Cyclone Separator Wear Materials For Abrasive Dust Streams

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Wear Challenges and Objectives

Cyclone separators are critical components in various industrial processes, particularly in handling abrasive dust streams. However, these separators face significant wear challenges due to the harsh operating conditions they endure. The primary objective of this research is to address the wear issues in cyclone separators and develop innovative solutions to enhance their durability and performance.

The wear problem in cyclone separators is primarily caused by the high-velocity impact of abrasive particles on the separator walls. This continuous bombardment leads to material erosion, reducing the separator's efficiency and lifespan. The severity of wear depends on factors such as particle size, hardness, velocity, and impact angle. Understanding these parameters is crucial for developing effective wear-resistant materials and designs.

One of the main challenges in cyclone separator wear research is the complex nature of particle-wall interactions. The flow patterns within the separator are turbulent and multiphase, making it difficult to predict and model wear patterns accurately. This complexity necessitates advanced simulation techniques and experimental studies to gain a comprehensive understanding of the wear mechanisms.

Another significant challenge is the trade-off between wear resistance and other desirable properties. Materials with high wear resistance often lack other essential characteristics such as corrosion resistance, thermal stability, or cost-effectiveness. Balancing these properties to create an optimal solution is a key objective of this research.

The development of novel materials and coatings is a primary focus area. Advanced ceramics, metal matrix composites, and nanostructured materials show promise in combating wear. However, their integration into existing separator designs and manufacturing processes presents additional challenges that need to be addressed.

Improving the design of cyclone separators to minimize wear is another crucial objective. This includes optimizing the geometry of the separator to reduce particle impact velocity and altering flow patterns to minimize abrasive contact with critical surfaces. Computational fluid dynamics (CFD) simulations play a vital role in this aspect of the research.

The research also aims to develop in-situ monitoring and predictive maintenance techniques. Early detection of wear can significantly extend the operational life of cyclone separators and reduce downtime. This involves the integration of sensors and data analytics to provide real-time wear assessment and predictive maintenance schedules.

Ultimately, the goal is to significantly extend the service life of cyclone separators in abrasive dust stream applications while maintaining or improving their separation efficiency. This research has far-reaching implications for industries such as mining, cement production, and power generation, where cyclone separators are extensively used in harsh, abrasive environments.

The wear problem in cyclone separators is primarily caused by the high-velocity impact of abrasive particles on the separator walls. This continuous bombardment leads to material erosion, reducing the separator's efficiency and lifespan. The severity of wear depends on factors such as particle size, hardness, velocity, and impact angle. Understanding these parameters is crucial for developing effective wear-resistant materials and designs.

One of the main challenges in cyclone separator wear research is the complex nature of particle-wall interactions. The flow patterns within the separator are turbulent and multiphase, making it difficult to predict and model wear patterns accurately. This complexity necessitates advanced simulation techniques and experimental studies to gain a comprehensive understanding of the wear mechanisms.

Another significant challenge is the trade-off between wear resistance and other desirable properties. Materials with high wear resistance often lack other essential characteristics such as corrosion resistance, thermal stability, or cost-effectiveness. Balancing these properties to create an optimal solution is a key objective of this research.

The development of novel materials and coatings is a primary focus area. Advanced ceramics, metal matrix composites, and nanostructured materials show promise in combating wear. However, their integration into existing separator designs and manufacturing processes presents additional challenges that need to be addressed.

Improving the design of cyclone separators to minimize wear is another crucial objective. This includes optimizing the geometry of the separator to reduce particle impact velocity and altering flow patterns to minimize abrasive contact with critical surfaces. Computational fluid dynamics (CFD) simulations play a vital role in this aspect of the research.

The research also aims to develop in-situ monitoring and predictive maintenance techniques. Early detection of wear can significantly extend the operational life of cyclone separators and reduce downtime. This involves the integration of sensors and data analytics to provide real-time wear assessment and predictive maintenance schedules.

Ultimately, the goal is to significantly extend the service life of cyclone separators in abrasive dust stream applications while maintaining or improving their separation efficiency. This research has far-reaching implications for industries such as mining, cement production, and power generation, where cyclone separators are extensively used in harsh, abrasive environments.

Market Analysis for Wear-Resistant Cyclone Separators

The market for wear-resistant cyclone separators is experiencing significant growth, driven by increasing demand across various industries. The global cyclone separator market is projected to expand at a steady rate, with a particular emphasis on wear-resistant materials to enhance durability and performance in abrasive dust stream applications.

