Laminar Flow Solutions for Innovative Cooling Systems

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Cooling Background and Objectives

Laminar flow cooling has emerged as a promising technology in the field of thermal management, offering innovative solutions for efficient heat dissipation in various applications. The concept of laminar flow, characterized by smooth and predictable fluid motion, has been known for centuries, but its application in cooling systems has gained significant attention in recent years due to its potential for enhanced energy efficiency and improved thermal performance.

The evolution of laminar flow cooling technology can be traced back to the fundamental principles of fluid dynamics established by pioneers such as Osborne Reynolds in the late 19th century. However, it was not until the mid-20th century that researchers began to explore its potential in cooling applications. The development of advanced computational fluid dynamics (CFD) tools and experimental techniques in the latter half of the 20th century further accelerated research in this field, enabling more accurate modeling and optimization of laminar flow cooling systems.

In recent years, the increasing demand for more efficient and compact cooling solutions in various industries, including electronics, automotive, and aerospace, has driven renewed interest in laminar flow cooling. The miniaturization of electronic devices, the push for higher performance in computing systems, and the need for more efficient thermal management in electric vehicles have all contributed to the growing importance of innovative cooling technologies.

The primary objective of research on laminar flow solutions for innovative cooling systems is to develop and optimize cooling techniques that leverage the unique properties of laminar flow to achieve superior thermal performance while minimizing energy consumption. This involves exploring novel geometries, materials, and control strategies that can maintain laminar flow conditions over a wide range of operating parameters, thereby maximizing heat transfer efficiency and reducing pumping power requirements.

Key research goals in this field include enhancing heat transfer coefficients in laminar flow regimes, extending the range of Reynolds numbers over which laminar flow can be maintained, and developing adaptive cooling systems that can dynamically adjust to varying thermal loads. Additionally, researchers aim to integrate laminar flow cooling solutions with other advanced thermal management technologies, such as phase change materials and thermoelectric devices, to create hybrid systems capable of addressing complex cooling challenges.

As the field progresses, there is a growing focus on developing laminar flow cooling solutions that are not only thermally efficient but also environmentally sustainable. This includes exploring the use of eco-friendly coolants, designing systems with reduced material footprint, and optimizing energy consumption throughout the lifecycle of cooling devices. The ultimate aim is to create cooling technologies that can meet the increasing thermal management demands of modern applications while contributing to global efforts towards energy conservation and environmental protection.

The evolution of laminar flow cooling technology can be traced back to the fundamental principles of fluid dynamics established by pioneers such as Osborne Reynolds in the late 19th century. However, it was not until the mid-20th century that researchers began to explore its potential in cooling applications. The development of advanced computational fluid dynamics (CFD) tools and experimental techniques in the latter half of the 20th century further accelerated research in this field, enabling more accurate modeling and optimization of laminar flow cooling systems.

In recent years, the increasing demand for more efficient and compact cooling solutions in various industries, including electronics, automotive, and aerospace, has driven renewed interest in laminar flow cooling. The miniaturization of electronic devices, the push for higher performance in computing systems, and the need for more efficient thermal management in electric vehicles have all contributed to the growing importance of innovative cooling technologies.

The primary objective of research on laminar flow solutions for innovative cooling systems is to develop and optimize cooling techniques that leverage the unique properties of laminar flow to achieve superior thermal performance while minimizing energy consumption. This involves exploring novel geometries, materials, and control strategies that can maintain laminar flow conditions over a wide range of operating parameters, thereby maximizing heat transfer efficiency and reducing pumping power requirements.

Key research goals in this field include enhancing heat transfer coefficients in laminar flow regimes, extending the range of Reynolds numbers over which laminar flow can be maintained, and developing adaptive cooling systems that can dynamically adjust to varying thermal loads. Additionally, researchers aim to integrate laminar flow cooling solutions with other advanced thermal management technologies, such as phase change materials and thermoelectric devices, to create hybrid systems capable of addressing complex cooling challenges.

