Regulatory Standards for Battery Thermal Runaway Response in Consumer Goods

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Safety Evolution and Regulatory Objectives

Battery safety has evolved significantly over the past three decades, driven by the rapid proliferation of lithium-ion batteries in consumer electronics. In the early 1990s, following initial commercialization by Sony, safety concerns were primarily addressed through basic cell-level protections. The regulatory landscape was sparse, with minimal standardization across different markets and applications.

The period from 2000 to 2010 marked a critical transition as portable electronics became ubiquitous. Several high-profile battery failure incidents, including laptop fires and mobile phone explosions, highlighted the urgent need for comprehensive safety standards. This era saw the emergence of foundational regulations such as IEC 62133 for portable batteries and UN 38.3 for battery transportation safety.

Between 2010 and 2020, the diversification of battery applications into larger consumer goods including power tools, e-mobility devices, and home energy storage systems necessitated more sophisticated safety frameworks. Regulatory bodies expanded their focus from cell-level safety to system-level thermal management and failure containment strategies. The UL 1642 standard for lithium batteries and UL 2054 for household battery systems became industry benchmarks during this period.

The current regulatory landscape reflects a mature understanding of thermal runaway risks, with objectives centered on three key pillars: prevention, detection, and containment. Prevention focuses on manufacturing quality controls and electrical protection circuits. Detection encompasses early warning systems and real-time monitoring technologies. Containment strategies address how to minimize damage when thermal events occur despite preventive measures.

Global harmonization of standards represents a significant regulatory objective, with efforts to align requirements across North American (UL), European (EN), and Asian (particularly Chinese GB and Japanese JIS) frameworks. This aims to reduce compliance burdens while ensuring consistent safety levels worldwide.

Recent regulatory developments have increasingly emphasized consumer protection through transparent risk communication and post-market surveillance requirements. Manufacturers must now demonstrate not only compliance with minimum safety thresholds but also ongoing commitment to safety through the product lifecycle.

The ultimate regulatory objective has evolved from simply preventing catastrophic failures to establishing a comprehensive safety ecosystem that addresses the entire battery lifecycle from manufacturing through disposal, with particular emphasis on thermal event mitigation in consumer environments where technical expertise is limited and exposure risks are high.

The period from 2000 to 2010 marked a critical transition as portable electronics became ubiquitous. Several high-profile battery failure incidents, including laptop fires and mobile phone explosions, highlighted the urgent need for comprehensive safety standards. This era saw the emergence of foundational regulations such as IEC 62133 for portable batteries and UN 38.3 for battery transportation safety.

Between 2010 and 2020, the diversification of battery applications into larger consumer goods including power tools, e-mobility devices, and home energy storage systems necessitated more sophisticated safety frameworks. Regulatory bodies expanded their focus from cell-level safety to system-level thermal management and failure containment strategies. The UL 1642 standard for lithium batteries and UL 2054 for household battery systems became industry benchmarks during this period.

The current regulatory landscape reflects a mature understanding of thermal runaway risks, with objectives centered on three key pillars: prevention, detection, and containment. Prevention focuses on manufacturing quality controls and electrical protection circuits. Detection encompasses early warning systems and real-time monitoring technologies. Containment strategies address how to minimize damage when thermal events occur despite preventive measures.

Global harmonization of standards represents a significant regulatory objective, with efforts to align requirements across North American (UL), European (EN), and Asian (particularly Chinese GB and Japanese JIS) frameworks. This aims to reduce compliance burdens while ensuring consistent safety levels worldwide.

Recent regulatory developments have increasingly emphasized consumer protection through transparent risk communication and post-market surveillance requirements. Manufacturers must now demonstrate not only compliance with minimum safety thresholds but also ongoing commitment to safety through the product lifecycle.

The ultimate regulatory objective has evolved from simply preventing catastrophic failures to establishing a comprehensive safety ecosystem that addresses the entire battery lifecycle from manufacturing through disposal, with particular emphasis on thermal event mitigation in consumer environments where technical expertise is limited and exposure risks are high.

Market Demand for Enhanced Battery Safety Solutions

The global market for enhanced battery safety solutions has witnessed unprecedented growth in recent years, driven primarily by the proliferation of lithium-ion batteries across diverse consumer electronic devices. Market research indicates that the global lithium-ion battery market reached $46.2 billion in 2022 and is projected to grow at a CAGR of 15.2% through 2030, underscoring the critical need for advanced safety mechanisms.

