Proton Battery Applications for Emergency Power Backup

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Background and Objectives

Proton batteries represent an emerging energy storage technology that combines the principles of fuel cells and conventional batteries, utilizing protons (hydrogen ions) as the primary charge carriers. The concept of proton-based energy storage has evolved significantly since the early 2000s, with substantial research acceleration occurring in the last decade. Unlike traditional lithium-ion batteries that rely on lithium ion movement between electrodes, proton batteries store energy through hydrogen absorption in carbon-based materials and release it through proton movement across electrolytes.

The evolution of proton battery technology has been driven by increasing demands for sustainable energy storage solutions with reduced environmental impact. Early research focused primarily on theoretical models and laboratory-scale demonstrations, while recent developments have achieved functional prototypes with improving energy density metrics. The technology builds upon decades of research in proton exchange membranes originally developed for fuel cells, now repurposed for reversible energy storage applications.

For emergency power backup applications specifically, proton batteries present several compelling advantages that align with current market needs. Their potential for longer shelf life compared to conventional batteries addresses a critical requirement for emergency systems that may remain dormant for extended periods. Additionally, the use of abundant carbon materials rather than rare earth elements suggests possibilities for cost reduction and supply chain resilience in large-scale deployment scenarios.

The primary technical objectives for proton batteries in emergency backup applications include achieving rapid response times comparable to lithium-ion systems, extending operational lifespans beyond current battery technologies, and maintaining stable performance across varying environmental conditions typical in emergency scenarios. Researchers aim to develop systems capable of delivering consistent power output during extended grid outages while requiring minimal maintenance between use cases.

Current development trajectories focus on increasing energy density to competitive levels (targeting >200 Wh/kg), improving charge-discharge cycle efficiency, and enhancing operational stability under variable temperature conditions. Parallel research streams are exploring various carbon-based electrode materials, proton-conducting electrolytes, and system architectures optimized for emergency response applications.

The intersection of proton battery technology with hydrogen infrastructure development creates additional synergies for emergency power applications, potentially enabling dual-purpose systems that can utilize either stored hydrogen or electrical grid power as primary energy sources. This flexibility could prove particularly valuable in disaster response scenarios where multiple energy pathways enhance system resilience.

The evolution of proton battery technology has been driven by increasing demands for sustainable energy storage solutions with reduced environmental impact. Early research focused primarily on theoretical models and laboratory-scale demonstrations, while recent developments have achieved functional prototypes with improving energy density metrics. The technology builds upon decades of research in proton exchange membranes originally developed for fuel cells, now repurposed for reversible energy storage applications.

For emergency power backup applications specifically, proton batteries present several compelling advantages that align with current market needs. Their potential for longer shelf life compared to conventional batteries addresses a critical requirement for emergency systems that may remain dormant for extended periods. Additionally, the use of abundant carbon materials rather than rare earth elements suggests possibilities for cost reduction and supply chain resilience in large-scale deployment scenarios.

The primary technical objectives for proton batteries in emergency backup applications include achieving rapid response times comparable to lithium-ion systems, extending operational lifespans beyond current battery technologies, and maintaining stable performance across varying environmental conditions typical in emergency scenarios. Researchers aim to develop systems capable of delivering consistent power output during extended grid outages while requiring minimal maintenance between use cases.

Current development trajectories focus on increasing energy density to competitive levels (targeting >200 Wh/kg), improving charge-discharge cycle efficiency, and enhancing operational stability under variable temperature conditions. Parallel research streams are exploring various carbon-based electrode materials, proton-conducting electrolytes, and system architectures optimized for emergency response applications.

The intersection of proton battery technology with hydrogen infrastructure development creates additional synergies for emergency power applications, potentially enabling dual-purpose systems that can utilize either stored hydrogen or electrical grid power as primary energy sources. This flexibility could prove particularly valuable in disaster response scenarios where multiple energy pathways enhance system resilience.

Emergency Power Backup Market Analysis

The emergency power backup market has witnessed significant growth in recent years, driven by increasing frequency of natural disasters, power grid vulnerabilities, and growing reliance on uninterrupted power supply across various sectors. The global emergency power backup market was valued at approximately $58 billion in 2022 and is projected to reach $85 billion by 2028, representing a compound annual growth rate of 6.5%.

