Cyclone Separator Maintenance KPI: Inspection And Replacement Intervals

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator KPI Background and Objectives

Cyclone separators have been a cornerstone in industrial processes for over a century, playing a crucial role in separating particles from gas streams. The technology's evolution has been driven by the increasing demand for more efficient and environmentally friendly separation methods across various industries, including oil and gas, chemical processing, and power generation.

The primary objective of this research is to establish optimal Key Performance Indicators (KPIs) for cyclone separator maintenance, specifically focusing on inspection and replacement intervals. This goal is rooted in the critical need to balance operational efficiency with cost-effectiveness in industrial settings. By determining precise maintenance schedules, companies can minimize downtime, reduce operational costs, and extend the lifespan of their equipment.

The development of cyclone separator technology has seen significant advancements in design and materials, leading to improved separation efficiency and durability. However, these improvements have also introduced new challenges in maintenance and performance monitoring. As cyclone separators operate in harsh environments with high-velocity particle-laden flows, they are subject to wear and degradation over time, which can compromise their efficiency and reliability.

Current industry practices often rely on conservative, time-based maintenance schedules that may not accurately reflect the actual condition of the equipment. This approach can lead to unnecessary maintenance activities and associated costs, or conversely, unexpected failures due to inadequate maintenance. The need for more precise, condition-based maintenance strategies has become increasingly apparent, driving the focus on developing robust KPIs for inspection and replacement intervals.

The technological trend in this field is moving towards the integration of smart sensors and data analytics to enable real-time monitoring of cyclone separator performance. This shift aligns with the broader Industry 4.0 movement, which emphasizes the use of data-driven decision-making in industrial processes. By leveraging these technologies, it becomes possible to develop more accurate and dynamic maintenance schedules based on actual equipment condition and performance metrics.

The research aims to identify key parameters that indicate cyclone separator wear and efficiency loss, such as pressure drop, separation efficiency, and particle size distribution. By correlating these parameters with operational conditions and historical maintenance data, the study seeks to develop predictive models that can accurately forecast optimal inspection and replacement intervals. This approach promises to optimize maintenance activities, reduce operational costs, and enhance overall system reliability.

Furthermore, the research will explore the potential of emerging technologies, such as machine learning algorithms and digital twin simulations, to refine KPI predictions and maintenance strategies. These advanced tools offer the possibility of creating more sophisticated models that can adapt to changing operational conditions and provide increasingly accurate maintenance recommendations over time.

The primary objective of this research is to establish optimal Key Performance Indicators (KPIs) for cyclone separator maintenance, specifically focusing on inspection and replacement intervals. This goal is rooted in the critical need to balance operational efficiency with cost-effectiveness in industrial settings. By determining precise maintenance schedules, companies can minimize downtime, reduce operational costs, and extend the lifespan of their equipment.

The development of cyclone separator technology has seen significant advancements in design and materials, leading to improved separation efficiency and durability. However, these improvements have also introduced new challenges in maintenance and performance monitoring. As cyclone separators operate in harsh environments with high-velocity particle-laden flows, they are subject to wear and degradation over time, which can compromise their efficiency and reliability.

Current industry practices often rely on conservative, time-based maintenance schedules that may not accurately reflect the actual condition of the equipment. This approach can lead to unnecessary maintenance activities and associated costs, or conversely, unexpected failures due to inadequate maintenance. The need for more precise, condition-based maintenance strategies has become increasingly apparent, driving the focus on developing robust KPIs for inspection and replacement intervals.

The technological trend in this field is moving towards the integration of smart sensors and data analytics to enable real-time monitoring of cyclone separator performance. This shift aligns with the broader Industry 4.0 movement, which emphasizes the use of data-driven decision-making in industrial processes. By leveraging these technologies, it becomes possible to develop more accurate and dynamic maintenance schedules based on actual equipment condition and performance metrics.

The research aims to identify key parameters that indicate cyclone separator wear and efficiency loss, such as pressure drop, separation efficiency, and particle size distribution. By correlating these parameters with operational conditions and historical maintenance data, the study seeks to develop predictive models that can accurately forecast optimal inspection and replacement intervals. This approach promises to optimize maintenance activities, reduce operational costs, and enhance overall system reliability.

