Precipitation Hardening in High-Entropy Alloys

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Precipitation Hardening Background

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, departing from conventional alloy design principles that typically focus on one principal element with minor additions. Instead, HEAs incorporate multiple principal elements (usually five or more) in near-equiatomic proportions, creating unique crystalline structures with exceptional properties. Since their conceptualization in the early 2000s by Yeh and Cantor independently, HEAs have garnered significant attention due to their remarkable mechanical properties, including high strength, excellent ductility, exceptional thermal stability, and superior corrosion resistance.

The evolution of HEAs has progressed through several distinct phases. Initially, research focused primarily on single-phase solid solutions, leveraging the high configurational entropy to stabilize simple crystal structures. This approach yielded alloys with good thermal stability but often limited strength. The second wave of development explored multi-phase HEAs, incorporating intermetallic compounds to enhance mechanical properties while maintaining reasonable ductility.

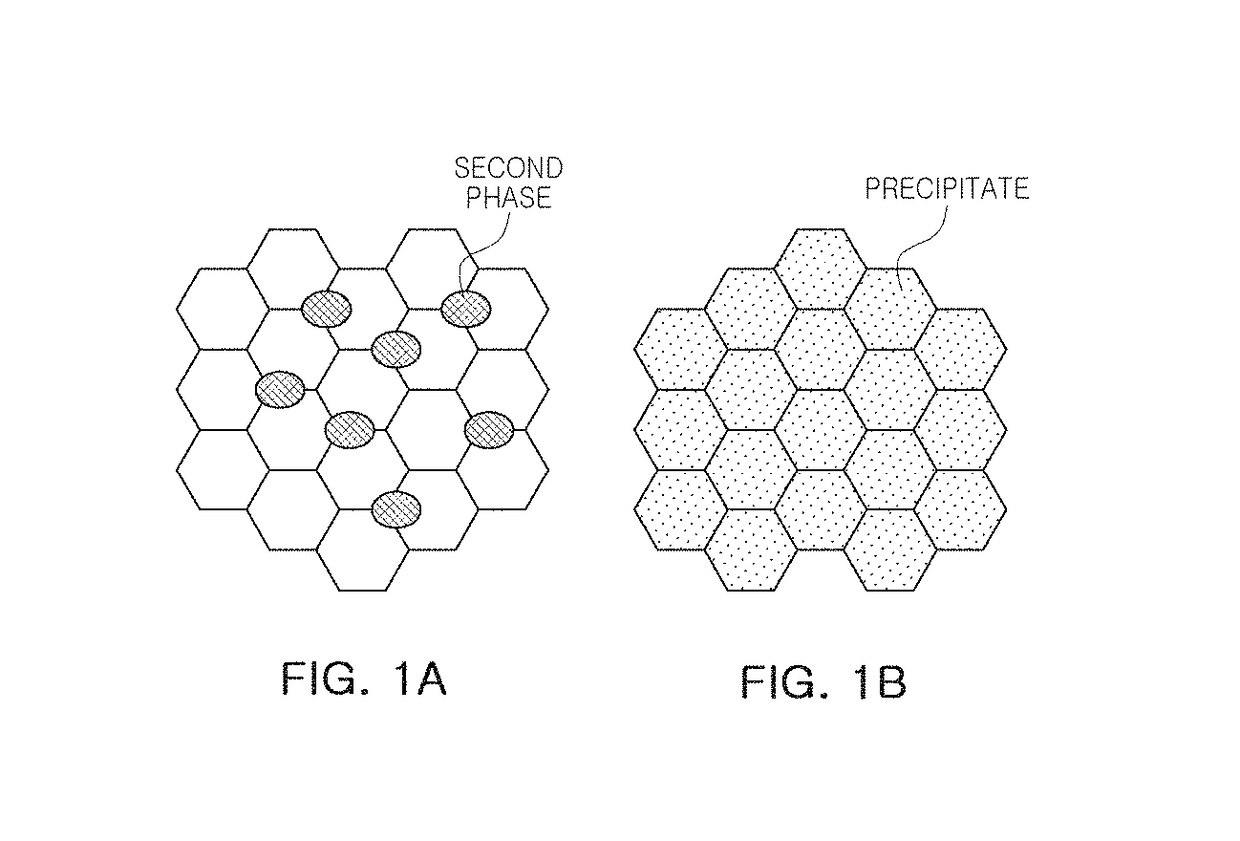

Precipitation hardening emerged as a critical advancement in HEA development, representing the third major phase in their technological evolution. This strengthening mechanism involves the controlled formation of secondary phase precipitates within the matrix through specific heat treatment protocols. These nanoscale precipitates effectively impede dislocation movement, significantly enhancing yield strength while potentially maintaining acceptable ductility.

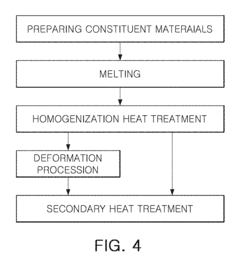

The fundamental principles of precipitation hardening in HEAs build upon classical metallurgical theories but exhibit unique characteristics due to the complex compositional landscape. The process typically involves solution treatment at elevated temperatures to homogenize the microstructure, followed by controlled cooling and aging treatments to induce the nucleation and growth of strengthening precipitates. The multi-principal element nature of HEAs creates distinctive thermodynamic and kinetic conditions that influence precipitation behavior, often resulting in novel precipitate structures and distributions.

