Nichrome Wire Applications in Renewable Water Heating Solutions

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution

Nichrome wire has undergone significant evolution since its inception in the early 20th century, particularly in its applications for renewable water heating solutions. Initially developed as a resistance heating element, nichrome wire's unique properties of high electrical resistance and excellent heat tolerance quickly made it a staple in various heating applications.

In the 1920s and 1930s, nichrome wire began to be used in domestic appliances, including early electric water heaters. These initial applications were relatively inefficient and energy-intensive, but they laid the groundwork for future innovations. The post-World War II era saw a surge in domestic appliance development, leading to more refined uses of nichrome wire in water heating systems.

The 1970s energy crisis sparked renewed interest in energy-efficient technologies, including solar water heating. This period marked a turning point for nichrome wire in renewable water heating applications. Engineers began exploring ways to integrate nichrome wire into solar thermal systems, using it as a backup heating element for cloudy days or periods of high demand.

The 1980s and 1990s witnessed advancements in nichrome wire composition and manufacturing techniques. Improved alloys with higher nickel content enhanced the wire's durability and heat resistance, making it more suitable for long-term use in water heating systems. This period also saw the development of more precise temperature control mechanisms, allowing for better energy management in nichrome wire-based heating elements.

The turn of the millennium brought about a focus on smart and connected technologies. Nichrome wire heating elements were integrated with digital controls and sensors, enabling more efficient operation and remote management of water heating systems. This integration allowed for dynamic adjustment of heating patterns based on usage habits and energy availability, particularly beneficial for renewable energy systems with variable output.

Recent years have seen a push towards miniaturization and increased efficiency. Advanced manufacturing techniques have allowed for the production of thinner, more responsive nichrome wire elements. These innovations have led to the development of on-demand water heating systems that can quickly heat water at the point of use, reducing energy waste associated with storing large volumes of hot water.

In the context of renewable water heating solutions, nichrome wire has found new applications in hybrid systems. These systems combine solar thermal collectors with electric heating elements, using nichrome wire to provide supplementary heating when solar energy is insufficient. The wire's rapid heating capability and precise control make it an ideal complement to renewable energy sources, ensuring consistent hot water supply regardless of weather conditions.

Looking forward, ongoing research is focused on further improving the energy efficiency and responsiveness of nichrome wire in water heating applications. This includes exploring new alloy compositions, optimizing wire geometries for better heat distribution, and developing more sophisticated control algorithms to maximize the synergy between nichrome wire heating elements and renewable energy sources.

In the 1920s and 1930s, nichrome wire began to be used in domestic appliances, including early electric water heaters. These initial applications were relatively inefficient and energy-intensive, but they laid the groundwork for future innovations. The post-World War II era saw a surge in domestic appliance development, leading to more refined uses of nichrome wire in water heating systems.

The 1970s energy crisis sparked renewed interest in energy-efficient technologies, including solar water heating. This period marked a turning point for nichrome wire in renewable water heating applications. Engineers began exploring ways to integrate nichrome wire into solar thermal systems, using it as a backup heating element for cloudy days or periods of high demand.

The 1980s and 1990s witnessed advancements in nichrome wire composition and manufacturing techniques. Improved alloys with higher nickel content enhanced the wire's durability and heat resistance, making it more suitable for long-term use in water heating systems. This period also saw the development of more precise temperature control mechanisms, allowing for better energy management in nichrome wire-based heating elements.

The turn of the millennium brought about a focus on smart and connected technologies. Nichrome wire heating elements were integrated with digital controls and sensors, enabling more efficient operation and remote management of water heating systems. This integration allowed for dynamic adjustment of heating patterns based on usage habits and energy availability, particularly beneficial for renewable energy systems with variable output.

Recent years have seen a push towards miniaturization and increased efficiency. Advanced manufacturing techniques have allowed for the production of thinner, more responsive nichrome wire elements. These innovations have led to the development of on-demand water heating systems that can quickly heat water at the point of use, reducing energy waste associated with storing large volumes of hot water.

In the context of renewable water heating solutions, nichrome wire has found new applications in hybrid systems. These systems combine solar thermal collectors with electric heating elements, using nichrome wire to provide supplementary heating when solar energy is insufficient. The wire's rapid heating capability and precise control make it an ideal complement to renewable energy sources, ensuring consistent hot water supply regardless of weather conditions.

