Regulations in Microinjection Molding: Ensuring Compliance and Innovation

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Regulatory Background and Objectives

Microinjection molding emerged in the late 1980s as a specialized adaptation of conventional injection molding technology, designed to produce extremely small and precise components. The evolution of this technology has been driven by increasing demands in industries such as medical devices, electronics, and microfluidics, where miniaturization continues to push manufacturing boundaries. Initially limited to simple geometries, the technology has progressed to enable complex microstructures with features measured in micrometers, representing a significant technological leap in precision manufacturing.

The regulatory landscape governing microinjection molding has evolved substantially over the past two decades. Early regulations focused primarily on basic safety standards, but have since expanded to encompass material biocompatibility, sterilization protocols, and environmental considerations. This regulatory evolution reflects the growing application of micro-molded components in critical applications such as implantable medical devices, drug delivery systems, and diagnostic equipment.

Current global regulatory frameworks affecting microinjection molding include ISO 13485 for medical device quality management systems, FDA 21 CFR Part 820 for quality system regulations, EU Medical Device Regulation (MDR), and various environmental directives such as RoHS and REACH. These regulations establish stringent requirements for process validation, material traceability, and quality assurance that manufacturers must navigate to bring products to market.

The technical trajectory of microinjection molding shows a clear trend toward increased precision, with current capabilities allowing for features as small as 2-5 micrometers and tolerances within ±1 micrometer. Material science advancements have expanded the range of polymers suitable for microinjection, including high-performance engineering plastics, bioresorbable polymers, and specialized compounds with enhanced properties.

The primary objective of this technical assessment is to comprehensively evaluate the current regulatory requirements affecting microinjection molding across major global markets, identifying compliance challenges and opportunities for innovation within regulatory constraints. Additionally, we aim to forecast regulatory trends that may impact future development of microinjection molding technologies and applications.

Secondary objectives include mapping the relationship between regulatory compliance and technical innovation, analyzing how regulations have historically influenced technological development in this field, and identifying strategies for maintaining compliance while pursuing technical advancement. This assessment will also examine how emerging technologies such as additive manufacturing and Industry 4.0 concepts intersect with microinjection molding regulations.

Understanding this regulatory landscape is crucial as the market for micro-molded components is projected to grow at a CAGR of 11.2% through 2028, with particularly strong growth in medical and electronics applications where regulatory requirements are most stringent.

The regulatory landscape governing microinjection molding has evolved substantially over the past two decades. Early regulations focused primarily on basic safety standards, but have since expanded to encompass material biocompatibility, sterilization protocols, and environmental considerations. This regulatory evolution reflects the growing application of micro-molded components in critical applications such as implantable medical devices, drug delivery systems, and diagnostic equipment.

Current global regulatory frameworks affecting microinjection molding include ISO 13485 for medical device quality management systems, FDA 21 CFR Part 820 for quality system regulations, EU Medical Device Regulation (MDR), and various environmental directives such as RoHS and REACH. These regulations establish stringent requirements for process validation, material traceability, and quality assurance that manufacturers must navigate to bring products to market.

The technical trajectory of microinjection molding shows a clear trend toward increased precision, with current capabilities allowing for features as small as 2-5 micrometers and tolerances within ±1 micrometer. Material science advancements have expanded the range of polymers suitable for microinjection, including high-performance engineering plastics, bioresorbable polymers, and specialized compounds with enhanced properties.

The primary objective of this technical assessment is to comprehensively evaluate the current regulatory requirements affecting microinjection molding across major global markets, identifying compliance challenges and opportunities for innovation within regulatory constraints. Additionally, we aim to forecast regulatory trends that may impact future development of microinjection molding technologies and applications.

Secondary objectives include mapping the relationship between regulatory compliance and technical innovation, analyzing how regulations have historically influenced technological development in this field, and identifying strategies for maintaining compliance while pursuing technical advancement. This assessment will also examine how emerging technologies such as additive manufacturing and Industry 4.0 concepts intersect with microinjection molding regulations.

Understanding this regulatory landscape is crucial as the market for micro-molded components is projected to grow at a CAGR of 11.2% through 2028, with particularly strong growth in medical and electronics applications where regulatory requirements are most stringent.

Market Demand Analysis for Compliant Microinjection Molded Products

The global market for compliant microinjection molded products has experienced significant growth, driven primarily by increasing demand in medical devices, electronics, automotive components, and emerging biotechnology applications. Current market valuations indicate that the microinjection molding industry is expanding at a compound annual growth rate of approximately 8-9%, with particular acceleration in regions with strong regulatory frameworks.

Healthcare and medical device sectors represent the largest market segment, accounting for nearly 40% of the total demand for compliant microinjection molded products. This dominance stems from stringent regulatory requirements in medical applications, where precision, biocompatibility, and traceability are paramount. The trend toward minimally invasive procedures has further accelerated demand for micro-scale components with documented regulatory compliance.

