Patent Review of Microinjection Molding in Automotive Components

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Technology Evolution and Objectives

Microinjection molding technology emerged in the late 1980s as a specialized adaptation of conventional injection molding, designed to produce miniaturized components with high precision. The evolution began with simple adaptations of traditional equipment, gradually transitioning to purpose-built systems capable of handling microscale features. This technological progression was primarily driven by the increasing demand for miniaturization across various industries, with automotive applications becoming a significant focus by the early 2000s.

The development trajectory shows three distinct phases: the experimental phase (1985-1995), where fundamental principles were established; the commercialization phase (1995-2010), marked by the introduction of specialized equipment and materials; and the current advanced integration phase (2010-present), characterized by sophisticated process control and material innovations specifically tailored for automotive applications.

A critical milestone occurred around 2005 when microinjection molding techniques became sufficiently refined to meet the stringent quality and durability requirements of the automotive industry. This breakthrough enabled the production of microfluidic components for fuel management systems, miniaturized sensor housings, and micro-structured surfaces for improved aerodynamics and aesthetics.

The technology has evolved from simple thermoplastic processing to encompass multi-material capabilities, allowing for the integration of rigid and flexible components within a single part. Recent advancements include the development of specialized polymers with enhanced thermal stability and mechanical properties specifically designed for under-hood automotive applications where operating conditions are particularly demanding.

Current technological objectives focus on several key areas: improving process repeatability for high-volume automotive production; enhancing surface finish quality to meet aesthetic requirements without secondary operations; developing in-line quality control methods capable of detecting microscale defects; and reducing cycle times to improve economic viability for mass production scenarios.

Another significant objective is the integration of microinjection molding with other manufacturing technologies, such as in-mold electronics and functional surface treatments, to create components with embedded functionality. This convergence aims to reduce assembly steps and create more compact, lightweight automotive components that contribute to overall vehicle efficiency.

Environmental considerations have also shaped recent technological goals, with increasing emphasis on developing processes compatible with sustainable and recyclable materials while maintaining the precision and performance characteristics required for automotive applications. The industry is actively pursuing bio-based polymers and recycled materials that can withstand the rigorous conditions of automotive use while meeting increasingly stringent environmental regulations.

The development trajectory shows three distinct phases: the experimental phase (1985-1995), where fundamental principles were established; the commercialization phase (1995-2010), marked by the introduction of specialized equipment and materials; and the current advanced integration phase (2010-present), characterized by sophisticated process control and material innovations specifically tailored for automotive applications.

A critical milestone occurred around 2005 when microinjection molding techniques became sufficiently refined to meet the stringent quality and durability requirements of the automotive industry. This breakthrough enabled the production of microfluidic components for fuel management systems, miniaturized sensor housings, and micro-structured surfaces for improved aerodynamics and aesthetics.

The technology has evolved from simple thermoplastic processing to encompass multi-material capabilities, allowing for the integration of rigid and flexible components within a single part. Recent advancements include the development of specialized polymers with enhanced thermal stability and mechanical properties specifically designed for under-hood automotive applications where operating conditions are particularly demanding.

Current technological objectives focus on several key areas: improving process repeatability for high-volume automotive production; enhancing surface finish quality to meet aesthetic requirements without secondary operations; developing in-line quality control methods capable of detecting microscale defects; and reducing cycle times to improve economic viability for mass production scenarios.

Another significant objective is the integration of microinjection molding with other manufacturing technologies, such as in-mold electronics and functional surface treatments, to create components with embedded functionality. This convergence aims to reduce assembly steps and create more compact, lightweight automotive components that contribute to overall vehicle efficiency.

Environmental considerations have also shaped recent technological goals, with increasing emphasis on developing processes compatible with sustainable and recyclable materials while maintaining the precision and performance characteristics required for automotive applications. The industry is actively pursuing bio-based polymers and recycled materials that can withstand the rigorous conditions of automotive use while meeting increasingly stringent environmental regulations.

Automotive Market Demand for Microinjection Molded Components

The automotive industry is experiencing a significant shift towards lightweight, fuel-efficient vehicles with enhanced performance capabilities. This transformation has created a substantial market demand for microinjection molded components, which offer precision, miniaturization, and material efficiency. Current market analysis indicates that the global automotive microinjection molding market is growing at a compound annual growth rate exceeding 10%, driven primarily by stringent emission regulations and consumer demand for improved fuel economy.

