Research on Vapor Chamber Surface Modification for Enhanced Performance

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Background and Enhancement Goals

Vapor chambers have emerged as critical thermal management solutions in modern electronics, evolving significantly since their initial development in the 1960s. These two-phase heat transfer devices utilize the principle of evaporation and condensation within a sealed, flat container to efficiently dissipate heat from high-power electronic components. The technology has progressed from simple heat pipes to sophisticated vapor chambers with complex internal structures, driven by the increasing thermal demands of miniaturized electronic devices.

The evolution of vapor chamber technology has been marked by several key milestones, including the development of sintered powder wick structures in the 1980s, the introduction of ultra-thin vapor chambers for mobile devices in the early 2000s, and recent advancements in manufacturing techniques enabling mass production. Current state-of-the-art vapor chambers feature thicknesses below 0.5mm while maintaining impressive thermal performance characteristics.

Industry trends indicate a growing focus on enhancing the fundamental heat transfer mechanisms within vapor chambers, particularly at the critical evaporator surface where heat enters the system. Surface modification techniques have emerged as a promising frontier for performance enhancement, with research exploring micro/nano-structured surfaces, hybrid wicking structures, and advanced coating technologies to overcome the limitations of conventional designs.

The primary technical goals for vapor chamber surface modification research include increasing the critical heat flux (CHF) to prevent dry-out conditions, reducing thermal resistance at the evaporator interface, enhancing capillary-driven liquid return to the evaporator, and improving overall system reliability under varying operational conditions. These improvements aim to address the thermal management challenges posed by next-generation electronics with power densities exceeding 500 W/cm².

Surface modification approaches under investigation range from physical texturing methods like etching, laser processing, and additive manufacturing to chemical treatments including hydrophilic/hydrophobic coatings and nanoparticle deposition. Biomimetic surface designs inspired by natural systems with exceptional liquid transport properties represent another innovative direction in this field.

The ultimate objective of vapor chamber surface modification research is to achieve a step-change improvement in thermal performance metrics, including a 30-50% increase in heat flux capacity, 20-30% reduction in thermal resistance, and enhanced operational stability across wider temperature ranges. These advancements would enable vapor chambers to support emerging applications in high-performance computing, electric vehicle power electronics, telecommunications infrastructure, and aerospace systems where thermal management requirements continue to become more demanding.

The evolution of vapor chamber technology has been marked by several key milestones, including the development of sintered powder wick structures in the 1980s, the introduction of ultra-thin vapor chambers for mobile devices in the early 2000s, and recent advancements in manufacturing techniques enabling mass production. Current state-of-the-art vapor chambers feature thicknesses below 0.5mm while maintaining impressive thermal performance characteristics.

Industry trends indicate a growing focus on enhancing the fundamental heat transfer mechanisms within vapor chambers, particularly at the critical evaporator surface where heat enters the system. Surface modification techniques have emerged as a promising frontier for performance enhancement, with research exploring micro/nano-structured surfaces, hybrid wicking structures, and advanced coating technologies to overcome the limitations of conventional designs.

The primary technical goals for vapor chamber surface modification research include increasing the critical heat flux (CHF) to prevent dry-out conditions, reducing thermal resistance at the evaporator interface, enhancing capillary-driven liquid return to the evaporator, and improving overall system reliability under varying operational conditions. These improvements aim to address the thermal management challenges posed by next-generation electronics with power densities exceeding 500 W/cm².

Surface modification approaches under investigation range from physical texturing methods like etching, laser processing, and additive manufacturing to chemical treatments including hydrophilic/hydrophobic coatings and nanoparticle deposition. Biomimetic surface designs inspired by natural systems with exceptional liquid transport properties represent another innovative direction in this field.

The ultimate objective of vapor chamber surface modification research is to achieve a step-change improvement in thermal performance metrics, including a 30-50% increase in heat flux capacity, 20-30% reduction in thermal resistance, and enhanced operational stability across wider temperature ranges. These advancements would enable vapor chambers to support emerging applications in high-performance computing, electric vehicle power electronics, telecommunications infrastructure, and aerospace systems where thermal management requirements continue to become more demanding.

