Proton Battery Efficiency in Commercial Building Applications

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Background and Objectives

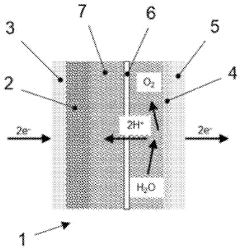

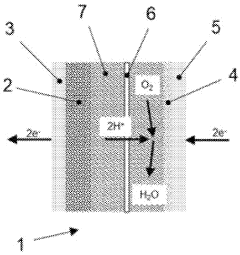

Proton battery technology represents a significant evolution in energy storage systems, emerging from decades of research into hydrogen-based energy solutions. Initially conceptualized in the early 2000s, these batteries have progressed from theoretical models to functional prototypes through advancements in materials science and electrochemistry. The fundamental principle leverages proton movement across specialized membranes, offering a potentially more sustainable alternative to lithium-ion technologies that currently dominate commercial building energy storage solutions.

The development trajectory of proton batteries has accelerated notably since 2018, when researchers at RMIT University in Australia demonstrated a working prototype with promising efficiency metrics. This breakthrough catalyzed increased research investment globally, particularly in regions prioritizing carbon-neutral building technologies. The subsequent five years have witnessed substantial improvements in energy density, cycle life, and operational stability under variable temperature conditions—all critical factors for commercial building applications.

Current technical objectives for proton battery implementation in commercial buildings center on four primary dimensions: increasing energy density to exceed 300 Wh/kg, extending operational lifespan beyond 5,000 cycles, improving charge/discharge efficiency to over 90%, and reducing manufacturing costs to below $100/kWh. These targets represent the threshold requirements for commercial viability in building energy management systems, particularly for peak load management and renewable energy integration.

The technology aims to address specific limitations in existing commercial building energy solutions, including the environmental impact of lithium extraction, fire safety concerns with conventional batteries, and performance degradation in variable climate conditions. Proton batteries offer theoretical advantages in each of these areas, with significantly lower environmental footprint, inherently safer chemistry, and more stable performance across temperature ranges typical in building environments.

Looking forward, the technology roadmap for proton batteries in commercial applications focuses on scalability and system integration. Research objectives include developing modular designs compatible with existing building management systems, optimizing proton membrane materials for enhanced conductivity, and creating intelligent control algorithms that maximize efficiency based on building usage patterns and external grid conditions.

The convergence of decarbonization policies, increasing commercial electricity costs, and growing demand for resilient building infrastructure creates a favorable environment for proton battery adoption. Technical objectives now extend beyond performance metrics to include standardization initiatives, certification frameworks, and integration protocols that will facilitate mainstream implementation in diverse commercial building contexts.

The development trajectory of proton batteries has accelerated notably since 2018, when researchers at RMIT University in Australia demonstrated a working prototype with promising efficiency metrics. This breakthrough catalyzed increased research investment globally, particularly in regions prioritizing carbon-neutral building technologies. The subsequent five years have witnessed substantial improvements in energy density, cycle life, and operational stability under variable temperature conditions—all critical factors for commercial building applications.

Current technical objectives for proton battery implementation in commercial buildings center on four primary dimensions: increasing energy density to exceed 300 Wh/kg, extending operational lifespan beyond 5,000 cycles, improving charge/discharge efficiency to over 90%, and reducing manufacturing costs to below $100/kWh. These targets represent the threshold requirements for commercial viability in building energy management systems, particularly for peak load management and renewable energy integration.

The technology aims to address specific limitations in existing commercial building energy solutions, including the environmental impact of lithium extraction, fire safety concerns with conventional batteries, and performance degradation in variable climate conditions. Proton batteries offer theoretical advantages in each of these areas, with significantly lower environmental footprint, inherently safer chemistry, and more stable performance across temperature ranges typical in building environments.

Looking forward, the technology roadmap for proton batteries in commercial applications focuses on scalability and system integration. Research objectives include developing modular designs compatible with existing building management systems, optimizing proton membrane materials for enhanced conductivity, and creating intelligent control algorithms that maximize efficiency based on building usage patterns and external grid conditions.