Weight reduction remains a critical factor in automotive design, with manufacturers actively seeking components that can decrease overall vehicle mass while maintaining structural integrity. Microinjection molded parts, being significantly lighter than their conventional counterparts, directly address this need. The market particularly values components that can achieve weight reductions of 20-30% compared to traditional manufacturing methods.

Precision requirements in modern vehicles have escalated dramatically with the integration of advanced driver assistance systems (ADAS) and autonomous driving technologies. These systems require highly accurate sensors and connectors that maintain consistent performance under varying environmental conditions. Microinjection molding meets these demands through its ability to produce components with tolerances measured in micrometers rather than millimeters.

The electrification trend in the automotive sector has further amplified demand for microinjection molded components. Electric vehicles require specialized connectors, battery components, and thermal management systems that benefit from the precision and material versatility offered by microinjection molding. Market research shows that this segment is growing at nearly twice the rate of traditional automotive applications.

Interior comfort features represent another significant market driver. Modern vehicles incorporate numerous small, complex components in dashboard controls, infotainment systems, and ambient lighting. These components must combine aesthetic appeal with functional reliability, creating demand for microinjection molding's ability to produce complex geometries with high-quality surface finishes.

Cost considerations remain paramount for automotive manufacturers. While microinjection molded components may have higher initial tooling costs, they offer substantial savings through material reduction, part consolidation, and decreased assembly requirements. Market analysis reveals that manufacturers are increasingly willing to invest in these technologies when the total cost of ownership demonstrates clear advantages over conventional manufacturing approaches.

Regional market analysis shows particularly strong growth in Asia-Pacific and North America, where automotive manufacturing is embracing advanced technologies most rapidly. European markets show steady growth driven by stringent environmental regulations and the premium vehicle segment's demand for sophisticated components.

Weight reduction remains a critical factor in automotive design, with manufacturers actively seeking components that can decrease overall vehicle mass while maintaining structural integrity. Microinjection molded parts, being significantly lighter than their conventional counterparts, directly address this need. The market particularly values components that can achieve weight reductions of 20-30% compared to traditional manufacturing methods.

Precision requirements in modern vehicles have escalated dramatically with the integration of advanced driver assistance systems (ADAS) and autonomous driving technologies. These systems require highly accurate sensors and connectors that maintain consistent performance under varying environmental conditions. Microinjection molding meets these demands through its ability to produce components with tolerances measured in micrometers rather than millimeters.

The electrification trend in the automotive sector has further amplified demand for microinjection molded components. Electric vehicles require specialized connectors, battery components, and thermal management systems that benefit from the precision and material versatility offered by microinjection molding. Market research shows that this segment is growing at nearly twice the rate of traditional automotive applications.

Interior comfort features represent another significant market driver. Modern vehicles incorporate numerous small, complex components in dashboard controls, infotainment systems, and ambient lighting. These components must combine aesthetic appeal with functional reliability, creating demand for microinjection molding's ability to produce complex geometries with high-quality surface finishes.

Cost considerations remain paramount for automotive manufacturers. While microinjection molded components may have higher initial tooling costs, they offer substantial savings through material reduction, part consolidation, and decreased assembly requirements. Market analysis reveals that manufacturers are increasingly willing to invest in these technologies when the total cost of ownership demonstrates clear advantages over conventional manufacturing approaches.

Regional market analysis shows particularly strong growth in Asia-Pacific and North America, where automotive manufacturing is embracing advanced technologies most rapidly. European markets show steady growth driven by stringent environmental regulations and the premium vehicle segment's demand for sophisticated components.

Current Technological Landscape and Challenges in Automotive Microinjection

Microinjection molding technology in the automotive industry has evolved significantly over the past decade, with current applications spanning from intricate interior components to critical under-hood parts. The global landscape shows varying levels of technological maturity, with European and Japanese manufacturers generally leading in precision and material innovation, while North American and Chinese manufacturers excel in production efficiency and cost optimization.