Market Demand Analysis for High-Performance Thermal Solutions

The global thermal management market is experiencing unprecedented growth, driven primarily by the rapid advancement of high-performance computing systems, miniaturization of electronic devices, and increasing power densities. Current market analysis indicates that the thermal management solutions market is projected to reach $20.7 billion by 2025, growing at a CAGR of 8.2% from 2020. Within this broader market, vapor chamber technology represents one of the fastest-growing segments due to its superior heat dissipation capabilities compared to traditional heat pipes and heat sinks.

The demand for enhanced vapor chamber technology is particularly strong in several key sectors. The consumer electronics industry, especially premium smartphones and ultrabooks, is increasingly adopting vapor chamber solutions to manage thermal issues in thinner form factors. Market research shows that over 40% of flagship smartphones released in 2022 incorporated some form of vapor chamber cooling, compared to just 15% in 2019.

Data centers and server farms constitute another significant market driver, with cooling costs representing approximately 40% of their total operational expenses. The shift toward high-density computing and edge computing has intensified the need for more efficient thermal solutions that can handle localized heat loads exceeding 150 W/cm². Surface-modified vapor chambers offer the potential to reduce these costs while enabling higher computational densities.

The gaming hardware sector presents a particularly lucrative market opportunity, with gaming laptops and consoles requiring increasingly sophisticated thermal management solutions. The global gaming hardware market, valued at $36.2 billion in 2021, demands thermal solutions that can maintain optimal performance during extended high-load operations while remaining acoustically acceptable.

Automotive electronics, particularly in electric vehicles and autonomous driving systems, represent an emerging market with substantial growth potential. As power electronics in vehicles become more sophisticated, the thermal management requirements become more stringent, with operating temperatures needing to be maintained within ±5°C of optimal conditions.

Industry surveys indicate that engineers and product designers across these sectors are specifically seeking thermal solutions that offer 30-40% improvement in heat transfer efficiency without significant increases in size or weight. Surface modification of vapor chambers directly addresses this market need by enhancing the critical heat flux and reducing thermal resistance without altering the fundamental form factor.

The willingness to pay premium prices for advanced thermal solutions is evident in the market, with manufacturers accepting 15-25% cost increases for components that can demonstrably improve device performance and reliability. This price elasticity creates a favorable environment for the commercialization of surface-modified vapor chamber technology.

The demand for enhanced vapor chamber technology is particularly strong in several key sectors. The consumer electronics industry, especially premium smartphones and ultrabooks, is increasingly adopting vapor chamber solutions to manage thermal issues in thinner form factors. Market research shows that over 40% of flagship smartphones released in 2022 incorporated some form of vapor chamber cooling, compared to just 15% in 2019.

Data centers and server farms constitute another significant market driver, with cooling costs representing approximately 40% of their total operational expenses. The shift toward high-density computing and edge computing has intensified the need for more efficient thermal solutions that can handle localized heat loads exceeding 150 W/cm². Surface-modified vapor chambers offer the potential to reduce these costs while enabling higher computational densities.

The gaming hardware sector presents a particularly lucrative market opportunity, with gaming laptops and consoles requiring increasingly sophisticated thermal management solutions. The global gaming hardware market, valued at $36.2 billion in 2021, demands thermal solutions that can maintain optimal performance during extended high-load operations while remaining acoustically acceptable.

Automotive electronics, particularly in electric vehicles and autonomous driving systems, represent an emerging market with substantial growth potential. As power electronics in vehicles become more sophisticated, the thermal management requirements become more stringent, with operating temperatures needing to be maintained within ±5°C of optimal conditions.

Industry surveys indicate that engineers and product designers across these sectors are specifically seeking thermal solutions that offer 30-40% improvement in heat transfer efficiency without significant increases in size or weight. Surface modification of vapor chambers directly addresses this market need by enhancing the critical heat flux and reducing thermal resistance without altering the fundamental form factor.

The willingness to pay premium prices for advanced thermal solutions is evident in the market, with manufacturers accepting 15-25% cost increases for components that can demonstrably improve device performance and reliability. This price elasticity creates a favorable environment for the commercialization of surface-modified vapor chamber technology.

Current Status and Challenges in Vapor Chamber Surface Modification

Vapor chamber technology has witnessed significant advancements globally, with surface modification emerging as a critical area for performance enhancement. Current research indicates that conventional vapor chambers face limitations in thermal conductivity and heat dissipation efficiency, particularly in high-power density applications. The primary challenge lies in the wicking structure design, which directly impacts the capillary pressure and fluid transport capabilities within the chamber.