Consumer electronics manufacturers constitute the second-largest market segment, particularly for microconnectors, switches, and precision components. This sector values suppliers who can demonstrate compliance with RoHS, REACH, and similar environmental regulations while maintaining the high precision required for miniaturized electronic components.

Market research reveals a growing premium for regulatory-compliant products, with customers willing to pay 15-20% more for components with comprehensive documentation and certification. This price differential highlights the market's recognition of the value embedded in regulatory compliance, particularly in high-consequence applications.

Regional analysis shows that North America and Europe lead in demand for highly regulated microinjection molded products, while Asia-Pacific markets are rapidly adopting similar compliance standards as their medical device and electronics manufacturing capabilities mature. This geographical shift is creating new market opportunities for suppliers who can navigate multiple regulatory environments.

Emerging application areas showing substantial growth potential include microfluidic devices for point-of-care diagnostics, biodegradable implants, and components for wearable technology. These applications face complex regulatory pathways that combine traditional manufacturing compliance with application-specific requirements.

Customer surveys indicate that procurement decisions increasingly prioritize suppliers' regulatory expertise alongside traditional factors like price and quality. Over 70% of OEMs in regulated industries cite regulatory compliance capabilities as a "critical" or "very important" supplier selection criterion, representing a significant shift from five years ago when this figure was below 50%.

The market is also witnessing increased demand for transparency in material sourcing, processing conditions, and quality control measures throughout the supply chain, driven by end-users' need to satisfy their own regulatory documentation requirements.

Healthcare and medical device sectors represent the largest market segment, accounting for nearly 40% of the total demand for compliant microinjection molded products. This dominance stems from stringent regulatory requirements in medical applications, where precision, biocompatibility, and traceability are paramount. The trend toward minimally invasive procedures has further accelerated demand for micro-scale components with documented regulatory compliance.

Consumer electronics manufacturers constitute the second-largest market segment, particularly for microconnectors, switches, and precision components. This sector values suppliers who can demonstrate compliance with RoHS, REACH, and similar environmental regulations while maintaining the high precision required for miniaturized electronic components.

Market research reveals a growing premium for regulatory-compliant products, with customers willing to pay 15-20% more for components with comprehensive documentation and certification. This price differential highlights the market's recognition of the value embedded in regulatory compliance, particularly in high-consequence applications.

Regional analysis shows that North America and Europe lead in demand for highly regulated microinjection molded products, while Asia-Pacific markets are rapidly adopting similar compliance standards as their medical device and electronics manufacturing capabilities mature. This geographical shift is creating new market opportunities for suppliers who can navigate multiple regulatory environments.

Emerging application areas showing substantial growth potential include microfluidic devices for point-of-care diagnostics, biodegradable implants, and components for wearable technology. These applications face complex regulatory pathways that combine traditional manufacturing compliance with application-specific requirements.

Customer surveys indicate that procurement decisions increasingly prioritize suppliers' regulatory expertise alongside traditional factors like price and quality. Over 70% of OEMs in regulated industries cite regulatory compliance capabilities as a "critical" or "very important" supplier selection criterion, representing a significant shift from five years ago when this figure was below 50%.

The market is also witnessing increased demand for transparency in material sourcing, processing conditions, and quality control measures throughout the supply chain, driven by end-users' need to satisfy their own regulatory documentation requirements.

Regulatory Landscape and Technical Challenges

The microinjection molding industry operates within a complex regulatory framework that varies significantly across regions and applications. In the medical device sector, regulations such as FDA 21 CFR Part 820 in the United States, EU Medical Device Regulation (MDR), and ISO 13485 standards impose stringent requirements on manufacturing processes, material selection, and quality control. These regulations necessitate comprehensive documentation, validation protocols, and traceability systems that present significant technical challenges for manufacturers.

Environmental regulations have also become increasingly stringent, with directives like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe limiting the use of certain materials and additives in plastic components. This regulatory landscape has forced manufacturers to develop alternative formulations and processing techniques that maintain product performance while eliminating restricted substances.

The miniaturization trend in microinjection molding introduces unique regulatory challenges related to material purity and process control. As component dimensions decrease to sub-millimeter scales, even microscopic contaminants can significantly impact product functionality and safety. Regulatory bodies increasingly require advanced analytical methods for material characterization and process validation that push the boundaries of current metrology capabilities.

Quality assurance presents another major technical challenge, as traditional inspection methods often prove inadequate for microinjection molded parts. Regulatory compliance frequently demands 100% inspection protocols that can detect defects at microscopic scales without damaging delicate components. This has driven innovation in non-contact measurement technologies and statistical process control methodologies specifically adapted for micro-scale manufacturing.

Cross-border regulatory differences create additional complexities for global manufacturers. A component that meets standards in one market may require significant redesign or revalidation for another, increasing development costs and time-to-market. The technical challenge of designing universal solutions that satisfy multiple regulatory frameworks simultaneously has become a competitive differentiator in the industry.

