Optimize Brine Concentration: Lithium Chloride Applications

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Brine Concentration Technology Background and Objectives

Lithium extraction from brine has evolved significantly over the past several decades, transforming from a niche process to a critical component in the global energy transition. Initially developed in the 1950s, brine concentration technologies have undergone substantial refinement, particularly since the early 2000s when lithium demand began to accelerate due to the proliferation of lithium-ion batteries. The technological trajectory has moved from simple solar evaporation methods toward more sophisticated, energy-efficient, and environmentally sustainable approaches.

The current technological landscape is characterized by a blend of traditional and innovative methodologies, with lithium chloride brine concentration representing a pivotal process in the lithium value chain. Traditional solar evaporation, while still widely employed, faces challenges related to lengthy processing times (12-18 months), weather dependence, and substantial land requirements. These limitations have spurred research into alternative concentration technologies including membrane processes, adsorption techniques, and electrochemical methods.

Recent advancements have focused on direct lithium extraction (DLE) technologies that can selectively remove lithium from brines with higher efficiency and reduced environmental impact. These technologies aim to address the growing demand for lithium in electric vehicles, renewable energy storage systems, and consumer electronics, which is projected to increase by 500% by 2030.

The primary technical objectives in lithium chloride brine concentration include increasing lithium recovery rates beyond the current industry average of 50-70%, reducing water consumption, minimizing chemical reagent usage, and shortening processing times. Additionally, there is a strong emphasis on developing technologies capable of processing lower-grade brines and those with complex chemical compositions that have traditionally been considered uneconomical.

Energy efficiency represents another critical objective, as conventional evaporation processes are energy-intensive and contribute significantly to the carbon footprint of lithium production. Innovative approaches seek to reduce energy requirements while maintaining or improving lithium yield and purity, with targets to decrease energy consumption by at least 30% compared to conventional methods.

Water conservation has emerged as a paramount concern, particularly as many lithium brine operations are located in water-stressed regions. Technologies that enable water recycling and minimize freshwater consumption are receiving increased attention, with goals to reduce water usage by up to 90% compared to traditional evaporation pond methods.

The ultimate technological goal is to develop scalable, economically viable processes that can meet the exponentially growing demand for lithium while adhering to increasingly stringent environmental standards and addressing community concerns in lithium-producing regions.

The current technological landscape is characterized by a blend of traditional and innovative methodologies, with lithium chloride brine concentration representing a pivotal process in the lithium value chain. Traditional solar evaporation, while still widely employed, faces challenges related to lengthy processing times (12-18 months), weather dependence, and substantial land requirements. These limitations have spurred research into alternative concentration technologies including membrane processes, adsorption techniques, and electrochemical methods.

Recent advancements have focused on direct lithium extraction (DLE) technologies that can selectively remove lithium from brines with higher efficiency and reduced environmental impact. These technologies aim to address the growing demand for lithium in electric vehicles, renewable energy storage systems, and consumer electronics, which is projected to increase by 500% by 2030.

The primary technical objectives in lithium chloride brine concentration include increasing lithium recovery rates beyond the current industry average of 50-70%, reducing water consumption, minimizing chemical reagent usage, and shortening processing times. Additionally, there is a strong emphasis on developing technologies capable of processing lower-grade brines and those with complex chemical compositions that have traditionally been considered uneconomical.

Energy efficiency represents another critical objective, as conventional evaporation processes are energy-intensive and contribute significantly to the carbon footprint of lithium production. Innovative approaches seek to reduce energy requirements while maintaining or improving lithium yield and purity, with targets to decrease energy consumption by at least 30% compared to conventional methods.

Water conservation has emerged as a paramount concern, particularly as many lithium brine operations are located in water-stressed regions. Technologies that enable water recycling and minimize freshwater consumption are receiving increased attention, with goals to reduce water usage by up to 90% compared to traditional evaporation pond methods.

The ultimate technological goal is to develop scalable, economically viable processes that can meet the exponentially growing demand for lithium while adhering to increasingly stringent environmental standards and addressing community concerns in lithium-producing regions.

Market Demand Analysis for Concentrated Lithium Chloride Solutions

The global market for concentrated lithium chloride solutions has experienced significant growth in recent years, driven primarily by the expanding lithium-ion battery industry. As electric vehicle adoption accelerates worldwide, the demand for high-purity lithium compounds continues to surge. Market research indicates that the global lithium market value reached approximately $7.5 billion in 2022, with projections suggesting it could exceed $18 billion by 2030, representing a compound annual growth rate of over 11%.

