Cyclone Separator Energy Consumption Versus Collection Efficiency

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Background and Objectives

Cyclone separators have been a cornerstone in industrial particle separation for over a century, with their origins dating back to the late 1800s. These devices utilize centrifugal force to separate particles from a gas stream, making them invaluable in various industries such as cement production, power generation, and air pollution control. The evolution of cyclone separators has been driven by the need for more efficient and cost-effective particle removal systems, particularly in the face of increasingly stringent environmental regulations.

The primary objective of cyclone separator technology is to achieve optimal particle collection efficiency while minimizing energy consumption. This balance is crucial for industrial applications where operational costs and environmental impact are significant concerns. Over the years, researchers and engineers have focused on improving the design and performance of cyclone separators to meet these dual objectives.

The development of cyclone separators has seen several key milestones. Early designs were simple and relatively inefficient, but they laid the groundwork for more sophisticated models. The introduction of reverse-flow cyclones in the mid-20th century marked a significant improvement in separation efficiency. Subsequently, the advent of computational fluid dynamics (CFD) in the 1970s and 1980s revolutionized cyclone design, allowing for more precise modeling and optimization of flow patterns within the separator.

Recent technological advancements have focused on enhancing the cyclone's geometry, including modifications to the inlet, body, and cone sections. These improvements aim to reduce pressure drop while maintaining or increasing collection efficiency. Additionally, researchers have explored novel materials and surface treatments to minimize particle adhesion and improve overall performance.

The current research landscape in cyclone separator technology is characterized by a push towards more sustainable and energy-efficient designs. This includes the development of low-pressure drop cyclones, multi-cyclone systems, and hybrid separators that combine cyclonic action with other separation mechanisms. The integration of smart sensors and control systems is also emerging as a promising area, enabling real-time monitoring and adjustment of cyclone performance.

As industries worldwide strive to meet more stringent particulate emission standards while reducing energy consumption, the importance of cyclone separator research continues to grow. The ultimate goal is to develop next-generation cyclone separators that can achieve near-perfect particle removal with minimal energy input, thereby contributing to cleaner industrial processes and a more sustainable future.

The primary objective of cyclone separator technology is to achieve optimal particle collection efficiency while minimizing energy consumption. This balance is crucial for industrial applications where operational costs and environmental impact are significant concerns. Over the years, researchers and engineers have focused on improving the design and performance of cyclone separators to meet these dual objectives.

The development of cyclone separators has seen several key milestones. Early designs were simple and relatively inefficient, but they laid the groundwork for more sophisticated models. The introduction of reverse-flow cyclones in the mid-20th century marked a significant improvement in separation efficiency. Subsequently, the advent of computational fluid dynamics (CFD) in the 1970s and 1980s revolutionized cyclone design, allowing for more precise modeling and optimization of flow patterns within the separator.

Recent technological advancements have focused on enhancing the cyclone's geometry, including modifications to the inlet, body, and cone sections. These improvements aim to reduce pressure drop while maintaining or increasing collection efficiency. Additionally, researchers have explored novel materials and surface treatments to minimize particle adhesion and improve overall performance.

The current research landscape in cyclone separator technology is characterized by a push towards more sustainable and energy-efficient designs. This includes the development of low-pressure drop cyclones, multi-cyclone systems, and hybrid separators that combine cyclonic action with other separation mechanisms. The integration of smart sensors and control systems is also emerging as a promising area, enabling real-time monitoring and adjustment of cyclone performance.

As industries worldwide strive to meet more stringent particulate emission standards while reducing energy consumption, the importance of cyclone separator research continues to grow. The ultimate goal is to develop next-generation cyclone separators that can achieve near-perfect particle removal with minimal energy input, thereby contributing to cleaner industrial processes and a more sustainable future.

Market Analysis for Energy-Efficient Separators

The market for energy-efficient separators, particularly cyclone separators, has been experiencing significant growth due to increasing industrial demand and stringent environmental regulations. The global cyclone separator market is projected to expand at a steady rate, driven by the need for more efficient and cost-effective particle separation technologies across various industries.

Key industries driving the demand for energy-efficient cyclone separators include oil and gas, mining, chemical processing, and power generation. These sectors are increasingly focused on optimizing their processes to reduce energy consumption while maintaining or improving separation efficiency. The oil and gas industry, in particular, has been a major contributor to market growth, as cyclone separators play a crucial role in removing particulates from drilling fluids and production streams.