Emerging technologies like bioresorbable polymers and nanomaterial-enhanced composites face particularly uncertain regulatory pathways. Authorities worldwide are still developing appropriate frameworks for these novel materials, creating a challenging environment where technical innovation must proceed alongside regulatory engagement and risk assessment.

The pace of regulatory evolution also presents challenges, as standards frequently update to address new safety concerns or technological capabilities. Manufacturers must maintain flexible production systems capable of adapting to changing requirements without compromising efficiency or quality. This necessitates investment in reconfigurable automation systems and robust quality management infrastructures that can evolve alongside the regulatory landscape.

Environmental regulations have also become increasingly stringent, with directives like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe limiting the use of certain materials and additives in plastic components. This regulatory landscape has forced manufacturers to develop alternative formulations and processing techniques that maintain product performance while eliminating restricted substances.

The miniaturization trend in microinjection molding introduces unique regulatory challenges related to material purity and process control. As component dimensions decrease to sub-millimeter scales, even microscopic contaminants can significantly impact product functionality and safety. Regulatory bodies increasingly require advanced analytical methods for material characterization and process validation that push the boundaries of current metrology capabilities.

Quality assurance presents another major technical challenge, as traditional inspection methods often prove inadequate for microinjection molded parts. Regulatory compliance frequently demands 100% inspection protocols that can detect defects at microscopic scales without damaging delicate components. This has driven innovation in non-contact measurement technologies and statistical process control methodologies specifically adapted for micro-scale manufacturing.

Cross-border regulatory differences create additional complexities for global manufacturers. A component that meets standards in one market may require significant redesign or revalidation for another, increasing development costs and time-to-market. The technical challenge of designing universal solutions that satisfy multiple regulatory frameworks simultaneously has become a competitive differentiator in the industry.

Emerging technologies like bioresorbable polymers and nanomaterial-enhanced composites face particularly uncertain regulatory pathways. Authorities worldwide are still developing appropriate frameworks for these novel materials, creating a challenging environment where technical innovation must proceed alongside regulatory engagement and risk assessment.

The pace of regulatory evolution also presents challenges, as standards frequently update to address new safety concerns or technological capabilities. Manufacturers must maintain flexible production systems capable of adapting to changing requirements without compromising efficiency or quality. This necessitates investment in reconfigurable automation systems and robust quality management infrastructures that can evolve alongside the regulatory landscape.

Current Compliance Solutions and Methodologies

01 Process optimization for microinjection molding compliance

Optimizing process parameters is crucial for achieving compliance in microinjection molding. This includes precise control of injection speed, pressure, temperature, and cooling time to ensure consistent part quality. Advanced process monitoring systems can be implemented to detect and correct deviations in real-time, maintaining compliance with dimensional and quality requirements. Proper process validation and documentation are essential for regulatory compliance, particularly in industries with strict standards.- Process optimization for microinjection molding compliance: Optimizing process parameters is crucial for achieving compliance in microinjection molding. This includes controlling injection speed, pressure, temperature, and cooling time to ensure consistent part quality. Advanced process monitoring systems can be implemented to detect and correct deviations in real-time, maintaining compliance with dimensional and quality requirements. Proper process validation and documentation are essential for regulatory compliance, particularly in industries with strict standards.

- Material selection and characterization for compliant microinjection molding: The selection of appropriate materials is critical for microinjection molding compliance. Materials must exhibit suitable flow properties, dimensional stability, and mechanical characteristics at the micro scale. Proper characterization of materials, including rheological properties and shrinkage behavior, helps ensure consistent part quality. Biocompatible and medical-grade polymers may be required for applications in healthcare, while specialized materials with enhanced flow properties are often needed for complex microfeatures.

- Tooling design and precision for microinjection molding compliance: Tooling design plays a significant role in achieving compliance in microinjection molding. High-precision molds with accurate micro-features are essential for producing compliant parts. Advanced manufacturing techniques such as micro-EDM, laser machining, and precision CNC are used to create molds with the necessary accuracy. Proper venting, gating, and runner systems must be designed to ensure complete filling of micro-cavities and prevent defects. Mold surface treatments may be applied to improve release properties and part quality.

- Quality control and inspection methods for microinjection molded parts: Specialized quality control and inspection methods are necessary to verify compliance of microinjection molded parts. This includes high-resolution optical and electron microscopy, micro-CT scanning, and laser measurement systems capable of detecting defects at the micro scale. Automated vision systems can be implemented for in-line inspection to ensure dimensional accuracy and surface quality. Statistical process control methods help maintain consistent quality across production batches, while documentation of inspection results supports regulatory compliance.

- Regulatory and industry standards for microinjection molding: Compliance with regulatory and industry standards is essential for microinjection molding, particularly in medical, automotive, and electronics applications. This includes adherence to ISO standards for quality management systems, FDA regulations for medical devices, and industry-specific requirements. Documentation of validation processes, material traceability, and production controls is necessary to demonstrate compliance. Environmental regulations may also apply, requiring consideration of material selection, waste management, and energy efficiency in the microinjection molding process.

