Regulations Impacting Microinjection Molding in Pharmaceutical Manufacturing

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Regulatory Background and Objectives

Microinjection molding has emerged as a critical technology in pharmaceutical manufacturing, enabling the production of precise, miniaturized components essential for drug delivery systems, diagnostic devices, and medical implants. The evolution of this technology traces back to the 1980s when conventional injection molding techniques were adapted for microscale applications. Over the past four decades, significant advancements in materials science, equipment precision, and process control have transformed microinjection molding into a sophisticated manufacturing method capable of producing components with tolerances in the micrometer range.

The regulatory landscape governing microinjection molding in pharmaceutical applications has evolved concurrently with technological advancements. Initially, regulations focused primarily on material biocompatibility and basic quality standards. However, as applications expanded into critical medical devices and drug delivery systems, regulatory frameworks became increasingly comprehensive, addressing aspects such as process validation, contamination control, and traceability requirements.

Current global regulatory trends indicate a movement toward harmonization of standards across major markets, though significant regional variations persist. The FDA in the United States, the European Medicines Agency (EMA), and various Asian regulatory bodies have established specific guidelines addressing microinjection molding processes when used in pharmaceutical manufacturing contexts. These regulations typically encompass material selection criteria, validation protocols, quality management systems, and documentation requirements.

The primary technical objectives in this domain focus on achieving regulatory compliance while maintaining manufacturing efficiency and product innovation. Key goals include developing standardized validation methodologies specific to microinjection molding processes, establishing clear guidelines for material qualification, and implementing robust quality control systems capable of detecting microscale defects that could impact pharmaceutical product safety or efficacy.

Industry stakeholders are increasingly focused on anticipating regulatory developments rather than merely responding to them. This proactive approach necessitates understanding emerging concerns such as leachables and extractables from novel polymers, potential microplastic generation, and the qualification of recycled materials in pharmaceutical applications. Additionally, as personalized medicine advances, regulations regarding small-batch production and rapid changeover capabilities are becoming increasingly relevant.

The intersection of digitalization trends with regulatory requirements presents both challenges and opportunities. While digital process monitoring and artificial intelligence-based quality control systems offer potential for enhanced compliance, they also introduce new regulatory considerations regarding data integrity, cybersecurity, and validation of computerized systems in GMP environments.

The regulatory landscape governing microinjection molding in pharmaceutical applications has evolved concurrently with technological advancements. Initially, regulations focused primarily on material biocompatibility and basic quality standards. However, as applications expanded into critical medical devices and drug delivery systems, regulatory frameworks became increasingly comprehensive, addressing aspects such as process validation, contamination control, and traceability requirements.

Current global regulatory trends indicate a movement toward harmonization of standards across major markets, though significant regional variations persist. The FDA in the United States, the European Medicines Agency (EMA), and various Asian regulatory bodies have established specific guidelines addressing microinjection molding processes when used in pharmaceutical manufacturing contexts. These regulations typically encompass material selection criteria, validation protocols, quality management systems, and documentation requirements.

The primary technical objectives in this domain focus on achieving regulatory compliance while maintaining manufacturing efficiency and product innovation. Key goals include developing standardized validation methodologies specific to microinjection molding processes, establishing clear guidelines for material qualification, and implementing robust quality control systems capable of detecting microscale defects that could impact pharmaceutical product safety or efficacy.

Industry stakeholders are increasingly focused on anticipating regulatory developments rather than merely responding to them. This proactive approach necessitates understanding emerging concerns such as leachables and extractables from novel polymers, potential microplastic generation, and the qualification of recycled materials in pharmaceutical applications. Additionally, as personalized medicine advances, regulations regarding small-batch production and rapid changeover capabilities are becoming increasingly relevant.

The intersection of digitalization trends with regulatory requirements presents both challenges and opportunities. While digital process monitoring and artificial intelligence-based quality control systems offer potential for enhanced compliance, they also introduce new regulatory considerations regarding data integrity, cybersecurity, and validation of computerized systems in GMP environments.