Consumer demand for improved battery safety features has intensified following high-profile incidents involving thermal runaway in smartphones, laptops, and electric vehicles. A survey conducted among electronics manufacturers revealed that 78% of consumers now consider safety ratings when purchasing battery-powered devices, compared to just 32% five years ago. This shift in consumer awareness has created a substantial market pull for products with demonstrable thermal management capabilities.

The insurance sector has emerged as another significant driver for enhanced battery safety solutions. Major insurers have begun implementing premium adjustments based on the presence of advanced thermal runaway prevention systems in consumer electronics and electric vehicles. This financial incentive structure has accelerated adoption rates among manufacturers seeking to maintain competitive insurance rates for their products and customers.

Regulatory pressures have further catalyzed market growth, with the implementation of stringent safety standards across North America, Europe, and Asia. The EU Battery Directive revision and similar regulatory frameworks in other regions have established clear compliance requirements, creating immediate market demand for solutions that can meet these evolving standards. Industry analysts estimate the market for regulatory compliance technologies specific to battery thermal management at $3.8 billion annually.

The transportation sector represents the fastest-growing segment for battery safety solutions, with electric vehicle manufacturers investing heavily in thermal runaway prevention and containment technologies. This sector's demand is expected to grow at 22.7% annually through 2028, outpacing the broader market. Consumer electronics follows as the second-largest market segment, with particular emphasis on wearable technology and portable computing devices.

Geographically, Asia-Pacific dominates the market demand landscape, accounting for 43% of global consumption of battery safety solutions. This regional concentration aligns with the region's manufacturing dominance in both battery production and consumer electronics assembly. North America and Europe follow with 27% and 24% market share respectively, with both regions showing accelerated growth rates driven by electric vehicle adoption and stringent regulatory frameworks.

Consumer demand for improved battery safety features has intensified following high-profile incidents involving thermal runaway in smartphones, laptops, and electric vehicles. A survey conducted among electronics manufacturers revealed that 78% of consumers now consider safety ratings when purchasing battery-powered devices, compared to just 32% five years ago. This shift in consumer awareness has created a substantial market pull for products with demonstrable thermal management capabilities.

The insurance sector has emerged as another significant driver for enhanced battery safety solutions. Major insurers have begun implementing premium adjustments based on the presence of advanced thermal runaway prevention systems in consumer electronics and electric vehicles. This financial incentive structure has accelerated adoption rates among manufacturers seeking to maintain competitive insurance rates for their products and customers.

Regulatory pressures have further catalyzed market growth, with the implementation of stringent safety standards across North America, Europe, and Asia. The EU Battery Directive revision and similar regulatory frameworks in other regions have established clear compliance requirements, creating immediate market demand for solutions that can meet these evolving standards. Industry analysts estimate the market for regulatory compliance technologies specific to battery thermal management at $3.8 billion annually.

The transportation sector represents the fastest-growing segment for battery safety solutions, with electric vehicle manufacturers investing heavily in thermal runaway prevention and containment technologies. This sector's demand is expected to grow at 22.7% annually through 2028, outpacing the broader market. Consumer electronics follows as the second-largest market segment, with particular emphasis on wearable technology and portable computing devices.

Geographically, Asia-Pacific dominates the market demand landscape, accounting for 43% of global consumption of battery safety solutions. This regional concentration aligns with the region's manufacturing dominance in both battery production and consumer electronics assembly. North America and Europe follow with 27% and 24% market share respectively, with both regions showing accelerated growth rates driven by electric vehicle adoption and stringent regulatory frameworks.

Current Thermal Runaway Prevention Technologies and Challenges

The current landscape of thermal runaway prevention technologies encompasses multiple layers of protection designed to mitigate risks in consumer battery applications. Hardware-based solutions include thermal fuses that physically disconnect circuits when temperatures exceed safe thresholds, and positive temperature coefficient (PTC) devices that increase resistance as temperature rises, effectively limiting current flow. Current interrupt devices (CIDs) provide another critical safety mechanism by breaking electrical connections when internal pressure builds up due to gas generation during thermal events.