Within this broader lithium market, concentrated lithium chloride solutions occupy a critical position as an intermediate product in the lithium extraction and processing chain. The brine concentration optimization segment specifically addresses efficiency improvements in lithium production from natural brines, which accounts for nearly 60% of global lithium production.

Industrial applications beyond batteries are creating additional demand vectors for concentrated lithium chloride. The compound's hygroscopic properties make it valuable in dehumidification systems and air conditioning applications, particularly in regions experiencing increasing humidity due to climate change. The pharmaceutical and chemical manufacturing sectors also utilize purified lithium chloride in various processes, contributing to market diversification.

Regional analysis reveals that Latin America, particularly the "Lithium Triangle" encompassing Chile, Argentina, and Bolivia, represents the largest market for brine concentration technologies, given their vast lithium-rich salt flat resources. North America and Australia are rapidly expanding their lithium production capabilities, creating new market opportunities for advanced brine concentration solutions.

Market segmentation by end-use shows that battery material manufacturers constitute approximately 78% of the demand for concentrated lithium chloride, followed by industrial chemical producers (12%), pharmaceutical companies (7%), and other applications (3%). This distribution highlights the critical importance of battery technology in driving market growth.

Customer requirements are increasingly focused on purity levels and production efficiency. Battery manufacturers specifically demand lithium chloride solutions with impurity levels below 100 ppm, creating premium market segments for high-purity products. Additionally, water conservation concerns in lithium-producing regions are driving demand for more efficient brine concentration technologies that minimize freshwater consumption.

Market barriers include technological challenges in selective extraction, environmental regulations regarding water usage and waste disposal, and price volatility in the broader lithium market. Despite these challenges, the fundamental demand drivers remain strong, supported by global electrification trends and renewable energy adoption.

Within this broader lithium market, concentrated lithium chloride solutions occupy a critical position as an intermediate product in the lithium extraction and processing chain. The brine concentration optimization segment specifically addresses efficiency improvements in lithium production from natural brines, which accounts for nearly 60% of global lithium production.

Industrial applications beyond batteries are creating additional demand vectors for concentrated lithium chloride. The compound's hygroscopic properties make it valuable in dehumidification systems and air conditioning applications, particularly in regions experiencing increasing humidity due to climate change. The pharmaceutical and chemical manufacturing sectors also utilize purified lithium chloride in various processes, contributing to market diversification.

Regional analysis reveals that Latin America, particularly the "Lithium Triangle" encompassing Chile, Argentina, and Bolivia, represents the largest market for brine concentration technologies, given their vast lithium-rich salt flat resources. North America and Australia are rapidly expanding their lithium production capabilities, creating new market opportunities for advanced brine concentration solutions.

Market segmentation by end-use shows that battery material manufacturers constitute approximately 78% of the demand for concentrated lithium chloride, followed by industrial chemical producers (12%), pharmaceutical companies (7%), and other applications (3%). This distribution highlights the critical importance of battery technology in driving market growth.

Customer requirements are increasingly focused on purity levels and production efficiency. Battery manufacturers specifically demand lithium chloride solutions with impurity levels below 100 ppm, creating premium market segments for high-purity products. Additionally, water conservation concerns in lithium-producing regions are driving demand for more efficient brine concentration technologies that minimize freshwater consumption.

Market barriers include technological challenges in selective extraction, environmental regulations regarding water usage and waste disposal, and price volatility in the broader lithium market. Despite these challenges, the fundamental demand drivers remain strong, supported by global electrification trends and renewable energy adoption.

Current State and Technical Challenges in Brine Concentration

The global lithium extraction industry is currently experiencing a significant transformation, driven by the exponential growth in demand for lithium-ion batteries. Traditional brine concentration methods, primarily solar evaporation, remain dominant but face substantial efficiency challenges. These conventional approaches typically require 18-24 months to achieve desired concentration levels, resulting in considerable lithium loss and environmental impact. The industry's average recovery rate hovers around 50%, indicating substantial room for technological improvement.

Recent advancements in membrane technology have shown promise, with selective lithium extraction membranes demonstrating potential to reduce processing time to weeks rather than years. However, these technologies still struggle with membrane fouling and degradation when exposed to high concentrations of competing ions present in most brine sources. The technical challenge lies in developing membranes with both high selectivity for lithium ions and sufficient durability in harsh brine environments.