The primary technological challenge facing automotive microinjection molding is achieving consistent quality at microscale dimensions. When producing components with wall thicknesses below 100 micrometers or features smaller than 10 micrometers, conventional molding principles become inadequate. Material flow behavior changes dramatically at these scales, requiring specialized equipment and process controls that many manufacturers have yet to fully master.

Material limitations represent another significant hurdle. While traditional thermoplastics like polypropylene and polyamide remain industry standards, their performance characteristics often fall short when miniaturized. Advanced polymer blends and composites show promise but introduce complexities in processing parameters and quality control. The industry is particularly challenged by the need for materials that maintain mechanical integrity while accommodating increasingly complex geometries.

Equipment precision presents a third major challenge. Conventional injection molding machinery lacks the necessary precision for microcomponents, with standard tolerances of ±0.05mm proving insufficient for parts requiring ±0.005mm or better. Specialized micro-molding equipment exists but requires substantial capital investment and specialized operator training, creating barriers to widespread adoption.

Process monitoring and quality control systems face limitations in real-time data acquisition at the microscale. Current sensor technologies struggle to provide accurate measurements without interfering with the molding process itself. This creates a significant blind spot in production monitoring, increasing rejection rates and quality inconsistencies.

The automotive industry's shift toward electrification has introduced new requirements for microinjection molded components, particularly regarding thermal management and electrical insulation properties. Current molding technologies must adapt to these emerging needs while maintaining cost-effectiveness and production efficiency.

Sustainability concerns have also emerged as a critical challenge. Environmental regulations increasingly demand recyclable or biodegradable materials, yet these often exhibit less predictable behavior during microinjection processes. The industry faces the dual challenge of meeting sustainability goals while maintaining the precision and reliability demanded by automotive applications.

The primary technological challenge facing automotive microinjection molding is achieving consistent quality at microscale dimensions. When producing components with wall thicknesses below 100 micrometers or features smaller than 10 micrometers, conventional molding principles become inadequate. Material flow behavior changes dramatically at these scales, requiring specialized equipment and process controls that many manufacturers have yet to fully master.

Material limitations represent another significant hurdle. While traditional thermoplastics like polypropylene and polyamide remain industry standards, their performance characteristics often fall short when miniaturized. Advanced polymer blends and composites show promise but introduce complexities in processing parameters and quality control. The industry is particularly challenged by the need for materials that maintain mechanical integrity while accommodating increasingly complex geometries.

Equipment precision presents a third major challenge. Conventional injection molding machinery lacks the necessary precision for microcomponents, with standard tolerances of ±0.05mm proving insufficient for parts requiring ±0.005mm or better. Specialized micro-molding equipment exists but requires substantial capital investment and specialized operator training, creating barriers to widespread adoption.

Process monitoring and quality control systems face limitations in real-time data acquisition at the microscale. Current sensor technologies struggle to provide accurate measurements without interfering with the molding process itself. This creates a significant blind spot in production monitoring, increasing rejection rates and quality inconsistencies.

The automotive industry's shift toward electrification has introduced new requirements for microinjection molded components, particularly regarding thermal management and electrical insulation properties. Current molding technologies must adapt to these emerging needs while maintaining cost-effectiveness and production efficiency.

Sustainability concerns have also emerged as a critical challenge. Environmental regulations increasingly demand recyclable or biodegradable materials, yet these often exhibit less predictable behavior during microinjection processes. The industry faces the dual challenge of meeting sustainability goals while maintaining the precision and reliability demanded by automotive applications.