Looking forward, ongoing research is focused on further improving the energy efficiency and responsiveness of nichrome wire in water heating applications. This includes exploring new alloy compositions, optimizing wire geometries for better heat distribution, and developing more sophisticated control algorithms to maximize the synergy between nichrome wire heating elements and renewable energy sources.

Renewable Water Heating Market

The renewable water heating market has experienced significant growth in recent years, driven by increasing environmental awareness, government incentives, and the rising cost of traditional energy sources. This market segment encompasses various technologies, including solar thermal systems, heat pumps, and geothermal solutions, all aimed at providing sustainable and cost-effective water heating for residential, commercial, and industrial applications.

Global market trends indicate a steady increase in the adoption of renewable water heating systems. The market size was valued at approximately $9.3 billion in 2020 and is projected to reach $13.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth is primarily attributed to the increasing focus on reducing carbon emissions and the implementation of stringent energy efficiency regulations across various countries.

Regionally, Europe has been at the forefront of renewable water heating adoption, with countries like Germany, France, and Spain leading the way. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid urbanization, increasing disposable income, and government initiatives promoting clean energy solutions in countries like China and India.

The residential sector currently dominates the market, accounting for over 60% of the total market share. However, the commercial and industrial sectors are expected to show significant growth potential as businesses increasingly prioritize sustainability and energy efficiency in their operations.

Key market drivers include the rising awareness of environmental issues, the need for energy independence, and the long-term cost savings associated with renewable water heating systems. Government incentives, such as tax credits and rebates, have also played a crucial role in promoting the adoption of these technologies.

Despite the positive outlook, the market faces several challenges. High initial installation costs, particularly for solar thermal systems, remain a significant barrier to widespread adoption. Additionally, the intermittent nature of some renewable energy sources and the need for backup systems can impact the overall efficiency and reliability of these solutions.

Technological advancements are expected to address some of these challenges, with innovations focusing on improving energy storage capabilities, enhancing system efficiency, and reducing installation costs. The integration of smart technologies and IoT-enabled devices is also expected to drive market growth by offering improved control and monitoring capabilities to end-users.

In conclusion, the renewable water heating market presents significant opportunities for growth and innovation. As technology continues to evolve and costs decrease, the adoption of these sustainable solutions is expected to accelerate, contributing to global efforts in reducing carbon emissions and promoting energy efficiency.

Global market trends indicate a steady increase in the adoption of renewable water heating systems. The market size was valued at approximately $9.3 billion in 2020 and is projected to reach $13.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth is primarily attributed to the increasing focus on reducing carbon emissions and the implementation of stringent energy efficiency regulations across various countries.

Regionally, Europe has been at the forefront of renewable water heating adoption, with countries like Germany, France, and Spain leading the way. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid urbanization, increasing disposable income, and government initiatives promoting clean energy solutions in countries like China and India.

The residential sector currently dominates the market, accounting for over 60% of the total market share. However, the commercial and industrial sectors are expected to show significant growth potential as businesses increasingly prioritize sustainability and energy efficiency in their operations.

Key market drivers include the rising awareness of environmental issues, the need for energy independence, and the long-term cost savings associated with renewable water heating systems. Government incentives, such as tax credits and rebates, have also played a crucial role in promoting the adoption of these technologies.

Despite the positive outlook, the market faces several challenges. High initial installation costs, particularly for solar thermal systems, remain a significant barrier to widespread adoption. Additionally, the intermittent nature of some renewable energy sources and the need for backup systems can impact the overall efficiency and reliability of these solutions.

Technological advancements are expected to address some of these challenges, with innovations focusing on improving energy storage capabilities, enhancing system efficiency, and reducing installation costs. The integration of smart technologies and IoT-enabled devices is also expected to drive market growth by offering improved control and monitoring capabilities to end-users.

In conclusion, the renewable water heating market presents significant opportunities for growth and innovation. As technology continues to evolve and costs decrease, the adoption of these sustainable solutions is expected to accelerate, contributing to global efforts in reducing carbon emissions and promoting energy efficiency.

Nichrome Wire Challenges

Despite the widespread use of nichrome wire in renewable water heating solutions, several challenges persist in its application. One of the primary issues is the gradual degradation of the wire over time due to repeated heating and cooling cycles. This thermal fatigue can lead to reduced efficiency and potential failure of the heating element, necessitating frequent replacements and increasing maintenance costs.