Recent technological trends indicate growing interest in tailored precipitation sequences in HEAs, where multiple types of precipitates form in controlled succession to optimize mechanical properties across different temperature ranges. Additionally, researchers are exploring compositionally complex precipitates that inherit the high-entropy concept, potentially offering superior thermal stability compared to conventional precipitates.

The technological trajectory suggests that precipitation-hardened HEAs represent a promising frontier for next-generation structural materials, particularly for extreme environment applications where conventional alloys reach their performance limits. Understanding and controlling precipitation phenomena in these complex alloy systems remains a central challenge that, when mastered, could unlock unprecedented combinations of strength, ductility, and environmental resistance.

The evolution of HEAs has progressed through several distinct phases. Initially, research focused primarily on single-phase solid solutions, leveraging the high configurational entropy to stabilize simple crystal structures. This approach yielded alloys with good thermal stability but often limited strength. The second wave of development explored multi-phase HEAs, incorporating intermetallic compounds to enhance mechanical properties while maintaining reasonable ductility.

Precipitation hardening emerged as a critical advancement in HEA development, representing the third major phase in their technological evolution. This strengthening mechanism involves the controlled formation of secondary phase precipitates within the matrix through specific heat treatment protocols. These nanoscale precipitates effectively impede dislocation movement, significantly enhancing yield strength while potentially maintaining acceptable ductility.

The fundamental principles of precipitation hardening in HEAs build upon classical metallurgical theories but exhibit unique characteristics due to the complex compositional landscape. The process typically involves solution treatment at elevated temperatures to homogenize the microstructure, followed by controlled cooling and aging treatments to induce the nucleation and growth of strengthening precipitates. The multi-principal element nature of HEAs creates distinctive thermodynamic and kinetic conditions that influence precipitation behavior, often resulting in novel precipitate structures and distributions.

Recent technological trends indicate growing interest in tailored precipitation sequences in HEAs, where multiple types of precipitates form in controlled succession to optimize mechanical properties across different temperature ranges. Additionally, researchers are exploring compositionally complex precipitates that inherit the high-entropy concept, potentially offering superior thermal stability compared to conventional precipitates.

The technological trajectory suggests that precipitation-hardened HEAs represent a promising frontier for next-generation structural materials, particularly for extreme environment applications where conventional alloys reach their performance limits. Understanding and controlling precipitation phenomena in these complex alloy systems remains a central challenge that, when mastered, could unlock unprecedented combinations of strength, ductility, and environmental resistance.

Market Applications of Precipitation-Hardened HEAs

Precipitation-hardened High-Entropy Alloys (HEAs) are emerging as transformative materials across multiple industrial sectors due to their exceptional mechanical properties, thermal stability, and corrosion resistance. The aerospace industry represents one of the most promising application markets, where precipitation-hardened HEAs are being evaluated for critical components in aircraft engines, turbine blades, and structural elements. These materials offer superior high-temperature strength and creep resistance compared to conventional superalloys, potentially extending component lifespans by 30-40% while reducing overall weight.

The automotive sector is increasingly adopting precipitation-hardened HEAs for high-performance engine components, particularly in racing and luxury vehicles where thermal stability and wear resistance are paramount. As electric vehicles gain market share, these alloys are finding applications in battery housing structures and thermal management systems where their combination of strength and corrosion resistance provides significant advantages over traditional materials.

In the energy sector, precipitation-hardened HEAs show remarkable potential for power generation equipment, particularly in harsh environments. Their application in steam turbines, nuclear reactors, and geothermal systems leverages their exceptional resistance to radiation damage, thermal cycling, and corrosive media. The oil and gas industry is exploring these materials for downhole tools and offshore platform components where extreme conditions demand materials with superior mechanical properties and corrosion resistance.

The medical device industry represents an emerging market for precipitation-hardened HEAs, particularly for implantable devices requiring biocompatibility combined with mechanical strength. Orthopedic implants, dental prosthetics, and surgical instruments manufactured from these alloys can offer improved wear resistance and reduced risk of metal ion release compared to conventional biomaterials.

Advanced manufacturing sectors, including additive manufacturing, are developing specialized precipitation-hardened HEA formulations optimized for 3D printing processes. This convergence of advanced materials and manufacturing technologies is enabling complex geometries and functionally graded structures previously impossible with conventional manufacturing methods.

Defense applications constitute a significant market driver, with precipitation-hardened HEAs being evaluated for armor systems, projectiles, and hypersonic vehicle components where extreme mechanical properties and thermal stability are essential performance requirements. The classified nature of many defense applications makes market size difficult to quantify, but industry analysts suggest substantial investment in this sector.

The automotive sector is increasingly adopting precipitation-hardened HEAs for high-performance engine components, particularly in racing and luxury vehicles where thermal stability and wear resistance are paramount. As electric vehicles gain market share, these alloys are finding applications in battery housing structures and thermal management systems where their combination of strength and corrosion resistance provides significant advantages over traditional materials.