As the field progresses, there is a growing focus on developing laminar flow cooling solutions that are not only thermally efficient but also environmentally sustainable. This includes exploring the use of eco-friendly coolants, designing systems with reduced material footprint, and optimizing energy consumption throughout the lifecycle of cooling devices. The ultimate aim is to create cooling technologies that can meet the increasing thermal management demands of modern applications while contributing to global efforts towards energy conservation and environmental protection.

Market Analysis for Advanced Cooling Solutions

The market for advanced cooling solutions is experiencing significant growth, driven by the increasing demand for efficient thermal management across various industries. As data centers, electric vehicles, and high-performance electronics continue to evolve, the need for innovative cooling systems has become paramount. The global market for advanced cooling solutions is expected to expand rapidly in the coming years, with a particular focus on laminar flow technologies.

One of the key drivers of this market growth is the exponential increase in data center infrastructure worldwide. As cloud computing, artificial intelligence, and big data analytics continue to proliferate, the heat generated by densely packed servers and computing equipment has become a critical challenge. Traditional cooling methods are often inadequate or inefficient for these high-density environments, creating a strong demand for advanced cooling solutions that can provide better thermal management while reducing energy consumption.

The automotive industry, particularly the electric vehicle (EV) sector, is another significant contributor to the market demand for innovative cooling systems. As EV batteries and power electronics generate substantial heat during operation, efficient cooling solutions are essential for maintaining optimal performance and extending battery life. Laminar flow cooling technologies offer promising solutions for these applications, potentially improving the range and reliability of electric vehicles.

In the consumer electronics market, the trend towards more powerful and compact devices has intensified the need for advanced cooling solutions. Smartphones, laptops, and gaming consoles are pushing the limits of thermal management in small form factors. Manufacturers are increasingly looking for innovative cooling technologies to maintain device performance while ensuring user comfort and safety.

The industrial sector also presents significant opportunities for advanced cooling solutions. As manufacturing processes become more automated and energy-intensive, the demand for efficient cooling systems in factories and production facilities is on the rise. Laminar flow technologies can offer improved precision and energy efficiency in cooling critical industrial equipment and processes.

Geographically, North America and Asia-Pacific are expected to be the leading markets for advanced cooling solutions. The concentration of data centers, technology companies, and manufacturing hubs in these regions drives the adoption of innovative cooling technologies. Europe is also showing strong growth potential, particularly in the automotive and renewable energy sectors.

As environmental concerns and energy efficiency regulations become more stringent, the market is shifting towards eco-friendly cooling solutions. This trend is creating opportunities for laminar flow technologies that can offer reduced energy consumption and lower environmental impact compared to traditional cooling methods.

One of the key drivers of this market growth is the exponential increase in data center infrastructure worldwide. As cloud computing, artificial intelligence, and big data analytics continue to proliferate, the heat generated by densely packed servers and computing equipment has become a critical challenge. Traditional cooling methods are often inadequate or inefficient for these high-density environments, creating a strong demand for advanced cooling solutions that can provide better thermal management while reducing energy consumption.

The automotive industry, particularly the electric vehicle (EV) sector, is another significant contributor to the market demand for innovative cooling systems. As EV batteries and power electronics generate substantial heat during operation, efficient cooling solutions are essential for maintaining optimal performance and extending battery life. Laminar flow cooling technologies offer promising solutions for these applications, potentially improving the range and reliability of electric vehicles.

In the consumer electronics market, the trend towards more powerful and compact devices has intensified the need for advanced cooling solutions. Smartphones, laptops, and gaming consoles are pushing the limits of thermal management in small form factors. Manufacturers are increasingly looking for innovative cooling technologies to maintain device performance while ensuring user comfort and safety.

The industrial sector also presents significant opportunities for advanced cooling solutions. As manufacturing processes become more automated and energy-intensive, the demand for efficient cooling systems in factories and production facilities is on the rise. Laminar flow technologies can offer improved precision and energy efficiency in cooling critical industrial equipment and processes.