The convergence of decarbonization policies, increasing commercial electricity costs, and growing demand for resilient building infrastructure creates a favorable environment for proton battery adoption. Technical objectives now extend beyond performance metrics to include standardization initiatives, certification frameworks, and integration protocols that will facilitate mainstream implementation in diverse commercial building contexts.

Commercial Building Energy Storage Market Analysis

The commercial building energy storage market has experienced significant growth over the past decade, driven primarily by increasing energy costs, grid reliability concerns, and sustainability initiatives. As of 2023, this market is valued at approximately $4.2 billion globally, with projections indicating a compound annual growth rate (CAGR) of 16.8% through 2030. North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%), with the remaining regions accounting for 9%.

The demand for energy storage solutions in commercial buildings is primarily fueled by three key factors. First, the rising electricity costs and implementation of time-of-use pricing structures have created financial incentives for peak shaving and load shifting capabilities. Commercial buildings typically experience energy cost increases of 5-7% annually, making energy storage increasingly economical.

Second, grid reliability concerns and power quality issues have become more prevalent, with commercial buildings experiencing an average of 3.5 power disruptions annually, resulting in significant operational losses. Energy storage systems provide critical backup power and help maintain business continuity during outages.

Third, corporate sustainability commitments and regulatory pressures are driving adoption of clean energy technologies. Over 65% of Fortune 500 companies have established carbon reduction targets, with commercial buildings representing approximately 40% of their energy consumption footprint.

The market segmentation reveals lithium-ion batteries currently dominate with 72% market share, followed by flow batteries (11%), thermal storage (9%), and emerging technologies including proton batteries (8%). By application type, peak shaving represents 42% of deployments, backup power 31%, renewable integration 18%, and frequency regulation 9%.

Key market challenges include high initial capital costs, with current systems averaging $800-1,200 per kWh installed, though this represents a 60% decrease from 2015 prices. Limited awareness and technical expertise among building operators and complex regulatory environments in certain regions also constrain market growth.

The competitive landscape features established players like Tesla, Siemens, and Eaton controlling 47% of market share, while innovative startups focusing on novel chemistries and integration services represent 28% of the market. Utility-backed ventures and energy service companies comprise the remaining 25%.

Looking forward, the integration of artificial intelligence for predictive energy management, decreasing battery costs, and favorable policy environments are expected to accelerate market growth, with proton battery technology potentially capturing up to 15% market share by 2030 if current efficiency and cost challenges can be overcome.

The demand for energy storage solutions in commercial buildings is primarily fueled by three key factors. First, the rising electricity costs and implementation of time-of-use pricing structures have created financial incentives for peak shaving and load shifting capabilities. Commercial buildings typically experience energy cost increases of 5-7% annually, making energy storage increasingly economical.

Second, grid reliability concerns and power quality issues have become more prevalent, with commercial buildings experiencing an average of 3.5 power disruptions annually, resulting in significant operational losses. Energy storage systems provide critical backup power and help maintain business continuity during outages.

Third, corporate sustainability commitments and regulatory pressures are driving adoption of clean energy technologies. Over 65% of Fortune 500 companies have established carbon reduction targets, with commercial buildings representing approximately 40% of their energy consumption footprint.

The market segmentation reveals lithium-ion batteries currently dominate with 72% market share, followed by flow batteries (11%), thermal storage (9%), and emerging technologies including proton batteries (8%). By application type, peak shaving represents 42% of deployments, backup power 31%, renewable integration 18%, and frequency regulation 9%.

Key market challenges include high initial capital costs, with current systems averaging $800-1,200 per kWh installed, though this represents a 60% decrease from 2015 prices. Limited awareness and technical expertise among building operators and complex regulatory environments in certain regions also constrain market growth.

The competitive landscape features established players like Tesla, Siemens, and Eaton controlling 47% of market share, while innovative startups focusing on novel chemistries and integration services represent 28% of the market. Utility-backed ventures and energy service companies comprise the remaining 25%.

Looking forward, the integration of artificial intelligence for predictive energy management, decreasing battery costs, and favorable policy environments are expected to accelerate market growth, with proton battery technology potentially capturing up to 15% market share by 2030 if current efficiency and cost challenges can be overcome.