Furthermore, the research will explore the potential of emerging technologies, such as machine learning algorithms and digital twin simulations, to refine KPI predictions and maintenance strategies. These advanced tools offer the possibility of creating more sophisticated models that can adapt to changing operational conditions and provide increasingly accurate maintenance recommendations over time.

Market Demand Analysis for Efficient Maintenance

The market demand for efficient maintenance of cyclone separators has been steadily increasing due to the critical role these devices play in various industries. Cyclone separators are widely used in power plants, cement factories, chemical processing facilities, and other industrial settings for separating particulates from gas or liquid streams. As these industries face growing pressure to optimize operations and reduce downtime, the need for effective maintenance strategies has become paramount.

Recent market research indicates that the global industrial cyclone separator market is expected to grow significantly in the coming years. This growth is driven by factors such as increasing industrialization, stringent environmental regulations, and the need for improved air quality in manufacturing processes. As a result, there is a growing demand for maintenance solutions that can extend the lifespan of cyclone separators and ensure their optimal performance.

The market for cyclone separator maintenance is characterized by a strong focus on predictive and preventive maintenance approaches. Companies are increasingly seeking solutions that can help them anticipate potential issues before they lead to costly breakdowns or reduced efficiency. This has led to a rise in demand for advanced monitoring systems, data analytics tools, and expert maintenance services.

One of the key drivers of market demand is the potential for cost savings through efficient maintenance practices. Properly maintained cyclone separators can significantly reduce energy consumption, minimize product loss, and extend equipment life. Industries are recognizing that investing in regular inspections and timely replacements can lead to substantial long-term savings and improved operational efficiency.

Environmental regulations are also playing a crucial role in shaping market demand. As governments worldwide implement stricter emissions standards, industries are under pressure to ensure their cyclone separators are operating at peak efficiency. This has led to increased interest in maintenance solutions that can help companies comply with regulations while minimizing environmental impact.

The market is also seeing a growing demand for customized maintenance solutions. Different industries and applications have unique requirements for cyclone separator performance, and maintenance providers are increasingly offering tailored services to meet these specific needs. This trend is driving innovation in maintenance techniques and technologies, as providers seek to differentiate themselves in a competitive market.

In conclusion, the market demand for efficient maintenance of cyclone separators is robust and growing. Industries are recognizing the importance of regular inspections and timely replacements in ensuring operational efficiency, cost savings, and regulatory compliance. As the global industrial landscape continues to evolve, the demand for advanced maintenance solutions is expected to remain strong, presenting significant opportunities for service providers and technology developers in this space.

Recent market research indicates that the global industrial cyclone separator market is expected to grow significantly in the coming years. This growth is driven by factors such as increasing industrialization, stringent environmental regulations, and the need for improved air quality in manufacturing processes. As a result, there is a growing demand for maintenance solutions that can extend the lifespan of cyclone separators and ensure their optimal performance.

The market for cyclone separator maintenance is characterized by a strong focus on predictive and preventive maintenance approaches. Companies are increasingly seeking solutions that can help them anticipate potential issues before they lead to costly breakdowns or reduced efficiency. This has led to a rise in demand for advanced monitoring systems, data analytics tools, and expert maintenance services.

One of the key drivers of market demand is the potential for cost savings through efficient maintenance practices. Properly maintained cyclone separators can significantly reduce energy consumption, minimize product loss, and extend equipment life. Industries are recognizing that investing in regular inspections and timely replacements can lead to substantial long-term savings and improved operational efficiency.

Environmental regulations are also playing a crucial role in shaping market demand. As governments worldwide implement stricter emissions standards, industries are under pressure to ensure their cyclone separators are operating at peak efficiency. This has led to increased interest in maintenance solutions that can help companies comply with regulations while minimizing environmental impact.