Another significant challenge is the optimization of power consumption. While nichrome wire is known for its high electrical resistance, which makes it suitable for heating applications, achieving the right balance between power input and heat output remains a complex task. This is particularly crucial in renewable energy systems where energy efficiency is paramount.

Corrosion resistance is also a concern, especially in environments with high humidity or when the wire comes into direct contact with water. Although nichrome has good corrosion resistance properties, prolonged exposure to certain conditions can still lead to degradation, affecting the longevity and performance of the heating system.

The uniformity of heat distribution presents another challenge. Ensuring even heating across the entire surface area of the water heating system can be difficult, potentially leading to hot spots or cold zones that reduce overall efficiency and user comfort.

Manufacturing consistency is also a critical issue. Producing nichrome wire with uniform composition and properties across different batches can be challenging, potentially leading to variations in performance and lifespan of heating elements in different units.

Environmental concerns are increasingly coming to the forefront. While nichrome wire itself is relatively inert, the mining and processing of its constituent metals (nickel and chromium) can have significant environmental impacts. This raises questions about the long-term sustainability of nichrome wire production in the context of renewable energy solutions.

Lastly, the cost factor remains a challenge. Although nichrome wire is widely available, the fluctuating prices of nickel and chromium in the global market can impact the overall cost of renewable water heating systems, potentially affecting their adoption rates in price-sensitive markets.

Another significant challenge is the optimization of power consumption. While nichrome wire is known for its high electrical resistance, which makes it suitable for heating applications, achieving the right balance between power input and heat output remains a complex task. This is particularly crucial in renewable energy systems where energy efficiency is paramount.

Corrosion resistance is also a concern, especially in environments with high humidity or when the wire comes into direct contact with water. Although nichrome has good corrosion resistance properties, prolonged exposure to certain conditions can still lead to degradation, affecting the longevity and performance of the heating system.

The uniformity of heat distribution presents another challenge. Ensuring even heating across the entire surface area of the water heating system can be difficult, potentially leading to hot spots or cold zones that reduce overall efficiency and user comfort.

Manufacturing consistency is also a critical issue. Producing nichrome wire with uniform composition and properties across different batches can be challenging, potentially leading to variations in performance and lifespan of heating elements in different units.

Environmental concerns are increasingly coming to the forefront. While nichrome wire itself is relatively inert, the mining and processing of its constituent metals (nickel and chromium) can have significant environmental impacts. This raises questions about the long-term sustainability of nichrome wire production in the context of renewable energy solutions.

Lastly, the cost factor remains a challenge. Although nichrome wire is widely available, the fluctuating prices of nickel and chromium in the global market can impact the overall cost of renewable water heating systems, potentially affecting their adoption rates in price-sensitive markets.

Current Nichrome Solutions

01 Composition and properties of nichrome wire

Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and heat resistance, making it suitable for various applications in heating elements and electrical devices. The specific composition and properties of nichrome wire can be tailored to meet different requirements for temperature resistance and electrical conductivity.- Composition and properties of nichrome wire: Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and heat resistance, making it suitable for various applications in heating elements and electrical devices. The specific composition and properties of nichrome wire can be tailored to meet different requirements for temperature resistance and electrical conductivity.

- Applications in heating elements: Nichrome wire is widely used in heating elements due to its high resistance and ability to withstand high temperatures. It is commonly employed in electric heaters, toasters, hair dryers, and other appliances that require controlled heating. The wire can be shaped into coils or other forms to optimize heat distribution and efficiency in various heating devices.

- Use in sensors and measurement devices: Nichrome wire finds applications in sensors and measurement devices, particularly those involving temperature sensing or resistance-based measurements. Its stable electrical properties and temperature coefficient make it suitable for use in thermocouples, strain gauges, and other precision instruments where accurate and consistent measurements are crucial.

- Manufacturing processes and techniques: Various manufacturing processes and techniques are employed to produce nichrome wire with specific characteristics. These may include drawing, annealing, and surface treatments to achieve desired diameter, tensile strength, and surface properties. Advanced manufacturing methods can enhance the wire's performance and longevity in different applications.

- Innovations in nichrome wire technology: Ongoing research and development in nichrome wire technology focus on improving its properties and expanding its applications. This includes developing new alloy compositions, enhancing corrosion resistance, and exploring novel manufacturing techniques. Innovations aim to extend the wire's lifespan, increase its efficiency, and adapt it for use in emerging technologies and industries.