International research institutions, predominantly in the United States, Japan, China, and South Korea, have made substantial progress in surface modification techniques. These include micro/nano-structured surfaces, hydrophilic/hydrophobic patterning, and advanced coating technologies. However, the integration of these modifications into mass production remains problematic due to scalability issues and manufacturing complexity.

Material compatibility presents another significant challenge, as surface modifications must withstand the working fluid's chemical properties while maintaining long-term stability under thermal cycling conditions. Research indicates that degradation of modified surfaces over time can lead to decreased performance and reliability concerns, particularly in applications requiring extended operational lifespans.

The thermal interface between the vapor chamber and heat source represents a persistent bottleneck. Current surface modification approaches have not fully resolved the contact resistance issues, resulting in suboptimal thermal transfer at critical junctions. This limitation becomes increasingly pronounced as device power densities continue to escalate in modern electronics.

Fabrication techniques for precise surface modification at scale constitute a major technical hurdle. While laboratory demonstrations have shown promising results with techniques such as laser texturing, chemical etching, and plasma treatment, translating these processes to high-volume manufacturing environments presents significant challenges in terms of cost, consistency, and quality control.

Environmental and regulatory considerations further complicate advancement in this field. Many effective surface treatments involve chemicals or processes with environmental implications, necessitating the development of more sustainable alternatives that maintain performance benefits while meeting increasingly stringent regulatory requirements.

The geographical distribution of vapor chamber surface modification technology shows concentration in East Asia for manufacturing implementation, while fundamental research is more evenly distributed across North America, Europe, and Asia. This distribution creates challenges in technology transfer and commercialization pathways, often resulting in delays between research breakthroughs and market implementation.

International research institutions, predominantly in the United States, Japan, China, and South Korea, have made substantial progress in surface modification techniques. These include micro/nano-structured surfaces, hydrophilic/hydrophobic patterning, and advanced coating technologies. However, the integration of these modifications into mass production remains problematic due to scalability issues and manufacturing complexity.

Material compatibility presents another significant challenge, as surface modifications must withstand the working fluid's chemical properties while maintaining long-term stability under thermal cycling conditions. Research indicates that degradation of modified surfaces over time can lead to decreased performance and reliability concerns, particularly in applications requiring extended operational lifespans.

The thermal interface between the vapor chamber and heat source represents a persistent bottleneck. Current surface modification approaches have not fully resolved the contact resistance issues, resulting in suboptimal thermal transfer at critical junctions. This limitation becomes increasingly pronounced as device power densities continue to escalate in modern electronics.

Fabrication techniques for precise surface modification at scale constitute a major technical hurdle. While laboratory demonstrations have shown promising results with techniques such as laser texturing, chemical etching, and plasma treatment, translating these processes to high-volume manufacturing environments presents significant challenges in terms of cost, consistency, and quality control.

Environmental and regulatory considerations further complicate advancement in this field. Many effective surface treatments involve chemicals or processes with environmental implications, necessitating the development of more sustainable alternatives that maintain performance benefits while meeting increasingly stringent regulatory requirements.

The geographical distribution of vapor chamber surface modification technology shows concentration in East Asia for manufacturing implementation, while fundamental research is more evenly distributed across North America, Europe, and Asia. This distribution creates challenges in technology transfer and commercialization pathways, often resulting in delays between research breakthroughs and market implementation.

Current Surface Modification Techniques for Vapor Chambers

01 Thermal design and heat dissipation efficiency

Vapor chambers are designed to efficiently dissipate heat in electronic devices. The performance of vapor chambers can be enhanced through optimized thermal design, including improved wick structures, working fluid selection, and chamber geometry. These design elements contribute to better heat transfer capabilities, reduced thermal resistance, and more efficient cooling of electronic components.- Thermal design and heat dissipation efficiency: Vapor chambers are designed to efficiently dissipate heat in electronic devices. The thermal performance of vapor chambers depends on factors such as the internal structure, working fluid, and wick design. Advanced designs incorporate optimized vapor flow channels and condensation surfaces to enhance heat transfer capabilities. These improvements allow for better thermal management in high-power density applications, resulting in more efficient cooling solutions.