The market is also seeing a growing demand for customized maintenance solutions. Different industries and applications have unique requirements for cyclone separator performance, and maintenance providers are increasingly offering tailored services to meet these specific needs. This trend is driving innovation in maintenance techniques and technologies, as providers seek to differentiate themselves in a competitive market.

In conclusion, the market demand for efficient maintenance of cyclone separators is robust and growing. Industries are recognizing the importance of regular inspections and timely replacements in ensuring operational efficiency, cost savings, and regulatory compliance. As the global industrial landscape continues to evolve, the demand for advanced maintenance solutions is expected to remain strong, presenting significant opportunities for service providers and technology developers in this space.

Current Challenges in Cyclone Separator Maintenance

Cyclone separators, despite their widespread use and relatively simple design, face several maintenance challenges that impact their performance and longevity. One of the primary issues is the wear and tear caused by the abrasive particles in the gas stream. The high-velocity cyclonic motion of these particles leads to erosion of the separator's internal surfaces, particularly in areas of high impact such as the inlet and the cone section. This erosion not only reduces the efficiency of separation but also shortens the lifespan of the equipment.

Another significant challenge is the buildup of particulate matter on the internal surfaces of the separator. This accumulation can alter the flow patterns within the cyclone, reducing its separation efficiency and increasing pressure drop. In severe cases, it can lead to blockages that require unscheduled shutdowns for cleaning, resulting in production losses and increased maintenance costs.

The determination of optimal inspection and replacement intervals presents a complex challenge. Overly frequent inspections and replacements lead to unnecessary downtime and expenses, while insufficient maintenance can result in sudden failures and costly emergency repairs. The variability in operating conditions across different industries and even within the same facility further complicates the establishment of standardized maintenance schedules.

Corrosion is another critical issue, especially in environments where the gas stream contains corrosive elements. This can lead to material degradation, compromising the structural integrity of the separator and potentially causing leaks or failures. The selection of appropriate materials that balance corrosion resistance with cost-effectiveness is an ongoing challenge for maintenance engineers.

The detection of internal wear and damage without frequent disassembly is a persistent problem. Non-invasive inspection techniques are limited in their ability to accurately assess the condition of internal components, making it difficult to predict when maintenance or replacement is necessary. This uncertainty can lead to either premature replacements or unexpected failures.

Lastly, the optimization of maintenance procedures to minimize downtime while ensuring thorough inspection and repair is a constant challenge. Balancing the need for comprehensive maintenance with the pressure to maintain operational continuity requires careful planning and execution. The development of quick-change components and modular designs that facilitate rapid maintenance is an area of ongoing research and development in cyclone separator technology.

Another significant challenge is the buildup of particulate matter on the internal surfaces of the separator. This accumulation can alter the flow patterns within the cyclone, reducing its separation efficiency and increasing pressure drop. In severe cases, it can lead to blockages that require unscheduled shutdowns for cleaning, resulting in production losses and increased maintenance costs.

The determination of optimal inspection and replacement intervals presents a complex challenge. Overly frequent inspections and replacements lead to unnecessary downtime and expenses, while insufficient maintenance can result in sudden failures and costly emergency repairs. The variability in operating conditions across different industries and even within the same facility further complicates the establishment of standardized maintenance schedules.

Corrosion is another critical issue, especially in environments where the gas stream contains corrosive elements. This can lead to material degradation, compromising the structural integrity of the separator and potentially causing leaks or failures. The selection of appropriate materials that balance corrosion resistance with cost-effectiveness is an ongoing challenge for maintenance engineers.

The detection of internal wear and damage without frequent disassembly is a persistent problem. Non-invasive inspection techniques are limited in their ability to accurately assess the condition of internal components, making it difficult to predict when maintenance or replacement is necessary. This uncertainty can lead to either premature replacements or unexpected failures.

Lastly, the optimization of maintenance procedures to minimize downtime while ensuring thorough inspection and repair is a constant challenge. Balancing the need for comprehensive maintenance with the pressure to maintain operational continuity requires careful planning and execution. The development of quick-change components and modular designs that facilitate rapid maintenance is an area of ongoing research and development in cyclone separator technology.