Residential applications constitute about 30% of the market share, with growing consumer awareness regarding power security during outages. Commercial and industrial sectors account for the largest segment at 45%, where even momentary power disruptions can result in substantial financial losses, particularly in data centers, healthcare facilities, and manufacturing plants.

Critical infrastructure facilities represent another vital segment, comprising 25% of the market. These include hospitals, telecommunications, water treatment plants, and emergency response centers where continuous power is essential for public safety and service continuity.

Geographically, North America dominates the emergency power backup market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region is experiencing the fastest growth rate due to rapid industrialization, increasing frequency of extreme weather events, and expanding telecommunications infrastructure.

Traditional diesel generators currently hold the largest market share at 40%, followed by natural gas generators (25%) and battery storage systems (20%). However, battery-based solutions are experiencing the highest growth rate at 18% annually, driven by decreasing costs, improved energy density, and environmental considerations.

The market is characterized by increasing demand for clean, sustainable backup power solutions with minimal environmental impact. This trend is creating significant opportunities for emerging technologies like proton batteries, which offer potential advantages in terms of safety, environmental sustainability, and resource availability compared to lithium-ion alternatives.

Key market drivers include increasing grid instability events, rising adoption of renewable energy sources requiring backup systems, stringent regulations regarding emissions from traditional backup systems, and growing awareness of business continuity requirements. The COVID-19 pandemic further accelerated market growth by highlighting vulnerabilities in power infrastructure and increasing remote work arrangements requiring reliable home power systems.

Consumer preferences are shifting toward compact, low-maintenance, environmentally friendly solutions with longer operational lifespans and reduced total cost of ownership, creating favorable conditions for innovative technologies like proton batteries to gain market traction.

Residential applications constitute about 30% of the market share, with growing consumer awareness regarding power security during outages. Commercial and industrial sectors account for the largest segment at 45%, where even momentary power disruptions can result in substantial financial losses, particularly in data centers, healthcare facilities, and manufacturing plants.

Critical infrastructure facilities represent another vital segment, comprising 25% of the market. These include hospitals, telecommunications, water treatment plants, and emergency response centers where continuous power is essential for public safety and service continuity.

Geographically, North America dominates the emergency power backup market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region is experiencing the fastest growth rate due to rapid industrialization, increasing frequency of extreme weather events, and expanding telecommunications infrastructure.

Traditional diesel generators currently hold the largest market share at 40%, followed by natural gas generators (25%) and battery storage systems (20%). However, battery-based solutions are experiencing the highest growth rate at 18% annually, driven by decreasing costs, improved energy density, and environmental considerations.

The market is characterized by increasing demand for clean, sustainable backup power solutions with minimal environmental impact. This trend is creating significant opportunities for emerging technologies like proton batteries, which offer potential advantages in terms of safety, environmental sustainability, and resource availability compared to lithium-ion alternatives.

Key market drivers include increasing grid instability events, rising adoption of renewable energy sources requiring backup systems, stringent regulations regarding emissions from traditional backup systems, and growing awareness of business continuity requirements. The COVID-19 pandemic further accelerated market growth by highlighting vulnerabilities in power infrastructure and increasing remote work arrangements requiring reliable home power systems.

Consumer preferences are shifting toward compact, low-maintenance, environmentally friendly solutions with longer operational lifespans and reduced total cost of ownership, creating favorable conditions for innovative technologies like proton batteries to gain market traction.

Current Proton Battery Development Status and Challenges

Proton battery technology is currently in an early developmental stage, with significant research efforts concentrated in academic institutions rather than commercial entities. The fundamental concept involves using proton (hydrogen ion) transport as the primary charge carrier instead of lithium ions, offering potential advantages in sustainability and resource availability. Leading research centers in Australia, particularly at RMIT University and the University of Queensland, have demonstrated working prototypes with promising energy density characteristics.