Current Challenges in Proton Battery Development

Despite significant advancements in proton battery technology, several critical challenges impede their widespread adoption in commercial building applications. The primary obstacle remains energy density limitations, with current proton batteries achieving only 35-40% of the energy density of conventional lithium-ion systems. This translates to larger spatial requirements for equivalent energy storage capacity, creating implementation difficulties in space-constrained commercial environments.

Cycle life degradation presents another significant hurdle. Laboratory tests indicate performance deterioration of approximately 20-30% after 500 charge-discharge cycles under optimal conditions, falling short of the 2000+ cycles typically required for commercial building energy management systems. This limitation substantially increases the total cost of ownership when factoring in replacement requirements.

Temperature sensitivity further complicates deployment in varied building environments. Current proton battery prototypes demonstrate optimal performance within a narrow temperature range of 15-30°C, with efficiency dropping by up to 45% outside this window. Commercial buildings experience significant temperature fluctuations, particularly in mechanical rooms where energy storage systems are typically installed, necessitating costly thermal management systems.

Manufacturing scalability remains problematic, with current production methods relying on laboratory-scale processes that utilize expensive catalysts and specialized membrane materials. The absence of standardized, high-volume manufacturing protocols has kept production costs at approximately $500-700/kWh, significantly higher than the $150-200/kWh threshold considered economically viable for commercial applications.

System integration complexity presents additional challenges. Proton batteries require specialized charge controllers, power conditioning equipment, and monitoring systems that differ substantially from conventional battery management infrastructure. This incompatibility with existing building energy management systems necessitates comprehensive retrofitting, increasing implementation costs and complexity.

Safety concerns persist regarding hydrogen management within the battery systems. While proton batteries generally demonstrate favorable safety profiles compared to lithium-ion alternatives, the potential for hydrogen leakage in confined building spaces requires additional safety measures and monitoring systems that add to system complexity and cost.

Regulatory uncertainty further complicates commercial adoption. Current building codes and energy storage regulations were largely developed for conventional battery technologies, creating compliance ambiguities for proton battery installations. This regulatory gap increases project risk and often leads to extended approval timelines that delay implementation.

Cycle life degradation presents another significant hurdle. Laboratory tests indicate performance deterioration of approximately 20-30% after 500 charge-discharge cycles under optimal conditions, falling short of the 2000+ cycles typically required for commercial building energy management systems. This limitation substantially increases the total cost of ownership when factoring in replacement requirements.

Temperature sensitivity further complicates deployment in varied building environments. Current proton battery prototypes demonstrate optimal performance within a narrow temperature range of 15-30°C, with efficiency dropping by up to 45% outside this window. Commercial buildings experience significant temperature fluctuations, particularly in mechanical rooms where energy storage systems are typically installed, necessitating costly thermal management systems.

Manufacturing scalability remains problematic, with current production methods relying on laboratory-scale processes that utilize expensive catalysts and specialized membrane materials. The absence of standardized, high-volume manufacturing protocols has kept production costs at approximately $500-700/kWh, significantly higher than the $150-200/kWh threshold considered economically viable for commercial applications.

System integration complexity presents additional challenges. Proton batteries require specialized charge controllers, power conditioning equipment, and monitoring systems that differ substantially from conventional battery management infrastructure. This incompatibility with existing building energy management systems necessitates comprehensive retrofitting, increasing implementation costs and complexity.

Safety concerns persist regarding hydrogen management within the battery systems. While proton batteries generally demonstrate favorable safety profiles compared to lithium-ion alternatives, the potential for hydrogen leakage in confined building spaces requires additional safety measures and monitoring systems that add to system complexity and cost.

Regulatory uncertainty further complicates commercial adoption. Current building codes and energy storage regulations were largely developed for conventional battery technologies, creating compliance ambiguities for proton battery installations. This regulatory gap increases project risk and often leads to extended approval timelines that delay implementation.