Direct lithium extraction (DLE) technologies represent another emerging approach, utilizing adsorbents, ion exchange materials, or electrochemical systems to selectively capture lithium. While laboratory results show potential recovery rates exceeding 90%, scaling these technologies to commercial production volumes remains problematic. Energy consumption in these processes often exceeds sustainable levels, particularly when processing low-concentration brines.

Geographically, lithium brine concentration technologies are unevenly distributed. The "Lithium Triangle" of South America (Argentina, Bolivia, and Chile) continues to rely heavily on traditional evaporation methods due to favorable climatic conditions. In contrast, China has made significant investments in advanced membrane and electrochemical technologies, establishing a competitive advantage in processing efficiency.

A critical technical bottleneck exists in the selective separation of lithium chloride from other chloride salts, particularly magnesium chloride, which often co-occurs in natural brines. Current separation processes require multiple stages of precipitation and re-dissolution, significantly increasing operational costs and reducing overall yield.

Water management represents another major challenge, with conventional evaporation methods consuming or losing substantial quantities of water in water-scarce regions. Advanced technologies must address both lithium recovery efficiency and water conservation to achieve sustainability targets.

The industry also faces significant materials science challenges in developing corrosion-resistant equipment capable of withstanding the highly concentrated lithium chloride solutions. Standard stainless steel components typically experience accelerated degradation, necessitating frequent replacement and increasing operational costs.

Recent advancements in membrane technology have shown promise, with selective lithium extraction membranes demonstrating potential to reduce processing time to weeks rather than years. However, these technologies still struggle with membrane fouling and degradation when exposed to high concentrations of competing ions present in most brine sources. The technical challenge lies in developing membranes with both high selectivity for lithium ions and sufficient durability in harsh brine environments.

Direct lithium extraction (DLE) technologies represent another emerging approach, utilizing adsorbents, ion exchange materials, or electrochemical systems to selectively capture lithium. While laboratory results show potential recovery rates exceeding 90%, scaling these technologies to commercial production volumes remains problematic. Energy consumption in these processes often exceeds sustainable levels, particularly when processing low-concentration brines.

Geographically, lithium brine concentration technologies are unevenly distributed. The "Lithium Triangle" of South America (Argentina, Bolivia, and Chile) continues to rely heavily on traditional evaporation methods due to favorable climatic conditions. In contrast, China has made significant investments in advanced membrane and electrochemical technologies, establishing a competitive advantage in processing efficiency.

A critical technical bottleneck exists in the selective separation of lithium chloride from other chloride salts, particularly magnesium chloride, which often co-occurs in natural brines. Current separation processes require multiple stages of precipitation and re-dissolution, significantly increasing operational costs and reducing overall yield.

Water management represents another major challenge, with conventional evaporation methods consuming or losing substantial quantities of water in water-scarce regions. Advanced technologies must address both lithium recovery efficiency and water conservation to achieve sustainability targets.

The industry also faces significant materials science challenges in developing corrosion-resistant equipment capable of withstanding the highly concentrated lithium chloride solutions. Standard stainless steel components typically experience accelerated degradation, necessitating frequent replacement and increasing operational costs.

Current Brine Concentration Methodologies and Solutions

01 Evaporation and crystallization methods for lithium chloride concentration

Various evaporation and crystallization techniques are employed to concentrate lithium chloride from brine solutions. These methods typically involve controlled heating and cooling processes to remove water and precipitate lithium chloride crystals. Advanced crystallization systems can optimize the purity and recovery rate of lithium chloride from brine sources, often incorporating multiple stages to progressively increase concentration levels.- Evaporation and crystallization methods for lithium chloride concentration: Various evaporation and crystallization techniques are employed to concentrate lithium chloride from brine solutions. These methods typically involve controlled heating and cooling processes to remove water and precipitate impurities, resulting in concentrated lithium chloride solutions. Advanced crystallization technologies can selectively separate lithium chloride from other salts present in the brine, improving the purity and concentration of the final product.