Geographically, North America and Asia-Pacific are expected to be the leading markets for advanced cooling solutions. The concentration of data centers, technology companies, and manufacturing hubs in these regions drives the adoption of innovative cooling technologies. Europe is also showing strong growth potential, particularly in the automotive and renewable energy sectors.

As environmental concerns and energy efficiency regulations become more stringent, the market is shifting towards eco-friendly cooling solutions. This trend is creating opportunities for laminar flow technologies that can offer reduced energy consumption and lower environmental impact compared to traditional cooling methods.

Current Challenges in Laminar Flow Cooling

Laminar flow cooling systems face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is maintaining laminar flow conditions across a wide range of operating parameters. As cooling demands increase, the tendency for flow to transition from laminar to turbulent becomes more pronounced, reducing the system's efficiency and effectiveness.

The design of cooling channels and heat exchange surfaces presents another major challenge. Creating geometries that promote laminar flow while maximizing heat transfer is a complex task. Traditional designs often struggle to balance these competing requirements, leading to suboptimal performance or increased manufacturing complexity.

Scaling laminar flow cooling solutions for larger systems or higher heat loads poses significant difficulties. As the size of the cooling system increases, maintaining laminar flow becomes increasingly challenging due to the higher Reynolds numbers associated with larger flow paths. This limitation often restricts the application of laminar flow cooling to smaller-scale or low-power devices.

Material selection and compatibility issues also present ongoing challenges. The materials used in laminar flow cooling systems must possess specific thermal and fluid dynamic properties to maintain laminar flow and efficient heat transfer. Additionally, these materials need to be compatible with the coolants used and resistant to corrosion or degradation over time.

Control and regulation of laminar flow cooling systems present another set of challenges. Precise flow control is essential to maintain laminar conditions, but achieving this across varying heat loads and environmental conditions can be difficult. Developing robust control systems that can adapt to changing conditions while maintaining laminar flow is an ongoing area of research.

The integration of laminar flow cooling solutions into existing systems and manufacturing processes presents practical challenges. Retrofitting or redesigning systems to incorporate laminar flow cooling can be costly and complex, often requiring significant changes to established designs and production methods.

Lastly, the cost-effectiveness of laminar flow cooling solutions remains a challenge in many applications. While these systems can offer superior cooling performance in certain scenarios, the increased complexity and potential manufacturing costs can make them less attractive compared to more conventional cooling methods. Balancing the performance benefits against economic considerations is an ongoing challenge for researchers and engineers in this field.

The design of cooling channels and heat exchange surfaces presents another major challenge. Creating geometries that promote laminar flow while maximizing heat transfer is a complex task. Traditional designs often struggle to balance these competing requirements, leading to suboptimal performance or increased manufacturing complexity.

Scaling laminar flow cooling solutions for larger systems or higher heat loads poses significant difficulties. As the size of the cooling system increases, maintaining laminar flow becomes increasingly challenging due to the higher Reynolds numbers associated with larger flow paths. This limitation often restricts the application of laminar flow cooling to smaller-scale or low-power devices.

Material selection and compatibility issues also present ongoing challenges. The materials used in laminar flow cooling systems must possess specific thermal and fluid dynamic properties to maintain laminar flow and efficient heat transfer. Additionally, these materials need to be compatible with the coolants used and resistant to corrosion or degradation over time.

Control and regulation of laminar flow cooling systems present another set of challenges. Precise flow control is essential to maintain laminar conditions, but achieving this across varying heat loads and environmental conditions can be difficult. Developing robust control systems that can adapt to changing conditions while maintaining laminar flow is an ongoing area of research.

The integration of laminar flow cooling solutions into existing systems and manufacturing processes presents practical challenges. Retrofitting or redesigning systems to incorporate laminar flow cooling can be costly and complex, often requiring significant changes to established designs and production methods.

Lastly, the cost-effectiveness of laminar flow cooling solutions remains a challenge in many applications. While these systems can offer superior cooling performance in certain scenarios, the increased complexity and potential manufacturing costs can make them less attractive compared to more conventional cooling methods. Balancing the performance benefits against economic considerations is an ongoing challenge for researchers and engineers in this field.