Environmental concerns and regulatory pressures have also been significant factors in shaping the market landscape. Governments worldwide are implementing stricter emission control standards, compelling industries to adopt more efficient separation technologies. This has led to a surge in demand for cyclone separators that can achieve high collection efficiencies while consuming less energy.

The market is witnessing a shift towards advanced cyclone separator designs that offer improved performance characteristics. Manufacturers are investing in research and development to create innovative solutions that address the trade-off between energy consumption and collection efficiency. This includes the development of high-efficiency cyclones, multi-cyclone systems, and hybrid separators that combine cyclone technology with other separation methods.

Geographically, Asia-Pacific has emerged as a key market for energy-efficient separators, driven by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure with more efficient technologies.

The competitive landscape of the energy-efficient separator market is characterized by the presence of both established players and innovative start-ups. Major companies are focusing on product differentiation and technological advancements to gain a competitive edge. Collaborations between industry players and research institutions are becoming more common, aiming to develop next-generation separation technologies.

As industries continue to prioritize energy efficiency and environmental sustainability, the market for energy-efficient separators is expected to witness sustained growth. The ongoing research on optimizing cyclone separator performance, particularly in balancing energy consumption with collection efficiency, will play a crucial role in shaping future market trends and technological advancements in this field.

Key industries driving the demand for energy-efficient cyclone separators include oil and gas, mining, chemical processing, and power generation. These sectors are increasingly focused on optimizing their processes to reduce energy consumption while maintaining or improving separation efficiency. The oil and gas industry, in particular, has been a major contributor to market growth, as cyclone separators play a crucial role in removing particulates from drilling fluids and production streams.

Environmental concerns and regulatory pressures have also been significant factors in shaping the market landscape. Governments worldwide are implementing stricter emission control standards, compelling industries to adopt more efficient separation technologies. This has led to a surge in demand for cyclone separators that can achieve high collection efficiencies while consuming less energy.

The market is witnessing a shift towards advanced cyclone separator designs that offer improved performance characteristics. Manufacturers are investing in research and development to create innovative solutions that address the trade-off between energy consumption and collection efficiency. This includes the development of high-efficiency cyclones, multi-cyclone systems, and hybrid separators that combine cyclone technology with other separation methods.

Geographically, Asia-Pacific has emerged as a key market for energy-efficient separators, driven by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure with more efficient technologies.

The competitive landscape of the energy-efficient separator market is characterized by the presence of both established players and innovative start-ups. Major companies are focusing on product differentiation and technological advancements to gain a competitive edge. Collaborations between industry players and research institutions are becoming more common, aiming to develop next-generation separation technologies.

As industries continue to prioritize energy efficiency and environmental sustainability, the market for energy-efficient separators is expected to witness sustained growth. The ongoing research on optimizing cyclone separator performance, particularly in balancing energy consumption with collection efficiency, will play a crucial role in shaping future market trends and technological advancements in this field.

Current Challenges in Cyclone Separator Design

Cyclone separators face several significant challenges in their design and operation, particularly when balancing energy consumption and collection efficiency. One of the primary issues is the trade-off between these two critical factors. As designers strive to improve collection efficiency, they often encounter increased pressure drop, which leads to higher energy consumption. This inverse relationship poses a considerable obstacle in optimizing cyclone performance.

The geometry of cyclone separators presents another challenge. The complex flow patterns within the cyclone, including the outer vortex and inner vortex, are highly sensitive to geometric parameters such as inlet dimensions, body diameter, and cone angle. Slight modifications in these parameters can significantly impact both collection efficiency and pressure drop. Engineers struggle to find the optimal configuration that maximizes efficiency while minimizing energy use across a wide range of operating conditions.

Particle size distribution in the inlet stream adds another layer of complexity to cyclone design. Cyclones are most effective for particles within a specific size range, typically above 5 microns. However, many industrial applications involve a broad spectrum of particle sizes. Designing a cyclone that maintains high collection efficiency across various particle sizes without excessive energy consumption remains a significant challenge.