02 Applications in heating elements

Nichrome wire is widely used in heating elements for various appliances and industrial equipment. Its high resistance to heat and electricity makes it ideal for generating controlled heat in devices such as electric heaters, ovens, and hair dryers. The wire can be shaped into coils or other forms to optimize heat distribution and efficiency.Expand Specific Solutions03 Use in electrical resistors and sensors

Nichrome wire is utilized in the manufacturing of precision electrical resistors and sensors. Its stable electrical properties and temperature coefficient make it suitable for creating accurate and reliable components for electronic circuits and measurement devices. These applications often require careful control of wire diameter and composition to achieve desired resistance values.Expand Specific Solutions04 Fabrication techniques for nichrome wire

Various fabrication techniques are employed to produce nichrome wire with specific characteristics. These may include drawing, annealing, and surface treatment processes. Advanced manufacturing methods can be used to create ultra-thin wires or specialized shapes for specific applications, such as in microelectronics or aerospace industries.Expand Specific Solutions05 Protective coatings and insulation for nichrome wire

To enhance durability and performance, nichrome wire can be coated with protective materials or insulated. These coatings may improve corrosion resistance, electrical insulation, or thermal properties. Insulation techniques can include the application of ceramic or polymer materials, allowing the wire to be used in more diverse environments and applications.Expand Specific Solutions

Key Nichrome Manufacturers

The market for nichrome wire applications in renewable water heating solutions is in a growth phase, driven by increasing demand for energy-efficient technologies. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like Heraeus Precious Metals and Hon Hai Precision Industry leading innovation. These firms, along with others like Panasonic and DENSO, are developing more efficient and cost-effective solutions, improving the technology's maturity. Universities such as Tongji and Shanghai University are contributing to research and development, further accelerating technological progress in this sector.

Heraeus Precious Metals GmbH & Co. KG (New)

Technical Solution: Heraeus has developed advanced nichrome wire solutions for renewable water heating applications. Their technology focuses on optimizing the electrical resistance and thermal conductivity of nichrome alloys. They have implemented a proprietary coating process that enhances the wire's corrosion resistance and longevity in water heating environments[1]. Heraeus' nichrome wires are designed to operate efficiently at high temperatures, typically ranging from 800°C to 1200°C, which is crucial for rapid water heating[2]. The company has also introduced a nano-structured surface treatment that improves heat transfer efficiency by up to 15% compared to conventional nichrome wires[3].

Strengths: Superior corrosion resistance, high-temperature performance, and improved heat transfer efficiency. Weaknesses: Potentially higher production costs due to advanced manufacturing processes and materials.

Panasonic Holdings Corp.

Technical Solution: Panasonic has integrated nichrome wire technology into their renewable water heating solutions, focusing on energy efficiency and durability. Their approach involves using precision-wound nichrome coils with variable pitch to optimize heat distribution in water tanks[4]. Panasonic's nichrome elements are designed to work in conjunction with heat pump systems, creating hybrid water heaters that are up to 3.5 times more efficient than standard electric models[5]. They have also developed a self-cleaning mechanism that uses the thermal expansion properties of nichrome to shed mineral deposits, extending the lifespan of the heating elements[6]. Additionally, Panasonic incorporates smart controls that adjust the nichrome wire's power output based on usage patterns and renewable energy availability, further enhancing energy efficiency.

Strengths: High energy efficiency, integration with heat pump technology, and self-cleaning capabilities. Weaknesses: Complexity of hybrid systems may lead to higher initial costs and potential maintenance challenges.

Nichrome Wire Innovations

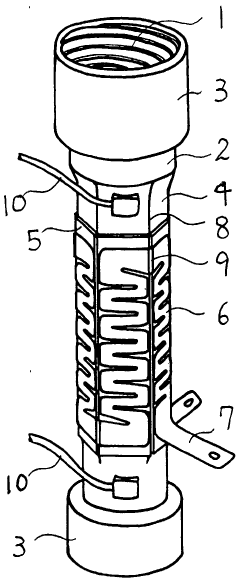

Electric water heater, liquid heater, steam generator

PatentWO2002090836A1

Innovation

- A heater line formed from a thin metal plate with high electrical resistance, sandwiched between a thermally conductive heating wall made of copper or silver, and an insulator like aluminum nitride, allowing immediate heat transfer and rapid heating of water or liquids.