Existing Maintenance Strategies and Methodologies

01 Regular inspection intervals for cyclone separators

Cyclone separators require regular inspections to ensure optimal performance and prevent unexpected failures. These inspections typically involve checking for wear, erosion, and buildup of materials. The frequency of inspections may vary depending on the operating conditions and the type of material being processed.- Regular inspection intervals: Cyclone separators require regular inspections to maintain optimal performance. These inspections should be scheduled based on operating conditions, with more frequent checks for high-stress environments. Inspections typically involve examining the cyclone body, inlet, outlet, and collection hopper for wear, damage, or buildup that could affect efficiency.

- Wear monitoring and predictive maintenance: Implementing wear monitoring systems and predictive maintenance techniques can help determine optimal replacement intervals. These systems may use sensors to detect changes in pressure drop, separation efficiency, or wall thickness. By analyzing this data, operators can predict when components are likely to need replacement before failure occurs.

- Component-specific replacement schedules: Different components of a cyclone separator may have varying lifespans and replacement needs. For example, the vortex finder and cone section often experience more wear than other parts. Establishing component-specific replacement schedules based on historical data and manufacturer recommendations can optimize maintenance efforts and reduce downtime.

- Material selection for extended lifespan: Choosing appropriate materials for cyclone separator components can significantly impact their lifespan and replacement intervals. Wear-resistant materials such as ceramic linings or hardened steel alloys can be used in high-wear areas to extend the time between replacements. The selection should consider factors like the abrasiveness of the particles being separated and operating conditions.

- Online monitoring and automated inspection systems: Advanced cyclone separators may incorporate online monitoring and automated inspection systems. These can include acoustic sensors, vibration analysis, or imaging technologies to continuously assess the separator's condition. Such systems can provide real-time data on wear patterns, allowing for more accurate determination of inspection and replacement intervals.

02 Replacement criteria for cyclone separator components

Specific criteria are used to determine when components of a cyclone separator need replacement. These may include measurable wear thresholds, changes in separation efficiency, or visible damage to critical parts. Regular monitoring and documentation of these criteria help in planning timely replacements.Expand Specific Solutions03 Predictive maintenance techniques for cyclone separators

Advanced predictive maintenance techniques are employed to optimize inspection and replacement intervals. These may include sensor-based monitoring, data analytics, and machine learning algorithms to predict component wear and potential failures before they occur, allowing for more efficient maintenance scheduling.Expand Specific Solutions04 Impact of operating conditions on maintenance intervals

The operating conditions of the cyclone separator, such as the type and abrasiveness of the processed material, flow rates, and temperature, significantly influence the required inspection and replacement intervals. Harsh conditions may necessitate more frequent inspections and shorter component lifespans.Expand Specific Solutions05 Innovative designs for extended component lifespan

New cyclone separator designs incorporate features to extend the lifespan of critical components. These innovations may include wear-resistant materials, self-cleaning mechanisms, or modular designs that facilitate easier inspections and replacements, potentially increasing the intervals between maintenance activities.Expand Specific Solutions

Key Players in Cyclone Separator Industry

The cyclone separator maintenance KPI research field is in a mature stage, with established players and technologies. The market size is substantial, driven by the widespread use of cyclone separators across industries. Technologically, the field is well-developed, with companies like Dyson Technology Ltd., MANN+HUMMEL GmbH, and China Petroleum & Chemical Corp. leading innovations. These firms have extensive experience in filtration and separation technologies, continuously improving inspection and replacement interval methodologies. The competitive landscape is characterized by a mix of specialized equipment manufacturers and large industrial conglomerates, each contributing to advancements in maintenance practices and efficiency optimization for cyclone separators.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL GmbH has developed the Intelligent Cyclone Monitoring and Maintenance System (ICMMS) for various industrial applications. The ICMMS combines advanced filtration expertise with digital technologies to optimize cyclone separator performance and maintenance. The system utilizes a network of sensors to monitor key performance indicators such as pressure differential, flow rate, and separation efficiency. MANN+HUMMEL's proprietary algorithms analyze this data to predict wear patterns and optimal cleaning or replacement intervals[10]. The ICMMS also incorporates a self-learning component that continuously refines its predictive models based on historical performance data. This approach has been reported to reduce maintenance costs by up to 40% and improve overall cyclone efficiency by 10-15% in industrial trials[11].