02 Material selection and characterization for compliant microinjection molding

The selection of appropriate materials is fundamental to achieving compliance in microinjection molding. Materials must possess suitable flow properties, thermal stability, and mechanical characteristics for microscale applications. Comprehensive material characterization, including rheological testing and thermal analysis, helps ensure consistent processing behavior. Biocompatible and medical-grade polymers may be required for applications in healthcare, while specialized materials with controlled shrinkage properties help maintain dimensional accuracy in precision components.Expand Specific Solutions03 Tooling design and precision for microinjection molding compliance

Specialized tooling design is essential for compliant microinjection molding processes. Micro-features require high-precision molds with excellent surface finish and tight tolerances. Advanced manufacturing techniques such as micro-EDM, laser machining, and precision CNC are employed to create mold cavities with microscale features. Proper venting, gating, and runner systems must be carefully designed to ensure complete filling of microscale cavities while preventing defects. Mold monitoring systems can be integrated to track performance and wear over time.Expand Specific Solutions04 Quality control and inspection methods for microinjection molded parts

Rigorous quality control protocols are necessary to verify compliance of microinjection molded components. This includes implementing advanced inspection technologies such as optical and electron microscopy, 3D surface profiling, and non-contact measurement systems. Statistical process control methods help monitor critical parameters and detect trends before they lead to non-compliance. Automated vision systems can be employed for 100% inspection of micro-features that would be difficult to verify manually. Documentation of inspection results provides traceability for regulatory compliance.Expand Specific Solutions05 Regulatory and industry standards for microinjection molding

Compliance with relevant regulatory frameworks and industry standards is critical for microinjection molding operations. This includes adherence to ISO standards for quality management systems, industry-specific regulations like FDA requirements for medical devices, and environmental compliance standards. Documentation systems must be implemented to maintain records of material certifications, process validation, and quality testing. Regular audits and certification processes help ensure ongoing compliance with evolving standards. Training programs for personnel on compliance requirements and proper documentation practices are also essential.Expand Specific Solutions

Key Industry Players and Regulatory Bodies

The microinjection molding regulatory landscape is evolving within a maturing industry that combines established practices with emerging innovations. The global market is experiencing steady growth, projected to reach approximately $1.5 billion by 2027, driven by increasing demand in medical, electronics, and automotive sectors. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Industry leaders like Husky Injection Molding Systems, FANUC Corp, and Sumitomo Heavy Industries have established comprehensive compliance frameworks, while innovative players such as iMFLUX (Procter & Gamble subsidiary) and Priamus System Technologies are developing advanced process control technologies that address regulatory requirements while enabling greater precision. Academic-industry partnerships with institutions like Politécnico de Leiria and Tsinghua Shenzhen International Graduate School are accelerating compliance-focused innovation.

Battenfeld GmbH

Technical Solution: Battenfeld (now part of Wittmann Battenfeld) addresses microinjection molding regulatory compliance through their MicroPower series, specifically designed for precision micro components. Their technology incorporates a two-stage injection unit with a 5-14mm screw for plasticizing and an 8mm injection plunger that ensures precise shot control down to 0.05g, critical for meeting tight tolerance requirements in regulated industries. The system features a fully electric drive system that eliminates hydraulic oil contamination risks, making it suitable for clean room environments up to ISO Class 6. Battenfeld's UNILOG B8 control system provides comprehensive process documentation with automatic parameter monitoring that flags deviations from validated settings, ensuring consistent compliance with regulatory specifications. Their machines incorporate specialized material handling systems that minimize degradation and contamination, maintaining material properties within approved regulatory parameters. Additionally, Battenfeld offers HiQ-Flow technology that compensates for viscosity fluctuations in real-time, ensuring consistent part quality even with batch-to-batch material variations that could otherwise affect regulatory compliance.

Strengths: Purpose-built micro molding technology with exceptional precision for regulated components; oil-free operation ideal for clean room environments; comprehensive process monitoring and documentation systems. Weaknesses: Limited shot size range compared to larger systems; higher cost per part for larger production volumes; specialized nature requires dedicated operator training and expertise.

Priamus System Technologies

Technical Solution: Priamus System Technologies focuses on process monitoring and quality control systems specifically designed to ensure regulatory compliance in microinjection molding. Their FillControl system utilizes cavity pressure and temperature sensors with sensitivity optimized for micro-scale applications, detecting variations as small as 0.01 MPa and 0.1°C. This precision is critical for validating process consistency in regulated medical and electronics applications. Priamus's Quality Monitor automatically generates statistical process control (SPC) documentation that aligns with FDA 21 CFR Part 820 and ISO 13485 requirements, providing real-time verification of process parameters against validated settings. Their technology includes automatic cavity balancing that ensures uniform filling across multi-cavity micro molds, eliminating part-to-part variations that could lead to regulatory non-compliance. The system's BlueLine amplifiers feature specialized calibration protocols that maintain measurement accuracy over time, ensuring consistent quality documentation for regulatory audits. Additionally, Priamus offers integration with electronic batch record systems, creating unbroken documentation chains from raw material to finished product as required by pharmaceutical and medical device regulations.