Pharmaceutical Market Demand for Microinjection Molded Components

The pharmaceutical industry is experiencing a significant shift towards miniaturization and precision delivery systems, creating substantial market demand for microinjection molded components. This demand is primarily driven by the growing prevalence of targeted drug delivery systems, which require increasingly complex and precise components that can only be manufactured through advanced microinjection molding techniques.

Market analysis indicates that the global drug delivery systems market, where microinjection molded components play a crucial role, is projected to grow at a compound annual growth rate of 7.8% through 2028. Particularly strong demand exists in the areas of autoinjectors, wearable injectors, and implantable drug delivery devices, all of which rely heavily on microinjection molded components for their functionality and reliability.

Patient-centric healthcare trends are further accelerating this demand, as pharmaceutical companies seek to develop more user-friendly and less invasive drug delivery options. Self-administration devices, which often incorporate multiple microinjection molded components, are seeing particularly robust growth as healthcare systems worldwide aim to reduce hospitalization rates and associated costs.

The biologics sector represents another significant driver for microinjection molded pharmaceutical components. As biologic drugs continue to dominate new drug approvals, their specific delivery requirements—including protection from degradation and precise dosing—necessitate sophisticated delivery systems with components that can only be produced through microinjection molding processes.

Geographically, North America currently leads the market demand for these components, followed by Europe and rapidly growing Asian markets, particularly Japan and China. The latter are investing heavily in advanced pharmaceutical manufacturing capabilities, creating new opportunities for microinjection molding technology providers.

Cost pressures within healthcare systems worldwide are paradoxically boosting demand for these components, as they enable the development of more efficient drug delivery systems that can reduce overall treatment costs despite higher initial component prices. The ability of microinjection molding to produce complex geometries with high precision while minimizing material waste makes it increasingly attractive from both economic and environmental perspectives.

Industry forecasts suggest that demand for microinjection molded components in pharmaceutical applications will outpace supply capabilities in the near term, creating potential bottlenecks but also significant opportunities for manufacturers who can scale their production capabilities while maintaining the stringent quality standards required for pharmaceutical applications.

Market analysis indicates that the global drug delivery systems market, where microinjection molded components play a crucial role, is projected to grow at a compound annual growth rate of 7.8% through 2028. Particularly strong demand exists in the areas of autoinjectors, wearable injectors, and implantable drug delivery devices, all of which rely heavily on microinjection molded components for their functionality and reliability.

Patient-centric healthcare trends are further accelerating this demand, as pharmaceutical companies seek to develop more user-friendly and less invasive drug delivery options. Self-administration devices, which often incorporate multiple microinjection molded components, are seeing particularly robust growth as healthcare systems worldwide aim to reduce hospitalization rates and associated costs.

The biologics sector represents another significant driver for microinjection molded pharmaceutical components. As biologic drugs continue to dominate new drug approvals, their specific delivery requirements—including protection from degradation and precise dosing—necessitate sophisticated delivery systems with components that can only be produced through microinjection molding processes.

Geographically, North America currently leads the market demand for these components, followed by Europe and rapidly growing Asian markets, particularly Japan and China. The latter are investing heavily in advanced pharmaceutical manufacturing capabilities, creating new opportunities for microinjection molding technology providers.

Cost pressures within healthcare systems worldwide are paradoxically boosting demand for these components, as they enable the development of more efficient drug delivery systems that can reduce overall treatment costs despite higher initial component prices. The ability of microinjection molding to produce complex geometries with high precision while minimizing material waste makes it increasingly attractive from both economic and environmental perspectives.

Industry forecasts suggest that demand for microinjection molded components in pharmaceutical applications will outpace supply capabilities in the near term, creating potential bottlenecks but also significant opportunities for manufacturers who can scale their production capabilities while maintaining the stringent quality standards required for pharmaceutical applications.

Regulatory Challenges in Pharmaceutical Microinjection Molding

The pharmaceutical industry faces a complex web of regulatory requirements when implementing microinjection molding technologies. The FDA's Quality System Regulation (21 CFR Part 820) establishes comprehensive requirements for manufacturers, demanding rigorous validation of both equipment and processes. This includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) for all microinjection molding systems, creating significant documentation burdens for manufacturers.