In the energy sector, precipitation-hardened HEAs show remarkable potential for power generation equipment, particularly in harsh environments. Their application in steam turbines, nuclear reactors, and geothermal systems leverages their exceptional resistance to radiation damage, thermal cycling, and corrosive media. The oil and gas industry is exploring these materials for downhole tools and offshore platform components where extreme conditions demand materials with superior mechanical properties and corrosion resistance.

The medical device industry represents an emerging market for precipitation-hardened HEAs, particularly for implantable devices requiring biocompatibility combined with mechanical strength. Orthopedic implants, dental prosthetics, and surgical instruments manufactured from these alloys can offer improved wear resistance and reduced risk of metal ion release compared to conventional biomaterials.

Advanced manufacturing sectors, including additive manufacturing, are developing specialized precipitation-hardened HEA formulations optimized for 3D printing processes. This convergence of advanced materials and manufacturing technologies is enabling complex geometries and functionally graded structures previously impossible with conventional manufacturing methods.

Defense applications constitute a significant market driver, with precipitation-hardened HEAs being evaluated for armor systems, projectiles, and hypersonic vehicle components where extreme mechanical properties and thermal stability are essential performance requirements. The classified nature of many defense applications makes market size difficult to quantify, but industry analysts suggest substantial investment in this sector.

Current Challenges in HEA Precipitation Mechanisms

Despite significant advancements in High-Entropy Alloy (HEA) research, precipitation hardening mechanisms in these complex alloys present several unresolved challenges. The multi-principal element composition of HEAs creates unprecedented complexity in phase transformation pathways, making precipitation behavior difficult to predict using conventional metallurgical models. Researchers struggle to establish comprehensive thermodynamic and kinetic frameworks that accurately describe precipitation sequences across diverse HEA systems.

A fundamental challenge lies in understanding the nucleation barriers for precipitate formation in HEAs. The severe lattice distortion and chemical disorder inherent to these alloys significantly alter diffusion pathways and interfacial energies compared to traditional alloys. This complexity makes it difficult to apply classical nucleation theory without substantial modifications, resulting in unpredictable precipitation behaviors during heat treatment processes.

The growth kinetics of precipitates in HEAs also remains poorly understood. The sluggish diffusion effect, often cited as a core HEA characteristic, varies considerably across different compositional spaces. This variability creates inconsistent precipitation rates and morphologies, complicating efforts to develop standardized heat treatment protocols for industrial applications. Furthermore, the competitive formation of multiple precipitate phases frequently occurs, making it challenging to isolate and optimize specific strengthening mechanisms.