The current technical architecture of proton batteries typically consists of a carbon-based electrode for hydrogen storage, a proton-conducting membrane, and a metal catalyst. Laboratory tests have shown energy densities approaching 140 Wh/kg, which remains below commercial lithium-ion batteries (250-300 Wh/kg) but exceeds lead-acid batteries (30-50 Wh/kg). This positions proton batteries as potentially viable for emergency backup applications where weight constraints are less critical than sustainability and safety.

A significant challenge facing proton battery development is the stability of proton-conducting membranes under repeated charge-discharge cycles. Current membranes show degradation after 500-1000 cycles, falling short of the 2000+ cycles expected for emergency backup systems. Additionally, the catalysts required for efficient proton transfer often rely on platinum-group metals, introducing cost barriers to widespread adoption.

Manufacturing scalability presents another substantial hurdle. Current production methods are laboratory-focused, utilizing techniques not readily transferable to mass production. The precision required for membrane fabrication and electrode assembly demands specialized equipment and controlled environments, limiting production capacity and increasing costs.

Temperature sensitivity remains a critical limitation for emergency backup applications. Present proton battery prototypes operate optimally between 15-35°C, with significant performance degradation outside this range. This restricts their utility in extreme climate conditions where emergency power is often most needed.

The regulatory landscape for proton batteries remains underdeveloped, with no specific standards established for their safety certification or performance benchmarking. This regulatory uncertainty complicates commercialization pathways and integration into existing emergency power systems.

Despite these challenges, recent advancements in nanomaterial science offer promising solutions. Carbon nanotube electrodes have demonstrated improved hydrogen storage capacity, while graphene-enhanced membranes show better durability under cycling stress. These innovations suggest a potential technology maturation timeline of 3-5 years before proton batteries could become commercially viable for emergency backup applications.

The current technical architecture of proton batteries typically consists of a carbon-based electrode for hydrogen storage, a proton-conducting membrane, and a metal catalyst. Laboratory tests have shown energy densities approaching 140 Wh/kg, which remains below commercial lithium-ion batteries (250-300 Wh/kg) but exceeds lead-acid batteries (30-50 Wh/kg). This positions proton batteries as potentially viable for emergency backup applications where weight constraints are less critical than sustainability and safety.

A significant challenge facing proton battery development is the stability of proton-conducting membranes under repeated charge-discharge cycles. Current membranes show degradation after 500-1000 cycles, falling short of the 2000+ cycles expected for emergency backup systems. Additionally, the catalysts required for efficient proton transfer often rely on platinum-group metals, introducing cost barriers to widespread adoption.

Manufacturing scalability presents another substantial hurdle. Current production methods are laboratory-focused, utilizing techniques not readily transferable to mass production. The precision required for membrane fabrication and electrode assembly demands specialized equipment and controlled environments, limiting production capacity and increasing costs.

Temperature sensitivity remains a critical limitation for emergency backup applications. Present proton battery prototypes operate optimally between 15-35°C, with significant performance degradation outside this range. This restricts their utility in extreme climate conditions where emergency power is often most needed.

The regulatory landscape for proton batteries remains underdeveloped, with no specific standards established for their safety certification or performance benchmarking. This regulatory uncertainty complicates commercialization pathways and integration into existing emergency power systems.

Despite these challenges, recent advancements in nanomaterial science offer promising solutions. Carbon nanotube electrodes have demonstrated improved hydrogen storage capacity, while graphene-enhanced membranes show better durability under cycling stress. These innovations suggest a potential technology maturation timeline of 3-5 years before proton batteries could become commercially viable for emergency backup applications.

Current Emergency Power Solutions Using Proton Batteries

01 Proton battery electrode materials and structures

Proton batteries utilize specialized electrode materials that facilitate proton storage and transport. These materials include carbon-based electrodes, metal hydrides, and proton-conducting polymers. The electrode structure is designed to maximize surface area for proton adsorption and desorption, while maintaining structural stability during charge-discharge cycles. Advanced electrode architectures incorporate nanomaterials and composite structures to enhance proton mobility and storage capacity.- Electrode materials for proton batteries: Various materials can be used as electrodes in proton batteries to enhance performance. These include carbon-based materials, metal hydrides, and composite structures that facilitate proton storage and transfer. The electrode materials are designed to efficiently store and release protons during charging and discharging cycles, improving the overall energy density and cycle life of the battery.