Advanced battery management systems (BMS) represent the intelligence layer of prevention technologies, continuously monitoring cell parameters including temperature, voltage, and current. Modern BMS implementations employ sophisticated algorithms to detect early warning signs of thermal instability and can preemptively reduce charging rates or disconnect cells before cascading failures occur. These systems have evolved significantly with machine learning capabilities that improve anomaly detection accuracy over time.

Material innovations constitute another important technological approach, with ceramic-coated separators and flame-retardant electrolyte additives gaining prominence. These materials can withstand higher temperatures before degradation and suppress combustion processes, providing valuable additional response time during thermal events. Solid-state electrolytes represent a promising frontier, potentially eliminating the flammable liquid electrolytes that contribute significantly to runaway severity.

Despite these advancements, significant challenges persist in thermal runaway prevention. The fundamental trade-off between energy density and safety remains unresolved, as higher energy density batteries inherently store more potential energy that can be released during failure. Miniaturization trends in consumer electronics further exacerbate this challenge by reducing thermal dissipation pathways while maintaining or increasing energy requirements.

Detection latency presents another critical challenge, as the transition from normal operation to thermal runaway can occur within seconds under certain failure conditions. Current sensing technologies often struggle to provide sufficient warning time for intervention, particularly in consumer devices where cost constraints limit sensor deployment. The variability of environmental conditions in which consumer devices operate further complicates reliable early detection.

Regulatory fragmentation across global markets creates compliance challenges for manufacturers, with different regions establishing varying requirements for thermal runaway testing and mitigation. This inconsistency increases development costs and can slow the implementation of new safety technologies, particularly for products intended for international distribution.

Advanced battery management systems (BMS) represent the intelligence layer of prevention technologies, continuously monitoring cell parameters including temperature, voltage, and current. Modern BMS implementations employ sophisticated algorithms to detect early warning signs of thermal instability and can preemptively reduce charging rates or disconnect cells before cascading failures occur. These systems have evolved significantly with machine learning capabilities that improve anomaly detection accuracy over time.

Material innovations constitute another important technological approach, with ceramic-coated separators and flame-retardant electrolyte additives gaining prominence. These materials can withstand higher temperatures before degradation and suppress combustion processes, providing valuable additional response time during thermal events. Solid-state electrolytes represent a promising frontier, potentially eliminating the flammable liquid electrolytes that contribute significantly to runaway severity.

Despite these advancements, significant challenges persist in thermal runaway prevention. The fundamental trade-off between energy density and safety remains unresolved, as higher energy density batteries inherently store more potential energy that can be released during failure. Miniaturization trends in consumer electronics further exacerbate this challenge by reducing thermal dissipation pathways while maintaining or increasing energy requirements.

Detection latency presents another critical challenge, as the transition from normal operation to thermal runaway can occur within seconds under certain failure conditions. Current sensing technologies often struggle to provide sufficient warning time for intervention, particularly in consumer devices where cost constraints limit sensor deployment. The variability of environmental conditions in which consumer devices operate further complicates reliable early detection.

Regulatory fragmentation across global markets creates compliance challenges for manufacturers, with different regions establishing varying requirements for thermal runaway testing and mitigation. This inconsistency increases development costs and can slow the implementation of new safety technologies, particularly for products intended for international distribution.

Existing Thermal Runaway Mitigation Strategies

01 Thermal management systems for battery safety

Advanced thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal operating temperatures. By effectively managing heat distribution and dissipation, these systems can significantly reduce the risk of thermal runaway events and enhance overall battery safety in compliance with regulatory standards.- Thermal management systems for preventing battery thermal runaway: Various thermal management systems are designed to prevent battery thermal runaway by monitoring temperature, controlling heat dissipation, and implementing cooling mechanisms. These systems include advanced sensors for early detection of temperature anomalies, active cooling technologies, and thermal isolation strategies to prevent propagation of thermal events between battery cells. Regulatory standards require these systems to maintain battery temperatures within safe operating ranges under various conditions.

- Battery safety testing protocols and certification requirements: Regulatory standards mandate specific testing protocols to evaluate battery safety under extreme conditions. These include abuse tests such as overcharging, short-circuit, crush, penetration, and thermal shock tests. Certification requirements often follow standards like UL 1642, IEC 62133, and UN 38.3 for transportation safety. Manufacturers must demonstrate compliance with these standards through rigorous testing and documentation before batteries can be approved for commercial use.