Strengths: Specialized sensor technology optimized for micro-scale applications; comprehensive data collection and analysis capabilities; vendor-neutral systems that can integrate with various molding machine brands. Weaknesses: Requires additional investment beyond the molding machine itself; complex setup and calibration procedures; primarily focused on monitoring rather than direct process control.

Critical Regulatory Patents and Technical Documentation

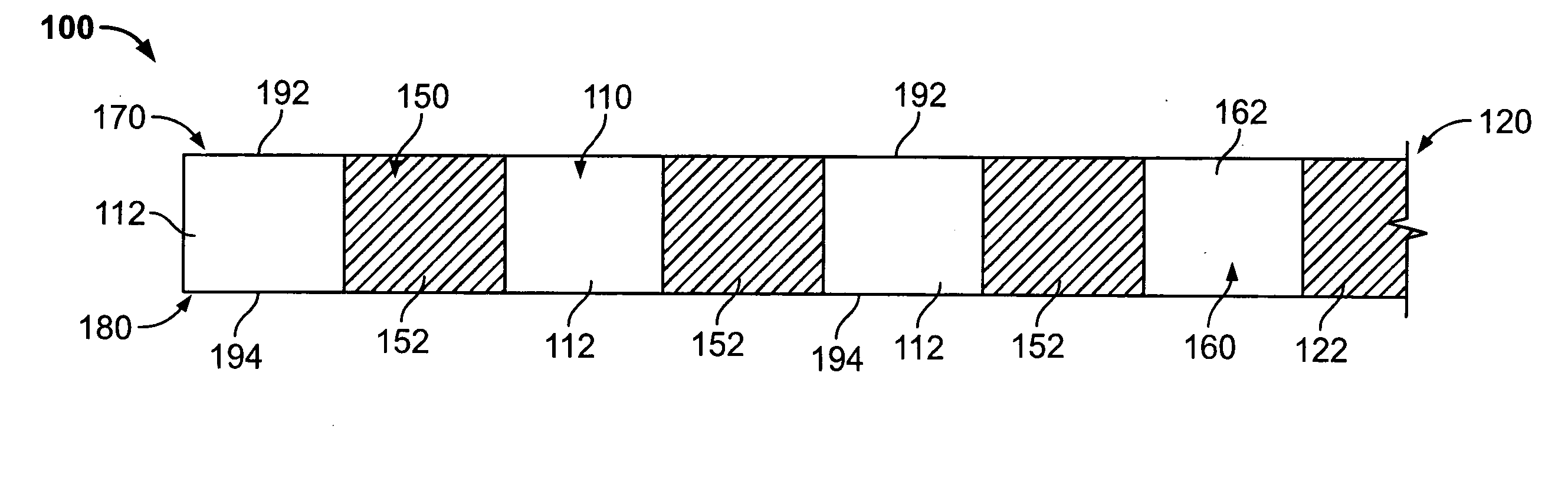

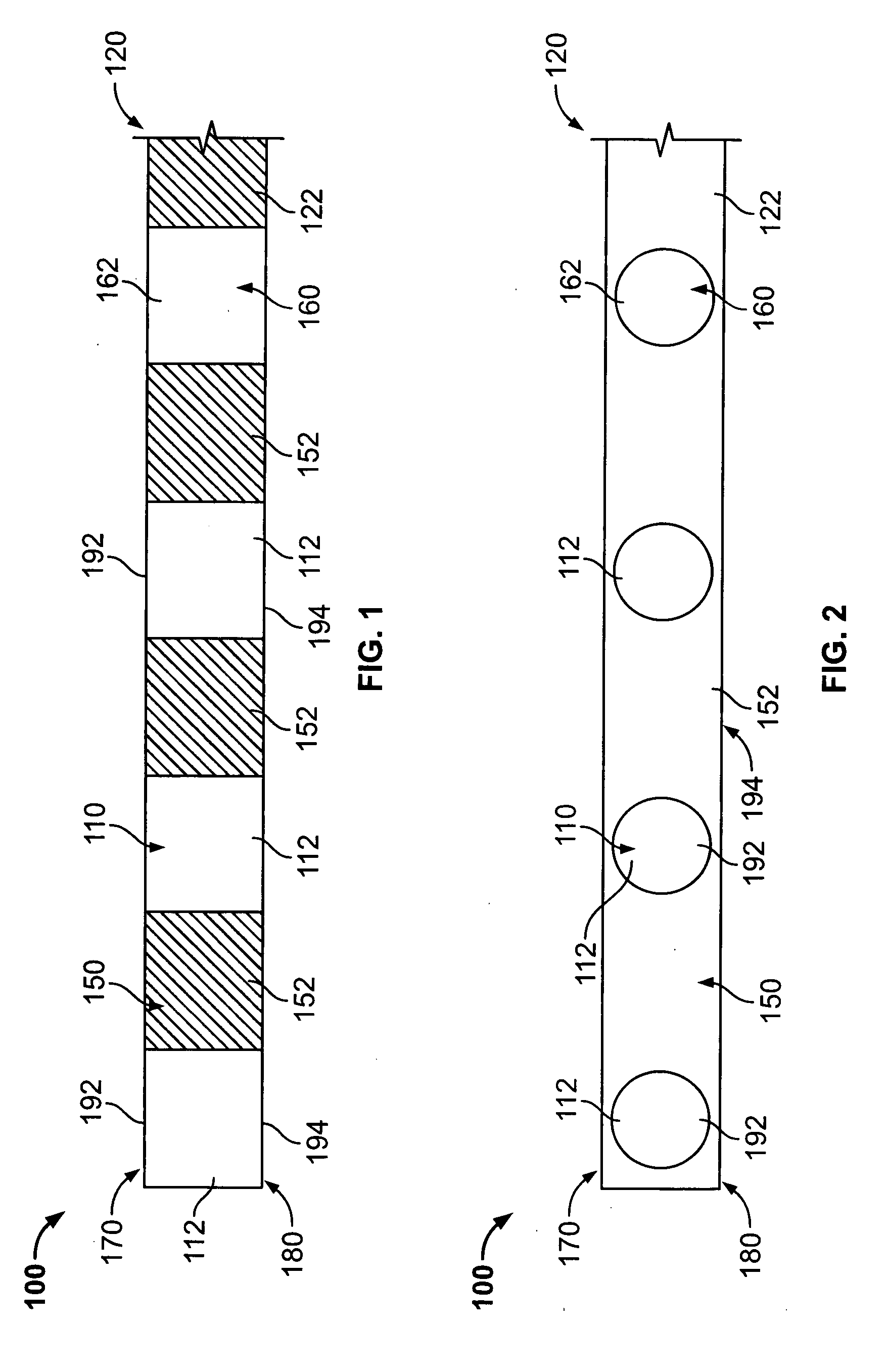

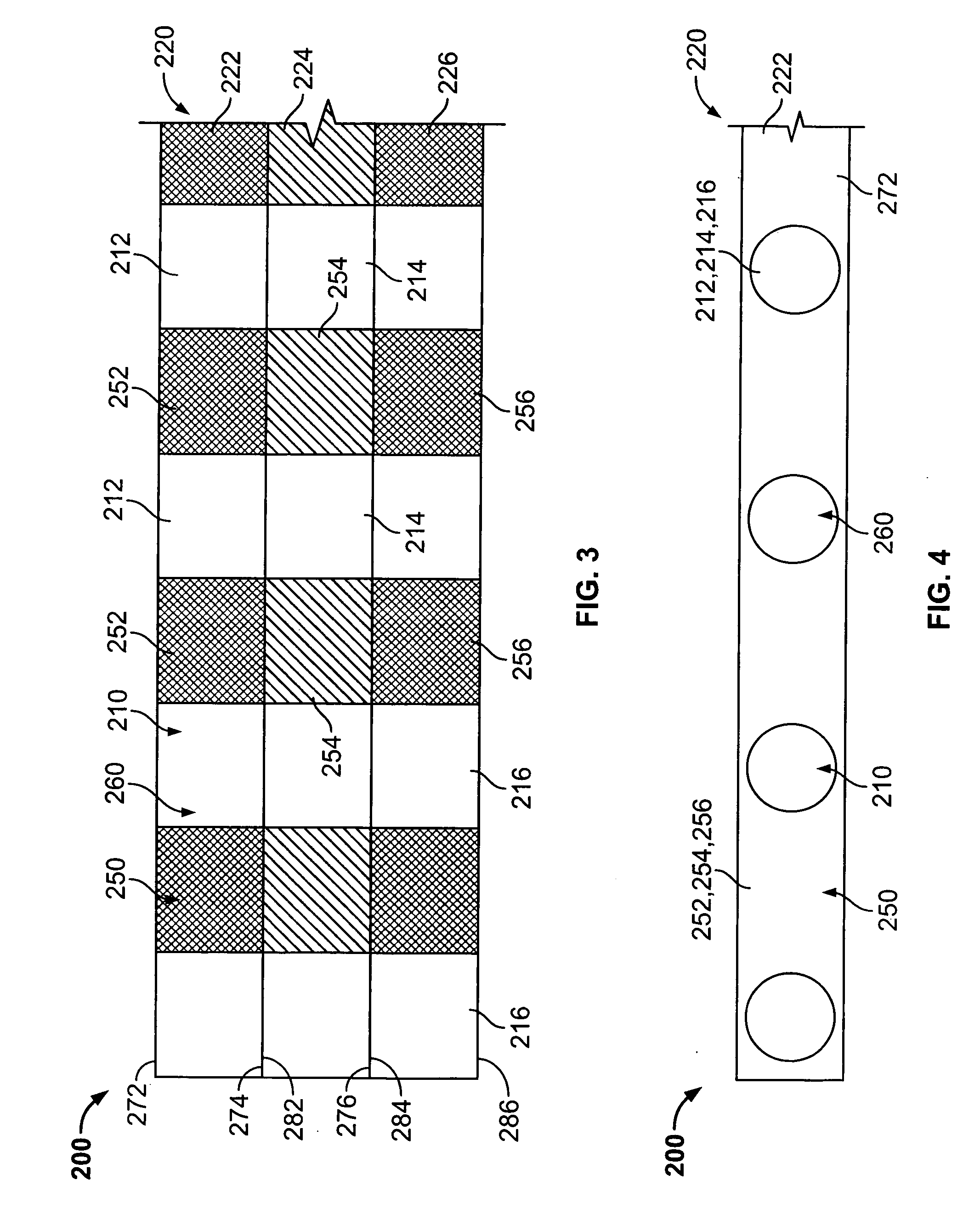

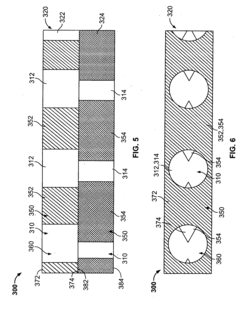

System and method of micromolded filtration microstructure and devices

PatentInactiveUS20070151920A1

Innovation

- The use of injection micromolding technology with advanced tool micro-machining techniques like EDM, MEDM, or laser beam machining to create precise filtration microstructures with a one-shot or multi-shot molding process, allowing for the production of filters with varying channel configurations and rigid structures that maintain consistency and efficiency.

Cross-Border Regulatory Harmonization Strategies

The fragmented regulatory landscape across different regions presents significant challenges for microinjection molding manufacturers operating globally. Harmonizing regulatory approaches between major markets such as the EU, US, Japan, and China requires strategic initiatives that balance compliance with innovation potential. Effective cross-border regulatory harmonization can reduce redundant testing, streamline approval processes, and accelerate time-to-market while maintaining safety standards.