The issue of re-entrainment further complicates cyclone separator design. As particles are separated and collect on the walls, there is a risk of them being re-entrained into the gas stream, reducing overall collection efficiency. This phenomenon is particularly problematic at high gas velocities, which are often necessary for effective separation but also contribute to increased energy consumption.

Material properties of both the particles and the cyclone walls play a crucial role in separator performance. Sticky or cohesive particles can adhere to cyclone walls, altering the internal geometry and flow patterns over time. Conversely, abrasive particles can cause wear, changing the cyclone's dimensions and efficiency. Designing cyclones that maintain consistent performance under these varying material conditions while keeping energy consumption in check is an ongoing challenge.

Scaling up cyclone separators for industrial applications presents its own set of difficulties. The performance characteristics observed in small-scale or laboratory cyclones do not always translate directly to larger units. This scaling issue makes it challenging to predict and optimize the energy consumption and collection efficiency of industrial-scale cyclones based on smaller prototypes.

The geometry of cyclone separators presents another challenge. The complex flow patterns within the cyclone, including the outer vortex and inner vortex, are highly sensitive to geometric parameters such as inlet dimensions, body diameter, and cone angle. Slight modifications in these parameters can significantly impact both collection efficiency and pressure drop. Engineers struggle to find the optimal configuration that maximizes efficiency while minimizing energy use across a wide range of operating conditions.

Particle size distribution in the inlet stream adds another layer of complexity to cyclone design. Cyclones are most effective for particles within a specific size range, typically above 5 microns. However, many industrial applications involve a broad spectrum of particle sizes. Designing a cyclone that maintains high collection efficiency across various particle sizes without excessive energy consumption remains a significant challenge.

The issue of re-entrainment further complicates cyclone separator design. As particles are separated and collect on the walls, there is a risk of them being re-entrained into the gas stream, reducing overall collection efficiency. This phenomenon is particularly problematic at high gas velocities, which are often necessary for effective separation but also contribute to increased energy consumption.

Material properties of both the particles and the cyclone walls play a crucial role in separator performance. Sticky or cohesive particles can adhere to cyclone walls, altering the internal geometry and flow patterns over time. Conversely, abrasive particles can cause wear, changing the cyclone's dimensions and efficiency. Designing cyclones that maintain consistent performance under these varying material conditions while keeping energy consumption in check is an ongoing challenge.

Scaling up cyclone separators for industrial applications presents its own set of difficulties. The performance characteristics observed in small-scale or laboratory cyclones do not always translate directly to larger units. This scaling issue makes it challenging to predict and optimize the energy consumption and collection efficiency of industrial-scale cyclones based on smaller prototypes.

Existing Energy-Efficiency Solutions

01 Optimization of cyclone separator design

Improving the design of cyclone separators can enhance energy efficiency and collection performance. This includes optimizing the geometry, such as the inlet shape, cone angle, and body dimensions, to reduce pressure drop and increase particle separation efficiency. Advanced computational fluid dynamics (CFD) simulations can be used to analyze and refine the design for optimal performance.- Optimization of cyclone separator design: Improving the design of cyclone separators can enhance their energy efficiency and collection performance. This includes optimizing the geometry, such as the inlet shape, cone angle, and body dimensions, to reduce pressure drop and increase particle separation efficiency. Advanced computational fluid dynamics (CFD) simulations can be used to analyze and refine the design for optimal performance.

- Energy-efficient control systems: Implementing intelligent control systems can significantly reduce energy consumption in cyclone separators. These systems can adjust operating parameters such as inlet velocity and pressure based on real-time monitoring of particle load and separation efficiency. Machine learning algorithms can be employed to optimize the control strategy over time, further improving energy efficiency.

- Advanced particle collection mechanisms: Incorporating innovative particle collection mechanisms can enhance the efficiency of cyclone separators. This may include electrostatic precipitation, acoustic agglomeration, or multi-stage separation techniques. These advanced methods can improve the capture of fine particles while maintaining low energy consumption, leading to higher overall collection efficiency.

- Integration with other separation technologies: Combining cyclone separators with other separation technologies can optimize both energy consumption and collection efficiency. For example, integrating cyclones with bag filters or scrubbers can create a hybrid system that leverages the strengths of each technology. This approach can lead to improved overall performance, especially for challenging particle size distributions.

