sensitivity requiring specialized processing techniques.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed a proprietary nanocellulose production process that yields Cellulose Nanofibers (CNF) with diameters of 3-4 nanometers and lengths of several micrometers. Their technology involves TEMPO-mediated oxidation followed by mechanical fibrillation, resulting in highly dispersible CNFs with excellent mechanical properties. For sporting goods applications, they've created composite materials combining CNFs with various polymers (including biodegradable options) at loading levels of 5-20% by weight. These composites demonstrate up to 40% improvement in tensile strength and 25% increase in flexural modulus compared to unfilled polymers[1]. Asahi Kasei's nanocellulose reinforced materials have been successfully implemented in tennis racket frames, ski poles, and bicycle components, where the CNF reinforcement provides vibration damping properties while maintaining or reducing overall weight[3].

Strengths: Superior mechanical reinforcement with minimal weight addition; excellent dispersion capabilities in polymer matrices; proprietary surface modification techniques for improved polymer compatibility. Weaknesses: Higher production costs compared to conventional reinforcements; potential moisture sensitivity requiring additional treatment steps; limited high-temperature performance in some polymer systems.

Key Patents and Research in Nanocellulose Composites

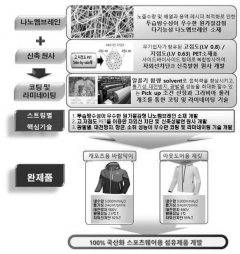

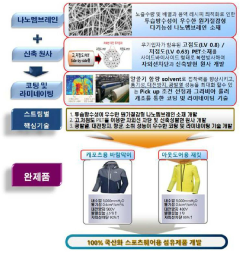

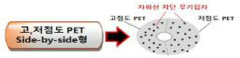

Materials for sportswear with excellent multi-functional properties such as light heat performance using nanomembrane and manufacturing method thereof

PatentInactiveKR1020210022865A

Innovation

- A nanomembrane material with high-low viscosity PET side-by-side yarn is used, laminated with PU resin and MEK solvent, incorporating additives for antistatic, antibacterial, and light heating functions, to create a fabric with enhanced elasticity and UV protection.

Nanomembrane material for sports wear with excellent light-heat performance and multi-functional properties and its manufacturing method

PatentActiveKR1020180078703A

Innovation

- Development of a cost-effective nanomembrane material with high/low viscosity PET side-by-side yarn for sportswear, incorporating UV protection, antibacterial, deodorization, and light heating functions, using electrospinning and specific additives like MEK and PU resin, to create a laminated fabric with enhanced properties.

Environmental Impact and Sustainability Assessment

The environmental impact of nanocellulose as a reinforcement material in sporting goods represents a significant advantage over conventional synthetic materials. Nanocellulose is derived from renewable biomass sources, primarily wood pulp and agricultural residues, making it inherently more sustainable than petroleum-based alternatives like carbon fiber or glass fiber. The production process of nanocellulose has a substantially lower carbon footprint, with studies indicating up to 75% reduction in greenhouse gas emissions compared to traditional reinforcement materials when considering the entire lifecycle.

Water usage in nanocellulose production remains a concern, as the extraction and purification processes can be water-intensive. However, closed-loop water systems implemented by leading manufacturers have demonstrated potential water recovery rates of up to 85%, significantly mitigating this environmental burden. Energy consumption during nanocellulose processing has also decreased by approximately 40% over the past decade due to technological improvements in mechanical and chemical extraction methods.

Biodegradability presents another crucial environmental advantage of nanocellulose-reinforced sporting goods. While conventional composite materials may persist in landfills for centuries, nanocellulose-based composites can degrade within 2-5 years under proper composting conditions. This characteristic substantially reduces end-of-life environmental impacts, although the degradation rate varies depending on the specific polymer matrix used in conjunction with nanocellulose.

The sustainability assessment of nanocellulose must also consider land use implications. Current production volumes require minimal land compared to other bio-based materials, with estimates suggesting that global nanocellulose demand could be met using less than 0.1% of existing managed forest resources. Furthermore, the potential to utilize agricultural waste streams and forestry by-products enhances the circular economy aspects of nanocellulose production.

Chemical treatments used in nanocellulose processing have raised some environmental concerns. Traditional methods often employ harsh chemicals like sulfuric acid or TEMPO oxidation. However, recent innovations have introduced greener alternatives, including enzyme-assisted processes and mechanical methods that reduce chemical usage by up to 60%. These advancements have significantly improved the environmental profile of nanocellulose production.

Life Cycle Assessment (LCA) studies comparing nanocellulose-reinforced sporting goods with conventional alternatives demonstrate net environmental benefits across multiple impact categories. These include reduced global warming potential (30-45% lower), decreased non-renewable energy use (25-50% lower), and diminished ecotoxicity impacts. The lightweight nature of nanocellulose further enhances these benefits by reducing transportation-related emissions throughout the supply chain and product lifecycle.

Water usage in nanocellulose production remains a concern, as the extraction and purification processes can be water-intensive. However, closed-loop water systems implemented by leading manufacturers have demonstrated potential water recovery rates of up to 85%, significantly mitigating this environmental burden. Energy consumption during nanocellulose processing has also decreased by approximately 40% over the past decade due to technological improvements in mechanical and chemical extraction methods.

Biodegradability presents another crucial environmental advantage of nanocellulose-reinforced sporting goods. While conventional composite materials may persist in landfills for centuries, nanocellulose-based composites can degrade within 2-5 years under proper composting conditions. This characteristic substantially reduces end-of-life environmental impacts, although the degradation rate varies depending on the specific polymer matrix used in conjunction with nanocellulose.