Strengths: Combines filtration expertise with advanced digital technologies, self-learning capability for continuous improvement. Weaknesses: May require extensive historical data for optimal performance, potential challenges in retrofitting existing systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced cyclone separator maintenance strategies for their refining operations. They utilize predictive maintenance techniques, incorporating real-time monitoring systems and data analytics to optimize inspection and replacement intervals. Their approach includes the use of acoustic sensors to detect changes in cyclone performance, allowing for early identification of wear and potential failures[1]. Sinopec has also implemented a risk-based inspection (RBI) methodology, which considers factors such as operating conditions, material properties, and historical performance data to determine optimal inspection frequencies[2]. This approach has reportedly reduced unplanned downtime by up to 25% in some of their refineries[3].

Strengths: Comprehensive data-driven approach, integration with existing refinery operations, and proven reduction in downtime. Weaknesses: High initial implementation costs and potential complexity in data interpretation for less experienced personnel.

Innovative KPI Approaches for Inspection Intervals

Cyclone separator

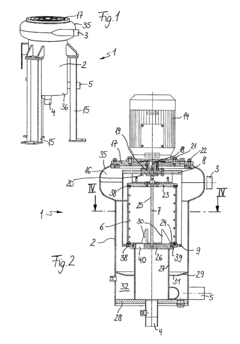

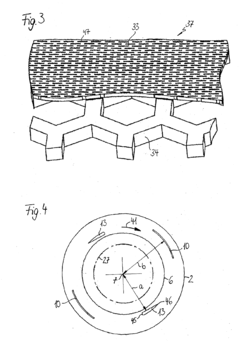

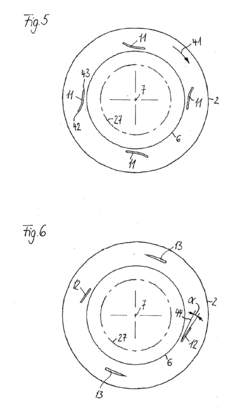

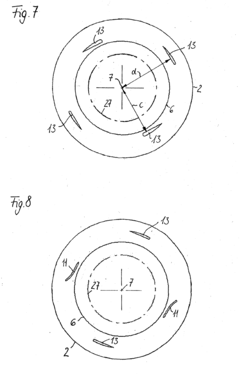

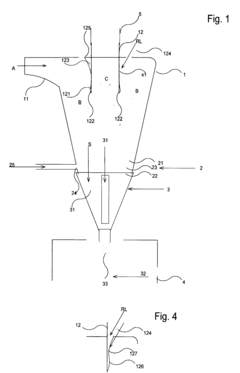

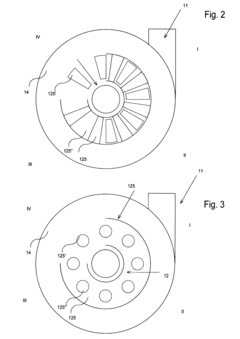

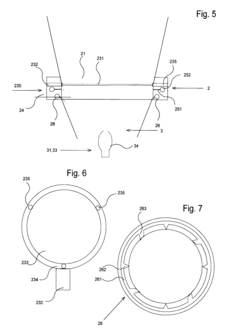

PatentInactiveEP1424134A2

Innovation

- The cyclone separator design incorporates at least two connecting struts between upper and lower retaining rings, which serve as flow guide surfaces, enhancing the nozzle effect for effective cleaning while reducing rotational speed and mechanical stress. This design includes an even number of symmetrically arranged connecting struts, support profiles, and flow guide surfaces like paddles or metal sheets, along with an outlet valve for controlled discharge of separated substances, and an automatic control unit for adjusting motor speed based on differential pressure.