- Monitoring and predictive maintenance: Implementing advanced monitoring systems and predictive maintenance strategies can help maintain optimal performance of cyclone separators over time. Sensors can be used to track key performance indicators, while data analytics and machine learning algorithms can predict maintenance needs. This proactive approach can prevent efficiency losses due to wear and tear, ensuring consistent energy consumption and collection efficiency.

02 Energy-efficient control systems

Implementing intelligent control systems can significantly reduce energy consumption in cyclone separators. These systems can adjust operating parameters such as inlet velocity and flow rate based on real-time monitoring of particle load and separation efficiency. Machine learning algorithms can be employed to optimize the control strategy over time, further improving energy efficiency.Expand Specific Solutions03 Advanced particle collection mechanisms

Incorporating innovative particle collection mechanisms can enhance the efficiency of cyclone separators. This may include electrostatic precipitation, acoustic agglomeration, or hybrid systems that combine multiple separation techniques. These advanced mechanisms can improve the collection of fine particles while maintaining low energy consumption.Expand Specific Solutions04 Low-friction materials and coatings

Utilizing low-friction materials or applying specialized coatings to the internal surfaces of cyclone separators can reduce energy losses due to friction. This approach can decrease the overall energy consumption while maintaining or even improving particle collection efficiency. Nano-engineered surfaces and self-cleaning coatings are among the innovative solutions in this area.Expand Specific Solutions05 Multi-stage separation systems

Developing multi-stage cyclone separation systems can optimize both energy consumption and collection efficiency. By strategically arranging multiple cyclones in series or parallel configurations, different particle size ranges can be targeted more effectively. This approach allows for lower pressure drops in individual stages while achieving high overall separation efficiency.Expand Specific Solutions

Key Players in Cyclone Separator Industry

The research on cyclone separator energy consumption versus collection efficiency is in a mature stage, with a competitive landscape shaped by established industry players and academic institutions. The market for cyclone separators is substantial, driven by applications in various industries including oil and gas, manufacturing, and environmental protection. Key players like Dyson Technology, Donaldson Filtration, and Mitsubishi Electric are at the forefront of innovation, focusing on improving energy efficiency and separation performance. Academic institutions such as China Petroleum University Beijing and Southeast University contribute significantly to fundamental research. The technology's maturity is evident in the diverse range of companies involved, from specialized firms like Cyclotech to conglomerates like Panasonic, indicating widespread adoption and ongoing refinement of cyclone separator technology.

Dyson Technology Ltd.

Technical Solution: Dyson has developed advanced cyclone separator technology for their vacuum cleaners and air purifiers. Their patented Root Cyclone™ technology uses centrifugal forces up to 150,000G to separate microscopic particles from the airflow[1]. The company has optimized the cyclone geometry and airflow paths to maximize dust separation while minimizing energy consumption. Dyson's latest cyclone designs incorporate multiple tiers of cyclones working in sequence, with each tier optimized to remove progressively smaller particles[2]. This multi-stage approach allows for high efficiency particle removal across a wide size range while maintaining strong suction power.

Strengths: Highly efficient particle separation, strong brand recognition in consumer appliances. Weaknesses: Technology primarily focused on small-scale applications, may not scale well to industrial processes.

Donaldson Filtration Deutschland GmbH

Technical Solution: Donaldson has developed a range of cyclone separators for industrial applications, focusing on optimizing the balance between energy consumption and collection efficiency. Their PowerCore CycloPleat technology combines cyclonic pre-separation with pleated filter elements to achieve high efficiency with lower pressure drop[3]. The company utilizes computational fluid dynamics (CFD) simulations to optimize cyclone geometry for specific applications, allowing for tailored solutions that maximize separation efficiency while minimizing energy use. Donaldson's cyclones often incorporate tangential inlet designs and optimized vortex finder configurations to enhance particle separation without excessive pressure loss[4].

Strengths: Wide range of industrial applications, customizable solutions. Weaknesses: May require higher initial investment compared to simpler cyclone designs.

Core Innovations in Separator Design

Cyclone separator

PatentWO1987002275A1

Innovation

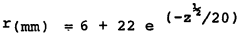

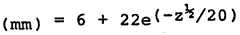

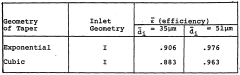

- The design incorporates an elongated separating chamber with a tangentially directed feed inlet and a profile that is either generally exponential or cubic in form, minimizing shear planes and stagnation flows by gradually changing the chamber's cross-sectional dimensions, thereby enhancing phase separation and reducing energy consumption.