- Structural innovations for improved performance: Innovative structural designs in vapor chambers can significantly enhance their performance. These include multi-layer structures, composite materials, and specialized internal configurations that optimize the phase change process. Some designs incorporate support structures to prevent chamber collapse under vacuum while maintaining efficient vapor flow. These structural innovations help to increase the effective thermal conductivity and overall heat transfer capacity of vapor chambers.

- Integration with electronic devices and cooling systems: Vapor chambers are increasingly integrated into electronic devices and cooling systems to manage thermal loads. The performance of these integrated solutions depends on the interface quality between the vapor chamber and heat source, as well as the overall system design. Advanced integration techniques include direct contact with heat-generating components and combination with other cooling technologies such as heat sinks and fans. These integrated approaches provide comprehensive thermal management solutions for modern electronic devices.

- Working fluid selection and optimization: The selection and optimization of working fluids significantly impact vapor chamber performance. Different fluids offer varying thermodynamic properties that affect heat transfer efficiency, operating temperature range, and long-term reliability. Research focuses on developing fluids with high latent heat of vaporization, appropriate vapor pressure characteristics, and compatibility with chamber materials. Some advanced designs use engineered fluids or fluid mixtures to achieve optimal performance across different operating conditions.

- Performance monitoring and testing methodologies: Accurate performance monitoring and testing methodologies are essential for evaluating vapor chamber efficiency. These include thermal imaging, temperature sensors, and computational fluid dynamics simulations to assess heat distribution and transfer rates. Standardized testing protocols help compare different vapor chamber designs under consistent conditions. Advanced monitoring systems can provide real-time performance data, allowing for adaptive thermal management strategies and optimization of cooling system operation.

02 Structural innovations for vapor chambers

Structural innovations in vapor chambers focus on improving their physical characteristics to enhance performance. These innovations include novel chamber shapes, reinforcement structures to prevent collapse under vacuum, and integration methods with heat sinks or heat pipes. Advanced manufacturing techniques allow for thinner profiles and custom shapes that can fit into space-constrained electronic devices while maintaining optimal heat transfer efficiency.Expand Specific Solutions03 Working fluid compositions and circulation mechanisms

The selection and composition of working fluids significantly impact vapor chamber performance. Research focuses on developing fluid mixtures with optimal phase change properties, low viscosity for better circulation, and compatibility with chamber materials. Advanced circulation mechanisms, including capillary structures and micro-channels, enhance fluid movement within the chamber, resulting in improved heat transfer and more uniform temperature distribution.Expand Specific Solutions04 Performance testing and evaluation methods

Various methods and systems have been developed to test and evaluate vapor chamber performance. These include thermal imaging, temperature sensors, computational fluid dynamics simulations, and standardized testing protocols. Performance metrics such as thermal resistance, temperature uniformity, response time, and long-term reliability are measured to assess vapor chamber efficiency under different operating conditions and heat loads.Expand Specific Solutions05 Integration with electronic devices and cooling systems

Vapor chambers are increasingly integrated into comprehensive cooling solutions for electronic devices. Integration approaches include direct attachment to processors or high-heat components, combination with traditional cooling methods like fans or heat sinks, and incorporation into portable devices with space constraints. Advanced designs focus on optimizing the interface between vapor chambers and heat sources to minimize thermal resistance and maximize heat transfer efficiency.Expand Specific Solutions

Key Industry Players in Advanced Thermal Management Solutions

The vapor chamber surface modification technology market is currently in a growth phase, characterized by increasing demand for enhanced thermal management solutions in electronics and automotive sectors. The market size is expanding rapidly, driven by the need for more efficient cooling systems in high-performance devices. From a technological maturity perspective, companies like Furukawa Electric, Cooler Master, and Asia Vital Components are leading with established vapor chamber technologies, while Applied Materials and Tokyo Electron are advancing manufacturing processes. Research institutions such as North Carolina State University and University of Science & Technology Beijing are contributing fundamental innovations. Companies including Nidec, BorgWarner, and Mitsubishi Motors are integrating these technologies into automotive applications, indicating cross-industry adoption. The competitive landscape shows a mix of specialized thermal solution providers and diversified technology corporations exploring surface modification techniques to enhance heat dissipation efficiency.

Furukawa Electric Co., Ltd.