Cyclone separator

PatentInactiveEP0979679A2

Innovation

- The cyclone separator design includes an aerodynamically profiled dip tube with a drip edge and intermittent cleaning air supply to minimize deposition, combined with a screening system to maintain particle size uniformity and reduce mechanical stress through self-cleaning mechanisms.

Environmental Impact of Cyclone Separator Maintenance

The environmental impact of cyclone separator maintenance is a critical aspect that requires careful consideration in industrial operations. Regular maintenance of cyclone separators not only ensures optimal performance but also contributes significantly to environmental protection efforts.

Proper maintenance of cyclone separators helps minimize particulate emissions, which is crucial for air quality management. When these devices are not maintained adequately, their efficiency in capturing and removing particles from gas streams decreases, leading to increased air pollution. This can have detrimental effects on local air quality, potentially impacting both human health and surrounding ecosystems.

Furthermore, well-maintained cyclone separators consume less energy, contributing to overall energy efficiency and reduced carbon footprint. Regular inspections and timely replacements of worn components ensure that the separator operates at peak efficiency, minimizing the energy required for particle separation processes.

The disposal of waste materials generated during maintenance activities also has environmental implications. Proper handling and disposal of replaced parts, cleaning agents, and collected particulates are essential to prevent soil and water contamination. Implementing environmentally friendly cleaning methods and using biodegradable cleaning agents can further reduce the ecological impact of maintenance procedures.

Maintenance practices can also influence the lifespan of cyclone separators. By extending the operational life of these devices through proper care, industries can reduce the frequency of replacements, thereby conserving resources and minimizing waste generation associated with manufacturing and disposing of entire units.

Water usage in cleaning processes during maintenance is another environmental concern. Adopting water-efficient cleaning techniques and implementing water recycling systems can significantly reduce the environmental footprint of maintenance activities.

The choice of replacement parts and materials used in maintenance can also impact sustainability. Opting for durable, recyclable, or eco-friendly materials can contribute to reducing the overall environmental impact of cyclone separator maintenance over time.

Lastly, the timing and frequency of maintenance activities play a role in environmental impact. Optimizing inspection and replacement intervals based on performance data and predictive maintenance techniques can help balance the need for efficient operation with minimizing unnecessary maintenance-related environmental disturbances.

Proper maintenance of cyclone separators helps minimize particulate emissions, which is crucial for air quality management. When these devices are not maintained adequately, their efficiency in capturing and removing particles from gas streams decreases, leading to increased air pollution. This can have detrimental effects on local air quality, potentially impacting both human health and surrounding ecosystems.

Furthermore, well-maintained cyclone separators consume less energy, contributing to overall energy efficiency and reduced carbon footprint. Regular inspections and timely replacements of worn components ensure that the separator operates at peak efficiency, minimizing the energy required for particle separation processes.

The disposal of waste materials generated during maintenance activities also has environmental implications. Proper handling and disposal of replaced parts, cleaning agents, and collected particulates are essential to prevent soil and water contamination. Implementing environmentally friendly cleaning methods and using biodegradable cleaning agents can further reduce the ecological impact of maintenance procedures.

Maintenance practices can also influence the lifespan of cyclone separators. By extending the operational life of these devices through proper care, industries can reduce the frequency of replacements, thereby conserving resources and minimizing waste generation associated with manufacturing and disposing of entire units.

Water usage in cleaning processes during maintenance is another environmental concern. Adopting water-efficient cleaning techniques and implementing water recycling systems can significantly reduce the environmental footprint of maintenance activities.

The choice of replacement parts and materials used in maintenance can also impact sustainability. Opting for durable, recyclable, or eco-friendly materials can contribute to reducing the overall environmental impact of cyclone separator maintenance over time.

Lastly, the timing and frequency of maintenance activities play a role in environmental impact. Optimizing inspection and replacement intervals based on performance data and predictive maintenance techniques can help balance the need for efficient operation with minimizing unnecessary maintenance-related environmental disturbances.

Cost-Benefit Analysis of Maintenance Optimization

Optimizing maintenance strategies for cyclone separators requires a comprehensive cost-benefit analysis to determine the most efficient inspection and replacement intervals. This analysis involves evaluating the trade-offs between maintenance costs and the potential consequences of equipment failure or reduced performance.