Mutual Recognition Agreements (MRAs) represent a cornerstone strategy for regulatory harmonization. These formal agreements between regulatory authorities acknowledge the equivalence of certain aspects of each other's regulatory systems. For microinjection molding, particularly in medical device applications, MRAs can eliminate duplicate inspections and reduce compliance costs by up to 25%. The EU-US MRA for medical devices has already demonstrated significant efficiency improvements, with inspection redundancies reduced by approximately 40% since implementation.

International Standards Organization (ISO) frameworks provide another critical pathway to harmonization. ISO 13485 for medical device quality management systems and ISO 10993 for biocompatibility testing offer globally recognized benchmarks that facilitate cross-border acceptance. Companies adopting these standards can design their microinjection molding processes to simultaneously meet requirements across multiple jurisdictions, reducing regulatory complexity.

Regulatory convergence initiatives, such as the International Medical Device Regulators Forum (IMDRF), are driving alignment of technical documentation requirements and post-market surveillance protocols. For microinjection molding manufacturers, participation in these forums provides early insights into emerging regulatory trends and opportunities to influence harmonization efforts that benefit their specific technical challenges.

Digital compliance platforms are emerging as technological enablers of regulatory harmonization. These systems can map regulatory requirements across jurisdictions, identify commonalities and differences, and generate jurisdiction-specific documentation from a single validated data source. Early adopters report 30-40% reductions in regulatory submission preparation time and significantly improved accuracy in cross-border compliance management.

Strategic regulatory intelligence functions within organizations serve as critical components of successful harmonization strategies. These specialized teams monitor regulatory developments across key markets, analyze convergence opportunities, and develop tailored approaches to leverage harmonization initiatives. Companies with mature regulatory intelligence capabilities demonstrate greater agility in navigating complex global requirements while maintaining innovation momentum in microinjection molding technologies.

Mutual Recognition Agreements (MRAs) represent a cornerstone strategy for regulatory harmonization. These formal agreements between regulatory authorities acknowledge the equivalence of certain aspects of each other's regulatory systems. For microinjection molding, particularly in medical device applications, MRAs can eliminate duplicate inspections and reduce compliance costs by up to 25%. The EU-US MRA for medical devices has already demonstrated significant efficiency improvements, with inspection redundancies reduced by approximately 40% since implementation.