Environmental Impact Assessment

Cyclone separators, widely used in industrial processes for particle separation, have significant environmental implications that warrant careful consideration. The environmental impact of cyclone separators is closely tied to their energy consumption and collection efficiency, two key factors that influence their overall performance and sustainability.

The energy consumption of cyclone separators directly affects their carbon footprint and contributes to greenhouse gas emissions. Higher energy requirements lead to increased electricity consumption, which, depending on the energy source, can result in greater CO2 emissions. Consequently, optimizing the energy efficiency of cyclone separators is crucial for minimizing their environmental impact. Research into low-energy cyclone designs and operational strategies can potentially reduce the overall energy demand and associated emissions.

Collection efficiency, on the other hand, plays a vital role in determining the environmental impact of cyclone separators. Higher collection efficiency means fewer particulate emissions are released into the atmosphere, reducing air pollution and potential health hazards. Improved collection efficiency also leads to better resource recovery, as more valuable materials can be captured and recycled rather than being lost to the environment. This aspect is particularly important in industries dealing with hazardous or toxic materials, where even small emissions can have significant environmental consequences.

The trade-off between energy consumption and collection efficiency presents a complex environmental challenge. While increasing collection efficiency often requires higher energy input, the environmental benefits of improved particle capture may outweigh the additional energy costs. This balance varies depending on the specific application, particle characteristics, and local environmental regulations. Therefore, a comprehensive life cycle assessment is essential to fully understand the environmental implications of different cyclone separator configurations.

Water usage is another environmental factor to consider in cyclone separator operations. Some designs incorporate water sprays to enhance particle collection, which can lead to increased water consumption and potential wastewater treatment requirements. The environmental impact of water usage and treatment should be weighed against the benefits of improved collection efficiency.

Noise pollution is an often-overlooked environmental aspect of cyclone separators. The high-speed rotation and turbulent flow within these devices can generate significant noise levels, potentially affecting both workers and surrounding communities. Addressing noise pollution through design improvements or sound insulation measures is important for minimizing the overall environmental impact.

In conclusion, the environmental impact assessment of cyclone separators must consider the intricate relationship between energy consumption and collection efficiency, as well as other factors such as water usage and noise pollution. Ongoing research and development efforts aimed at optimizing these parameters are crucial for enhancing the environmental sustainability of cyclone separator technology across various industrial applications.

The energy consumption of cyclone separators directly affects their carbon footprint and contributes to greenhouse gas emissions. Higher energy requirements lead to increased electricity consumption, which, depending on the energy source, can result in greater CO2 emissions. Consequently, optimizing the energy efficiency of cyclone separators is crucial for minimizing their environmental impact. Research into low-energy cyclone designs and operational strategies can potentially reduce the overall energy demand and associated emissions.

Collection efficiency, on the other hand, plays a vital role in determining the environmental impact of cyclone separators. Higher collection efficiency means fewer particulate emissions are released into the atmosphere, reducing air pollution and potential health hazards. Improved collection efficiency also leads to better resource recovery, as more valuable materials can be captured and recycled rather than being lost to the environment. This aspect is particularly important in industries dealing with hazardous or toxic materials, where even small emissions can have significant environmental consequences.

The trade-off between energy consumption and collection efficiency presents a complex environmental challenge. While increasing collection efficiency often requires higher energy input, the environmental benefits of improved particle capture may outweigh the additional energy costs. This balance varies depending on the specific application, particle characteristics, and local environmental regulations. Therefore, a comprehensive life cycle assessment is essential to fully understand the environmental implications of different cyclone separator configurations.

Water usage is another environmental factor to consider in cyclone separator operations. Some designs incorporate water sprays to enhance particle collection, which can lead to increased water consumption and potential wastewater treatment requirements. The environmental impact of water usage and treatment should be weighed against the benefits of improved collection efficiency.

Noise pollution is an often-overlooked environmental aspect of cyclone separators. The high-speed rotation and turbulent flow within these devices can generate significant noise levels, potentially affecting both workers and surrounding communities. Addressing noise pollution through design improvements or sound insulation measures is important for minimizing the overall environmental impact.