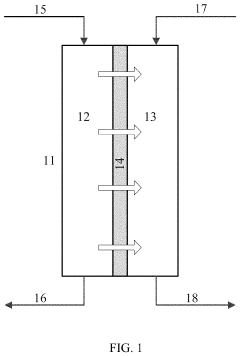

- Membrane and filtration technologies for brine processing: Membrane-based separation technologies, including nanofiltration, reverse osmosis, and electrodialysis, are utilized to concentrate lithium chloride from brine solutions. These processes selectively allow certain ions to pass through while retaining others, effectively increasing the lithium concentration. Filtration systems can be arranged in multi-stage configurations to progressively increase lithium chloride concentration while removing unwanted impurities such as magnesium, calcium, and sulfate ions.

- Chemical precipitation and selective extraction techniques: Chemical precipitation methods involve adding reagents to brine solutions to selectively precipitate impurities while leaving lithium in solution, thereby increasing its concentration. Selective extraction techniques utilize specialized solvents or adsorbents that preferentially bind to lithium ions, allowing for their separation from other components in the brine. These methods can significantly enhance the lithium chloride concentration and purity in the final product.

- Solar evaporation and natural concentration processes: Solar evaporation techniques leverage natural sunlight and atmospheric conditions to concentrate lithium chloride in brine solutions. These methods typically involve a series of evaporation ponds where brine is progressively concentrated as water evaporates. The process can be optimized by controlling pond depth, residence time, and flow patterns. While time-intensive, solar evaporation is energy-efficient and particularly suitable for regions with high solar radiation and low precipitation.

- Integrated multi-stage concentration systems: Integrated systems combine multiple concentration technologies in sequence to efficiently process lithium chloride brines. These systems typically incorporate pre-treatment stages to remove impurities, followed by concentration stages using various methods such as evaporation, membrane filtration, and ion exchange. The multi-stage approach allows for optimization at each step, resulting in higher overall recovery rates and concentration factors for lithium chloride while minimizing energy consumption and waste generation.

02 Membrane and filtration technologies for brine processing

Membrane-based separation technologies are increasingly used for lithium chloride brine concentration. These include nanofiltration, reverse osmosis, and electrodialysis systems that selectively separate lithium ions from other components in the brine. These technologies offer advantages in energy efficiency and can be operated continuously, allowing for more sustainable lithium extraction processes compared to traditional evaporation methods.Expand Specific Solutions03 Chemical precipitation and selective extraction methods

Chemical precipitation techniques involve adding reagents to lithium-rich brines to selectively precipitate lithium compounds while leaving impurities in solution. These methods often utilize pH adjustment and the addition of specific chemicals that form complexes with lithium ions. Selective extraction processes can significantly increase the concentration of lithium chloride in the final product while reducing contamination from other salts commonly found in brines.Expand Specific Solutions04 Continuous flow processing systems for industrial-scale concentration

Continuous flow systems for lithium chloride brine concentration enable large-scale industrial processing with improved efficiency. These systems integrate multiple concentration steps in a sequential process, often combining different technologies such as pre-concentration, purification, and final concentration stages. The continuous nature of these processes allows for better control of operating parameters and higher throughput compared to batch processing methods.Expand Specific Solutions05 Solar evaporation and sustainable concentration techniques

Solar evaporation represents a sustainable approach to lithium chloride brine concentration, utilizing natural solar energy to drive water evaporation from large ponds. These methods are often enhanced with specialized pond designs, reflective surfaces, or greenhouse structures to increase evaporation rates. Recent innovations include hybrid systems that combine solar evaporation with other concentration technologies to reduce energy consumption while maintaining production efficiency.Expand Specific Solutions

Key Industry Players in Lithium Extraction and Processing

The lithium chloride brine concentration technology market is currently in a growth phase, with increasing demand driven by the expanding electric vehicle and energy storage sectors. The global market size for lithium extraction technologies is projected to reach several billion dollars by 2025, with a CAGR exceeding 8%. Technologically, the field shows varying maturity levels across different approaches. Leading players include established mining companies like Albemarle Corp. and Orocobre Ltd., alongside innovative technology developers such as Lilac Solutions and Energy Exploration Technologies. Chinese entities including Qinghai Salt Lake Industry and BYD are making significant advances in domestic lithium production. Academic institutions like Qinghai Institute of Salt Lakes and Korea Institute of Geoscience & Mineral Resources are contributing fundamental research, while specialized companies like Pure Lithium and Forager Station are developing next-generation extraction methods with improved efficiency and reduced environmental impact.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