Technical Solution: Furukawa Electric has developed advanced vapor chamber technology with proprietary surface modification techniques that enhance thermal performance. Their approach involves nano-scale etching and coating processes to create optimized wicking structures on the internal surfaces of vapor chambers. The company utilizes a multi-layer sintering process to create porous copper structures with precisely controlled pore size distribution, which significantly improves capillary action and fluid transport. Their research has demonstrated that these modified surfaces can increase heat transfer coefficients by up to 40% compared to conventional designs. Furukawa has also pioneered the use of hydrophilic coatings with specific surface energy characteristics to enhance condensation and evaporation processes within the vapor chamber, resulting in more efficient phase change dynamics and reduced thermal resistance.

Strengths: Superior wicking structure design that enhances capillary action; proprietary nano-scale surface treatments that significantly improve heat transfer efficiency; established manufacturing capabilities for mass production. Weaknesses: Higher production costs compared to conventional heat pipes; more complex manufacturing process requiring specialized equipment; potential durability concerns with some surface treatments over extended operational lifetimes.

Cooler Master Co. Ltd.

Technical Solution: Cooler Master has developed innovative vapor chamber surface modification technologies focused on consumer electronics cooling applications. Their approach combines micro-structured copper mesh designs with specialized plasma treatment processes to create enhanced wicking surfaces. The company's research has focused on creating bionic-inspired surface patterns that mimic natural heat dissipation structures found in certain plant species. These biomimetic surfaces feature hierarchical micro-nano structures that optimize liquid return to evaporation zones. Cooler Master has also developed proprietary coating technologies that modify the surface energy characteristics of the internal vapor chamber walls, creating hydrophilic regions for evaporation and controlled hydrophobic regions for condensation. Their testing shows these modifications can improve thermal performance by 25-35% in thin form factor applications typical in gaming laptops and high-performance computing devices.

Strengths: Extensive experience in consumer electronics thermal solutions; innovative biomimetic surface designs that enhance capillary action; cost-effective manufacturing processes suitable for consumer products. Weaknesses: Less research depth compared to specialized industrial manufacturers; technologies primarily optimized for consumer electronics rather than industrial applications; limited in-house fundamental research capabilities.

Critical Patents and Research in Vapor Chamber Surface Engineering

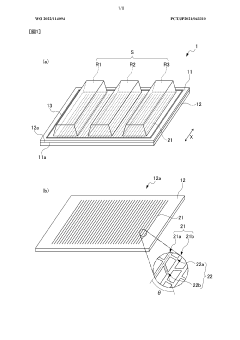

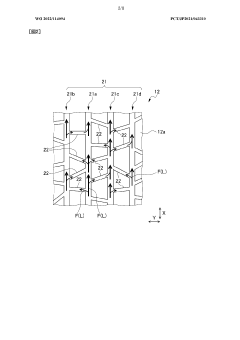

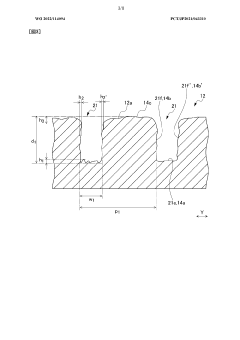

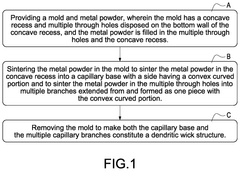

Vapor chamber and method for manufacturing vapor chamber

PatentWO2022114094A1

Innovation

- The vapor chamber design features main grooves and communication grooves with irregular arrangement pitches and widths, along with micro-rugged surfaces, to enhance capillary action and fluid flow, allowing for efficient transport of the working fluid and increased heat transfer, with manufacturing involving laser processing to form these grooves.

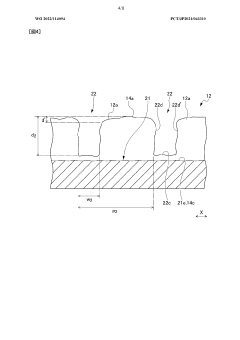

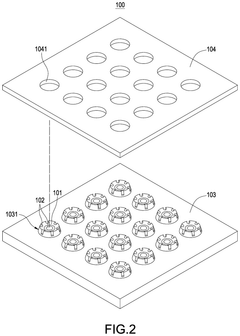

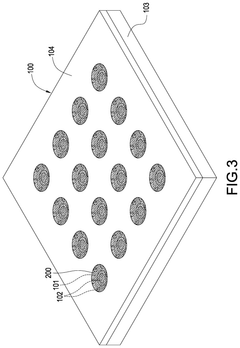

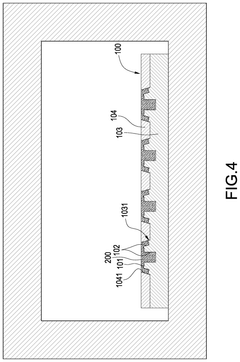

Vapor chamber and dendritic wick structure thereof

PatentPendingUS20250207865A1

Innovation

- A vapor chamber with a dendritic wick structure featuring multiple capillary branches and convex curved portions to increase cooling surface area, enhancing the evaporation process and improving heat exchange efficiency.