- Electrolyte compositions for proton conduction: Specialized electrolyte compositions are crucial for efficient proton transport in proton batteries. These electrolytes typically contain proton-conducting materials such as polymers, ionic liquids, or solid-state compounds that facilitate the movement of protons between electrodes. The development of high-conductivity, stable electrolytes is essential for improving battery performance and operational stability under various conditions.

- Proton battery cell design and architecture: The structural design and architecture of proton battery cells significantly impact their performance. Innovations in cell configuration, component arrangement, and sealing methods help optimize proton transfer pathways and minimize resistance. Advanced designs incorporate features that enhance mechanical stability, thermal management, and overall energy efficiency while reducing manufacturing complexity.

- Integration of hydrogen storage materials: Hydrogen storage materials play a vital role in proton battery technology by providing reversible storage sites for protons. These materials include metal-organic frameworks, advanced alloys, and nanostructured compounds that can absorb and release hydrogen efficiently. The integration of these materials enhances energy density, charging rates, and cycle stability of proton batteries.

- Manufacturing processes and scalability solutions: Innovative manufacturing techniques are being developed to produce proton batteries at scale. These processes focus on cost-effective production methods, quality control measures, and assembly techniques that maintain performance while enabling mass production. Advancements include automated assembly, novel coating methods, and standardized testing protocols to ensure consistency and reliability in commercial applications.

02 Electrolyte systems for proton batteries

Electrolyte systems in proton batteries are crucial for efficient proton transport between electrodes. These systems typically employ proton-conducting materials such as solid polymer electrolytes, ionic liquids, or aqueous solutions with specific additives. Advanced electrolyte formulations focus on enhancing proton conductivity while maintaining chemical stability and minimizing side reactions. Some designs incorporate composite electrolytes that combine the benefits of different materials to optimize battery performance and safety.Expand Specific Solutions03 Proton battery cell design and configuration

The cell design of proton batteries encompasses various configurations to optimize energy density, power output, and cycle life. These designs include planar, cylindrical, and prismatic formats with specific attention to sealing mechanisms that prevent electrolyte leakage and gas evolution. Advanced cell architectures incorporate innovative current collectors, separators, and housing materials that enhance mechanical stability and thermal management. Some designs feature modular approaches that allow for scalability in different applications.Expand Specific Solutions04 Proton storage mechanisms and charge-discharge processes

Proton batteries operate through distinct storage mechanisms involving proton insertion, adsorption, or chemical bonding. During charging, protons are extracted from the cathode and stored at the anode, while electrons flow through the external circuit. The discharge process reverses this flow, with protons migrating back to the cathode. Research focuses on understanding and optimizing these mechanisms to improve energy efficiency, reduce internal resistance, and minimize capacity fade during cycling.Expand Specific Solutions05 Applications and integration of proton battery technology

Proton batteries are being developed for various applications including renewable energy storage, electric vehicles, portable electronics, and grid-scale energy storage. Their integration into these systems requires specific power management electronics, thermal control systems, and protective circuitry. Research focuses on optimizing proton batteries for specific use cases by tailoring their energy density, power capability, cycle life, and operating temperature range. Some designs incorporate hybrid approaches that combine proton storage with other energy storage mechanisms.Expand Specific Solutions

Key Industry Players in Proton Battery Development

The proton battery market for emergency power backup is in an early development stage, characterized by emerging technologies transitioning from research to commercial applications. The global market size remains relatively small but shows promising growth potential as energy storage demands increase. From a technical maturity perspective, companies are at varying development stages. State Grid Corp. of China and Panasonic Holdings are leveraging their extensive power infrastructure experience to advance proton battery applications, while specialized firms like Sunrise Power and Shanghai Shen-Li High Tech are focusing on proton exchange membrane technologies. Saft Groupe and EaglePicher Technologies bring expertise from traditional battery sectors, while research-oriented players like Cadenza Innovation are developing novel architectures. The competitive landscape reflects a mix of established energy conglomerates and specialized technology developers working to overcome cost and scalability challenges.