Existing Laminar Flow Cooling Solutions

01 Laminar flow cooling systems for electronic devices

Laminar flow cooling solutions are utilized in electronic devices to efficiently dissipate heat. These systems employ controlled airflow to create a smooth, non-turbulent layer of air that effectively removes heat from components. This approach enhances cooling efficiency and helps maintain optimal operating temperatures for sensitive electronic equipment.- Laminar flow cooling systems for electronic devices: Laminar flow cooling solutions are utilized in electronic devices to efficiently dissipate heat. These systems employ controlled airflow to create a smooth, non-turbulent layer of air that effectively removes heat from components. This approach enhances cooling efficiency and helps maintain optimal operating temperatures for sensitive electronic equipment.

- Laminar flow in fluid measurement and control: Laminar flow principles are applied in fluid measurement and control systems. These solutions utilize the predictable behavior of laminar flow to accurately measure and regulate fluid flow rates. This technology is particularly useful in applications requiring precise flow control, such as in scientific instruments or industrial processes.

- Laminar flow cooling in automotive applications: Laminar flow cooling solutions are implemented in automotive systems to improve thermal management. These designs optimize airflow around engine components and within vehicle cabins, enhancing cooling efficiency and reducing drag. The controlled airflow helps maintain ideal operating temperatures and improves overall vehicle performance.

- Laminar flow in HVAC and air distribution systems: Laminar flow principles are applied in HVAC and air distribution systems to improve air quality and energy efficiency. These solutions create smooth, controlled airflow patterns that minimize turbulence and optimize air distribution. This approach enhances comfort in indoor environments while reducing energy consumption associated with air movement.

- Laminar flow in industrial cooling processes: Laminar flow cooling solutions are employed in various industrial processes to enhance heat transfer efficiency. These systems utilize controlled fluid flow to create uniform cooling across surfaces or within equipment. The laminar flow approach improves temperature control, reduces energy consumption, and enhances the overall efficiency of industrial cooling operations.

02 Laminar flow in fluid measurement and control

Laminar flow principles are applied in fluid measurement and control systems. These solutions utilize the predictable behavior of laminar flow to accurately measure and regulate fluid flow rates. This technology is particularly useful in applications requiring precise flow control, such as in scientific instruments or industrial processes.Expand Specific Solutions03 Laminar flow nozzles and spray systems

Specialized nozzles and spray systems are designed to produce laminar flow patterns for various applications. These systems create smooth, coherent streams of fluid that maintain their shape over longer distances. Such laminar flow nozzles are used in cooling systems, decorative fountains, and industrial processes where precise liquid application is required.Expand Specific Solutions04 Laminar flow in HVAC and air distribution systems

Laminar flow principles are incorporated into HVAC and air distribution systems to improve cooling efficiency and air quality. These solutions create controlled airflow patterns that minimize turbulence and optimize heat transfer. This approach enhances the overall performance of cooling systems in buildings and vehicles.Expand Specific Solutions05 Laminar flow in microfluidic cooling devices

Microfluidic cooling devices utilize laminar flow characteristics to enhance heat dissipation in compact electronic systems. These solutions employ precisely engineered channels to guide coolant flow, maximizing thermal transfer efficiency. This technology is particularly valuable in high-performance computing and miniaturized electronic devices where space is limited and heat management is critical.Expand Specific Solutions