European regulations add another layer of complexity through the EU Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which impose stricter requirements for clinical evidence, post-market surveillance, and technical documentation. These regulations have particularly impacted pharmaceutical companies utilizing microinjection molding for drug delivery systems and diagnostic components.

ISO 13485:2016 certification has become virtually mandatory for manufacturers in this space, requiring the implementation of quality management systems specifically designed for medical devices. The standard's risk management requirements (aligned with ISO 14971) necessitate thorough documentation of potential hazards throughout the product lifecycle, from design to disposal.

Material compliance presents another significant challenge. The USP Class VI and ISO 10993 standards govern biocompatibility testing for materials used in pharmaceutical applications. Manufacturers must demonstrate that their microinjection molded components do not leach harmful substances or cause adverse biological reactions, requiring extensive testing protocols and documentation.

Clean room requirements further complicate manufacturing processes. Many pharmaceutical applications require ISO Class 7 or 8 clean rooms (per ISO 14644), with some critical applications demanding even more stringent environments. Maintaining these controlled environments while operating microinjection molding equipment presents technical challenges and increases operational costs.

Regulatory divergence across global markets creates additional hurdles. While efforts toward harmonization exist through the International Medical Device Regulators Forum (IMDRF), significant regional differences persist. Companies must navigate country-specific requirements, particularly challenging for smaller manufacturers with limited regulatory resources.

The trend toward personalized medicine has introduced new regulatory considerations. As microinjection molding enables more customized pharmaceutical delivery systems, regulators are developing frameworks to address the unique challenges of small-batch or individualized production, though clear guidance remains limited in many jurisdictions.

Emerging technologies like smart drug delivery systems that incorporate microinjection molded components with electronics or connectivity features face regulatory uncertainty, as existing frameworks may not adequately address their novel characteristics and potential risks.

European regulations add another layer of complexity through the EU Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which impose stricter requirements for clinical evidence, post-market surveillance, and technical documentation. These regulations have particularly impacted pharmaceutical companies utilizing microinjection molding for drug delivery systems and diagnostic components.

ISO 13485:2016 certification has become virtually mandatory for manufacturers in this space, requiring the implementation of quality management systems specifically designed for medical devices. The standard's risk management requirements (aligned with ISO 14971) necessitate thorough documentation of potential hazards throughout the product lifecycle, from design to disposal.

Material compliance presents another significant challenge. The USP Class VI and ISO 10993 standards govern biocompatibility testing for materials used in pharmaceutical applications. Manufacturers must demonstrate that their microinjection molded components do not leach harmful substances or cause adverse biological reactions, requiring extensive testing protocols and documentation.

Clean room requirements further complicate manufacturing processes. Many pharmaceutical applications require ISO Class 7 or 8 clean rooms (per ISO 14644), with some critical applications demanding even more stringent environments. Maintaining these controlled environments while operating microinjection molding equipment presents technical challenges and increases operational costs.

Regulatory divergence across global markets creates additional hurdles. While efforts toward harmonization exist through the International Medical Device Regulators Forum (IMDRF), significant regional differences persist. Companies must navigate country-specific requirements, particularly challenging for smaller manufacturers with limited regulatory resources.

The trend toward personalized medicine has introduced new regulatory considerations. As microinjection molding enables more customized pharmaceutical delivery systems, regulators are developing frameworks to address the unique challenges of small-batch or individualized production, though clear guidance remains limited in many jurisdictions.

Emerging technologies like smart drug delivery systems that incorporate microinjection molded components with electronics or connectivity features face regulatory uncertainty, as existing frameworks may not adequately address their novel characteristics and potential risks.

Current Compliance Solutions for Microinjection Molding

01 Equipment and machinery for microinjection molding

Specialized equipment and machinery are essential for microinjection molding processes. These include precision molds, micro-scale injection units, and advanced control systems that enable the accurate formation of microscale components. The equipment must maintain precise temperature control, pressure regulation, and material flow to ensure consistent quality in the production of micro-sized parts.- Equipment and tooling for microinjection molding: Specialized equipment and tooling are essential for microinjection molding processes. This includes micro-molds with high precision features, specialized injection units capable of delivering small, precise amounts of material, and advanced control systems for maintaining tight process parameters. These equipment components are designed to handle the unique challenges of molding microscale parts, including precise temperature control, high injection pressures, and accurate cavity filling.