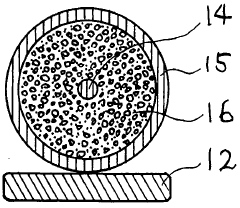

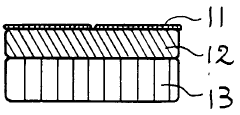

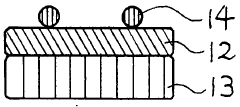

Electric heater and heat exchanger employing the same

PatentWO1985000084A1

Innovation

- A bare nichrome wire is immersed in silicone oil, which provides rapid temperature rise, excellent insulation, oxidation resistance, and durability, preventing oxidation and ensuring safety by using silicone oil with good thermal and electrical properties.

Energy Efficiency Standards

Energy efficiency standards play a crucial role in the development and implementation of renewable water heating solutions utilizing Nichrome wire applications. These standards serve as benchmarks for manufacturers, installers, and consumers, ensuring that water heating systems meet specific performance criteria and contribute to overall energy conservation efforts.

In the context of Nichrome wire applications for renewable water heating, energy efficiency standards typically focus on several key aspects. Firstly, they address the thermal efficiency of the heating element, which is directly related to the properties of Nichrome wire. Standards may specify minimum efficiency ratings for the conversion of electrical energy into heat, taking into account factors such as wire gauge, resistance, and power density.

Additionally, energy efficiency standards often encompass the insulation requirements for water heaters. This is particularly relevant for Nichrome wire applications, as proper insulation helps minimize heat loss and maintain water temperature, thereby reducing energy consumption. Standards may dictate minimum R-values for insulation materials and specify design requirements to minimize thermal bridging.

Another important aspect covered by energy efficiency standards is the control systems used in renewable water heating solutions. For Nichrome wire applications, this may include requirements for precise temperature regulation, programmable timers, and smart controls that optimize heating cycles based on usage patterns. These standards aim to ensure that water heaters operate only when necessary and maintain desired temperatures efficiently.

Energy efficiency standards also address the overall system performance, including factors such as standby heat loss, recovery efficiency, and annual energy consumption. For Nichrome wire-based water heaters, these standards may set maximum allowable energy consumption levels based on the heater's capacity and intended use.

Furthermore, energy efficiency standards often incorporate labeling requirements, such as the Energy Star certification in the United States. These labels provide consumers with clear information about the energy performance of water heating systems, enabling informed decision-making and promoting the adoption of more efficient technologies.

It is worth noting that energy efficiency standards for renewable water heating solutions are continually evolving to keep pace with technological advancements. As Nichrome wire applications in this field continue to improve, standards are regularly updated to reflect higher efficiency expectations and to drive further innovation in the industry.

Compliance with these standards not only ensures that Nichrome wire-based water heating solutions meet regulatory requirements but also contributes to broader energy conservation goals. By promoting the development and adoption of more efficient technologies, these standards help reduce overall energy consumption, lower utility costs for consumers, and minimize the environmental impact of water heating systems.

In the context of Nichrome wire applications for renewable water heating, energy efficiency standards typically focus on several key aspects. Firstly, they address the thermal efficiency of the heating element, which is directly related to the properties of Nichrome wire. Standards may specify minimum efficiency ratings for the conversion of electrical energy into heat, taking into account factors such as wire gauge, resistance, and power density.

Additionally, energy efficiency standards often encompass the insulation requirements for water heaters. This is particularly relevant for Nichrome wire applications, as proper insulation helps minimize heat loss and maintain water temperature, thereby reducing energy consumption. Standards may dictate minimum R-values for insulation materials and specify design requirements to minimize thermal bridging.

Another important aspect covered by energy efficiency standards is the control systems used in renewable water heating solutions. For Nichrome wire applications, this may include requirements for precise temperature regulation, programmable timers, and smart controls that optimize heating cycles based on usage patterns. These standards aim to ensure that water heaters operate only when necessary and maintain desired temperatures efficiently.

Energy efficiency standards also address the overall system performance, including factors such as standby heat loss, recovery efficiency, and annual energy consumption. For Nichrome wire-based water heaters, these standards may set maximum allowable energy consumption levels based on the heater's capacity and intended use.

Furthermore, energy efficiency standards often incorporate labeling requirements, such as the Energy Star certification in the United States. These labels provide consumers with clear information about the energy performance of water heating systems, enabling informed decision-making and promoting the adoption of more efficient technologies.

It is worth noting that energy efficiency standards for renewable water heating solutions are continually evolving to keep pace with technological advancements. As Nichrome wire applications in this field continue to improve, standards are regularly updated to reflect higher efficiency expectations and to drive further innovation in the industry.