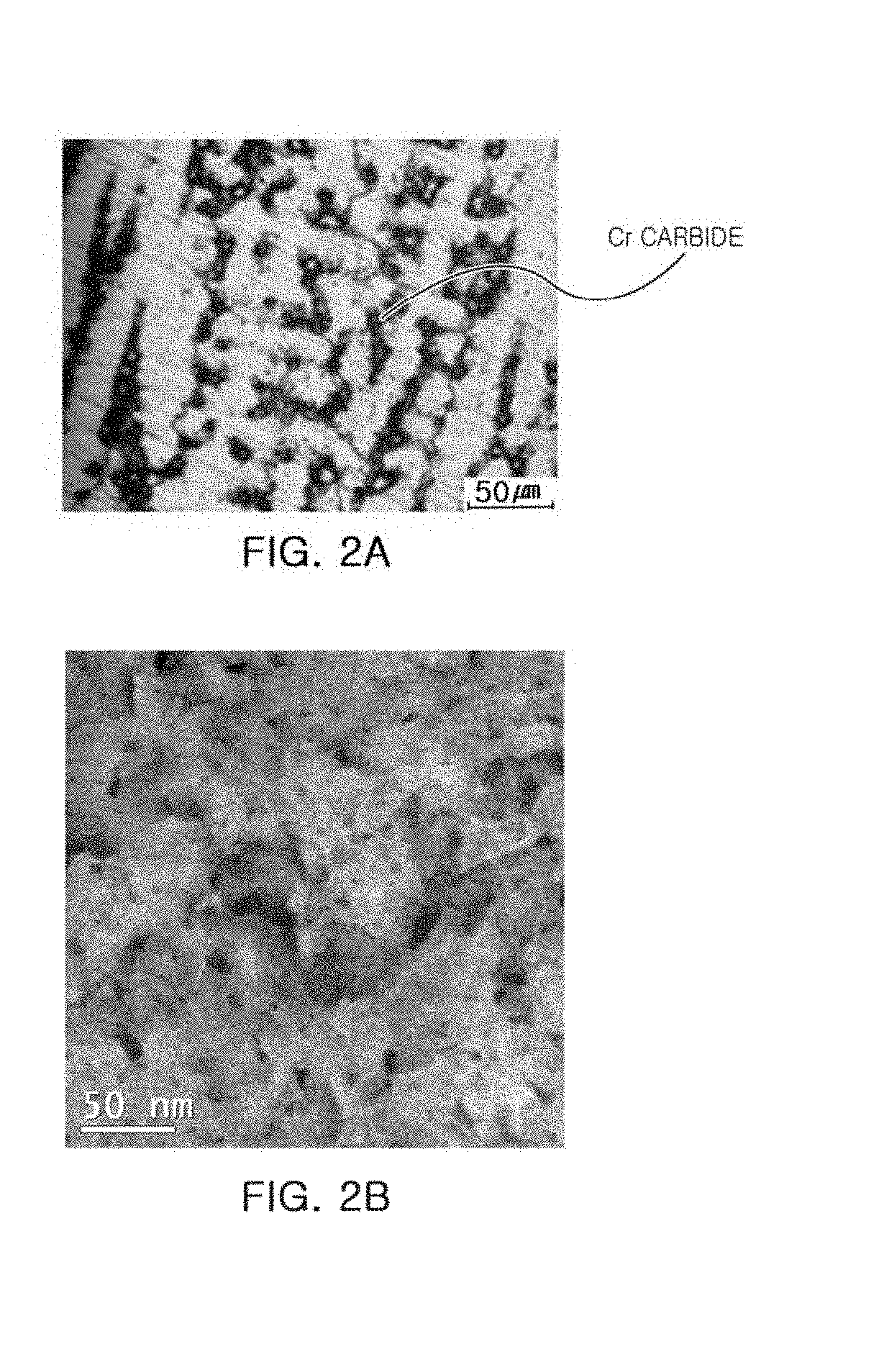

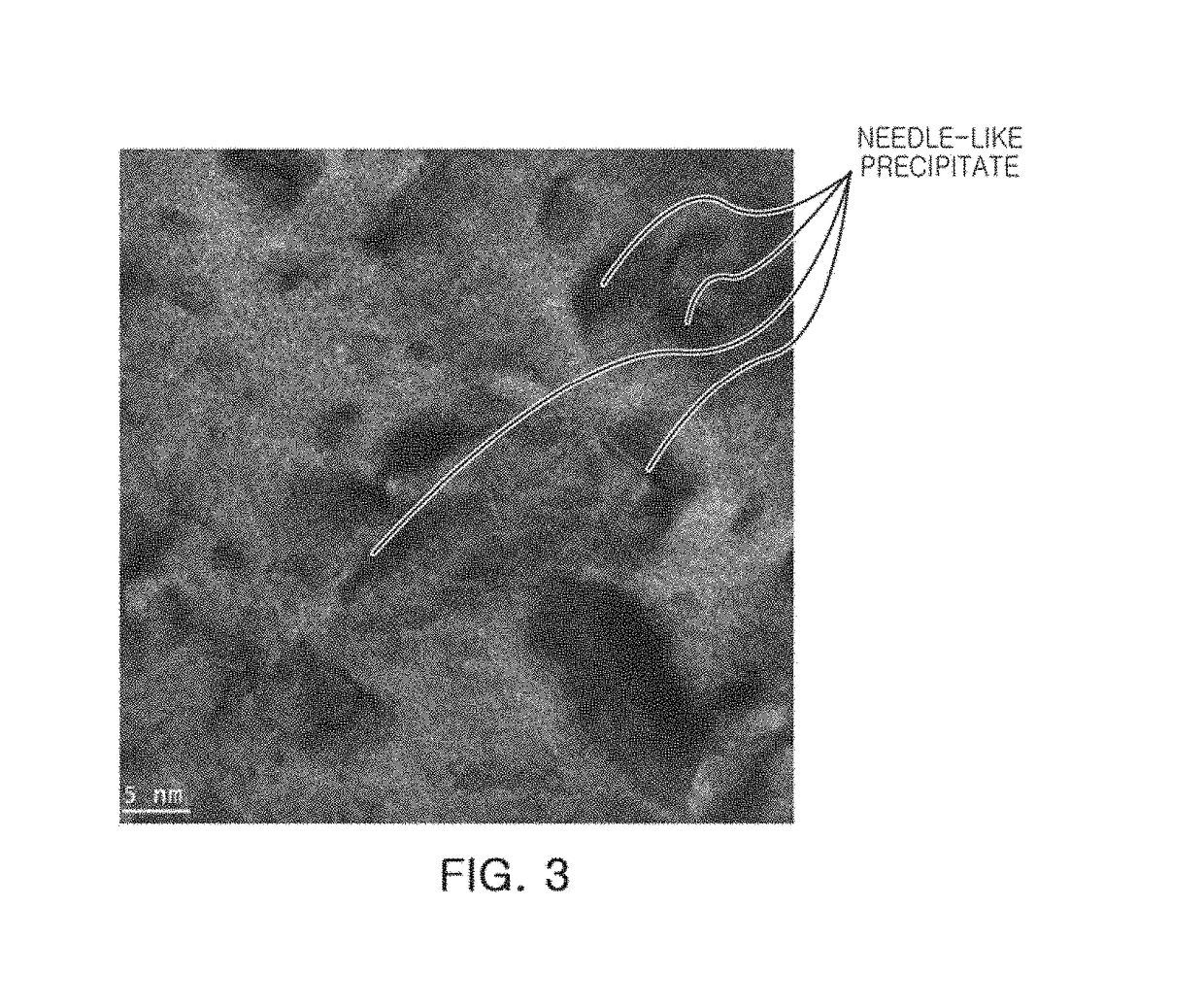

Characterization of precipitates presents another significant hurdle. The nanoscale dimensions of many strengthening precipitates in HEAs, coupled with similar atomic numbers among constituent elements, limit the effectiveness of conventional microscopy and spectroscopy techniques. Advanced characterization methods like atom probe tomography and high-resolution transmission electron microscopy are essential but remain costly and time-intensive for routine analysis.