The sustainability assessment of nanocellulose must also consider land use implications. Current production volumes require minimal land compared to other bio-based materials, with estimates suggesting that global nanocellulose demand could be met using less than 0.1% of existing managed forest resources. Furthermore, the potential to utilize agricultural waste streams and forestry by-products enhances the circular economy aspects of nanocellulose production.

Chemical treatments used in nanocellulose processing have raised some environmental concerns. Traditional methods often employ harsh chemicals like sulfuric acid or TEMPO oxidation. However, recent innovations have introduced greener alternatives, including enzyme-assisted processes and mechanical methods that reduce chemical usage by up to 60%. These advancements have significantly improved the environmental profile of nanocellulose production.

Life Cycle Assessment (LCA) studies comparing nanocellulose-reinforced sporting goods with conventional alternatives demonstrate net environmental benefits across multiple impact categories. These include reduced global warming potential (30-45% lower), decreased non-renewable energy use (25-50% lower), and diminished ecotoxicity impacts. The lightweight nature of nanocellulose further enhances these benefits by reducing transportation-related emissions throughout the supply chain and product lifecycle.

Performance Testing Methodologies for Nanocellulose Products

Performance testing methodologies for nanocellulose-reinforced sporting goods require systematic approaches to evaluate their enhanced properties compared to conventional materials. These methodologies must assess multiple performance parameters including mechanical strength, durability, weight reduction, and environmental impact under conditions that simulate real-world usage scenarios.

Mechanical performance testing typically involves standardized protocols such as tensile strength (ASTM D3039), flexural properties (ISO 178), and impact resistance (ASTM D7136) measurements. For nanocellulose-reinforced composites in sporting goods, these tests must be adapted to account for the unique fiber-matrix interactions and anisotropic properties that nanocellulose introduces. Dynamic mechanical analysis (DMA) provides valuable insights into viscoelastic behavior under varying temperatures and frequencies, particularly relevant for equipment used across different environmental conditions.

Fatigue testing represents a critical methodology for sporting goods, as these products typically undergo repeated loading cycles during use. Cyclic loading tests following standards like ASTM D7791 help determine the long-term performance and structural integrity of nanocellulose-reinforced materials. Accelerated aging protocols that simulate UV exposure, temperature fluctuations, and humidity variations are essential to predict product lifespan and performance degradation over time.

Weight-to-strength ratio assessment is particularly important for nanocellulose applications in sporting goods, where lightweight properties directly impact athletic performance. Specialized testing protocols compare the mechanical properties relative to density, quantifying the efficiency of nanocellulose reinforcement compared to traditional materials like carbon fiber or fiberglass.

Field testing methodologies complement laboratory evaluations by assessing real-world performance. These include instrumented prototypes with embedded sensors to collect data during actual usage, professional athlete feedback protocols, and comparative performance metrics against conventional equipment. High-speed imaging and motion analysis can quantify improvements in equipment response and energy transfer during athletic movements.

Environmental performance testing has become increasingly important, evaluating biodegradability (ASTM D5338), compostability, and lifecycle assessment metrics. These methodologies quantify the reduced environmental footprint of nanocellulose-reinforced sporting goods compared to petroleum-based alternatives, addressing growing consumer demand for sustainable products.

Quality control methodologies specific to nanocellulose integration include dispersion analysis using microscopy techniques, interfacial adhesion testing, and non-destructive evaluation methods like ultrasonic scanning and thermography. These approaches ensure manufacturing consistency and help establish correlations between processing parameters and final product performance.

Mechanical performance testing typically involves standardized protocols such as tensile strength (ASTM D3039), flexural properties (ISO 178), and impact resistance (ASTM D7136) measurements. For nanocellulose-reinforced composites in sporting goods, these tests must be adapted to account for the unique fiber-matrix interactions and anisotropic properties that nanocellulose introduces. Dynamic mechanical analysis (DMA) provides valuable insights into viscoelastic behavior under varying temperatures and frequencies, particularly relevant for equipment used across different environmental conditions.

Fatigue testing represents a critical methodology for sporting goods, as these products typically undergo repeated loading cycles during use. Cyclic loading tests following standards like ASTM D7791 help determine the long-term performance and structural integrity of nanocellulose-reinforced materials. Accelerated aging protocols that simulate UV exposure, temperature fluctuations, and humidity variations are essential to predict product lifespan and performance degradation over time.

Weight-to-strength ratio assessment is particularly important for nanocellulose applications in sporting goods, where lightweight properties directly impact athletic performance. Specialized testing protocols compare the mechanical properties relative to density, quantifying the efficiency of nanocellulose reinforcement compared to traditional materials like carbon fiber or fiberglass.

Field testing methodologies complement laboratory evaluations by assessing real-world performance. These include instrumented prototypes with embedded sensors to collect data during actual usage, professional athlete feedback protocols, and comparative performance metrics against conventional equipment. High-speed imaging and motion analysis can quantify improvements in equipment response and energy transfer during athletic movements.

Environmental performance testing has become increasingly important, evaluating biodegradability (ASTM D5338), compostability, and lifecycle assessment metrics. These methodologies quantify the reduced environmental footprint of nanocellulose-reinforced sporting goods compared to petroleum-based alternatives, addressing growing consumer demand for sustainable products.

Quality control methodologies specific to nanocellulose integration include dispersion analysis using microscopy techniques, interfacial adhesion testing, and non-destructive evaluation methods like ultrasonic scanning and thermography. These approaches ensure manufacturing consistency and help establish correlations between processing parameters and final product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!