- Fire suppression and containment systems for battery installations: Regulatory standards require appropriate fire suppression and containment systems for battery installations to mitigate the consequences of thermal runaway events. These include specialized fire detection systems, automatic extinguishing mechanisms using appropriate agents for battery fires, and physical containment structures designed to isolate thermal events. Standards specify minimum requirements for fire resistance ratings, ventilation systems, and emergency response protocols specific to battery storage facilities.

- Battery design and material requirements for thermal stability: Regulations specify design requirements and material standards to enhance the thermal stability of batteries. These include specifications for separator materials with thermal shutdown properties, flame-retardant electrolytes, and thermal-resistant cell casings. Standards also address the use of current interrupt devices, pressure relief mechanisms, and positive temperature coefficient materials. Manufacturers must demonstrate that battery designs incorporate these safety features to prevent or mitigate thermal runaway events.

- Monitoring and early warning systems for battery thermal events: Regulatory standards mandate the implementation of monitoring and early warning systems to detect precursors to thermal runaway. These systems include continuous monitoring of battery parameters such as temperature, voltage, and internal resistance. Advanced battery management systems must be capable of identifying abnormal patterns that might indicate impending thermal issues. Standards specify response times, alarm thresholds, and communication protocols for alerting users or automated safety systems when potentially dangerous conditions are detected.

02 Battery safety testing and certification standards

Regulatory frameworks require batteries to undergo rigorous safety testing and certification processes to ensure they meet established standards. These tests evaluate battery performance under various conditions including overcharging, short-circuiting, mechanical impact, and extreme temperatures. Certification standards such as UL, IEC, and UN regulations provide guidelines for manufacturers to design batteries that can withstand abuse conditions without experiencing catastrophic thermal runaway events.Expand Specific Solutions03 Early detection and warning systems

Early detection systems are critical for identifying potential thermal runaway conditions before they escalate. These systems incorporate sensors, monitoring circuits, and diagnostic algorithms that can detect abnormal temperature increases, voltage fluctuations, or gas emissions that precede thermal runaway. When integrated with warning mechanisms, these systems can alert users or automatically trigger protective measures, helping to prevent serious safety incidents and ensure compliance with regulatory requirements.Expand Specific Solutions04 Fire suppression and containment technologies

Fire suppression and containment technologies are designed to limit the spread and impact of thermal runaway events. These include specialized materials for battery enclosures, fire-resistant barriers, and active suppression systems that can deploy fire-extinguishing agents. Regulatory standards increasingly require these protective measures to be incorporated into battery systems, particularly for applications in sensitive environments such as transportation, energy storage, and consumer electronics.Expand Specific Solutions05 Battery design and material innovations for safety

Innovative battery designs and materials are being developed to inherently reduce thermal runaway risks. These include advanced separator materials with higher thermal stability, flame-retardant electrolytes, and novel electrode compositions that are less prone to exothermic reactions. Regulatory standards are evolving to encourage the adoption of these safer materials and designs, particularly for high-energy density batteries used in electric vehicles and grid storage applications.Expand Specific Solutions

Key Industry Players and Regulatory Bodies

The regulatory landscape for battery thermal runaway response in consumer goods is evolving rapidly as the market expands. Currently in the growth phase, this sector is experiencing significant attention due to increasing safety concerns. The global market for thermal runaway prevention technologies is projected to grow substantially with the expansion of electric vehicles and portable electronics. Leading companies like BYD, CATL, Tesla, and Samsung SDI are advancing thermal management solutions, while research institutions such as China Electric Power Research Institute and Industrial Technology Research Institute provide technical support. Companies including Aspen Aerogels and VOCAI Medical are developing innovative materials and chip-based solutions, indicating the technology is progressing from early development to commercial implementation, though standardization remains fragmented across regions.

BYD Co., Ltd.

Technical Solution: BYD has developed its proprietary Blade Battery technology specifically designed to address thermal runaway concerns in consumer applications. The system meets or exceeds standards including UN 38.3, IEC 62660, and GB 38031. BYD's approach utilizes a unique cell-to-pack design with long, thin cells arranged in parallel that inherently limits thermal propagation pathways. Their battery incorporates a non-flammable lithium iron phosphate (LFP) chemistry that has demonstrated exceptional performance in nail penetration tests without ignition or thermal runaway. BYD's thermal management system features intelligent cooling with predictive thermal modeling that can adjust cooling intensity based on usage patterns and environmental conditions. The company's battery packs include automated disconnection systems that can isolate damaged cells within milliseconds of detecting abnormal conditions, preventing cascade failures across the pack while maintaining compliance with UL 2580 standards.