Key Players in Innovative Cooling Systems

The research on laminar flow solutions for innovative cooling systems is in a dynamic phase, with the market showing significant growth potential. The technology is advancing rapidly, driven by increasing demand for efficient cooling solutions across industries. Key players like Gree Electric Appliances and Hanon Systems are leading innovation in this field, leveraging their expertise in HVAC systems. Companies such as Baoshan Iron & Steel and POSCO Holdings are exploring applications in industrial cooling, while tech giants like Hitachi and Mitsubishi Electric are integrating laminar flow solutions into their broader product portfolios. The involvement of research institutions like Northeastern University and The Charles Stark Draper Laboratory indicates ongoing fundamental research, suggesting that the technology is still evolving with room for breakthrough innovations.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed a cutting-edge laminar flow cooling solution for their air conditioning systems. Their approach utilizes a combination of specially designed air guides and micro-perforated panels to create a uniform, low-velocity airflow across cooling surfaces. This laminar flow technology is integrated with Gree's proprietary G-Micro inverter compressors, which allow for precise control of cooling capacity. The system also incorporates advanced CFD (Computational Fluid Dynamics) modeling to optimize airflow patterns and heat exchange efficiency[3]. Gree's laminar flow solution has demonstrated up to 25% improvement in cooling efficiency and a significant reduction in noise levels compared to traditional turbulent flow systems[4].

Strengths: High cooling efficiency, low noise operation, and integration with advanced compressor technology. Weaknesses: May require more space for implementation and potential higher manufacturing costs.

Hanon Systems

Technical Solution: Hanon Systems has developed an innovative laminar flow cooling solution for automotive applications. Their system utilizes a network of micro-channels and specially designed heat exchangers to create laminar flow conditions for coolant circulation. This approach maximizes heat transfer efficiency while minimizing pumping power requirements. Hanon's solution also incorporates smart valves and electronic control units to dynamically adjust coolant flow based on real-time thermal management needs[5]. The company has reported that their laminar flow cooling system can improve overall vehicle energy efficiency by up to 5% and reduce CO2 emissions accordingly[6]. Additionally, the compact design of their system allows for better packaging in limited spaces within vehicles.

Strengths: Optimized for automotive applications, energy-efficient, and compact design. Weaknesses: May require integration with vehicle's existing thermal management systems and potential higher initial costs.

Core Innovations in Laminar Flow Research

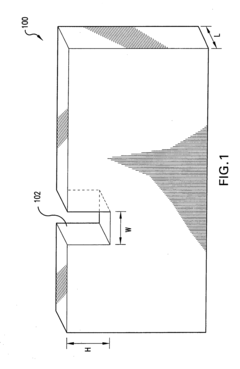

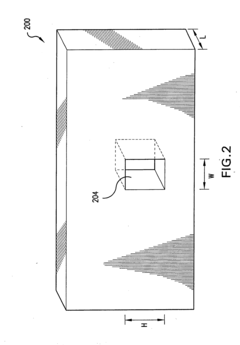

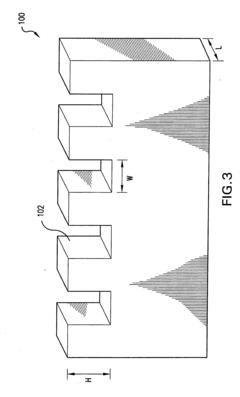

Method and systems for compact, micro-channel, laminar heat exchanging

PatentInactiveUS20080035319A1

Innovation

- A compact micro-channel heat exchanger with a heat conducting plate having channels with a channel length to hydraulic diameter ratio of less than 100, allowing for improved laminar flow and reduced pressure drop, which enhances heat transfer and reduces jitter.

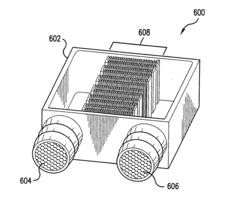

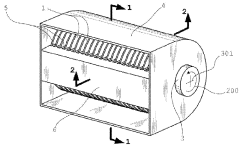

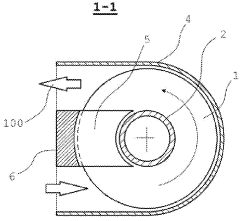

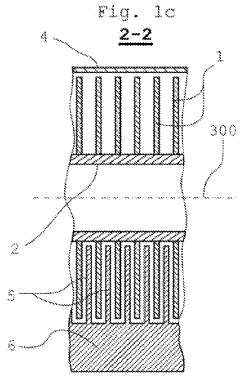

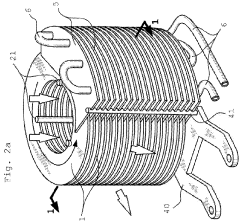

Multi-disk heat exchanger and fan unit

PatentActiveUS20180094869A1

Innovation

- A multi-disk heat exchanger system where rotating disks act as both a heat carrier and a fan, positioned between heat transferring fins, creating a laminar flow and reducing boundary layer resistance, allowing for enhanced heat transfer and fluid circulation within a housing that can envelop the thermal element and rotor.