Computational modeling of precipitation in HEAs faces severe limitations due to the high-dimensional compositional space. Current CALPHAD databases lack comprehensive thermodynamic parameters for many HEA systems, while molecular dynamics and phase-field models struggle with the computational demands of simulating five or more principal elements simultaneously. This gap between experimental observations and theoretical predictions hinders the development of predictive models for precipitation hardening.

The long-term stability of precipitates in HEAs under service conditions represents another critical challenge. Many applications require materials to maintain their properties at elevated temperatures or under irradiation. However, the metastable nature of many strengthening precipitates in HEAs raises concerns about microstructural evolution during extended service, potentially compromising the mechanical properties that initially made these alloys attractive.

A fundamental challenge lies in understanding the nucleation barriers for precipitate formation in HEAs. The severe lattice distortion and chemical disorder inherent to these alloys significantly alter diffusion pathways and interfacial energies compared to traditional alloys. This complexity makes it difficult to apply classical nucleation theory without substantial modifications, resulting in unpredictable precipitation behaviors during heat treatment processes.

The growth kinetics of precipitates in HEAs also remains poorly understood. The sluggish diffusion effect, often cited as a core HEA characteristic, varies considerably across different compositional spaces. This variability creates inconsistent precipitation rates and morphologies, complicating efforts to develop standardized heat treatment protocols for industrial applications. Furthermore, the competitive formation of multiple precipitate phases frequently occurs, making it challenging to isolate and optimize specific strengthening mechanisms.

Characterization of precipitates presents another significant hurdle. The nanoscale dimensions of many strengthening precipitates in HEAs, coupled with similar atomic numbers among constituent elements, limit the effectiveness of conventional microscopy and spectroscopy techniques. Advanced characterization methods like atom probe tomography and high-resolution transmission electron microscopy are essential but remain costly and time-intensive for routine analysis.

Computational modeling of precipitation in HEAs faces severe limitations due to the high-dimensional compositional space. Current CALPHAD databases lack comprehensive thermodynamic parameters for many HEA systems, while molecular dynamics and phase-field models struggle with the computational demands of simulating five or more principal elements simultaneously. This gap between experimental observations and theoretical predictions hinders the development of predictive models for precipitation hardening.

The long-term stability of precipitates in HEAs under service conditions represents another critical challenge. Many applications require materials to maintain their properties at elevated temperatures or under irradiation. However, the metastable nature of many strengthening precipitates in HEAs raises concerns about microstructural evolution during extended service, potentially compromising the mechanical properties that initially made these alloys attractive.

Current Precipitation Hardening Methods for HEAs

01 Precipitation hardening mechanisms in high-entropy alloys

Precipitation hardening is a key strengthening mechanism for high-entropy alloys (HEAs), involving the formation of secondary phase precipitates within the alloy matrix. These precipitates act as obstacles to dislocation movement, significantly enhancing the mechanical properties. The process typically involves solution treatment followed by aging to control precipitate size, distribution, and morphology. This approach can achieve superior hardness and strength while maintaining good ductility in HEAs.- Precipitation hardening mechanisms in high-entropy alloys: Precipitation hardening is a key strengthening mechanism for high-entropy alloys (HEAs), involving the formation of secondary phase precipitates within the alloy matrix. These precipitates act as obstacles to dislocation movement, significantly increasing the hardness and strength of the alloy. The process typically involves solution treatment followed by aging at specific temperatures to control precipitate size, distribution, and morphology, resulting in optimized mechanical properties.

- Grain boundary engineering for HEA strengthening: Grain boundary engineering involves controlling the grain size and boundary characteristics in high-entropy alloys to enhance hardness. By refining grain size through thermomechanical processing or adding grain refiners, the number of grain boundaries increases, providing more obstacles to dislocation movement. Additionally, specific grain boundary structures can be designed to improve strength while maintaining other desirable properties such as ductility and corrosion resistance.

- Solid solution strengthening in multi-component alloys: Solid solution strengthening is fundamental to high-entropy alloys, where multiple principal elements with different atomic sizes create lattice distortion. This distortion impedes dislocation movement, increasing the alloy's hardness. The severity of lattice distortion depends on the atomic size differences and concentration of constituent elements. By carefully selecting elements with appropriate size differences, the solid solution strengthening effect can be maximized while maintaining phase stability.