- Materials for microinjection molding: Various materials have been developed specifically for microinjection molding applications. These include specialized polymers with enhanced flow properties, biocompatible materials for medical applications, and composite materials with improved mechanical properties at the micro scale. Material selection is critical as it affects not only the final product properties but also the processing parameters required for successful molding of microscale features.

- Biomedical applications of microinjection molding: Microinjection molding has significant applications in the biomedical field, including the production of microfluidic devices, lab-on-a-chip systems, drug delivery devices, and diagnostic tools. The technology enables the creation of complex microstructures with high precision, which is essential for these applications. The ability to use biocompatible materials and maintain sterile production conditions makes this process particularly valuable for medical device manufacturing.

- Process optimization and control in microinjection molding: Advanced process control strategies are employed in microinjection molding to ensure consistent quality and high precision. This includes real-time monitoring of process parameters, adaptive control systems, simulation-based optimization, and statistical process control methods. Factors such as melt temperature, injection speed, holding pressure, and cooling time must be precisely controlled to achieve successful molding of microscale features with high repeatability.

- Innovations in microstructure design and fabrication: Novel approaches to designing and fabricating microstructures have been developed for microinjection molding. These include advanced mold insert fabrication techniques, multi-material molding strategies, and methods for creating hierarchical or biomimetic structures. Innovations in this area focus on overcoming traditional limitations in feature size, aspect ratio, and complexity, enabling the production of increasingly sophisticated microcomponents for various applications.

02 Materials for microinjection molding

Various materials can be used in microinjection molding processes, including specialized polymers, biocompatible materials, and composite materials. These materials must possess specific properties such as low viscosity, high flowability, and rapid solidification characteristics to enable successful molding at the micro scale. Material selection is critical for achieving desired mechanical properties, surface finish, and functionality in the final microinjected components.Expand Specific Solutions03 Biomedical applications of microinjection molding

Microinjection molding has significant applications in the biomedical field, including the production of medical devices, drug delivery systems, and diagnostic tools. The technology enables the fabrication of precise microstructures for cell culture, tissue engineering, and microfluidic devices. The ability to create complex geometries at the microscale makes microinjection molding particularly valuable for developing miniaturized medical components with high precision and reproducibility.Expand Specific Solutions04 Process optimization for microinjection molding

Optimizing the microinjection molding process involves careful control of parameters such as injection speed, pressure, temperature, and cooling rate. Advanced techniques like vacuum-assisted molding, variothermal processing, and precise demolding strategies are employed to enhance part quality and reduce defects. Simulation tools and real-time monitoring systems help in predicting and controlling material flow behavior at the microscale, leading to improved process efficiency and product quality.Expand Specific Solutions05 Innovations in mold design for microinjection molding

Innovative mold designs are crucial for successful microinjection molding. These include advanced micro-structured cavities, specialized gating systems, and precision venting mechanisms. Novel approaches to mold fabrication, such as laser micromachining, electroforming, and additive manufacturing, enable the creation of complex microfeatures with high aspect ratios. Smart mold designs incorporating sensors for real-time monitoring help maintain quality control during the microinjection molding process.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

The microinjection molding market in pharmaceutical manufacturing is currently in a growth phase, with increasing regulatory scrutiny shaping its competitive landscape. The market is expanding due to demand for precision drug delivery systems and miniaturized medical devices, with projections indicating significant growth over the next decade. Technologically, companies demonstrate varying maturity levels: established players like Nissei Plastic Industrial and SABIC Global Technologies offer advanced solutions, while pharmaceutical specialists such as Continuus Pharmaceuticals and Astellas Pharma are integrating microinjection capabilities into their manufacturing processes. Innovative startups like Feroka are developing novel applications in drug delivery. Academic institutions including MIT and Xi'an Jiaotong University are contributing fundamental research, while regulatory compliance capabilities are becoming a key differentiator as FDA and international standards evolve.

Continuus Pharmaceuticals, Inc.