Current Patented Solutions for Automotive Microinjection Applications

01 Equipment and machinery for microinjection molding

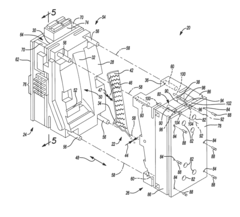

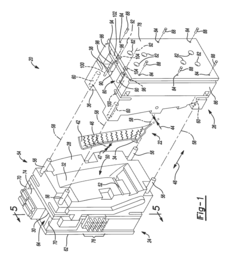

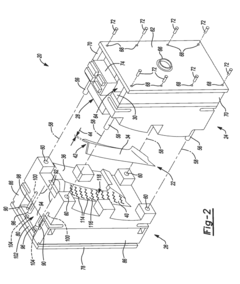

Specialized equipment and machinery are essential for microinjection molding processes. These include micro-molding machines with precise control systems, miniaturized injection units, and specialized molds designed for micro-scale production. The equipment often features advanced control mechanisms for temperature, pressure, and injection speed to ensure the high precision required for microinjection molding applications.- Microinjection molding equipment and machinery: Specialized equipment and machinery designed specifically for microinjection molding processes. These include micro-molding machines with precise control systems, specialized injection units capable of handling small shot sizes, and equipment with high precision movement control. The machinery often features advanced temperature control systems and specialized clamping mechanisms to ensure dimensional accuracy of micro-molded parts.

- Materials for microinjection molding: Various materials specifically formulated or selected for microinjection molding applications. These include specialized polymers with optimized flow properties, biocompatible materials for medical applications, and high-performance engineering plastics capable of forming microscale features. Material selection considers factors such as melt flow index, shrinkage characteristics, and mechanical properties at microscale dimensions.

- Microinjection molding for biomedical applications: Applications of microinjection molding technology in the biomedical field, including the production of medical devices, drug delivery systems, and diagnostic tools. This includes manufacturing of microfluidic devices, microneedles, implantable components, and lab-on-a-chip systems. The process enables the production of complex biomedical components with high precision and reproducibility while maintaining biocompatibility.

- Process optimization for microinjection molding: Techniques and methodologies for optimizing the microinjection molding process to achieve better quality, higher precision, and improved efficiency. This includes parameter optimization such as injection pressure, speed, temperature profiles, and cooling strategies. Advanced process control methods, simulation techniques, and real-time monitoring systems are employed to enhance process stability and part quality in microscale molding operations.

- Mold design for microinjection molding: Specialized mold design considerations for microinjection molding, including micro-feature creation, advanced gating systems, and precise venting mechanisms. These designs incorporate innovative cooling channel layouts, specialized surface treatments, and high-precision cavity and core components. Advanced manufacturing techniques such as micro-EDM, laser machining, and LIGA processes are used to create mold features at the microscale with exceptional accuracy.

02 Materials for microinjection molding

Various materials can be used in microinjection molding processes, including thermoplastics, thermosetting polymers, and specialized polymer blends. Material selection is critical as it affects flow properties, shrinkage, and final part quality. Advanced materials with specific properties such as high flow rates, minimal shrinkage, and enhanced mechanical characteristics are often developed specifically for microinjection molding applications.Expand Specific Solutions03 Biomedical applications of microinjection molding

Microinjection molding is widely used in biomedical applications for producing miniature components such as microfluidic devices, lab-on-a-chip systems, and medical implants. The technology enables the production of complex microstructures with high precision, which is essential for diagnostic devices, drug delivery systems, and tissue engineering scaffolds. The process allows for the use of biocompatible materials and can incorporate functional elements at the microscale.Expand Specific Solutions04 Process optimization and control in microinjection molding

Optimizing the microinjection molding process involves precise control of various parameters including injection speed, pressure, temperature, and cooling rate. Advanced monitoring systems and simulation tools are used to predict and control material flow behavior at the microscale. Process optimization techniques such as Design of Experiments (DOE) and statistical process control are employed to achieve consistent quality and reduce defects in micro-molded parts.Expand Specific Solutions05 Mold design and fabrication for microinjection molding

Specialized mold design and fabrication techniques are crucial for successful microinjection molding. These include micro-machining, laser ablation, LIGA processes, and other precision manufacturing methods to create mold cavities with micro-features. The mold design must address challenges such as proper venting, efficient cooling, and precise alignment to ensure accurate replication of micro-features and prevent defects like incomplete filling or flash.Expand Specific Solutions