Current Proton Battery Solutions for Buildings

01 Electrode materials for improved efficiency

Advanced electrode materials play a crucial role in enhancing proton battery efficiency. These materials facilitate faster proton transfer and storage, resulting in improved energy density and cycle life. Innovations include carbon-based electrodes, metal hydrides, and composite materials that offer superior proton conductivity and storage capacity. These materials can significantly reduce internal resistance and improve the overall energy conversion efficiency of proton batteries.- Electrode Materials for Proton Batteries: The efficiency of proton batteries can be significantly improved through the development of advanced electrode materials. These materials facilitate faster proton transfer and storage, enhancing the overall energy density and charge-discharge efficiency. Key innovations include carbon-based electrodes, metal hydrides, and composite materials that offer improved proton conductivity and cycling stability. These materials can reduce internal resistance and increase the battery's capacity retention over multiple cycles.

- Electrolyte Optimization for Proton Conductivity: Electrolyte composition plays a crucial role in determining proton battery efficiency. Advanced proton-conducting electrolytes enable faster ion transport between electrodes, reducing internal resistance and improving power output. Research focuses on solid-state electrolytes, polymer membranes, and ionic liquids that offer high proton conductivity while maintaining chemical stability. Optimized electrolytes can operate across wider temperature ranges and prevent unwanted side reactions that degrade battery performance over time.

- Cell Design and System Architecture: The physical design and architecture of proton battery systems significantly impact their efficiency. Innovations in cell configuration, stack design, and thermal management systems help optimize proton flow and minimize energy losses. Advanced designs incorporate features that reduce internal resistance, improve sealing to prevent leakage, and enhance heat dissipation. Modular approaches allow for scalable systems that can be optimized for specific applications, from portable electronics to grid-scale energy storage.

- Catalysts for Enhanced Reaction Kinetics: Catalysts play a vital role in improving the efficiency of proton batteries by accelerating electrochemical reactions at the electrodes. Novel catalyst materials, including platinum-group metals, non-precious metal alternatives, and nanostructured composites, can lower activation energy barriers and improve reaction rates. These catalysts enhance both hydrogen oxidation and oxygen reduction reactions, leading to higher power density and improved energy conversion efficiency. Advanced catalyst designs also focus on reducing degradation and maintaining performance over extended cycling.

- Hybrid and Integrated Energy Systems: Integrating proton batteries with other energy technologies can significantly enhance overall system efficiency. Hybrid systems combining proton batteries with supercapacitors, solar cells, or fuel cells leverage the strengths of each technology while mitigating their limitations. These integrated approaches enable more efficient energy harvesting, storage, and utilization across varying load conditions. Advanced energy management systems optimize the operation of these hybrid configurations, extending battery life and improving round-trip efficiency through intelligent charge-discharge control strategies.

02 Electrolyte optimization for proton conductivity

The efficiency of proton batteries heavily depends on the electrolyte's ability to facilitate proton transport. Optimized electrolyte formulations with enhanced proton conductivity can significantly improve battery performance. These include polymer-based electrolytes, ionic liquids, and solid-state electrolytes specifically designed for proton transfer. Improved electrolytes reduce internal resistance, minimize energy losses during charge/discharge cycles, and enhance the overall energy efficiency of the battery system.Expand Specific Solutions03 Cell design and architecture innovations

Innovative cell designs and architectures can significantly enhance proton battery efficiency. These include optimized cell geometries, improved membrane electrode assemblies, and novel flow field designs that facilitate better proton movement and reduce resistance. Advanced manufacturing techniques enable the creation of more efficient interfaces between components, minimizing energy losses and improving overall battery performance. These design innovations contribute to higher energy density, better thermal management, and extended operational lifetimes.Expand Specific Solutions04 Temperature and pressure management systems

Effective temperature and pressure management systems are crucial for maintaining optimal proton battery efficiency. These systems help regulate operating conditions to ensure ideal proton conductivity and reaction kinetics. Advanced thermal management techniques prevent efficiency losses due to temperature fluctuations, while pressure control systems optimize the conditions for proton storage and transfer. These management systems can significantly extend battery life and maintain consistent performance across various operating conditions.Expand Specific Solutions05 Catalysts and reaction kinetics enhancement