International Standards Organization (ISO) frameworks provide another critical pathway to harmonization. ISO 13485 for medical device quality management systems and ISO 10993 for biocompatibility testing offer globally recognized benchmarks that facilitate cross-border acceptance. Companies adopting these standards can design their microinjection molding processes to simultaneously meet requirements across multiple jurisdictions, reducing regulatory complexity.

Regulatory convergence initiatives, such as the International Medical Device Regulators Forum (IMDRF), are driving alignment of technical documentation requirements and post-market surveillance protocols. For microinjection molding manufacturers, participation in these forums provides early insights into emerging regulatory trends and opportunities to influence harmonization efforts that benefit their specific technical challenges.

Digital compliance platforms are emerging as technological enablers of regulatory harmonization. These systems can map regulatory requirements across jurisdictions, identify commonalities and differences, and generate jurisdiction-specific documentation from a single validated data source. Early adopters report 30-40% reductions in regulatory submission preparation time and significantly improved accuracy in cross-border compliance management.

Strategic regulatory intelligence functions within organizations serve as critical components of successful harmonization strategies. These specialized teams monitor regulatory developments across key markets, analyze convergence opportunities, and develop tailored approaches to leverage harmonization initiatives. Companies with mature regulatory intelligence capabilities demonstrate greater agility in navigating complex global requirements while maintaining innovation momentum in microinjection molding technologies.

Sustainability and Environmental Compliance Considerations

Sustainability and environmental compliance have become critical considerations in microinjection molding operations as regulatory frameworks worldwide increasingly emphasize ecological responsibility. Manufacturers must navigate complex environmental regulations that vary by region but generally focus on reducing carbon footprints, minimizing waste generation, and eliminating hazardous substances from production processes.

The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations significantly impact material selection for microinjection molding. These frameworks restrict the use of certain heavy metals and chemicals, compelling manufacturers to develop alternative formulations that maintain performance characteristics while meeting compliance standards.

Waste management presents another crucial compliance area, with regulations such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandating proper disposal and recycling of products. Microinjection molding facilities must implement comprehensive waste management systems that track material usage, minimize scrap rates, and establish proper disposal channels for production residues.

Energy efficiency regulations are increasingly affecting manufacturing operations, with many jurisdictions implementing carbon taxation or cap-and-trade systems. Microinjection molding companies are responding by investing in energy-efficient equipment, optimizing process parameters to reduce cycle times, and implementing heat recovery systems to capture and reuse thermal energy generated during production.

Biodegradable and bio-based polymers represent a growing trend in sustainable microinjection molding. Materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and various starch-based compounds offer promising alternatives to traditional petroleum-based plastics. However, these materials often present processing challenges in microinjection applications, including narrow processing windows, moisture sensitivity, and mechanical property limitations.

Closed-loop manufacturing systems are emerging as best practices for environmental compliance. These approaches incorporate recycled materials into new production, implement water recirculation systems, and utilize renewable energy sources. Leading manufacturers are developing proprietary technologies that enable the effective processing of recycled materials without compromising the precision requirements of microinjection molding.

Sustainability certifications such as ISO 14001 and cradle-to-cradle certification are becoming competitive differentiators in the marketplace. These frameworks provide structured approaches to environmental management and help manufacturers demonstrate compliance to customers and regulatory bodies. Forward-thinking companies are integrating these certification requirements into their quality management systems to streamline compliance efforts.

The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations significantly impact material selection for microinjection molding. These frameworks restrict the use of certain heavy metals and chemicals, compelling manufacturers to develop alternative formulations that maintain performance characteristics while meeting compliance standards.

Waste management presents another crucial compliance area, with regulations such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandating proper disposal and recycling of products. Microinjection molding facilities must implement comprehensive waste management systems that track material usage, minimize scrap rates, and establish proper disposal channels for production residues.

Energy efficiency regulations are increasingly affecting manufacturing operations, with many jurisdictions implementing carbon taxation or cap-and-trade systems. Microinjection molding companies are responding by investing in energy-efficient equipment, optimizing process parameters to reduce cycle times, and implementing heat recovery systems to capture and reuse thermal energy generated during production.

Biodegradable and bio-based polymers represent a growing trend in sustainable microinjection molding. Materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and various starch-based compounds offer promising alternatives to traditional petroleum-based plastics. However, these materials often present processing challenges in microinjection applications, including narrow processing windows, moisture sensitivity, and mechanical property limitations.

Closed-loop manufacturing systems are emerging as best practices for environmental compliance. These approaches incorporate recycled materials into new production, implement water recirculation systems, and utilize renewable energy sources. Leading manufacturers are developing proprietary technologies that enable the effective processing of recycled materials without compromising the precision requirements of microinjection molding.

Sustainability certifications such as ISO 14001 and cradle-to-cradle certification are becoming competitive differentiators in the marketplace. These frameworks provide structured approaches to environmental management and help manufacturers demonstrate compliance to customers and regulatory bodies. Forward-thinking companies are integrating these certification requirements into their quality management systems to streamline compliance efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!