Compliance with these standards not only ensures that Nichrome wire-based water heating solutions meet regulatory requirements but also contributes to broader energy conservation goals. By promoting the development and adoption of more efficient technologies, these standards help reduce overall energy consumption, lower utility costs for consumers, and minimize the environmental impact of water heating systems.

Environmental Impact Analysis

The environmental impact of nichrome wire applications in renewable water heating solutions is a critical aspect to consider in the context of sustainable energy development. Nichrome wire, an alloy of nickel and chromium, has gained prominence in various heating applications due to its excellent electrical resistance and heat-generating properties.

When used in renewable water heating systems, nichrome wire contributes to a reduction in fossil fuel consumption and greenhouse gas emissions compared to traditional water heating methods. This aligns with global efforts to mitigate climate change and transition towards cleaner energy sources. The integration of nichrome wire in solar water heaters, for instance, enhances the efficiency of heat transfer, maximizing the utilization of renewable solar energy.

However, the production and disposal of nichrome wire present environmental challenges that must be addressed. The mining and processing of nickel and chromium ores can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. Additionally, the energy-intensive manufacturing process of nichrome wire contributes to carbon emissions, albeit offset by the long-term environmental benefits of its application in renewable heating systems.

The durability and longevity of nichrome wire in water heating applications contribute to reduced waste generation and resource consumption over time. This aspect aligns with circular economy principles, as fewer replacements are needed compared to less durable heating elements. Nevertheless, end-of-life management of nichrome wire-containing devices requires careful consideration to prevent the release of potentially harmful metals into the environment.

Water conservation is another significant environmental benefit of nichrome wire applications in renewable heating solutions. By improving the efficiency of water heating processes, these systems can reduce overall water consumption, particularly in regions facing water scarcity. This efficiency also translates to energy savings, further diminishing the environmental footprint of water heating operations.

The scalability of nichrome wire-based renewable water heating solutions offers promising potential for widespread adoption, potentially leading to substantial cumulative environmental benefits. As these technologies become more prevalent, they could play a crucial role in reducing the carbon footprint of residential and industrial water heating on a global scale.

In conclusion, while nichrome wire applications in renewable water heating solutions present clear environmental advantages, particularly in terms of reduced emissions and energy efficiency, a holistic approach is necessary to address the full lifecycle impact of these technologies. Continued research and development in sustainable production methods and recycling technologies for nichrome wire will be essential to maximize its positive environmental contribution in the renewable energy sector.

When used in renewable water heating systems, nichrome wire contributes to a reduction in fossil fuel consumption and greenhouse gas emissions compared to traditional water heating methods. This aligns with global efforts to mitigate climate change and transition towards cleaner energy sources. The integration of nichrome wire in solar water heaters, for instance, enhances the efficiency of heat transfer, maximizing the utilization of renewable solar energy.

However, the production and disposal of nichrome wire present environmental challenges that must be addressed. The mining and processing of nickel and chromium ores can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. Additionally, the energy-intensive manufacturing process of nichrome wire contributes to carbon emissions, albeit offset by the long-term environmental benefits of its application in renewable heating systems.

The durability and longevity of nichrome wire in water heating applications contribute to reduced waste generation and resource consumption over time. This aspect aligns with circular economy principles, as fewer replacements are needed compared to less durable heating elements. Nevertheless, end-of-life management of nichrome wire-containing devices requires careful consideration to prevent the release of potentially harmful metals into the environment.

Water conservation is another significant environmental benefit of nichrome wire applications in renewable heating solutions. By improving the efficiency of water heating processes, these systems can reduce overall water consumption, particularly in regions facing water scarcity. This efficiency also translates to energy savings, further diminishing the environmental footprint of water heating operations.

The scalability of nichrome wire-based renewable water heating solutions offers promising potential for widespread adoption, potentially leading to substantial cumulative environmental benefits. As these technologies become more prevalent, they could play a crucial role in reducing the carbon footprint of residential and industrial water heating on a global scale.

In conclusion, while nichrome wire applications in renewable water heating solutions present clear environmental advantages, particularly in terms of reduced emissions and energy efficiency, a holistic approach is necessary to address the full lifecycle impact of these technologies. Continued research and development in sustainable production methods and recycling technologies for nichrome wire will be essential to maximize its positive environmental contribution in the renewable energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!