Key industries contributing to this market growth include mining, cement production, power generation, and chemical processing. These sectors require robust cyclone separators capable of withstanding harsh operating conditions and abrasive particulate matter. The mining industry, in particular, is a major consumer of wear-resistant cyclone separators due to the need for efficient dust collection and particle separation in mineral processing operations.

Geographically, Asia-Pacific is emerging as a dominant market for wear-resistant cyclone separators. This is attributed to rapid industrialization, infrastructure development, and stringent environmental regulations in countries like China and India. North America and Europe also maintain significant market shares, driven by ongoing technological advancements and the need for equipment upgrades in established industrial facilities.

The market is characterized by a growing focus on energy efficiency and environmental sustainability. End-users are increasingly seeking cyclone separators that not only offer superior wear resistance but also contribute to reduced energy consumption and improved overall process efficiency. This trend is fostering innovation in material science and design optimization for cyclone separators.

A notable market driver is the rising awareness of occupational health and safety standards. Industries are investing in advanced dust collection systems, including wear-resistant cyclone separators, to comply with stringent regulations and protect worker health. This factor is particularly influential in developed economies with strict environmental and safety guidelines.

The aftermarket segment for wear-resistant components in cyclone separators is also showing promising growth. As existing installations age, there is an increasing demand for replacement parts and retrofitting solutions that can extend the operational life of cyclone separators while improving their performance in handling abrasive dust streams.

Competition in the market is intensifying, with both established players and new entrants focusing on product differentiation through advanced wear-resistant materials and innovative designs. Companies are investing in research and development to create cyclone separators that offer longer service life, reduced maintenance requirements, and improved separation efficiency in abrasive environments.

Key industries contributing to this market growth include mining, cement production, power generation, and chemical processing. These sectors require robust cyclone separators capable of withstanding harsh operating conditions and abrasive particulate matter. The mining industry, in particular, is a major consumer of wear-resistant cyclone separators due to the need for efficient dust collection and particle separation in mineral processing operations.

Geographically, Asia-Pacific is emerging as a dominant market for wear-resistant cyclone separators. This is attributed to rapid industrialization, infrastructure development, and stringent environmental regulations in countries like China and India. North America and Europe also maintain significant market shares, driven by ongoing technological advancements and the need for equipment upgrades in established industrial facilities.

The market is characterized by a growing focus on energy efficiency and environmental sustainability. End-users are increasingly seeking cyclone separators that not only offer superior wear resistance but also contribute to reduced energy consumption and improved overall process efficiency. This trend is fostering innovation in material science and design optimization for cyclone separators.

A notable market driver is the rising awareness of occupational health and safety standards. Industries are investing in advanced dust collection systems, including wear-resistant cyclone separators, to comply with stringent regulations and protect worker health. This factor is particularly influential in developed economies with strict environmental and safety guidelines.

The aftermarket segment for wear-resistant components in cyclone separators is also showing promising growth. As existing installations age, there is an increasing demand for replacement parts and retrofitting solutions that can extend the operational life of cyclone separators while improving their performance in handling abrasive dust streams.

Competition in the market is intensifying, with both established players and new entrants focusing on product differentiation through advanced wear-resistant materials and innovative designs. Companies are investing in research and development to create cyclone separators that offer longer service life, reduced maintenance requirements, and improved separation efficiency in abrasive environments.

Current State and Limitations of Wear Materials

The current state of wear materials for cyclone separators in abrasive dust streams is characterized by a range of options, each with its own strengths and limitations. Traditional materials such as carbon steel and stainless steel are widely used due to their availability and cost-effectiveness. However, these materials often suffer from rapid wear in highly abrasive environments, leading to frequent replacements and increased maintenance costs.

Advanced ceramic materials, including alumina and silicon carbide, have gained popularity for their superior hardness and wear resistance. These materials can significantly extend the operational life of cyclone separators in abrasive dust streams. However, their brittle nature makes them susceptible to impact damage, and their high cost can be a barrier to widespread adoption in some industries.

Polymer-based materials, such as polyurethane and high-density polyethylene, offer excellent impact resistance and are often used in less severe abrasive environments. These materials provide good wear resistance for certain applications but may not withstand extreme temperatures or highly abrasive conditions for extended periods.

Composite materials, combining the properties of ceramics and polymers, have shown promise in recent years. These materials aim to balance wear resistance, impact strength, and cost-effectiveness. However, the development of optimal composite formulations for specific abrasive dust stream conditions remains an ongoing challenge.