- Thermomechanical processing for HEA hardening: Thermomechanical processing combines mechanical deformation with thermal treatments to enhance the hardness of high-entropy alloys. Techniques such as cold working, hot rolling, and forging introduce dislocations and refine the microstructure, while subsequent heat treatments can control recrystallization and grain growth. This approach allows for tailoring the microstructure to achieve specific combinations of strength, hardness, and ductility, making it particularly effective for optimizing mechanical properties in complex multi-component alloys.

- Novel compositional design for enhanced hardness: Innovative compositional design strategies are being developed to create high-entropy alloys with superior hardness. These approaches include incorporating elements that promote beneficial phase formation, utilizing machine learning algorithms to predict optimal compositions, and developing multi-phase structures that combine different strengthening mechanisms. By strategically selecting element combinations and their proportions, researchers can develop alloys with exceptional hardness while maintaining other critical properties such as thermal stability and corrosion resistance.

02 Grain boundary engineering for HEA strengthening

Grain boundary engineering involves controlling the grain size and boundary characteristics to enhance the mechanical properties of high-entropy alloys. By refining grain size through thermomechanical processing or severe plastic deformation, the hardness and strength can be significantly increased according to the Hall-Petch relationship. Additionally, manipulating grain boundary chemistry and structure can further improve hardening effects while maintaining other desirable properties.Expand Specific Solutions03 Solid solution strengthening in multi-principal element alloys

Solid solution strengthening is fundamental to high-entropy alloys, where multiple principal elements with different atomic sizes create lattice distortion. This distortion impedes dislocation movement, resulting in enhanced hardness and strength. The severe lattice strain fields generated by the atomic size differences contribute to the exceptional mechanical properties of HEAs. Optimizing element selection and concentration can maximize this strengthening effect while maintaining phase stability.Expand Specific Solutions04 Thermomechanical processing routes for HEA hardening

Various thermomechanical processing techniques can be applied to high-entropy alloys to enhance their hardness. These include cold/hot rolling, forging, extrusion, and cyclic heat treatments. Such processes induce work hardening, refine microstructure, and promote beneficial phase transformations. The combination of deformation and controlled thermal exposure creates optimized microstructures with enhanced dislocation density and subgrain formation, leading to superior mechanical properties.Expand Specific Solutions05 Novel compositional design for enhanced hardening response

Innovative compositional design approaches for high-entropy alloys focus on creating systems with enhanced hardening capabilities. This includes strategic element selection to promote beneficial phase formation, lattice distortion, and precipitation behavior. Advanced computational methods like CALPHAD and machine learning are employed to predict compositions with optimal hardening response. Additionally, minor element additions can significantly influence hardening mechanisms by altering stacking fault energy, phase stability, and diffusion kinetics.Expand Specific Solutions

Leading Research Groups and Industrial Players

High-entropy alloys (HEAs) precipitation hardening technology is currently in the growth phase of its development cycle, with an estimated market size of $150-200 million and expanding at 15-20% annually. The technology is transitioning from early research to commercial applications, particularly in aerospace and energy sectors. Technical maturity varies significantly among key players: research institutions like Central South University, Harbin Institute of Technology, and Korea Advanced Institute of Science & Technology lead fundamental research, while companies including QuesTek Innovations, POSCO Holdings, and Proterial Ltd. are advancing industrial applications. Established manufacturers such as Daido Steel and Kubota Corp are integrating HEA precipitation hardening into specialized product lines, creating a competitive landscape where academic-industrial partnerships are driving innovation and commercialization pathways.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has developed an innovative precipitation hardening approach for high-entropy alloys specifically targeting high-temperature applications in aerospace and power generation. Their technology focuses on refractory element-containing HEAs (Re-HEAs) with carefully controlled additions of Al, Ti, and Nb to promote formation of ordered L12 and B2 precipitates. Daido's process involves vacuum induction melting followed by directional solidification to control grain structure, then a proprietary three-stage heat treatment: solution treatment (1200-1300°C), primary aging (900-950°C), and secondary aging (700-750°C). This creates a hierarchical precipitate structure with primary strengthening phases (50-100nm) surrounded by nanoscale secondary precipitates (5-15nm). Their advanced Re-HEAs demonstrate exceptional creep resistance at temperatures up to 1100°C, with creep rates 40-60% lower than conventional nickel superalloys. Daido has successfully implemented these materials in experimental turbine components, demonstrating service life improvements of 30-40% under extreme thermal conditions.

Strengths: Exceptional high-temperature performance exceeding conventional superalloys, with remarkable microstructural stability during thermal cycling. Their vacuum processing techniques ensure excellent compositional control and minimal impurities. Weaknesses: The use of refractory elements significantly increases material costs and may present processing challenges. The complex multi-stage heat treatments require precise control and specialized equipment.

QuesTek Innovations LLC

Technical Solution: QuesTek has pioneered an Integrated Computational Materials Engineering (ICME) approach to precipitation hardening in high-entropy alloys (HEAs). Their proprietary methodology combines computational thermodynamics, kinetic simulations, and machine learning algorithms to predict optimal compositions and processing routes for HEAs. QuesTek's technology enables precise control over precipitate size, morphology, and distribution by manipulating thermal processing parameters. Their approach includes multi-stage heat treatments that first create a supersaturated solid solution followed by controlled nucleation and growth of nanoscale precipitates. The company has developed several proprietary HEA systems with tailored precipitation sequences that achieve exceptional combinations of strength, ductility, and thermal stability. QuesTek's materials have demonstrated superior mechanical properties at elevated temperatures compared to conventional superalloys, with some variants maintaining structural integrity above 1000°C.