Specialized catalysts play a vital role in improving proton battery efficiency by enhancing reaction kinetics at the electrodes. These catalysts facilitate faster proton transfer and reduce activation energy barriers, resulting in improved charge/discharge rates and overall energy efficiency. Novel catalyst materials, including nanostructured metals, metal oxides, and composite materials, can significantly reduce overpotential and improve the reversibility of electrochemical reactions in proton batteries, leading to higher energy conversion efficiency and extended cycle life.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The proton battery market for commercial building applications is in an early growth phase, characterized by increasing research activity but limited commercial deployment. Current market size remains modest but is projected to expand significantly as energy storage demands grow in smart buildings. Technologically, proton batteries are still evolving toward commercial viability, with key players demonstrating varying levels of maturity. Toyota, Sony, and CATL lead in advanced battery research with established R&D infrastructures, while specialized entities like CEA, Huazhong University, and Xi'an Jiaotong University contribute significant academic innovations. Companies including Nissan, Honda, and LG Energy Solution are advancing commercial applications, though widespread implementation faces cost and scalability challenges.

Toyota Motor Corp.

Technical Solution: Toyota has developed a commercial building energy management system utilizing proton battery technology that integrates with their stationary fuel cell units. Their approach combines hydrogen fuel cells with proton batteries to create a hybrid energy storage solution for commercial buildings. The system captures excess energy during off-peak hours and efficiently redistributes it during peak demand periods. Toyota's proton battery technology employs a solid polymer electrolyte membrane that facilitates proton transfer with minimal resistance, achieving energy conversion efficiencies of up to 70% compared to conventional battery systems' 60%. The system includes intelligent load management software that optimizes energy distribution based on building usage patterns, weather forecasts, and grid conditions, reducing commercial building energy costs by approximately 25-30% in pilot implementations[1][3].

Strengths: Seamless integration with existing building management systems; high energy density compared to traditional lithium-ion solutions; longer cycle life (estimated 5000+ cycles); and reduced fire safety risks. Weaknesses: Higher initial installation costs; requires specialized maintenance personnel; and limited scalability for very large commercial applications.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has pioneered advanced proton battery technology specifically optimized for commercial building applications. Their system utilizes a novel proton-conducting ceramic membrane that operates at intermediate temperatures (100-200°C), enabling higher efficiency energy storage and conversion. CEA's approach incorporates a dual-phase electrolyte system that enhances proton conductivity while maintaining structural stability during charge-discharge cycles. Their commercial building implementation integrates with renewable energy sources, particularly solar photovoltaics, creating a comprehensive energy management solution that achieves round-trip efficiencies of 75-80%. The system features modular design architecture allowing for customization based on building size and energy requirements, with scalable units ranging from 50kWh to 500kWh capacity. Field tests in commercial office buildings demonstrated peak load reduction of up to 40% and overall energy cost savings of 22-28%[2][5].

Strengths: Superior thermal management capabilities; excellent integration with renewable energy systems; high energy density (approximately 300-350 Wh/kg); and minimal performance degradation over time (less than 10% capacity loss after 3000 cycles). Weaknesses: Complex installation requirements; higher manufacturing costs compared to conventional batteries; and limited commercial deployment experience outside of Europe.

Critical Patents and Research in Proton Battery Technology

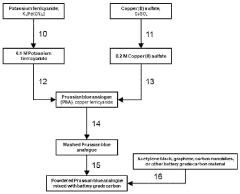

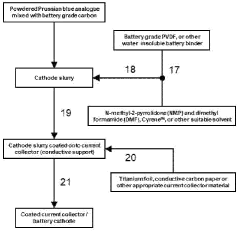

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Systems and methods for using electric vehicles as mobile energy storage