Technical Solution: Continuus Pharmaceuticals has developed an Integrated Continuous Manufacturing (ICM) platform that incorporates microinjection molding technology specifically designed to meet pharmaceutical regulatory requirements. Their system addresses FDA's Quality by Design (QbD) framework by implementing real-time monitoring and control of critical process parameters during micro-molding operations. The platform features automated Process Analytical Technology (PAT) tools that continuously verify product quality, reducing the need for end-product testing while maintaining compliance with cGMP regulations. Continuus has engineered their microinjection molding process to operate within closed systems that minimize contamination risks and operator exposure, satisfying containment requirements for potent compounds. Their technology includes validated cleaning protocols and material traceability systems that generate comprehensive documentation required for regulatory submissions across international markets.

Strengths: Seamless integration with continuous pharmaceutical manufacturing processes; robust real-time quality monitoring systems; reduced regulatory burden through comprehensive process understanding and control. Weaknesses: Complex implementation requiring significant validation efforts; higher initial capital investment compared to traditional batch processes; requires specialized technical expertise for operation and maintenance.

I.M.A. Industria Macchine Automatiche SpA

Technical Solution: I.M.A. has developed a comprehensive regulatory-compliant microinjection molding solution for pharmaceutical applications that addresses the complex requirements of both FDA and EMA guidelines. Their technology incorporates a validated clean room compatible system that meets ISO Class 7/8 requirements with fully automated material handling to minimize contamination risks. The platform features advanced process monitoring capabilities that track and document critical quality attributes throughout production cycles, generating the necessary data for regulatory submissions. I.M.A.'s system includes specialized tooling designed for pharmaceutical-grade polymers that maintains material integrity while achieving the precision required for drug delivery components. Their technology implements Process Analytical Technology (PAT) principles with in-line testing capabilities that verify dimensional accuracy and material properties in real-time, ensuring consistent compliance with predefined specifications while generating the documentation required by regulatory authorities.

Strengths: Extensive experience with pharmaceutical manufacturing equipment validation; integrated solutions that connect upstream and downstream processes; robust documentation systems that simplify regulatory submissions. Weaknesses: Less specialized in micro-scale applications compared to dedicated micro-molding companies; higher costs associated with comprehensive validation packages; complex implementation requiring significant technical support.

Critical Regulatory Standards and Guidelines Analysis

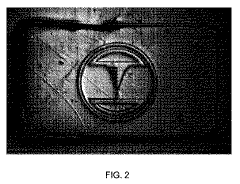

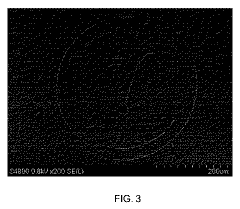

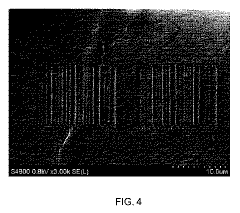

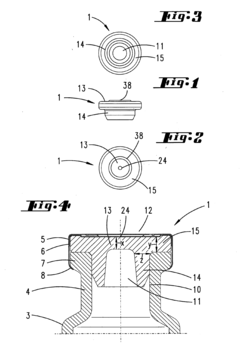

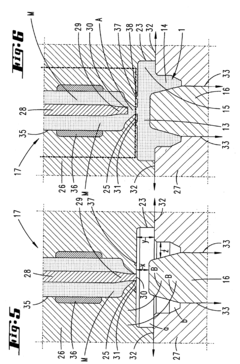

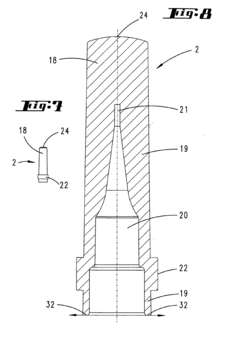

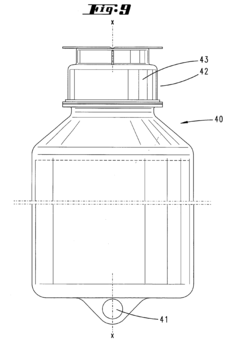

Injection molding of micron and nanoscale structures for pharmaceutical brand protection

PatentInactiveJP2013542106A

Innovation

- The use of injection molding to create pharmaceutical container parts with micro- and nanoscale identification structures, such as barcodes and moire patterns, integrated into the manufacturing process with minimal adjustments, allowing for durable and covert or overt authentication features.