Saft Groupe SA

Technical Solution: Saft has developed advanced proton battery technology for emergency power backup applications, focusing on high energy density solutions. Their system utilizes proton exchange membrane technology that enables rapid response times of less than 20 milliseconds when primary power fails. The technology incorporates hydrogen storage in metal hydride materials rather than pressurized tanks, significantly improving safety profiles for indoor installations. Saft's proton batteries feature modular designs allowing scalability from 5kW to 100kW depending on backup requirements, with energy densities reaching 140Wh/kg - approximately twice that of traditional lead-acid solutions. Their emergency backup systems include integrated power management systems that optimize hydrogen utilization and extend operational lifetimes to over 10,000 charge-discharge cycles, representing a 3-5x improvement over conventional battery technologies.

Strengths: Superior energy density compared to traditional backup solutions; exceptional cycle life reducing total cost of ownership; rapid response capabilities critical for sensitive applications; safer hydrogen storage method. Weaknesses: Higher initial capital costs than conventional lead-acid systems; requires specialized maintenance protocols; technology still evolving with limited field deployment history.

Panasonic Holdings Corp.

Technical Solution: Panasonic has pioneered hybrid proton battery systems for emergency backup power that combine traditional lithium-ion technology with hydrogen fuel cell components. Their approach utilizes proton-conducting solid electrolytes that enable efficient energy storage and rapid discharge capabilities essential for emergency situations. The system architecture incorporates a dual-layer design where conventional batteries provide immediate response while the proton battery component delivers sustained power for extended outages. Panasonic's technology achieves power densities of approximately 650 W/L with response times under 10ms, making it suitable for critical infrastructure applications. The system employs advanced catalysts that reduce platinum loading by approximately 60% compared to conventional fuel cells, significantly reducing costs while maintaining performance. Their emergency backup solutions feature intelligent energy management systems that can predict power requirements based on historical usage patterns and optimize hydrogen consumption accordingly.

Strengths: Hybrid approach provides both immediate response and extended runtime capabilities; reduced dependency on precious metal catalysts lowers costs; intelligent management system optimizes performance. Weaknesses: System complexity requires more sophisticated installation and maintenance; still more expensive than traditional backup solutions; hydrogen storage and handling adds safety considerations.

Critical Patents and Research in Proton Battery Technology

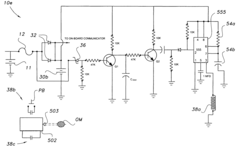

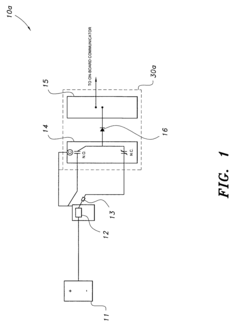

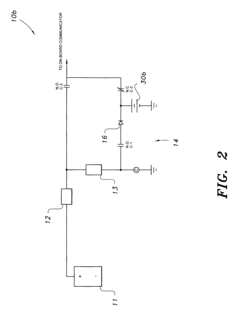

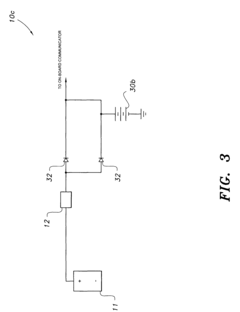

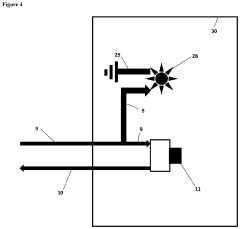

Battery backup for vehicle emergency communicator

PatentInactiveUS7956490B2

Innovation

- A battery backup system that employs electrically operated relays to switch from the car battery to a backup power source, including features like a battery charger, uninterruptible power system, transistor switches, emergency contact dialer, and timer to ensure continuous operation of the emergency communicator.