Energy Efficiency and Sustainability Aspects

Laminar flow solutions in innovative cooling systems offer significant potential for enhancing energy efficiency and sustainability in various applications. These systems leverage the principles of laminar flow to minimize energy consumption while maximizing heat transfer efficiency. By reducing turbulence and optimizing fluid dynamics, laminar flow cooling systems can achieve superior thermal management with lower power requirements compared to conventional cooling methods.

One of the primary advantages of laminar flow cooling systems is their ability to reduce pumping power consumption. The smooth, predictable flow patterns characteristic of laminar flow result in lower friction losses and pressure drops within the cooling system. This translates to decreased energy demand for fluid circulation, contributing to overall system efficiency. In data centers and high-performance computing environments, where cooling accounts for a substantial portion of energy usage, the implementation of laminar flow solutions can lead to significant reductions in operational costs and carbon footprint.

Furthermore, laminar flow cooling systems often enable more precise temperature control, which is crucial for energy-efficient operation in sensitive applications such as electronics cooling and industrial processes. By maintaining optimal operating temperatures with minimal fluctuations, these systems can extend the lifespan of equipment and reduce the frequency of energy-intensive maintenance procedures.

The sustainability aspects of laminar flow cooling solutions extend beyond energy efficiency. These systems typically require smaller volumes of coolant compared to turbulent flow systems, reducing the environmental impact associated with coolant production, transportation, and disposal. Additionally, the enhanced heat transfer efficiency of laminar flow systems can lead to more compact cooling unit designs, minimizing material usage and the associated embodied energy.

In the context of renewable energy integration, laminar flow cooling systems show promise for improving the efficiency of solar panels and other heat-sensitive renewable technologies. By maintaining optimal operating temperatures more effectively, these cooling solutions can help maximize energy harvesting and conversion efficiencies in renewable energy systems, further contributing to sustainability goals.

As global emphasis on energy efficiency and sustainability continues to grow, the development and implementation of laminar flow cooling solutions represent a significant opportunity for innovation in thermal management. These systems align with broader sustainability initiatives by offering a pathway to reduce energy consumption, minimize resource usage, and enhance the overall environmental performance of cooling-dependent technologies across various sectors.

One of the primary advantages of laminar flow cooling systems is their ability to reduce pumping power consumption. The smooth, predictable flow patterns characteristic of laminar flow result in lower friction losses and pressure drops within the cooling system. This translates to decreased energy demand for fluid circulation, contributing to overall system efficiency. In data centers and high-performance computing environments, where cooling accounts for a substantial portion of energy usage, the implementation of laminar flow solutions can lead to significant reductions in operational costs and carbon footprint.

Furthermore, laminar flow cooling systems often enable more precise temperature control, which is crucial for energy-efficient operation in sensitive applications such as electronics cooling and industrial processes. By maintaining optimal operating temperatures with minimal fluctuations, these systems can extend the lifespan of equipment and reduce the frequency of energy-intensive maintenance procedures.

The sustainability aspects of laminar flow cooling solutions extend beyond energy efficiency. These systems typically require smaller volumes of coolant compared to turbulent flow systems, reducing the environmental impact associated with coolant production, transportation, and disposal. Additionally, the enhanced heat transfer efficiency of laminar flow systems can lead to more compact cooling unit designs, minimizing material usage and the associated embodied energy.

In the context of renewable energy integration, laminar flow cooling systems show promise for improving the efficiency of solar panels and other heat-sensitive renewable technologies. By maintaining optimal operating temperatures more effectively, these cooling solutions can help maximize energy harvesting and conversion efficiencies in renewable energy systems, further contributing to sustainability goals.