Environmental Impact and Sustainability Considerations

The environmental impact of vapor chamber technology extends beyond its thermal performance benefits, encompassing the entire lifecycle from raw material extraction to end-of-life disposal. Surface modification techniques, while enhancing thermal efficiency, introduce additional environmental considerations that must be carefully evaluated. Traditional manufacturing processes for vapor chambers often involve chemical etching, electroplating, and other treatments that utilize hazardous substances such as acids, heavy metals, and volatile organic compounds (VOCs).

Recent advancements in environmentally friendly surface modification techniques have shown promising results. Plasma-based treatments offer a cleaner alternative to chemical processes, significantly reducing waste generation and hazardous material usage. Similarly, hydrophilic coating methods using water-based solutions present lower environmental risks compared to solvent-based approaches. These sustainable modifications not only reduce environmental impact but also improve workplace safety conditions.

Energy consumption during the manufacturing process represents another critical environmental factor. Surface modification techniques vary considerably in their energy requirements, with some advanced methods demanding substantial power input. However, this initial energy investment must be balanced against the lifetime energy savings achieved through improved thermal management in electronic devices. Studies indicate that enhanced vapor chamber performance can reduce overall device energy consumption by 5-15%, depending on application specifics.

Material selection for surface modification plays a crucial role in sustainability. Bio-inspired surface textures created using biodegradable templates offer an innovative approach to reducing environmental footprint. Additionally, the use of recyclable materials in vapor chamber construction facilitates end-of-life recovery and reprocessing. Research into copper alternatives and recycling processes has demonstrated potential for reducing primary resource extraction while maintaining thermal performance.

The longevity of modified vapor chamber surfaces directly impacts sustainability through extended product lifecycles. Surface treatments that enhance corrosion resistance and mechanical durability contribute to longer operational lifespans, reducing electronic waste generation. Furthermore, improvements in manufacturing precision have enabled thinner, more material-efficient vapor chamber designs that maintain or exceed the performance of conventional solutions while using fewer raw materials.

Regulatory compliance represents an increasingly important consideration for vapor chamber technology development. Global restrictions on hazardous substances, such as those outlined in RoHS and REACH regulations, are driving innovation toward greener surface modification approaches. Forward-thinking manufacturers are proactively developing compliant solutions that anticipate future environmental legislation, positioning themselves advantageously in an increasingly eco-conscious market landscape.

Recent advancements in environmentally friendly surface modification techniques have shown promising results. Plasma-based treatments offer a cleaner alternative to chemical processes, significantly reducing waste generation and hazardous material usage. Similarly, hydrophilic coating methods using water-based solutions present lower environmental risks compared to solvent-based approaches. These sustainable modifications not only reduce environmental impact but also improve workplace safety conditions.

Energy consumption during the manufacturing process represents another critical environmental factor. Surface modification techniques vary considerably in their energy requirements, with some advanced methods demanding substantial power input. However, this initial energy investment must be balanced against the lifetime energy savings achieved through improved thermal management in electronic devices. Studies indicate that enhanced vapor chamber performance can reduce overall device energy consumption by 5-15%, depending on application specifics.

Material selection for surface modification plays a crucial role in sustainability. Bio-inspired surface textures created using biodegradable templates offer an innovative approach to reducing environmental footprint. Additionally, the use of recyclable materials in vapor chamber construction facilitates end-of-life recovery and reprocessing. Research into copper alternatives and recycling processes has demonstrated potential for reducing primary resource extraction while maintaining thermal performance.

The longevity of modified vapor chamber surfaces directly impacts sustainability through extended product lifecycles. Surface treatments that enhance corrosion resistance and mechanical durability contribute to longer operational lifespans, reducing electronic waste generation. Furthermore, improvements in manufacturing precision have enabled thinner, more material-efficient vapor chamber designs that maintain or exceed the performance of conventional solutions while using fewer raw materials.