Strengths: Advanced computational modeling capabilities allow rapid alloy design iterations without extensive experimental trials. Their ICME approach significantly reduces development time and costs compared to traditional trial-and-error methods. Weaknesses: The complex processing routes required for optimal precipitation hardening may limit scalability for mass production, and the computational models may require extensive validation for each new alloy system.

Key Patents and Research Breakthroughs

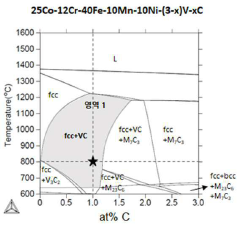

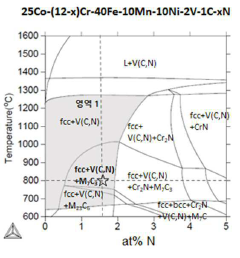

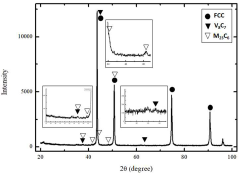

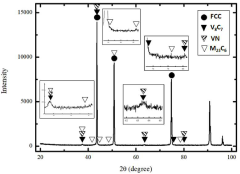

Precipitation hardening high entropy alloy having vanadium precipitates

PatentActiveKR1020220125962A

Innovation

- A high entropy alloy composition based on the FCC phase, incorporating vanadium carbide and/or vanadium nitride precipitates, is developed to enhance strength and elongation without causing grain boundary failure.

Precipitation Hardening High Entropy Alloy and Method of Manufacturing the Same

PatentInactiveUS20190024198A1

Innovation

- A high-entropy alloy with nanoscale and sub-micron precipitates is formed by adding alloying elements with limited solubility, such as nitride or carbide formers, to a matrix with high configurational entropy, using a manufacturing process involving homogenization and secondary heat treatment to disperse precipitates uniformly throughout the alloy.

Computational Modeling of HEA Precipitation Processes

Computational modeling has emerged as a powerful tool for understanding and predicting precipitation processes in High-Entropy Alloys (HEAs). These advanced simulation techniques provide insights into the complex thermodynamic and kinetic processes that govern precipitation hardening, offering a cost-effective alternative to extensive experimental trials.

Phase-field modeling represents one of the most promising computational approaches for HEA precipitation studies. This method can effectively simulate the nucleation, growth, and coarsening of precipitates across multiple length and time scales. Recent advancements have enabled researchers to incorporate the unique characteristics of HEAs, such as severe lattice distortion and complex diffusion pathways, into these models.

First-principles calculations, particularly those based on Density Functional Theory (DFT), have been instrumental in determining critical parameters for precipitation modeling in HEAs. These calculations provide accurate estimates of formation energies, interfacial energies, and diffusion barriers that serve as inputs for mesoscale simulations. The integration of DFT with CALPHAD (CALculation of PHAse Diagrams) has proven particularly effective for predicting phase stability in multi-component HEA systems.

Machine learning approaches are increasingly being applied to accelerate computational modeling of precipitation processes. Neural networks trained on experimental and simulation data can predict precipitation sequences and kinetics with remarkable accuracy. These methods are particularly valuable for navigating the vast compositional space of HEAs, where traditional computational approaches may become prohibitively expensive.

Monte Carlo simulations offer another valuable perspective on atomic-scale processes during precipitation. These simulations can capture the stochastic nature of diffusion and nucleation events in HEAs, providing insights into the early stages of precipitate formation that are difficult to observe experimentally.

Challenges in computational modeling of HEA precipitation include accurately representing the complex thermodynamic interactions in multi-component systems and bridging the gap between atomic-scale phenomena and macroscopic mechanical properties. Multi-scale modeling frameworks that integrate atomic, mesoscale, and continuum approaches are being developed to address these challenges.

Recent advances in high-performance computing have significantly expanded the capabilities of precipitation modeling in HEAs. Parallel computing architectures and GPU acceleration have enabled simulations of larger systems over longer time scales, bringing computational predictions closer to experimental reality.

Phase-field modeling represents one of the most promising computational approaches for HEA precipitation studies. This method can effectively simulate the nucleation, growth, and coarsening of precipitates across multiple length and time scales. Recent advancements have enabled researchers to incorporate the unique characteristics of HEAs, such as severe lattice distortion and complex diffusion pathways, into these models.

First-principles calculations, particularly those based on Density Functional Theory (DFT), have been instrumental in determining critical parameters for precipitation modeling in HEAs. These calculations provide accurate estimates of formation energies, interfacial energies, and diffusion barriers that serve as inputs for mesoscale simulations. The integration of DFT with CALPHAD (CALculation of PHAse Diagrams) has proven particularly effective for predicting phase stability in multi-component HEA systems.