In conclusion, the environmental impact assessment of cyclone separators must consider the intricate relationship between energy consumption and collection efficiency, as well as other factors such as water usage and noise pollution. Ongoing research and development efforts aimed at optimizing these parameters are crucial for enhancing the environmental sustainability of cyclone separator technology across various industrial applications.

Cost-Benefit Analysis of Improvements

The cost-benefit analysis of improvements in cyclone separator technology is crucial for evaluating the economic viability of enhancing energy efficiency and collection performance. This analysis involves a comprehensive assessment of the financial implications associated with implementing various technological advancements and operational modifications.

One of the primary considerations in this analysis is the initial investment required for upgrading existing cyclone separators or installing new, more efficient models. This upfront cost includes equipment procurement, installation, and potential downtime during the upgrade process. However, these costs must be weighed against the long-term benefits of improved energy consumption and collection efficiency.

Energy savings represent a significant potential benefit of cyclone separator improvements. By optimizing the design and operation of cyclone separators, industries can substantially reduce their energy consumption. This reduction translates directly into lower operational costs, particularly in energy-intensive industries where cyclone separators are widely used. The cumulative energy savings over the lifespan of the improved separator can often offset the initial investment costs.

Enhanced collection efficiency also contributes to the cost-benefit equation. Improved particle separation leads to reduced product loss, which is especially valuable in industries dealing with high-value materials. Additionally, better collection efficiency can result in decreased downstream processing costs and improved product quality, further enhancing the economic benefits.

Maintenance and operational costs are another critical factor in the analysis. While more advanced cyclone separators may have higher initial costs, they often require less frequent maintenance and have longer operational lifespans. This reduction in maintenance frequency and associated downtime can lead to significant cost savings over time.

Environmental compliance is an increasingly important consideration. Improved cyclone separators can help industries meet stricter environmental regulations without incurring hefty fines or requiring additional pollution control equipment. This compliance benefit can translate into avoided costs and improved corporate image.

The payback period for cyclone separator improvements varies depending on the specific industry and application. In some cases, the energy savings and efficiency gains can result in a relatively short payback period, making the investment highly attractive. However, in other scenarios, the benefits may accrue more gradually, requiring a longer-term perspective on the return on investment.

It's also important to consider the scalability of improvements. The cost-benefit ratio may change significantly when implementing improvements across multiple units or entire production lines. Economies of scale can often make large-scale upgrades more economically viable than isolated improvements.

One of the primary considerations in this analysis is the initial investment required for upgrading existing cyclone separators or installing new, more efficient models. This upfront cost includes equipment procurement, installation, and potential downtime during the upgrade process. However, these costs must be weighed against the long-term benefits of improved energy consumption and collection efficiency.

Energy savings represent a significant potential benefit of cyclone separator improvements. By optimizing the design and operation of cyclone separators, industries can substantially reduce their energy consumption. This reduction translates directly into lower operational costs, particularly in energy-intensive industries where cyclone separators are widely used. The cumulative energy savings over the lifespan of the improved separator can often offset the initial investment costs.

Enhanced collection efficiency also contributes to the cost-benefit equation. Improved particle separation leads to reduced product loss, which is especially valuable in industries dealing with high-value materials. Additionally, better collection efficiency can result in decreased downstream processing costs and improved product quality, further enhancing the economic benefits.

Maintenance and operational costs are another critical factor in the analysis. While more advanced cyclone separators may have higher initial costs, they often require less frequent maintenance and have longer operational lifespans. This reduction in maintenance frequency and associated downtime can lead to significant cost savings over time.

Environmental compliance is an increasingly important consideration. Improved cyclone separators can help industries meet stricter environmental regulations without incurring hefty fines or requiring additional pollution control equipment. This compliance benefit can translate into avoided costs and improved corporate image.

The payback period for cyclone separator improvements varies depending on the specific industry and application. In some cases, the energy savings and efficiency gains can result in a relatively short payback period, making the investment highly attractive. However, in other scenarios, the benefits may accrue more gradually, requiring a longer-term perspective on the return on investment.

It's also important to consider the scalability of improvements. The cost-benefit ratio may change significantly when implementing improvements across multiple units or entire production lines. Economies of scale can often make large-scale upgrades more economically viable than isolated improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!