Regulatory compliance represents an increasingly important consideration for vapor chamber technology development. Global restrictions on hazardous substances, such as those outlined in RoHS and REACH regulations, are driving innovation toward greener surface modification approaches. Forward-thinking manufacturers are proactively developing compliant solutions that anticipate future environmental legislation, positioning themselves advantageously in an increasingly eco-conscious market landscape.

Manufacturing Scalability and Cost Analysis

The scalability of vapor chamber manufacturing processes incorporating surface modification techniques presents both significant opportunities and challenges for mass production. Current manufacturing methods for traditional vapor chambers typically involve stamping, etching, and diffusion bonding processes that are well-established in industry. However, introducing surface modification techniques such as micro/nanostructure fabrication, hydrophilic/hydrophobic patterning, or advanced coating applications requires additional processing steps that impact both production efficiency and cost structures.

Analysis of manufacturing scalability reveals that certain surface modification techniques are more amenable to mass production than others. Plasma treatment and chemical etching processes can be relatively easily integrated into existing production lines with moderate capital investment. These methods offer good throughput rates and consistent quality when properly controlled. In contrast, more sophisticated techniques such as laser texturing or lithography-based approaches currently face throughput limitations that restrict their application to lower-volume, higher-value products.

Cost analysis indicates that material selection significantly influences the economic viability of surface-modified vapor chambers. While copper remains the predominant material for vapor chamber construction due to its excellent thermal conductivity, the addition of specialized coatings or surface treatments can increase material costs by 15-30%. Labor costs also increase with process complexity, particularly for multi-step modification techniques that require precise control and specialized equipment operation.

Equipment investment represents another critical cost factor. Implementing advanced surface modification capabilities typically requires specialized machinery with costs ranging from $200,000 to several million dollars depending on the technology and production capacity. Manufacturers must carefully evaluate the return on investment timeline, which our analysis suggests ranges from 2-5 years depending on production volume and target market segments.

Energy consumption during manufacturing increases with the addition of surface modification processes, particularly for techniques requiring high-temperature treatment or vacuum environments. This translates to approximately 10-25% higher energy costs compared to conventional vapor chamber production, though this can be partially offset by improved product performance and potential material savings in some designs.

Quality control requirements also escalate with surface modification complexity. Inspection systems capable of verifying micro/nanoscale features add to both capital and operational expenses. Rejection rates during early implementation phases typically range from 8-15% before process optimization, compared to 3-5% for conventional vapor chamber manufacturing, representing a significant cost factor that diminishes with production maturity and process refinement.

Analysis of manufacturing scalability reveals that certain surface modification techniques are more amenable to mass production than others. Plasma treatment and chemical etching processes can be relatively easily integrated into existing production lines with moderate capital investment. These methods offer good throughput rates and consistent quality when properly controlled. In contrast, more sophisticated techniques such as laser texturing or lithography-based approaches currently face throughput limitations that restrict their application to lower-volume, higher-value products.

Cost analysis indicates that material selection significantly influences the economic viability of surface-modified vapor chambers. While copper remains the predominant material for vapor chamber construction due to its excellent thermal conductivity, the addition of specialized coatings or surface treatments can increase material costs by 15-30%. Labor costs also increase with process complexity, particularly for multi-step modification techniques that require precise control and specialized equipment operation.

Equipment investment represents another critical cost factor. Implementing advanced surface modification capabilities typically requires specialized machinery with costs ranging from $200,000 to several million dollars depending on the technology and production capacity. Manufacturers must carefully evaluate the return on investment timeline, which our analysis suggests ranges from 2-5 years depending on production volume and target market segments.

Energy consumption during manufacturing increases with the addition of surface modification processes, particularly for techniques requiring high-temperature treatment or vacuum environments. This translates to approximately 10-25% higher energy costs compared to conventional vapor chamber production, though this can be partially offset by improved product performance and potential material savings in some designs.

Quality control requirements also escalate with surface modification complexity. Inspection systems capable of verifying micro/nanoscale features add to both capital and operational expenses. Rejection rates during early implementation phases typically range from 8-15% before process optimization, compared to 3-5% for conventional vapor chamber manufacturing, representing a significant cost factor that diminishes with production maturity and process refinement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!