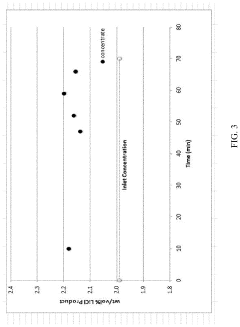

Technical Solution: The Qinghai Institute of Salt Lakes has developed an advanced multi-stage evaporation and concentration process specifically optimized for lithium extraction from salt lake brines. Their technology employs a series of solar evaporation ponds with precisely controlled residence times and transfer protocols based on brine density measurements. The institute has pioneered selective precipitation techniques that minimize magnesium contamination during lithium chloride concentration, achieving purities exceeding 99.5% through their proprietary chemical treatment process. Their system incorporates real-time monitoring of evaporation rates and brine chemistry, with automated adjustments to compensate for seasonal variations in solar radiation and temperature. Additionally, they've developed membrane-assisted concentration technologies that can accelerate the traditional solar evaporation process by up to 40% while maintaining high lithium recovery rates of approximately 85-90%.

Strengths: Extensive experience with the specific chemistry of Chinese salt lakes; integrated approach combining traditional solar evaporation with modern membrane technologies; high lithium recovery rates. Weaknesses: Technologies optimized primarily for the unique conditions of Qinghai salt lakes may require significant adaptation for other brine sources; relatively long processing times despite improvements.

Albemarle Corp.

Technical Solution: Albemarle has developed a comprehensive brine concentration technology called Advanced Lithium Extraction (ALEx) specifically for lithium chloride applications. This system employs selective adsorption materials that preferentially capture lithium ions from brine solutions while rejecting competing ions like sodium, magnesium, and calcium. Their process incorporates a multi-stage concentration approach that progressively increases lithium chloride concentration from initial levels of 0.1-0.2% to commercial-grade concentrations exceeding 35%. Albemarle's technology utilizes proprietary ion exchange resins with enhanced selectivity for lithium, allowing for effective processing of brines with varying chemical compositions. The company has also implemented advanced crystallization techniques that enable precise control over lithium chloride crystal formation, resulting in consistent product quality with impurity levels below 100 ppm. Their system features closed-loop water recycling that reduces freshwater consumption by approximately 60% compared to conventional evaporation methods, making it particularly suitable for water-scarce regions.

Strengths: Highly selective extraction technology that works across diverse brine compositions; reduced water consumption compared to traditional methods; faster processing times than solar evaporation. Weaknesses: Higher capital expenditure requirements; energy-intensive compared to passive solar methods; proprietary materials may have limited operational lifespans requiring periodic replacement.

Critical Patents and Innovations in Lithium Chloride Processing

Processes for producing lithium compounds using forward osmosis

PatentPendingUS20220105466A1

Innovation

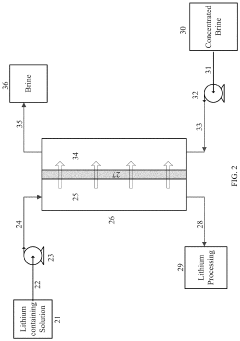

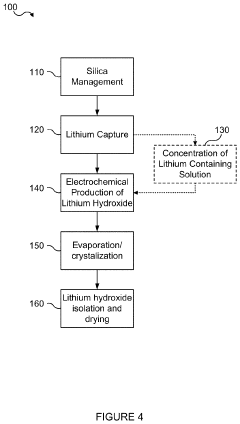

- A method involving pretreatment of lithium-containing solutions to reduce silica, followed by the use of a lithium-specific sorbent for selective lithium capture and subsequent concentration through forward osmosis, which preferentially enriches lithium ions over other ions, allowing for further processing into lithium hydroxide or carbonate.

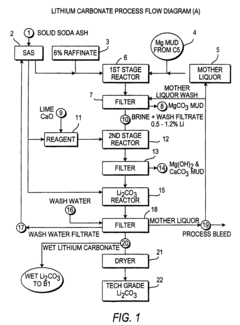

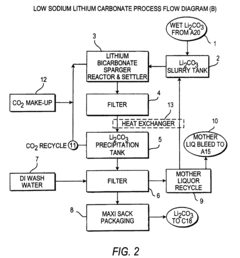

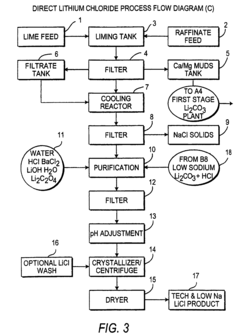

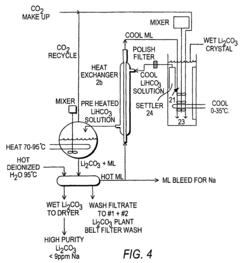

Production of lithium compounds directly from lithium containing brines

PatentInactiveUS7858057B2

Innovation

- A novel process that reduces the number of processing steps by directly producing high purity lithium carbonate and lithium chloride from concentrated natural brines using a carbon dioxide/bicarbonate cycle and hydrochloric acid reaction, eliminating the need for lithium hydroxide monohydrate recrystallization and incorporating ion exchange steps to achieve low sodium content.