Injection moulded part for pharmaceutical use and manufacturing method therefor

PatentInactiveEP1400458A1

Innovation

- The use of thermoplastic elastomeric material with a mineral filler content of 30% or more, combined with hot-runner injection molding, creates a smooth-surface impression at the injection point, ensuring defect-free and homogeneous parts with good puncture behavior, and the injection point is designed to merge seamlessly into the surrounding wall or be offset for specific applications.

Cross-Border Regulatory Harmonization Efforts

The pharmaceutical industry's global nature necessitates coordinated regulatory approaches for microinjection molding technologies. International harmonization efforts have gained significant momentum in recent years, with the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) playing a pivotal role in standardizing requirements across major markets. These initiatives aim to reduce redundant testing, streamline approval processes, and facilitate global market access while maintaining stringent quality and safety standards.

The Pharmaceutical Inspection Co-operation Scheme (PIC/S) has developed specific guidelines addressing microinjection molding processes that have been adopted by over 50 participating regulatory authorities. This framework provides manufacturers with consistent expectations regarding validation protocols, material qualification, and quality management systems across multiple jurisdictions.

Mutual Recognition Agreements (MRAs) between regulatory bodies like the FDA and EMA have further simplified compliance for microinjection molding manufacturers. These agreements allow for the recognition of inspections conducted by partner agencies, reducing duplicative regulatory burdens while maintaining oversight integrity. The 2017 FDA-EMA MRA specifically includes provisions for advanced manufacturing technologies, benefiting companies utilizing microinjection molding for pharmaceutical components.

Regional harmonization initiatives have emerged alongside global efforts. The Association of Southeast Asian Nations (ASEAN) Pharmaceutical Product Working Group has established common technical requirements for medical devices and drug delivery systems manufactured using microinjection molding. Similarly, the African Medicines Regulatory Harmonization (AMRH) program is working to standardize requirements across the continent, creating more accessible pathways for innovative drug delivery technologies.

Despite progress, significant challenges remain in achieving full regulatory convergence. Divergent approaches to novel materials used in microinjection molding persist, with some jurisdictions requiring extensive biocompatibility testing while others accept existing safety data. Implementation timelines for new regulations also vary considerably, creating compliance challenges for manufacturers operating across multiple markets.

Industry stakeholders are increasingly participating in harmonization efforts through organizations like the International Pharmaceutical Manufacturing Technology Association (IPMTA), which has established working groups focused on advanced manufacturing technologies including microinjection molding. These collaborative platforms enable knowledge sharing between regulators and industry experts, accelerating the development of scientifically sound, globally applicable standards.

The Pharmaceutical Inspection Co-operation Scheme (PIC/S) has developed specific guidelines addressing microinjection molding processes that have been adopted by over 50 participating regulatory authorities. This framework provides manufacturers with consistent expectations regarding validation protocols, material qualification, and quality management systems across multiple jurisdictions.

Mutual Recognition Agreements (MRAs) between regulatory bodies like the FDA and EMA have further simplified compliance for microinjection molding manufacturers. These agreements allow for the recognition of inspections conducted by partner agencies, reducing duplicative regulatory burdens while maintaining oversight integrity. The 2017 FDA-EMA MRA specifically includes provisions for advanced manufacturing technologies, benefiting companies utilizing microinjection molding for pharmaceutical components.

Regional harmonization initiatives have emerged alongside global efforts. The Association of Southeast Asian Nations (ASEAN) Pharmaceutical Product Working Group has established common technical requirements for medical devices and drug delivery systems manufactured using microinjection molding. Similarly, the African Medicines Regulatory Harmonization (AMRH) program is working to standardize requirements across the continent, creating more accessible pathways for innovative drug delivery technologies.

Despite progress, significant challenges remain in achieving full regulatory convergence. Divergent approaches to novel materials used in microinjection molding persist, with some jurisdictions requiring extensive biocompatibility testing while others accept existing safety data. Implementation timelines for new regulations also vary considerably, creating compliance challenges for manufacturers operating across multiple markets.