Strengths: Inherently safer LFP chemistry with proven resistance to thermal runaway; innovative structural design that physically limits thermal propagation; comprehensive testing exceeding regulatory requirements. Weaknesses: Lower energy density compared to some competing technologies; heavier overall system weight; more complex manufacturing process for the blade cell configuration.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power has developed an AI-enhanced thermal runaway prevention system for consumer electronics and energy storage applications that meets IEC 62619, UL 9540A, and GB 38031 standards. Their solution incorporates a three-tier safety architecture with cell-level monitoring using micro-sensors that can detect temperature anomalies with ±0.5°C precision. Huawei's thermal management system utilizes phase-change composite materials with graphene-enhanced heat spreaders that can absorb and dissipate thermal energy during potential runaway events. Their proprietary Battery Safety Guardian system employs AI algorithms that continuously analyze over 300 battery parameters to predict potential failures up to 30 minutes before occurrence. The company's battery packs include aerogel-based isolation barriers between modules that can withstand temperatures up to 1200°C for over 30 minutes, preventing thermal propagation while maintaining compliance with the stringent requirements of IEC 62619 and UL 9540A standards for thermal runaway mitigation in consumer applications.

Strengths: Advanced AI-based predictive capabilities with high accuracy; comprehensive sensor network providing detailed thermal monitoring; innovative materials science approach to thermal isolation. Weaknesses: High computational requirements for AI monitoring systems; increased manufacturing complexity due to extensive sensor network; higher cost compared to conventional thermal management systems.

Critical Patents and Research in Battery Safety Systems

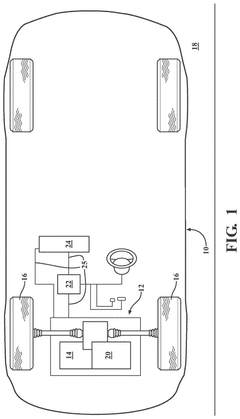

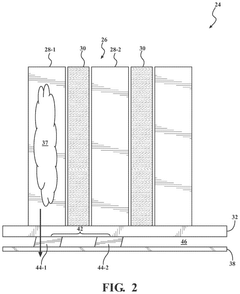

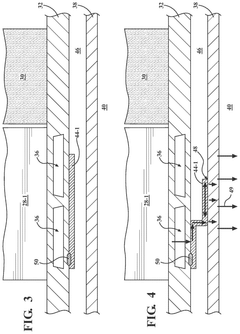

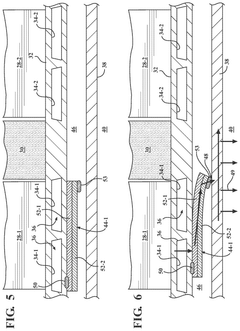

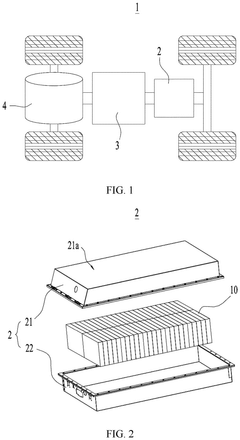

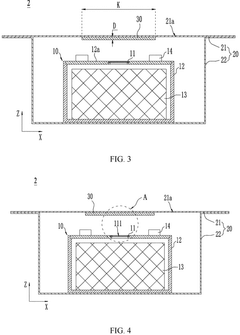

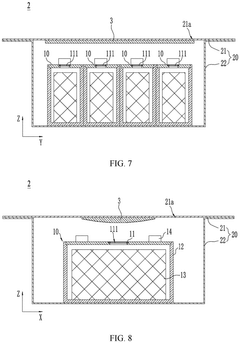

Mitigation of thermal runaway in a battery module

PatentActiveUS12308404B2

Innovation

- The battery module incorporates a heat sink in contact with each battery cell to absorb thermal energy, along with a heat transfer mechanism featuring a switch that detects temperature exceeding a predetermined value, bridging an air gap to direct thermal energy from the overheated cell to the module enclosure, thereby controlling the propagation of thermal runaway.