One of the primary limitations in the current state of wear materials is the trade-off between hardness and toughness. Materials that offer excellent wear resistance often lack the necessary impact resistance to withstand the dynamic conditions within cyclone separators. Conversely, materials with high impact resistance may not provide sufficient wear protection in highly abrasive environments.

Another significant challenge is the variability of abrasive dust streams across different industries and processes. The performance of wear materials can vary greatly depending on factors such as particle size, hardness, and velocity of the abrasive media. This variability makes it difficult to develop a one-size-fits-all solution for cyclone separator wear materials.

The cost-effectiveness of advanced wear materials remains a limiting factor for many applications. While high-performance materials can offer extended operational life and reduced maintenance, their initial cost may be prohibitive for some industries, particularly in large-scale operations where multiple cyclone separators are employed.

Advanced ceramic materials, including alumina and silicon carbide, have gained popularity for their superior hardness and wear resistance. These materials can significantly extend the operational life of cyclone separators in abrasive dust streams. However, their brittle nature makes them susceptible to impact damage, and their high cost can be a barrier to widespread adoption in some industries.

Polymer-based materials, such as polyurethane and high-density polyethylene, offer excellent impact resistance and are often used in less severe abrasive environments. These materials provide good wear resistance for certain applications but may not withstand extreme temperatures or highly abrasive conditions for extended periods.

Composite materials, combining the properties of ceramics and polymers, have shown promise in recent years. These materials aim to balance wear resistance, impact strength, and cost-effectiveness. However, the development of optimal composite formulations for specific abrasive dust stream conditions remains an ongoing challenge.

One of the primary limitations in the current state of wear materials is the trade-off between hardness and toughness. Materials that offer excellent wear resistance often lack the necessary impact resistance to withstand the dynamic conditions within cyclone separators. Conversely, materials with high impact resistance may not provide sufficient wear protection in highly abrasive environments.

Another significant challenge is the variability of abrasive dust streams across different industries and processes. The performance of wear materials can vary greatly depending on factors such as particle size, hardness, and velocity of the abrasive media. This variability makes it difficult to develop a one-size-fits-all solution for cyclone separator wear materials.

The cost-effectiveness of advanced wear materials remains a limiting factor for many applications. While high-performance materials can offer extended operational life and reduced maintenance, their initial cost may be prohibitive for some industries, particularly in large-scale operations where multiple cyclone separators are employed.

Existing Wear-Resistant Material Solutions

01 Use of ceramic materials for wear resistance

Ceramic materials are utilized in cyclone separators to enhance wear resistance. These materials, known for their hardness and durability, can significantly extend the lifespan of separator components exposed to abrasive particles. Ceramic linings or coatings are applied to critical areas of the separator to protect against erosion and wear.- Use of ceramic materials for wear resistance: Ceramic materials are utilized in cyclone separators to enhance wear resistance. These materials, known for their hardness and durability, can significantly extend the lifespan of separator components exposed to abrasive particles. The implementation of ceramic linings or inserts in high-wear areas can reduce maintenance frequency and improve overall efficiency.

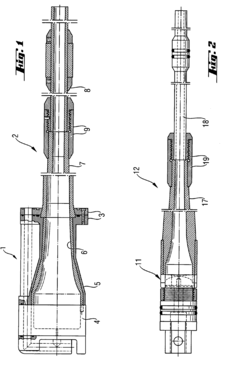

- Application of metal alloys for improved durability: Specialized metal alloys are employed to increase the wear resistance of cyclone separator components. These alloys, often containing elements like chromium, nickel, or tungsten, offer superior hardness and toughness compared to standard metals. The use of such alloys in critical areas subject to high wear can significantly enhance the longevity of the separator.

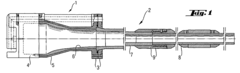

- Coating technologies for wear protection: Advanced coating technologies are applied to cyclone separator surfaces to improve wear resistance. These coatings, which may include thermal sprays, plasma coatings, or hard-facing techniques, create a protective layer that can withstand abrasive materials. The application of such coatings can extend the service life of separator components and maintain operational efficiency.

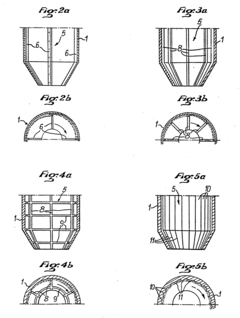

- Optimized geometry design for wear reduction: The geometry of cyclone separator components is optimized to minimize wear. This includes designing curved surfaces, adjusting angles, and creating flow patterns that reduce the impact and abrasion of particles on critical areas. Such design optimizations can significantly decrease wear rates and extend the operational life of the separator.