Machine learning approaches are increasingly being applied to accelerate computational modeling of precipitation processes. Neural networks trained on experimental and simulation data can predict precipitation sequences and kinetics with remarkable accuracy. These methods are particularly valuable for navigating the vast compositional space of HEAs, where traditional computational approaches may become prohibitively expensive.

Monte Carlo simulations offer another valuable perspective on atomic-scale processes during precipitation. These simulations can capture the stochastic nature of diffusion and nucleation events in HEAs, providing insights into the early stages of precipitate formation that are difficult to observe experimentally.

Challenges in computational modeling of HEA precipitation include accurately representing the complex thermodynamic interactions in multi-component systems and bridging the gap between atomic-scale phenomena and macroscopic mechanical properties. Multi-scale modeling frameworks that integrate atomic, mesoscale, and continuum approaches are being developed to address these challenges.

Recent advances in high-performance computing have significantly expanded the capabilities of precipitation modeling in HEAs. Parallel computing architectures and GPU acceleration have enabled simulations of larger systems over longer time scales, bringing computational predictions closer to experimental reality.

Sustainability Aspects of HEA Manufacturing

The sustainability of High-Entropy Alloy (HEA) manufacturing processes has become increasingly important as these novel materials gain traction in industrial applications. When examining precipitation hardening in HEAs from a sustainability perspective, several critical factors emerge that influence their environmental footprint and long-term viability.

Energy consumption represents one of the most significant sustainability challenges in HEA manufacturing. Precipitation hardening treatments typically require multiple heating cycles at precise temperatures, consuming substantial energy. Compared to conventional alloys, HEAs often demand higher solution treatment temperatures and longer aging times to achieve optimal precipitation structures, resulting in greater energy intensity per unit of production.

Raw material efficiency presents both challenges and opportunities. While HEAs utilize multiple principal elements in near-equiatomic proportions, they can potentially incorporate less critical or more abundant elements without sacrificing performance. This compositional flexibility allows manufacturers to reduce dependence on rare or environmentally problematic elements. Furthermore, precipitation-hardened HEAs often demonstrate superior durability and service life, reducing the frequency of replacement and associated material consumption.

Waste generation during HEA manufacturing requires careful consideration. The complex composition of HEAs can complicate recycling processes, as separation of multiple principal elements presents technical challenges. However, advancements in recycling technologies specifically designed for multi-element alloys show promise for improving end-of-life material recovery.

Water usage in HEA manufacturing processes, particularly during quenching stages of precipitation hardening treatments, represents another environmental concern. Closed-loop water systems and alternative quenching media are being explored to minimize water consumption and contamination risks.

Emissions from HEA production vary significantly based on manufacturing methods. While traditional melting approaches generate considerable carbon emissions, emerging technologies such as powder metallurgy routes may offer more environmentally friendly alternatives, though these must be balanced against energy requirements for powder production.

Life cycle assessment (LCA) studies of precipitation-hardened HEAs remain limited but indicate potential sustainability advantages through extended service life and reduced maintenance requirements. These benefits can offset higher initial manufacturing impacts when evaluated across the complete product lifecycle.

Future sustainability improvements in HEA precipitation hardening processes will likely focus on energy-efficient heat treatment technologies, increased use of recycled feedstock, and development of computational models to optimize processing parameters while minimizing resource consumption.

Energy consumption represents one of the most significant sustainability challenges in HEA manufacturing. Precipitation hardening treatments typically require multiple heating cycles at precise temperatures, consuming substantial energy. Compared to conventional alloys, HEAs often demand higher solution treatment temperatures and longer aging times to achieve optimal precipitation structures, resulting in greater energy intensity per unit of production.

Raw material efficiency presents both challenges and opportunities. While HEAs utilize multiple principal elements in near-equiatomic proportions, they can potentially incorporate less critical or more abundant elements without sacrificing performance. This compositional flexibility allows manufacturers to reduce dependence on rare or environmentally problematic elements. Furthermore, precipitation-hardened HEAs often demonstrate superior durability and service life, reducing the frequency of replacement and associated material consumption.

Waste generation during HEA manufacturing requires careful consideration. The complex composition of HEAs can complicate recycling processes, as separation of multiple principal elements presents technical challenges. However, advancements in recycling technologies specifically designed for multi-element alloys show promise for improving end-of-life material recovery.

Water usage in HEA manufacturing processes, particularly during quenching stages of precipitation hardening treatments, represents another environmental concern. Closed-loop water systems and alternative quenching media are being explored to minimize water consumption and contamination risks.

Emissions from HEA production vary significantly based on manufacturing methods. While traditional melting approaches generate considerable carbon emissions, emerging technologies such as powder metallurgy routes may offer more environmentally friendly alternatives, though these must be balanced against energy requirements for powder production.

Life cycle assessment (LCA) studies of precipitation-hardened HEAs remain limited but indicate potential sustainability advantages through extended service life and reduced maintenance requirements. These benefits can offset higher initial manufacturing impacts when evaluated across the complete product lifecycle.

Future sustainability improvements in HEA precipitation hardening processes will likely focus on energy-efficient heat treatment technologies, increased use of recycled feedstock, and development of computational models to optimize processing parameters while minimizing resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!