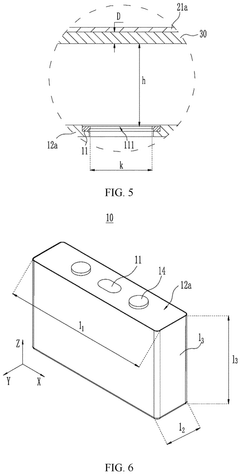

Battery and electric device

PatentPendingEP4517986A1

Innovation

- A battery design that incorporates a protective member with a minimum dimension of D in the axial direction, where D is optimized based on the highest temperature T of substances released during thermal runaway, ensuring a D/T ratio between 5×10^-4 and 5.3×10^-3 mm/°C to reduce the risk of the protective member being pierced and minimize energy density loss.

International Compliance Requirements for Consumer Electronics

The global landscape of battery safety regulations has evolved significantly in response to increasing incidents of thermal runaway in consumer electronics. Currently, major regulatory frameworks include IEC 62133/UL 1642 for cell-level safety, UL 2054 for battery packs, and UN 38.3 for transportation safety. These standards establish minimum requirements for design, manufacturing, and testing to prevent thermal events in normal and abnormal conditions.

European Union regulations under the CE marking system mandate compliance with EN 62133 and the Battery Directive 2006/66/EC, which focus on both safety and environmental aspects. The EU has recently strengthened requirements through amendments to these directives, particularly for lithium-ion batteries in portable electronics, requiring more rigorous thermal abuse testing and improved battery management systems.

In North America, UL and CSA standards predominate, with UL 1642, UL 2054, and UL 2056 forming the core compliance framework. The U.S. Consumer Product Safety Commission has issued additional guidelines following high-profile thermal runaway incidents, requiring manufacturers to implement enhanced safety features and warning systems.

Asian markets present varying regulatory landscapes. Japan's PSE certification system incorporates the J62133 standard with additional requirements for thermal protection. China's CCC certification mandates GB 31241 compliance, which includes some of the world's most stringent thermal runaway prevention requirements. South Korea's KC certification system has recently updated its standards to include advanced thermal management system requirements.

Emerging economies are rapidly adopting international standards while developing region-specific modifications. India has implemented BIS certification requirements based on IEC standards but with additional testing parameters for high-temperature environments. Brazil's INMETRO certification has recently incorporated specific thermal runaway prevention requirements.

Cross-jurisdictional compliance presents significant challenges for manufacturers. Testing methodologies vary between regions, with some requiring nail penetration tests while others mandate thermal shock or overcharge testing. Documentation requirements also differ substantially, with European markets requiring detailed technical files while Asian markets often emphasize factory inspection and sample testing.

Recent regulatory trends indicate movement toward harmonization of standards, with the International Electrotechnical Commission leading efforts to develop a unified approach to battery thermal safety. Industry stakeholders are actively participating in the development of next-generation standards that address emerging battery chemistries and higher energy densities in consumer electronics.

European Union regulations under the CE marking system mandate compliance with EN 62133 and the Battery Directive 2006/66/EC, which focus on both safety and environmental aspects. The EU has recently strengthened requirements through amendments to these directives, particularly for lithium-ion batteries in portable electronics, requiring more rigorous thermal abuse testing and improved battery management systems.

In North America, UL and CSA standards predominate, with UL 1642, UL 2054, and UL 2056 forming the core compliance framework. The U.S. Consumer Product Safety Commission has issued additional guidelines following high-profile thermal runaway incidents, requiring manufacturers to implement enhanced safety features and warning systems.

Asian markets present varying regulatory landscapes. Japan's PSE certification system incorporates the J62133 standard with additional requirements for thermal protection. China's CCC certification mandates GB 31241 compliance, which includes some of the world's most stringent thermal runaway prevention requirements. South Korea's KC certification system has recently updated its standards to include advanced thermal management system requirements.

Emerging economies are rapidly adopting international standards while developing region-specific modifications. India has implemented BIS certification requirements based on IEC standards but with additional testing parameters for high-temperature environments. Brazil's INMETRO certification has recently incorporated specific thermal runaway prevention requirements.