- Composite materials for enhanced wear resistance: Composite materials combining different substances are used to achieve superior wear resistance in cyclone separators. These materials may include metal matrix composites, polymer composites with reinforcing particles, or ceramic-metal composites. The synergistic properties of these composites can provide excellent wear resistance while maintaining other desirable characteristics such as lightweight or corrosion resistance.

02 Application of metal alloys for improved durability

Specialized metal alloys are employed in cyclone separators to increase wear resistance. These alloys, often containing elements like chromium, nickel, or tungsten, offer superior hardness and toughness compared to standard metals. They are used in the construction of separator components or as protective coatings to withstand the harsh operating conditions.Expand Specific Solutions03 Composite materials for enhanced wear protection

Composite materials combining different substances are used to improve wear resistance in cyclone separators. These materials may include metal matrix composites or polymer-based composites reinforced with hard particles. The combination of materials provides a balance of properties such as hardness, toughness, and impact resistance, making them suitable for high-wear applications.Expand Specific Solutions04 Surface treatment techniques for increased wear resistance

Various surface treatment techniques are applied to enhance the wear resistance of cyclone separator components. These may include thermal spraying, plasma nitriding, or laser surface hardening. Such treatments modify the surface properties of the materials, creating a hard, wear-resistant layer while maintaining the bulk properties of the underlying material.Expand Specific Solutions05 Design optimization for reducing wear

The design of cyclone separators is optimized to minimize wear on critical components. This includes modifications to the geometry of the separator, such as adjusting the inlet angle, vortex finder design, or cone angle. Additionally, the use of replaceable wear parts or modular designs allows for easier maintenance and replacement of high-wear areas, extending the overall lifespan of the separator.Expand Specific Solutions

Key Players in Cyclone Separator Industry

The research on cyclone separator wear materials for abrasive dust streams is in a mature stage of development, with a significant market size due to its widespread industrial applications. The technology's maturity is evident from the involvement of established players like Dyson Technology Ltd., UOP LLC, and MANN+HUMMEL GmbH. These companies have extensive experience in filtration and separation technologies, indicating a well-developed competitive landscape. The market is characterized by ongoing innovation, with firms like Gema Switzerland GmbH and Valmet AB focusing on improving efficiency and durability of cyclone separators. The presence of diverse players across different industries suggests a broad application range and potential for further growth in specialized sectors.

Dyson Technology Ltd.

Technical Solution: Dyson has developed advanced cyclone separator technology for their vacuum cleaners and air purifiers, focusing on improving wear resistance in abrasive dust environments. Their approach involves using a combination of high-performance polymers and ceramic coatings on critical components. The company has implemented a multi-stage cyclone system that reduces the velocity of particles in later stages, minimizing wear[1]. They have also introduced electrostatic charge manipulation techniques to enhance particle separation efficiency while reducing abrasive contact with surfaces[3]. Dyson's research includes computational fluid dynamics (CFD) simulations to optimize cyclone geometry for reduced wear and improved separation efficiency[5].

Strengths: Innovative materials and design, extensive R&D capabilities, and proven track record in consumer products. Weaknesses: Primarily focused on small-scale applications, potentially limiting industrial applicability.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL has developed innovative cyclone separator technology for automotive and industrial air filtration systems, with a focus on reducing wear in abrasive dust environments. Their approach includes the use of advanced polymer blends and surface treatments to enhance wear resistance. The company has implemented a multi-cyclone array design that distributes airflow and particulate matter more evenly, reducing localized wear[7]. MANN+HUMMEL's research includes the development of self-cleaning cyclone surfaces that use electrostatic repulsion to minimize particle adhesion and subsequent abrasion[9]. They have also explored the use of biomimetic surface textures inspired by naturally abrasion-resistant organisms to further enhance wear resistance in critical areas of the cyclone separator.

Strengths: Extensive experience in filtration technology, strong presence in automotive and industrial markets. Weaknesses: May have less experience with extremely abrasive or high-temperature dust streams compared to some mining-focused competitors.