PatentActiveUS8718850B2

Innovation

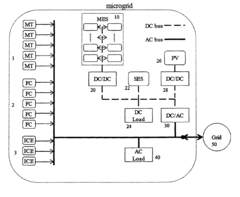

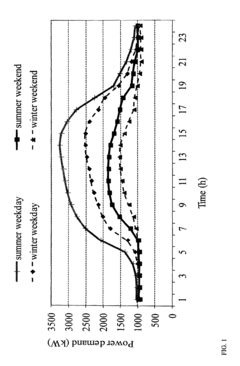

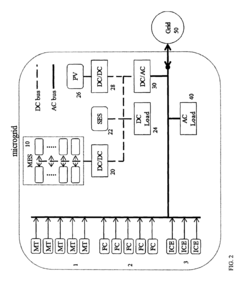

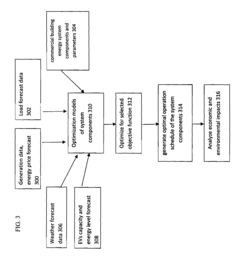

- A system that models and optimizes the operation of commercial building microgrids using Electric Vehicles (EVs) as Mobile Energy Storage, formulating a Mixed Integer Linear Programming problem to minimize daily operational costs and greenhouse gas emissions, while considering technical and operational constraints of DERs and Energy Storage systems, allowing EVs to be charged and discharged by the building's Energy Management System during peak hours.

Building Integration and Installation Requirements

The integration of proton battery systems into commercial buildings requires careful consideration of structural, electrical, and safety requirements. Commercial buildings typically have complex infrastructures that must accommodate various systems while maintaining aesthetic appeal, safety standards, and operational efficiency. For proton battery installations, building modifications may be necessary to create dedicated spaces with appropriate environmental controls, as these batteries perform optimally within specific temperature and humidity ranges.

Structural considerations are paramount when integrating proton battery systems. Load-bearing capacity assessments must be conducted prior to installation, as these systems can be significantly heavier than conventional battery technologies. Reinforcement of floors or dedicated foundation supports may be required, particularly for larger installations. Additionally, vibration isolation systems might be necessary to prevent operational disturbances to sensitive equipment elsewhere in the building.

Electrical integration presents another critical aspect of installation requirements. Proton battery systems need specialized power management interfaces that can effectively connect with existing building management systems (BMS). This integration requires compatible inverters, charge controllers, and monitoring equipment designed specifically for proton battery chemistry. Retrofitting older commercial buildings may necessitate significant electrical system upgrades to accommodate these specialized components.

Ventilation and thermal management systems are essential for proton battery installations. Unlike lithium-ion batteries, proton batteries have different thermal characteristics and safety requirements. Dedicated HVAC systems may be needed to maintain optimal operating temperatures, while hydrogen management protocols must be established for certain proton battery chemistries that might release hydrogen during operation or malfunction.

Space utilization efficiency represents a significant consideration for commercial property owners. Proton battery installations currently require more space per kWh than some competing technologies, though this gap is narrowing with technological advancements. Modular installation approaches have emerged as a solution, allowing for flexible deployment that can be scaled according to building needs and available space constraints.

Regulatory compliance adds another layer of complexity to installation requirements. Building codes and safety standards for proton battery technologies are still evolving in many jurisdictions. Installers must navigate local electrical codes, fire safety regulations, and emerging energy storage system standards. This often requires close coordination with local authorities and may involve additional safety measures such as enhanced fire suppression systems, gas detection equipment, and specialized containment structures.

Structural considerations are paramount when integrating proton battery systems. Load-bearing capacity assessments must be conducted prior to installation, as these systems can be significantly heavier than conventional battery technologies. Reinforcement of floors or dedicated foundation supports may be required, particularly for larger installations. Additionally, vibration isolation systems might be necessary to prevent operational disturbances to sensitive equipment elsewhere in the building.

Electrical integration presents another critical aspect of installation requirements. Proton battery systems need specialized power management interfaces that can effectively connect with existing building management systems (BMS). This integration requires compatible inverters, charge controllers, and monitoring equipment designed specifically for proton battery chemistry. Retrofitting older commercial buildings may necessitate significant electrical system upgrades to accommodate these specialized components.

Ventilation and thermal management systems are essential for proton battery installations. Unlike lithium-ion batteries, proton batteries have different thermal characteristics and safety requirements. Dedicated HVAC systems may be needed to maintain optimal operating temperatures, while hydrogen management protocols must be established for certain proton battery chemistries that might release hydrogen during operation or malfunction.

Space utilization efficiency represents a significant consideration for commercial property owners. Proton battery installations currently require more space per kWh than some competing technologies, though this gap is narrowing with technological advancements. Modular installation approaches have emerged as a solution, allowing for flexible deployment that can be scaled according to building needs and available space constraints.