Leading Companies and Patent Holders in Automotive Microinjection

Microinjection molding in automotive components is experiencing rapid growth in a maturing market, with an estimated global value of $1.5 billion. The technology has reached moderate maturity, with key players demonstrating varying levels of innovation. Leading automotive manufacturers like BMW, Honda, and Porsche are integrating this technology, while specialized suppliers such as Husky Injection Molding Systems and Magna International provide advanced solutions. Component manufacturers Robert Bosch GmbH and Johnson Controls are leveraging microinjection for precision parts. Taiwan Semiconductor Manufacturing Co. represents the growing intersection between automotive and semiconductor technologies, while research institutions like Jiangsu University and Hong Kong Polytechnic University are advancing fundamental knowledge in this field.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced microinjection molding technologies specifically for automotive sensor components and miniaturized electronic control units. Their patented process combines multi-material injection molding with integrated circuit embedding, allowing for the production of complex microstructured components with wall thicknesses down to 0.1mm. The company utilizes specialized micro-mold inserts with precision-engineered micro-features that enable the production of intricate geometries required for modern automotive sensors. Bosch's technology incorporates in-mold assembly techniques that reduce post-processing steps by 40% compared to conventional methods. Their process employs specialized high-precision injection units with screw diameters as small as 14mm to ensure accurate dosing of the minimal material quantities required for microcomponents. Additionally, Bosch has developed proprietary material formulations optimized for microinjection molding that maintain mechanical integrity despite the extreme flow conditions experienced during the process.

Strengths: Superior precision with tolerances down to ±0.005mm; integrated sensor functionality; reduced assembly steps; excellent material efficiency. Weaknesses: Higher initial tooling costs; limited to specialized high-value components; requires significant expertise to implement and maintain; process parameters have narrow operating windows.

Ford Global Technologies LLC

Technical Solution: Ford has developed proprietary microinjection molding technologies focused on lightweight automotive components with enhanced functionality. Their patented MicroLight process combines microinjection molding with strategic material distribution to create components with variable wall thicknesses as thin as 0.15mm in specific areas while maintaining structural integrity. The technology incorporates specialized gating systems that control material flow paths to achieve precise filling of micro-features without increasing overall part weight. Ford's approach utilizes advanced simulation tools specifically calibrated for microinjection behavior to predict and optimize flow patterns in complex micro-geometries before tooling is created. Their process employs specialized rapid heat/cool molding techniques that enable the production of components with high-gloss visible surfaces alongside functional microstructures in a single shot. Additionally, Ford has pioneered the integration of microinjection molding with in-mold assembly techniques, allowing for the direct overmolding of electronic components and sensors into structural parts, reducing assembly steps by up to 60% for certain components while improving reliability through the elimination of mechanical connections.

Strengths: Excellent weight reduction capabilities; integrated approach to component design and manufacturing; proven production implementation; compatibility with existing manufacturing infrastructure. Weaknesses: Technology primarily developed for internal use; requires specialized design knowledge; higher tooling maintenance requirements; limited to specific material combinations.

Critical Patent Analysis and Technical Innovations

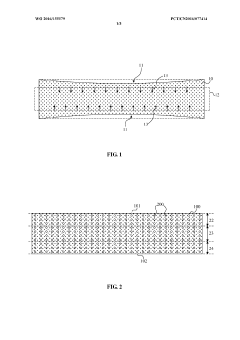

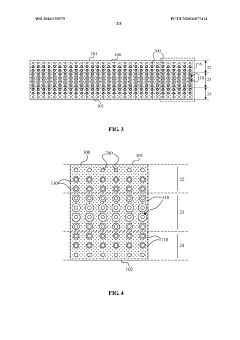

Injection molded component and method for forming the same, encapsulation structure and vehicle window

PatentWO2016155579A1

Innovation

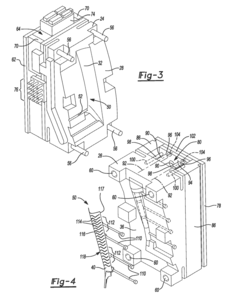

- The use of buffer particles in voids within the middle part of the injection molded component to reduce deformation and sinking during cooling and shrinking processes.

- Strategic placement of voids containing buffer particles to reduce pull forces applied on the component surface during cooling.

- Design of a three-part structure (first part, middle part with voids, second part) that improves dimensional stability of automotive injection molded components.