Core Innovations in Abrasive Dust Handling

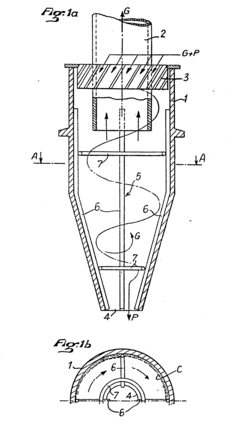

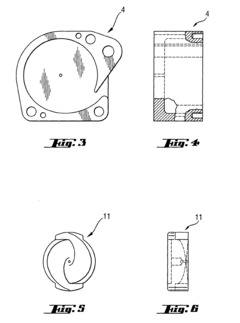

Protection of the wall of a centrifugal separator against abrasion by particles separated by centrifugation, and device for carrying out the method

PatentInactiveEP0052042A2

Innovation

- A layer of particles is created on the inner wall of the centrifuge by using elements in relief, such as strips or ribs, that oppose the sliding of particles, reducing friction and wear by forming a protective layer.

Centrifugal separator designed as cyclone

PatentInactiveEP1393813A1

Innovation

- The cyclone is constructed using tungsten carbide with a nickel and/or chromium binder, where the binder metal composition is optimized to reduce wear, incorporating additional carbides and tailored grain size, density, and hardness for enhanced abrasion resistance.

Environmental Impact of Cyclone Separator Materials

The environmental impact of cyclone separator materials is a critical consideration in the design and operation of these dust collection systems. Traditional materials used in cyclone separators, such as steel and various alloys, have significant environmental implications throughout their lifecycle. The production of these materials often involves energy-intensive processes and the extraction of raw materials, contributing to greenhouse gas emissions and resource depletion.

During operation, the wear of cyclone separator materials can lead to the release of particulate matter into the environment. This is particularly concerning when dealing with abrasive dust streams, as the rate of material degradation increases. The worn material may contaminate the collected dust, potentially rendering it unsuitable for recycling or safe disposal. Additionally, the need for frequent replacement of worn components results in increased waste generation and resource consumption.

The disposal of worn cyclone separator materials presents another environmental challenge. Many of these materials are not biodegradable and may persist in landfills for extended periods. Some materials may leach harmful substances into the soil and groundwater, posing risks to ecosystems and human health. The recycling of these materials, while preferable to landfilling, often requires energy-intensive processes and may not be economically viable for all types of wear-resistant materials.

Recent research has focused on developing more environmentally friendly materials for cyclone separators. Advanced ceramics and polymer composites are being explored as alternatives to traditional metal alloys. These materials often offer improved wear resistance, potentially reducing the frequency of replacement and associated environmental impacts. Some innovative materials incorporate recycled content or bio-based components, further reducing their environmental footprint.

The use of surface treatments and coatings on cyclone separator materials has also shown promise in mitigating environmental impacts. These treatments can enhance wear resistance without the need for entirely new material compositions. Some coatings are designed to be easily reapplied, extending the lifespan of components and reducing waste generation.

As environmental regulations become more stringent, the selection of cyclone separator materials is increasingly influenced by lifecycle assessments and sustainability considerations. Manufacturers are now exploring ways to optimize material selection not only for performance but also for minimal environmental impact. This holistic approach considers factors such as raw material sourcing, energy consumption during production, operational efficiency, and end-of-life management.

During operation, the wear of cyclone separator materials can lead to the release of particulate matter into the environment. This is particularly concerning when dealing with abrasive dust streams, as the rate of material degradation increases. The worn material may contaminate the collected dust, potentially rendering it unsuitable for recycling or safe disposal. Additionally, the need for frequent replacement of worn components results in increased waste generation and resource consumption.

The disposal of worn cyclone separator materials presents another environmental challenge. Many of these materials are not biodegradable and may persist in landfills for extended periods. Some materials may leach harmful substances into the soil and groundwater, posing risks to ecosystems and human health. The recycling of these materials, while preferable to landfilling, often requires energy-intensive processes and may not be economically viable for all types of wear-resistant materials.

Recent research has focused on developing more environmentally friendly materials for cyclone separators. Advanced ceramics and polymer composites are being explored as alternatives to traditional metal alloys. These materials often offer improved wear resistance, potentially reducing the frequency of replacement and associated environmental impacts. Some innovative materials incorporate recycled content or bio-based components, further reducing their environmental footprint.

The use of surface treatments and coatings on cyclone separator materials has also shown promise in mitigating environmental impacts. These treatments can enhance wear resistance without the need for entirely new material compositions. Some coatings are designed to be easily reapplied, extending the lifespan of components and reducing waste generation.