Environmental Impact Assessment of Lithium Brine Operations

The environmental impact of lithium brine operations represents a critical consideration in the optimization of lithium chloride applications. These operations, primarily conducted in arid regions with significant lithium-rich brine deposits such as the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), Australia, and increasingly China, create substantial ecological footprints that must be carefully assessed and managed.

Water consumption stands as the foremost environmental concern, with traditional evaporation pond methods requiring approximately 500,000 gallons of water per ton of lithium produced. This extensive water usage in already water-scarce regions creates significant hydrological imbalances, potentially affecting local communities and ecosystems dependent on limited water resources. The disruption of natural water cycles can lead to decreased biodiversity and habitat degradation in surrounding areas.

Land use transformation represents another significant impact, as evaporation ponds typically occupy vast land areas—sometimes extending over several square kilometers. This land conversion often results in habitat fragmentation and loss of native vegetation, directly impacting local wildlife populations and ecosystem services. The visual impact of these industrial operations also affects the aesthetic value of previously pristine landscapes.

Chemical contamination presents ongoing risks, as the process involves various chemicals including sodium carbonate, calcium hydroxide, and hydrochloric acid. Improper handling or accidental releases can contaminate soil and water sources, potentially introducing toxic elements into local ecosystems. Monitoring data from established operations indicates that without proper safeguards, groundwater quality degradation can extend beyond operational boundaries.

Energy consumption in brine concentration processes contributes significantly to the carbon footprint of lithium production. Traditional methods rely heavily on solar evaporation, which while renewable, requires supplementary energy for pumping, processing, and transportation. Advanced concentration technologies may reduce land and water requirements but often increase energy demands, creating a complex sustainability trade-off.

Recent technological innovations are addressing these environmental challenges through closed-loop systems, direct lithium extraction methods, and improved water recycling protocols. These approaches can potentially reduce freshwater consumption by 30-50% compared to conventional methods. Additionally, membrane-based concentration technologies show promise in minimizing both land use and chemical requirements while maintaining extraction efficiency.

Regulatory frameworks governing lithium brine operations vary significantly across jurisdictions, with Chile and Australia implementing more stringent environmental impact assessment requirements than many emerging lithium-producing regions. The development of international standards for sustainable lithium extraction represents an important step toward industry-wide environmental responsibility and operational optimization.

Water consumption stands as the foremost environmental concern, with traditional evaporation pond methods requiring approximately 500,000 gallons of water per ton of lithium produced. This extensive water usage in already water-scarce regions creates significant hydrological imbalances, potentially affecting local communities and ecosystems dependent on limited water resources. The disruption of natural water cycles can lead to decreased biodiversity and habitat degradation in surrounding areas.

Land use transformation represents another significant impact, as evaporation ponds typically occupy vast land areas—sometimes extending over several square kilometers. This land conversion often results in habitat fragmentation and loss of native vegetation, directly impacting local wildlife populations and ecosystem services. The visual impact of these industrial operations also affects the aesthetic value of previously pristine landscapes.

Chemical contamination presents ongoing risks, as the process involves various chemicals including sodium carbonate, calcium hydroxide, and hydrochloric acid. Improper handling or accidental releases can contaminate soil and water sources, potentially introducing toxic elements into local ecosystems. Monitoring data from established operations indicates that without proper safeguards, groundwater quality degradation can extend beyond operational boundaries.

Energy consumption in brine concentration processes contributes significantly to the carbon footprint of lithium production. Traditional methods rely heavily on solar evaporation, which while renewable, requires supplementary energy for pumping, processing, and transportation. Advanced concentration technologies may reduce land and water requirements but often increase energy demands, creating a complex sustainability trade-off.