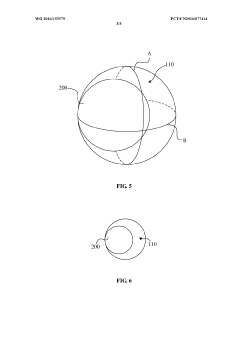

Injection mold for ultra thin wall components

PatentActiveUS20180229411A1

Innovation

- An improved injection mold design featuring a main cavity block and core block with induction heating coils and a serpentine gas flow path, allowing for the production of thin-walled components with enhanced rigidity and surface quality by using induction heating coils to heat the A-side surface and pressurized gas to support the B-side surface during molding.

Material Advancements for Automotive Microinjection Components

The evolution of materials for microinjection molding in automotive applications has accelerated significantly in the past decade, driven by demands for lighter, stronger, and more sustainable components. Traditional materials like polypropylene (PP) and polyamide (PA) have been enhanced with advanced fillers and reinforcements, creating composite materials with superior mechanical properties while maintaining processability in microinjection systems.

High-performance polymers such as PEEK (polyether ether ketone) and LCP (liquid crystal polymers) have emerged as critical materials for microinjection applications requiring exceptional thermal stability and chemical resistance. These materials enable the production of miniaturized components that can withstand harsh under-hood environments where temperatures can exceed 150°C.

Nano-reinforced polymers represent a revolutionary advancement in the field. Carbon nanotubes and graphene additives have demonstrated remarkable improvements in mechanical strength, electrical conductivity, and thermal properties when incorporated into base polymers at concentrations as low as 0.5-3%. Patents from major automotive suppliers show these materials achieving up to 40% weight reduction compared to metal alternatives while maintaining comparable performance characteristics.

Bio-based and sustainable materials have gained significant traction in recent patent filings. Companies like BASF and NatureWorks have developed specialized grades of PLA (polylactic acid) and bio-PA (bio-based polyamide) formulated specifically for microinjection applications. These materials address growing regulatory pressures while offering comparable processing characteristics to petroleum-based counterparts.

Multi-material microinjection technology has advanced considerably, with patents revealing sophisticated material combinations that optimize both functional performance and manufacturing efficiency. Two-component microinjection molding processes allow for the integration of rigid structural elements with flexible sealing features in a single production step, significantly reducing assembly requirements.

Metal-polymer hybrid materials have emerged as a particularly promising category, with patents describing specialized metal powders designed for co-injection with polymers. These materials enable the production of components with localized electromagnetic shielding properties, crucial for housing sensitive automotive electronics in increasingly connected vehicles.

Recent patent activity also reveals significant advancements in material formulations optimized specifically for thin-wall microinjection applications. These specialized compounds feature modified melt flow characteristics that enable filling of micro-features with wall thicknesses below 0.1mm while maintaining dimensional stability and minimizing internal stresses.

High-performance polymers such as PEEK (polyether ether ketone) and LCP (liquid crystal polymers) have emerged as critical materials for microinjection applications requiring exceptional thermal stability and chemical resistance. These materials enable the production of miniaturized components that can withstand harsh under-hood environments where temperatures can exceed 150°C.

Nano-reinforced polymers represent a revolutionary advancement in the field. Carbon nanotubes and graphene additives have demonstrated remarkable improvements in mechanical strength, electrical conductivity, and thermal properties when incorporated into base polymers at concentrations as low as 0.5-3%. Patents from major automotive suppliers show these materials achieving up to 40% weight reduction compared to metal alternatives while maintaining comparable performance characteristics.

Bio-based and sustainable materials have gained significant traction in recent patent filings. Companies like BASF and NatureWorks have developed specialized grades of PLA (polylactic acid) and bio-PA (bio-based polyamide) formulated specifically for microinjection applications. These materials address growing regulatory pressures while offering comparable processing characteristics to petroleum-based counterparts.

Multi-material microinjection technology has advanced considerably, with patents revealing sophisticated material combinations that optimize both functional performance and manufacturing efficiency. Two-component microinjection molding processes allow for the integration of rigid structural elements with flexible sealing features in a single production step, significantly reducing assembly requirements.

Metal-polymer hybrid materials have emerged as a particularly promising category, with patents describing specialized metal powders designed for co-injection with polymers. These materials enable the production of components with localized electromagnetic shielding properties, crucial for housing sensitive automotive electronics in increasingly connected vehicles.