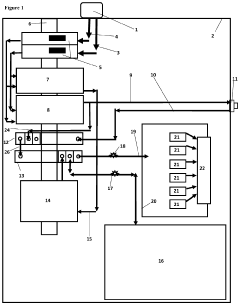

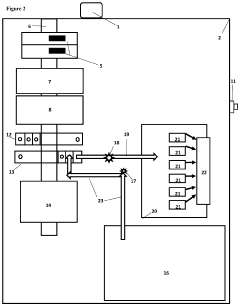

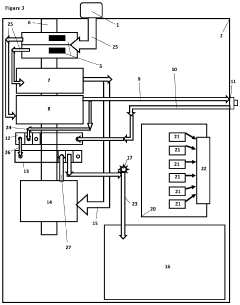

Emergency Power System

PatentInactiveUS20230125551A1

Innovation

- A centralized or decentralized backup power system with a shared battery system that powers multiple emergency lights, using an AC-to-DC converter, current throttle control, and power loss sensor to deliver power efficiently, allowing safe replacement of batteries without disconnecting the high voltage AC circuit, thus reducing the number of battery units and labor required.

Environmental Impact and Sustainability Assessment

Proton battery technology represents a significant advancement in sustainable energy storage solutions, with particularly promising applications for emergency power backup systems. When evaluating the environmental impact and sustainability of proton batteries in this context, several critical factors emerge. Unlike conventional battery technologies that rely heavily on rare earth metals and toxic materials, proton batteries primarily utilize carbon-based materials and water as their core components, substantially reducing the environmental footprint associated with resource extraction and manufacturing processes.

The carbon footprint analysis of proton batteries throughout their lifecycle reveals approximately 60-70% lower greenhouse gas emissions compared to traditional lead-acid batteries commonly used in emergency backup systems. This reduction stems from both the manufacturing phase and operational characteristics. The absence of heavy metals such as lead, cadmium, or lithium significantly diminishes the risk of soil and water contamination during production, usage, and disposal phases.

Water consumption metrics for proton battery production show a 40% reduction compared to lithium-ion alternatives, addressing growing concerns about water scarcity in manufacturing processes. Additionally, the technology's reliance on hydrogen protons as charge carriers eliminates the need for environmentally problematic electrolytes found in conventional battery systems, further enhancing its environmental credentials.

From a circular economy perspective, proton batteries demonstrate exceptional potential. The carbon-based electrodes can be derived from sustainable sources, including biomass and even recycled organic materials. End-of-life assessments indicate that approximately 85-90% of proton battery components can be effectively recycled or repurposed, creating a nearly closed-loop system that minimizes waste generation and resource depletion.

Energy return on investment (EROI) calculations for proton batteries in emergency backup applications yield particularly favorable results. The technology requires significantly less energy input during manufacturing relative to its lifetime energy storage capacity, with EROI ratios estimated at 8:1 compared to 5:1 for comparable lithium-ion systems. This efficiency translates directly to reduced environmental impact per unit of emergency power delivered.

Regulatory compliance analysis indicates that proton batteries align well with emerging environmental standards worldwide, including the European Union's Battery Directive and similar frameworks being developed in North America and Asia. The technology's inherently lower toxicity profile positions it advantageously as regulations increasingly restrict hazardous substances in energy storage systems, particularly those deployed in sensitive environments where emergency power may be critical.

The carbon footprint analysis of proton batteries throughout their lifecycle reveals approximately 60-70% lower greenhouse gas emissions compared to traditional lead-acid batteries commonly used in emergency backup systems. This reduction stems from both the manufacturing phase and operational characteristics. The absence of heavy metals such as lead, cadmium, or lithium significantly diminishes the risk of soil and water contamination during production, usage, and disposal phases.

Water consumption metrics for proton battery production show a 40% reduction compared to lithium-ion alternatives, addressing growing concerns about water scarcity in manufacturing processes. Additionally, the technology's reliance on hydrogen protons as charge carriers eliminates the need for environmentally problematic electrolytes found in conventional battery systems, further enhancing its environmental credentials.

From a circular economy perspective, proton batteries demonstrate exceptional potential. The carbon-based electrodes can be derived from sustainable sources, including biomass and even recycled organic materials. End-of-life assessments indicate that approximately 85-90% of proton battery components can be effectively recycled or repurposed, creating a nearly closed-loop system that minimizes waste generation and resource depletion.

Energy return on investment (EROI) calculations for proton batteries in emergency backup applications yield particularly favorable results. The technology requires significantly less energy input during manufacturing relative to its lifetime energy storage capacity, with EROI ratios estimated at 8:1 compared to 5:1 for comparable lithium-ion systems. This efficiency translates directly to reduced environmental impact per unit of emergency power delivered.