The primary costs associated with cyclone separator maintenance include direct expenses such as labor, replacement parts, and downtime during inspections or repairs. These costs can be significant, especially in industries where continuous operation is critical. Regular inspections may require temporary shutdowns, impacting production schedules and potentially resulting in lost revenue.

On the benefit side, proactive maintenance can prevent catastrophic failures, extend equipment lifespan, and maintain optimal performance. Well-maintained cyclone separators operate more efficiently, consuming less energy and providing better separation results. This improved performance can lead to reduced operational costs and higher product quality, ultimately contributing to increased profitability.

To optimize maintenance intervals, it is crucial to consider the reliability characteristics of cyclone separators. These devices typically exhibit a bathtub-shaped failure rate curve, with higher failure rates during initial operation and end-of-life stages. By analyzing historical data and failure patterns, maintenance schedules can be tailored to address these varying risk levels throughout the equipment's lifecycle.

Predictive maintenance techniques, such as condition monitoring and data analytics, can further enhance the cost-benefit ratio. By continuously monitoring key performance indicators like pressure drop, vibration levels, and separation efficiency, potential issues can be identified before they escalate into major problems. This approach allows for more targeted and timely interventions, reducing unnecessary maintenance activities while minimizing the risk of unexpected failures.

The economic impact of different maintenance strategies should be evaluated using metrics such as Net Present Value (NPV) and Return on Investment (ROI). These calculations should account for both immediate costs and long-term benefits, including the potential for extended equipment life and improved operational efficiency. Sensitivity analysis can help identify the most critical factors influencing the optimal maintenance schedule, allowing for more robust decision-making in the face of uncertainties.

Ultimately, the goal of maintenance optimization is to strike a balance between minimizing costs and maximizing equipment reliability and performance. This balance may vary depending on factors such as the specific application, operating environment, and regulatory requirements. By conducting a thorough cost-benefit analysis, organizations can develop data-driven maintenance strategies that align with their operational goals and financial objectives.

The primary costs associated with cyclone separator maintenance include direct expenses such as labor, replacement parts, and downtime during inspections or repairs. These costs can be significant, especially in industries where continuous operation is critical. Regular inspections may require temporary shutdowns, impacting production schedules and potentially resulting in lost revenue.

On the benefit side, proactive maintenance can prevent catastrophic failures, extend equipment lifespan, and maintain optimal performance. Well-maintained cyclone separators operate more efficiently, consuming less energy and providing better separation results. This improved performance can lead to reduced operational costs and higher product quality, ultimately contributing to increased profitability.

To optimize maintenance intervals, it is crucial to consider the reliability characteristics of cyclone separators. These devices typically exhibit a bathtub-shaped failure rate curve, with higher failure rates during initial operation and end-of-life stages. By analyzing historical data and failure patterns, maintenance schedules can be tailored to address these varying risk levels throughout the equipment's lifecycle.

Predictive maintenance techniques, such as condition monitoring and data analytics, can further enhance the cost-benefit ratio. By continuously monitoring key performance indicators like pressure drop, vibration levels, and separation efficiency, potential issues can be identified before they escalate into major problems. This approach allows for more targeted and timely interventions, reducing unnecessary maintenance activities while minimizing the risk of unexpected failures.

The economic impact of different maintenance strategies should be evaluated using metrics such as Net Present Value (NPV) and Return on Investment (ROI). These calculations should account for both immediate costs and long-term benefits, including the potential for extended equipment life and improved operational efficiency. Sensitivity analysis can help identify the most critical factors influencing the optimal maintenance schedule, allowing for more robust decision-making in the face of uncertainties.

Ultimately, the goal of maintenance optimization is to strike a balance between minimizing costs and maximizing equipment reliability and performance. This balance may vary depending on factors such as the specific application, operating environment, and regulatory requirements. By conducting a thorough cost-benefit analysis, organizations can develop data-driven maintenance strategies that align with their operational goals and financial objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!