Cross-jurisdictional compliance presents significant challenges for manufacturers. Testing methodologies vary between regions, with some requiring nail penetration tests while others mandate thermal shock or overcharge testing. Documentation requirements also differ substantially, with European markets requiring detailed technical files while Asian markets often emphasize factory inspection and sample testing.

Recent regulatory trends indicate movement toward harmonization of standards, with the International Electrotechnical Commission leading efforts to develop a unified approach to battery thermal safety. Industry stakeholders are actively participating in the development of next-generation standards that address emerging battery chemistries and higher energy densities in consumer electronics.

Environmental Impact of Battery Safety Technologies

The environmental implications of battery safety technologies extend far beyond the immediate safety concerns, encompassing the entire lifecycle of battery systems. Current thermal runaway prevention and containment technologies often utilize flame retardants, phase change materials, and specialized insulation materials that may contain potentially hazardous substances. When these materials are exposed to extreme heat during thermal events, they can release toxic gases and particulates into the atmosphere, contributing to air pollution and posing health risks to nearby populations.

Water-based cooling systems, while effective for thermal management, raise concerns regarding water consumption and potential contamination of water sources if improperly managed. The manufacturing processes for advanced ceramic separators and other safety components often require significant energy inputs and may involve environmentally problematic solvents and chemicals, contributing to the carbon footprint of battery production.

End-of-life considerations present another critical environmental dimension. Safety technologies can complicate recycling processes, as flame retardants and other additives may interfere with material recovery operations. This challenge is particularly pronounced for lithium-ion batteries, where efficient recycling is already technically challenging. The inability to effectively separate safety components from active materials can lead to increased landfill disposal, exacerbating resource depletion and pollution risks.

Regulatory frameworks increasingly recognize these environmental trade-offs. The European Union's Battery Directive and REACH regulations now include provisions addressing both safety performance and environmental impact, requiring manufacturers to consider the full lifecycle environmental footprint of their safety solutions. Similarly, California's advanced battery regulations incorporate environmental criteria alongside safety requirements.

Emerging environmentally conscious safety technologies show promise in addressing these concerns. Bio-based flame retardants derived from renewable resources, non-toxic phase change materials, and easily separable safety components designed for recyclability represent significant advancements. These innovations aim to maintain or enhance safety performance while reducing environmental impact.

The industry is gradually moving toward a more holistic approach that balances immediate safety needs with long-term environmental sustainability. This shift is evidenced by increasing research investment in green safety technologies and the development of comprehensive lifecycle assessment methodologies specifically tailored to battery safety systems. Such approaches will be essential as battery deployment continues to accelerate across consumer electronics, electric vehicles, and energy storage applications.

Water-based cooling systems, while effective for thermal management, raise concerns regarding water consumption and potential contamination of water sources if improperly managed. The manufacturing processes for advanced ceramic separators and other safety components often require significant energy inputs and may involve environmentally problematic solvents and chemicals, contributing to the carbon footprint of battery production.

End-of-life considerations present another critical environmental dimension. Safety technologies can complicate recycling processes, as flame retardants and other additives may interfere with material recovery operations. This challenge is particularly pronounced for lithium-ion batteries, where efficient recycling is already technically challenging. The inability to effectively separate safety components from active materials can lead to increased landfill disposal, exacerbating resource depletion and pollution risks.

Regulatory frameworks increasingly recognize these environmental trade-offs. The European Union's Battery Directive and REACH regulations now include provisions addressing both safety performance and environmental impact, requiring manufacturers to consider the full lifecycle environmental footprint of their safety solutions. Similarly, California's advanced battery regulations incorporate environmental criteria alongside safety requirements.

Emerging environmentally conscious safety technologies show promise in addressing these concerns. Bio-based flame retardants derived from renewable resources, non-toxic phase change materials, and easily separable safety components designed for recyclability represent significant advancements. These innovations aim to maintain or enhance safety performance while reducing environmental impact.

The industry is gradually moving toward a more holistic approach that balances immediate safety needs with long-term environmental sustainability. This shift is evidenced by increasing research investment in green safety technologies and the development of comprehensive lifecycle assessment methodologies specifically tailored to battery safety systems. Such approaches will be essential as battery deployment continues to accelerate across consumer electronics, electric vehicles, and energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!