As environmental regulations become more stringent, the selection of cyclone separator materials is increasingly influenced by lifecycle assessments and sustainability considerations. Manufacturers are now exploring ways to optimize material selection not only for performance but also for minimal environmental impact. This holistic approach considers factors such as raw material sourcing, energy consumption during production, operational efficiency, and end-of-life management.

Cost-Benefit Analysis of Advanced Wear Materials

The implementation of advanced wear materials in cyclone separators for abrasive dust streams presents a complex cost-benefit scenario that requires careful analysis. Initial investment in high-performance materials such as ceramic linings, tungsten carbide coatings, or advanced polymer composites typically involves higher upfront costs compared to traditional steel or cast iron components. However, these materials offer significant long-term economic advantages that can offset the initial expenditure.

Improved wear resistance of advanced materials translates to extended operational lifespans for cyclone separators, reducing the frequency of maintenance shutdowns and replacement cycles. This increased durability directly impacts operational continuity, minimizing production downtime and associated revenue losses. For industries dealing with highly abrasive dust streams, such as mining or cement production, the reduction in maintenance frequency can lead to substantial cost savings over time.

Energy efficiency is another crucial factor in the cost-benefit equation. Advanced wear materials often feature smoother surfaces that reduce friction and turbulence within the cyclone separator. This improved flow dynamics can result in lower power consumption for the system, contributing to reduced operational costs and improved overall energy efficiency of the process.

The enhanced performance characteristics of advanced wear materials can also lead to improved separation efficiency and product quality. By maintaining optimal geometry and surface conditions for longer periods, these materials ensure consistent particle separation, potentially increasing the value of the end product or reducing waste handling costs. This aspect is particularly relevant in industries where product purity is critical, such as pharmaceutical or food processing.

Environmental considerations play an increasingly important role in cost-benefit analyses. Advanced wear materials that reduce the need for frequent replacements contribute to lower material consumption and waste generation over the lifecycle of the equipment. This aligns with sustainability goals and may offer advantages in terms of regulatory compliance and corporate social responsibility initiatives.

While the benefits of advanced wear materials are significant, it is essential to consider the specific operational context when conducting a cost-benefit analysis. Factors such as the abrasiveness of the dust stream, operating temperatures, and chemical environment can greatly influence the performance and longevity of different materials. Therefore, a thorough assessment of these parameters is crucial to selecting the most cost-effective solution for a given application.

In conclusion, the cost-benefit analysis of advanced wear materials for cyclone separators in abrasive dust streams must balance higher initial investments against long-term operational savings, improved efficiency, and potential quality enhancements. The optimal choice depends on a comprehensive evaluation of specific operational requirements, environmental factors, and strategic business objectives.

Improved wear resistance of advanced materials translates to extended operational lifespans for cyclone separators, reducing the frequency of maintenance shutdowns and replacement cycles. This increased durability directly impacts operational continuity, minimizing production downtime and associated revenue losses. For industries dealing with highly abrasive dust streams, such as mining or cement production, the reduction in maintenance frequency can lead to substantial cost savings over time.

Energy efficiency is another crucial factor in the cost-benefit equation. Advanced wear materials often feature smoother surfaces that reduce friction and turbulence within the cyclone separator. This improved flow dynamics can result in lower power consumption for the system, contributing to reduced operational costs and improved overall energy efficiency of the process.

The enhanced performance characteristics of advanced wear materials can also lead to improved separation efficiency and product quality. By maintaining optimal geometry and surface conditions for longer periods, these materials ensure consistent particle separation, potentially increasing the value of the end product or reducing waste handling costs. This aspect is particularly relevant in industries where product purity is critical, such as pharmaceutical or food processing.

Environmental considerations play an increasingly important role in cost-benefit analyses. Advanced wear materials that reduce the need for frequent replacements contribute to lower material consumption and waste generation over the lifecycle of the equipment. This aligns with sustainability goals and may offer advantages in terms of regulatory compliance and corporate social responsibility initiatives.

While the benefits of advanced wear materials are significant, it is essential to consider the specific operational context when conducting a cost-benefit analysis. Factors such as the abrasiveness of the dust stream, operating temperatures, and chemical environment can greatly influence the performance and longevity of different materials. Therefore, a thorough assessment of these parameters is crucial to selecting the most cost-effective solution for a given application.

In conclusion, the cost-benefit analysis of advanced wear materials for cyclone separators in abrasive dust streams must balance higher initial investments against long-term operational savings, improved efficiency, and potential quality enhancements. The optimal choice depends on a comprehensive evaluation of specific operational requirements, environmental factors, and strategic business objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!