As global emphasis on energy efficiency and sustainability continues to grow, the development and implementation of laminar flow cooling solutions represent a significant opportunity for innovation in thermal management. These systems align with broader sustainability initiatives by offering a pathway to reduce energy consumption, minimize resource usage, and enhance the overall environmental performance of cooling-dependent technologies across various sectors.

Thermal Management Applications and Industries

Laminar flow cooling systems have found widespread applications across various industries, revolutionizing thermal management strategies. In the electronics sector, these innovative cooling solutions have become crucial for maintaining optimal operating temperatures in high-performance computing systems, data centers, and telecommunications equipment. The ability to efficiently dissipate heat from densely packed electronic components has enabled the development of more powerful and compact devices.

The automotive industry has also embraced laminar flow cooling technologies to enhance engine performance and fuel efficiency. Advanced cooling systems utilizing laminar flow principles have been integrated into electric vehicle battery packs, ensuring optimal temperature control and extending battery life. This application has played a significant role in overcoming thermal management challenges associated with electric vehicle adoption.

In the aerospace sector, laminar flow cooling systems have been instrumental in managing heat generated by aircraft engines and avionics. These systems have contributed to improved fuel efficiency, reduced emissions, and enhanced overall performance of modern aircraft. The ability to maintain stable temperatures in critical components has also increased the reliability and safety of aerospace applications.

The renewable energy industry has leveraged laminar flow cooling solutions to optimize the performance of solar panels and wind turbines. By effectively managing heat dissipation, these systems have helped increase the efficiency and longevity of renewable energy installations. This has been particularly important in regions with extreme climates, where temperature fluctuations can significantly impact energy production.

In the medical field, laminar flow cooling technologies have found applications in advanced imaging equipment, such as MRI machines and CT scanners. These systems ensure precise temperature control, maintaining the stability and accuracy of sensitive diagnostic instruments. Additionally, laminar flow cooling has been utilized in the development of innovative medical devices for targeted therapies and minimally invasive procedures.

The manufacturing sector has also benefited from laminar flow cooling applications, particularly in precision machining and additive manufacturing processes. These systems have enabled better control of thermal expansion and contraction, resulting in improved dimensional accuracy and overall product quality. In the chemical and pharmaceutical industries, laminar flow cooling has been employed in reactor design and process control, enhancing the efficiency and safety of chemical reactions and drug production.

The automotive industry has also embraced laminar flow cooling technologies to enhance engine performance and fuel efficiency. Advanced cooling systems utilizing laminar flow principles have been integrated into electric vehicle battery packs, ensuring optimal temperature control and extending battery life. This application has played a significant role in overcoming thermal management challenges associated with electric vehicle adoption.

In the aerospace sector, laminar flow cooling systems have been instrumental in managing heat generated by aircraft engines and avionics. These systems have contributed to improved fuel efficiency, reduced emissions, and enhanced overall performance of modern aircraft. The ability to maintain stable temperatures in critical components has also increased the reliability and safety of aerospace applications.

The renewable energy industry has leveraged laminar flow cooling solutions to optimize the performance of solar panels and wind turbines. By effectively managing heat dissipation, these systems have helped increase the efficiency and longevity of renewable energy installations. This has been particularly important in regions with extreme climates, where temperature fluctuations can significantly impact energy production.

In the medical field, laminar flow cooling technologies have found applications in advanced imaging equipment, such as MRI machines and CT scanners. These systems ensure precise temperature control, maintaining the stability and accuracy of sensitive diagnostic instruments. Additionally, laminar flow cooling has been utilized in the development of innovative medical devices for targeted therapies and minimally invasive procedures.

The manufacturing sector has also benefited from laminar flow cooling applications, particularly in precision machining and additive manufacturing processes. These systems have enabled better control of thermal expansion and contraction, resulting in improved dimensional accuracy and overall product quality. In the chemical and pharmaceutical industries, laminar flow cooling has been employed in reactor design and process control, enhancing the efficiency and safety of chemical reactions and drug production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!