Recent patent activity also reveals significant advancements in material formulations optimized specifically for thin-wall microinjection applications. These specialized compounds feature modified melt flow characteristics that enable filling of micro-features with wall thicknesses below 0.1mm while maintaining dimensional stability and minimizing internal stresses.

Sustainability and Environmental Impact Considerations

Microinjection molding in automotive components presents significant sustainability challenges and opportunities that warrant careful consideration. The automotive industry's shift towards more environmentally responsible manufacturing processes has placed increased scrutiny on plastic component production methods. Microinjection molding, while offering precision and material efficiency advantages, must be evaluated through a comprehensive sustainability lens that encompasses its entire lifecycle impact.

Material selection represents a critical environmental consideration in microinjection molding processes. Traditional petroleum-based polymers are increasingly being supplemented or replaced by bio-based alternatives, recycled materials, and biodegradable compounds. Recent patent developments have focused on novel formulations that maintain the mechanical properties required for automotive applications while reducing environmental footprint. These innovations include composite materials that incorporate natural fibers and fillers derived from agricultural waste streams.

Energy consumption during the microinjection molding process presents another significant environmental challenge. The high-pressure, high-temperature requirements of conventional molding operations contribute substantially to carbon emissions. Patents addressing this concern have introduced energy-efficient heating systems, improved insulation technologies, and advanced process control algorithms that optimize cycle times and minimize energy waste. Some innovative approaches utilize renewable energy sources to power molding operations, further reducing the carbon footprint.

Waste reduction strategies feature prominently in recent microinjection molding patents for automotive applications. Advanced runner systems, precise gate designs, and optimized mold filling simulations have dramatically reduced material waste during production. Additionally, closed-loop recycling systems have been developed to capture and reprocess production scrap, ensuring that virtually all material remains within the manufacturing ecosystem rather than entering waste streams.

End-of-life considerations have gained increasing attention in patent literature, reflecting growing regulatory pressure for extended producer responsibility. Designs that facilitate component disassembly, material identification, and recycling are becoming standard requirements. Some innovative approaches incorporate degradation triggers or design features that enable efficient separation of different materials at end-of-life, enhancing recyclability of complex automotive components.

Water usage and chemical emissions during production and part cleaning processes have also been addressed through recent technological innovations. Waterless cooling systems, dry cleaning technologies, and closed-loop water recycling approaches minimize both consumption and contamination risks. Patents have emerged for biodegradable mold release agents and cleaning compounds that reduce the environmental impact of these necessary production steps.

Material selection represents a critical environmental consideration in microinjection molding processes. Traditional petroleum-based polymers are increasingly being supplemented or replaced by bio-based alternatives, recycled materials, and biodegradable compounds. Recent patent developments have focused on novel formulations that maintain the mechanical properties required for automotive applications while reducing environmental footprint. These innovations include composite materials that incorporate natural fibers and fillers derived from agricultural waste streams.

Energy consumption during the microinjection molding process presents another significant environmental challenge. The high-pressure, high-temperature requirements of conventional molding operations contribute substantially to carbon emissions. Patents addressing this concern have introduced energy-efficient heating systems, improved insulation technologies, and advanced process control algorithms that optimize cycle times and minimize energy waste. Some innovative approaches utilize renewable energy sources to power molding operations, further reducing the carbon footprint.

Waste reduction strategies feature prominently in recent microinjection molding patents for automotive applications. Advanced runner systems, precise gate designs, and optimized mold filling simulations have dramatically reduced material waste during production. Additionally, closed-loop recycling systems have been developed to capture and reprocess production scrap, ensuring that virtually all material remains within the manufacturing ecosystem rather than entering waste streams.

End-of-life considerations have gained increasing attention in patent literature, reflecting growing regulatory pressure for extended producer responsibility. Designs that facilitate component disassembly, material identification, and recycling are becoming standard requirements. Some innovative approaches incorporate degradation triggers or design features that enable efficient separation of different materials at end-of-life, enhancing recyclability of complex automotive components.

Water usage and chemical emissions during production and part cleaning processes have also been addressed through recent technological innovations. Waterless cooling systems, dry cleaning technologies, and closed-loop water recycling approaches minimize both consumption and contamination risks. Patents have emerged for biodegradable mold release agents and cleaning compounds that reduce the environmental impact of these necessary production steps.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!