Industry stakeholders are increasingly participating in harmonization efforts through organizations like the International Pharmaceutical Manufacturing Technology Association (IPMTA), which has established working groups focused on advanced manufacturing technologies including microinjection molding. These collaborative platforms enable knowledge sharing between regulators and industry experts, accelerating the development of scientifically sound, globally applicable standards.

Environmental Sustainability Requirements for Molding Processes

Environmental sustainability has become a critical consideration in pharmaceutical manufacturing processes, particularly for microinjection molding operations. Regulatory bodies worldwide are implementing increasingly stringent requirements to minimize the environmental footprint of these precision manufacturing techniques. The European Union's Eco-Design Directive (2009/125/EC) specifically addresses energy efficiency in manufacturing equipment, requiring microinjection molding machines to meet minimum performance standards that reduce energy consumption during operation.

The pharmaceutical industry faces additional pressure from regulations such as the EU's Industrial Emissions Directive (2010/75/EU), which mandates the implementation of Best Available Techniques (BAT) for pollution prevention. For microinjection molding, this translates to requirements for closed-loop material handling systems that minimize material waste and prevent particulate emissions into the environment.

Water conservation regulations are similarly impacting molding processes in pharmaceutical manufacturing. The Water Framework Directive in Europe and similar regulations in North America require pharmaceutical manufacturers to implement water recycling systems for cooling processes in injection molding. These systems must achieve at least 80% water reuse efficiency to comply with current standards, with projections indicating this threshold will increase to 90% by 2030.

Material selection for microinjection molding is increasingly governed by sustainability regulations. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation restricts the use of certain plasticizers and additives commonly used in molding processes. Pharmaceutical manufacturers must now document full material life cycles and demonstrate end-of-life recyclability for molding materials, with a minimum of 30% recycled content increasingly becoming standard in non-critical components.

Energy efficiency certifications such as ISO 50001 are becoming de facto requirements for pharmaceutical manufacturing facilities. Modern microinjection molding equipment must incorporate energy monitoring systems that provide real-time consumption data and automatic optimization features. Regulations in several jurisdictions now mandate maximum energy consumption thresholds per unit of production, with penalties for non-compliance.

Carbon footprint reporting requirements are extending to the supply chain level, affecting how pharmaceutical companies select molding process providers. The EU's Corporate Sustainability Reporting Directive requires detailed greenhouse gas emissions reporting for manufacturing processes, including those outsourced to contract manufacturers. This has led to the development of industry-specific carbon accounting methodologies for microinjection molding processes in pharmaceutical applications.

The pharmaceutical industry faces additional pressure from regulations such as the EU's Industrial Emissions Directive (2010/75/EU), which mandates the implementation of Best Available Techniques (BAT) for pollution prevention. For microinjection molding, this translates to requirements for closed-loop material handling systems that minimize material waste and prevent particulate emissions into the environment.

Water conservation regulations are similarly impacting molding processes in pharmaceutical manufacturing. The Water Framework Directive in Europe and similar regulations in North America require pharmaceutical manufacturers to implement water recycling systems for cooling processes in injection molding. These systems must achieve at least 80% water reuse efficiency to comply with current standards, with projections indicating this threshold will increase to 90% by 2030.

Material selection for microinjection molding is increasingly governed by sustainability regulations. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation restricts the use of certain plasticizers and additives commonly used in molding processes. Pharmaceutical manufacturers must now document full material life cycles and demonstrate end-of-life recyclability for molding materials, with a minimum of 30% recycled content increasingly becoming standard in non-critical components.

Energy efficiency certifications such as ISO 50001 are becoming de facto requirements for pharmaceutical manufacturing facilities. Modern microinjection molding equipment must incorporate energy monitoring systems that provide real-time consumption data and automatic optimization features. Regulations in several jurisdictions now mandate maximum energy consumption thresholds per unit of production, with penalties for non-compliance.

Carbon footprint reporting requirements are extending to the supply chain level, affecting how pharmaceutical companies select molding process providers. The EU's Corporate Sustainability Reporting Directive requires detailed greenhouse gas emissions reporting for manufacturing processes, including those outsourced to contract manufacturers. This has led to the development of industry-specific carbon accounting methodologies for microinjection molding processes in pharmaceutical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!