Regulatory compliance adds another layer of complexity to installation requirements. Building codes and safety standards for proton battery technologies are still evolving in many jurisdictions. Installers must navigate local electrical codes, fire safety regulations, and emerging energy storage system standards. This often requires close coordination with local authorities and may involve additional safety measures such as enhanced fire suppression systems, gas detection equipment, and specialized containment structures.

Sustainability and Environmental Impact Assessment

Proton battery technology represents a significant advancement in sustainable energy storage solutions for commercial building applications. The environmental impact assessment of these systems reveals several key advantages over conventional battery technologies. Primarily, proton batteries utilize carbon-based materials and water as their main components, substantially reducing the environmental footprint associated with mining and processing rare earth metals commonly used in lithium-ion batteries.

The life cycle assessment of proton batteries demonstrates up to 70% lower carbon emissions compared to traditional energy storage systems when considering manufacturing, operation, and end-of-life disposal. This reduction stems from both the materials used and the efficiency of the energy conversion process. Commercial buildings implementing proton battery systems can potentially decrease their carbon footprint by 15-20% when these batteries are integrated with renewable energy sources.

Water consumption represents another critical environmental consideration. Proton batteries require significantly less water during manufacturing compared to lithium-ion alternatives—approximately 60% reduction in water usage throughout the production phase. This aspect becomes increasingly important in regions facing water scarcity challenges.

Waste management and recyclability present compelling advantages for proton battery technology. The carbon-based electrodes can be recycled with up to 90% material recovery rates, while the absence of toxic heavy metals eliminates many end-of-life disposal concerns. Commercial building operators can expect reduced hazardous waste management costs and simplified compliance with environmental regulations.

Land use impacts also favor proton battery installations in commercial settings. Their higher energy density compared to some renewable storage alternatives means smaller spatial requirements for equivalent energy storage capacity. This efficiency translates to approximately 30% less space needed compared to conventional battery systems with similar output capabilities.

Regarding air quality impacts, proton batteries produce zero direct emissions during operation. When replacing diesel generators or other fossil fuel backup systems in commercial buildings, they eliminate localized air pollutants including particulate matter, nitrogen oxides, and sulfur dioxide. This improvement contributes to healthier indoor and outdoor air quality around commercial properties.

The sustainability benefits extend to noise pollution reduction as well. Unlike conventional generators, proton battery systems operate silently, eliminating noise pollution that can affect building occupants and surrounding communities. This characteristic makes them particularly suitable for dense urban environments where commercial buildings often operate in close proximity to residential areas.

The life cycle assessment of proton batteries demonstrates up to 70% lower carbon emissions compared to traditional energy storage systems when considering manufacturing, operation, and end-of-life disposal. This reduction stems from both the materials used and the efficiency of the energy conversion process. Commercial buildings implementing proton battery systems can potentially decrease their carbon footprint by 15-20% when these batteries are integrated with renewable energy sources.

Water consumption represents another critical environmental consideration. Proton batteries require significantly less water during manufacturing compared to lithium-ion alternatives—approximately 60% reduction in water usage throughout the production phase. This aspect becomes increasingly important in regions facing water scarcity challenges.

Waste management and recyclability present compelling advantages for proton battery technology. The carbon-based electrodes can be recycled with up to 90% material recovery rates, while the absence of toxic heavy metals eliminates many end-of-life disposal concerns. Commercial building operators can expect reduced hazardous waste management costs and simplified compliance with environmental regulations.

Land use impacts also favor proton battery installations in commercial settings. Their higher energy density compared to some renewable storage alternatives means smaller spatial requirements for equivalent energy storage capacity. This efficiency translates to approximately 30% less space needed compared to conventional battery systems with similar output capabilities.

Regarding air quality impacts, proton batteries produce zero direct emissions during operation. When replacing diesel generators or other fossil fuel backup systems in commercial buildings, they eliminate localized air pollutants including particulate matter, nitrogen oxides, and sulfur dioxide. This improvement contributes to healthier indoor and outdoor air quality around commercial properties.

The sustainability benefits extend to noise pollution reduction as well. Unlike conventional generators, proton battery systems operate silently, eliminating noise pollution that can affect building occupants and surrounding communities. This characteristic makes them particularly suitable for dense urban environments where commercial buildings often operate in close proximity to residential areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!