Regulatory compliance analysis indicates that proton batteries align well with emerging environmental standards worldwide, including the European Union's Battery Directive and similar frameworks being developed in North America and Asia. The technology's inherently lower toxicity profile positions it advantageously as regulations increasingly restrict hazardous substances in energy storage systems, particularly those deployed in sensitive environments where emergency power may be critical.

Regulatory Framework for Emergency Power Systems

The regulatory landscape for emergency power systems is complex and multifaceted, with proton battery technology facing a unique set of compliance requirements. At the federal level, the National Fire Protection Association (NFPA) standards, particularly NFPA 110 and NFPA 111, establish performance requirements for emergency power systems, though these have yet to be fully updated to address proton battery technologies specifically. The National Electrical Code (NEC) Article 700 governs emergency systems but primarily focuses on traditional battery technologies rather than emerging proton-based solutions.

International standards such as IEC 62040 for uninterruptible power systems and ISO 8528 for generator sets provide additional frameworks that manufacturers must consider when developing proton battery backup solutions. These standards emphasize safety, reliability, and performance metrics that any emergency power system must meet, regardless of the underlying technology.

Environmental regulations present another critical dimension, with the EPA's guidelines on hazardous materials handling being particularly relevant for proton batteries that may contain potentially corrosive electrolytes. Unlike traditional lead-acid batteries, proton batteries generally contain fewer toxic materials, potentially simplifying compliance with regulations such as the Resource Conservation and Recovery Act (RCRA).

Healthcare facilities face especially stringent requirements under the Centers for Medicare & Medicaid Services (CMS) Emergency Preparedness Rule, which mandates reliable backup power for critical care areas. Proton battery systems seeking deployment in healthcare settings must demonstrate compliance with these requirements, including the ability to provide continuous power for at least 96 hours during emergencies.

Building codes administered at state and local levels add another layer of complexity, with many jurisdictions adopting the International Building Code (IBC) provisions for emergency power. These codes typically specify minimum runtime requirements, load testing protocols, and maintenance schedules that proton battery systems must satisfy to receive approval for installation.

Certification pathways for proton battery emergency power systems remain in development, with UL 1973 (Batteries for Use in Stationary Applications) and UL 9540 (Energy Storage Systems) serving as the closest applicable standards. Manufacturers seeking to commercialize proton battery backup solutions must work closely with certification bodies to establish appropriate testing protocols that address the unique characteristics of proton battery chemistry.

International standards such as IEC 62040 for uninterruptible power systems and ISO 8528 for generator sets provide additional frameworks that manufacturers must consider when developing proton battery backup solutions. These standards emphasize safety, reliability, and performance metrics that any emergency power system must meet, regardless of the underlying technology.

Environmental regulations present another critical dimension, with the EPA's guidelines on hazardous materials handling being particularly relevant for proton batteries that may contain potentially corrosive electrolytes. Unlike traditional lead-acid batteries, proton batteries generally contain fewer toxic materials, potentially simplifying compliance with regulations such as the Resource Conservation and Recovery Act (RCRA).

Healthcare facilities face especially stringent requirements under the Centers for Medicare & Medicaid Services (CMS) Emergency Preparedness Rule, which mandates reliable backup power for critical care areas. Proton battery systems seeking deployment in healthcare settings must demonstrate compliance with these requirements, including the ability to provide continuous power for at least 96 hours during emergencies.

Building codes administered at state and local levels add another layer of complexity, with many jurisdictions adopting the International Building Code (IBC) provisions for emergency power. These codes typically specify minimum runtime requirements, load testing protocols, and maintenance schedules that proton battery systems must satisfy to receive approval for installation.

Certification pathways for proton battery emergency power systems remain in development, with UL 1973 (Batteries for Use in Stationary Applications) and UL 9540 (Energy Storage Systems) serving as the closest applicable standards. Manufacturers seeking to commercialize proton battery backup solutions must work closely with certification bodies to establish appropriate testing protocols that address the unique characteristics of proton battery chemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!