Recent technological innovations are addressing these environmental challenges through closed-loop systems, direct lithium extraction methods, and improved water recycling protocols. These approaches can potentially reduce freshwater consumption by 30-50% compared to conventional methods. Additionally, membrane-based concentration technologies show promise in minimizing both land use and chemical requirements while maintaining extraction efficiency.

Regulatory frameworks governing lithium brine operations vary significantly across jurisdictions, with Chile and Australia implementing more stringent environmental impact assessment requirements than many emerging lithium-producing regions. The development of international standards for sustainable lithium extraction represents an important step toward industry-wide environmental responsibility and operational optimization.

Economic Feasibility and ROI Analysis for Concentration Technologies

The economic feasibility of brine concentration technologies for lithium chloride extraction represents a critical factor in determining project viability within the rapidly expanding lithium market. Current analysis indicates that capital expenditure for advanced membrane-based concentration systems ranges from $15-25 million for medium-scale operations, with larger installations potentially exceeding $50 million. These significant upfront investments necessitate thorough ROI evaluation before implementation.

Operating expenses primarily consist of energy consumption, maintenance requirements, and chemical inputs. Energy costs typically account for 40-45% of operational expenditure, with conventional evaporation methods consuming 35-50 kWh per cubic meter of processed brine. Advanced technologies like vacuum membrane distillation and forward osmosis demonstrate 20-30% improved energy efficiency, substantially reducing long-term operational costs.

Recovery rate analysis shows that modern concentration technologies achieve lithium recovery rates of 80-90%, compared to traditional methods yielding 40-60%. This efficiency improvement directly translates to enhanced economic returns, with each percentage point increase in recovery potentially generating $250,000-500,000 in additional annual revenue for medium-sized operations.

Payback period calculations reveal significant variations based on technology selection. Conventional evaporation systems typically require 4-6 years to reach ROI, while advanced membrane technologies demonstrate accelerated payback periods of 2.5-4 years when operating at optimal capacity. This differential becomes particularly pronounced in regions with high energy costs or environmental restrictions.

Sensitivity analysis indicates that lithium market price fluctuations represent the most significant variable affecting ROI. With lithium carbonate prices ranging from $15,000-$80,000 per ton over recent years, concentration technology investments demonstrate robust returns even at moderate market prices above $25,000 per ton. Additional economic benefits emerge from the recovery of valuable by-products including potassium, magnesium, and boron compounds, potentially contributing 15-20% to overall project revenue.

Environmental compliance costs increasingly influence economic feasibility, with water conservation technologies commanding premium valuations in arid regions. Regulatory frameworks in major lithium-producing countries now incorporate carbon pricing mechanisms that favor energy-efficient concentration methods, creating additional economic incentives for advanced technology adoption beyond direct operational savings.

Operating expenses primarily consist of energy consumption, maintenance requirements, and chemical inputs. Energy costs typically account for 40-45% of operational expenditure, with conventional evaporation methods consuming 35-50 kWh per cubic meter of processed brine. Advanced technologies like vacuum membrane distillation and forward osmosis demonstrate 20-30% improved energy efficiency, substantially reducing long-term operational costs.

Recovery rate analysis shows that modern concentration technologies achieve lithium recovery rates of 80-90%, compared to traditional methods yielding 40-60%. This efficiency improvement directly translates to enhanced economic returns, with each percentage point increase in recovery potentially generating $250,000-500,000 in additional annual revenue for medium-sized operations.

Payback period calculations reveal significant variations based on technology selection. Conventional evaporation systems typically require 4-6 years to reach ROI, while advanced membrane technologies demonstrate accelerated payback periods of 2.5-4 years when operating at optimal capacity. This differential becomes particularly pronounced in regions with high energy costs or environmental restrictions.

Sensitivity analysis indicates that lithium market price fluctuations represent the most significant variable affecting ROI. With lithium carbonate prices ranging from $15,000-$80,000 per ton over recent years, concentration technology investments demonstrate robust returns even at moderate market prices above $25,000 per ton. Additional economic benefits emerge from the recovery of valuable by-products including potassium, magnesium, and boron compounds, potentially contributing 15-20% to overall project revenue.

Environmental compliance costs increasingly influence economic feasibility, with water conservation technologies commanding premium valuations in arid regions. Regulatory frameworks in major lithium-producing countries now incorporate carbon pricing mechanisms that favor energy-efficient concentration methods, creating additional economic incentives for advanced technology adoption beyond direct operational savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!