Sodium silicate impact on organic dye removal from wastewater

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate in Wastewater Treatment: Background and Objectives

Sodium silicate, also known as water glass or liquid glass, has emerged as a significant component in wastewater treatment processes, particularly in the removal of organic dyes. The increasing global concern over water pollution has driven extensive research and development in this field, with a focus on efficient and cost-effective treatment methods.

The use of sodium silicate in wastewater treatment dates back to the early 20th century, but its application in organic dye removal has gained prominence in recent decades. This surge in interest is primarily due to the growing textile industry and the consequent increase in dye-contaminated wastewater. The textile sector alone accounts for approximately 20% of global industrial water pollution, making it a critical area for technological intervention.

The evolution of sodium silicate-based treatment methods has been marked by significant milestones. Initially, it was used as a simple coagulant aid. However, advancements in material science and nanotechnology have led to the development of more sophisticated applications, such as the creation of mesoporous silica adsorbents and silica-based nanocomposites.

The primary objective of utilizing sodium silicate in organic dye removal is to achieve high removal efficiency while maintaining cost-effectiveness and environmental sustainability. Researchers aim to develop methods that can handle a wide range of dye molecules, operate under various pH conditions, and be easily integrated into existing wastewater treatment systems.

Current technological goals in this field include enhancing the adsorption capacity of silica-based materials, improving their selectivity towards specific dye molecules, and developing regeneration techniques to extend the lifespan of these adsorbents. There is also a growing emphasis on creating multifunctional materials that can simultaneously remove dyes and other pollutants, such as heavy metals.

The environmental impact of the treatment process itself is another crucial consideration. Efforts are being made to ensure that the use of sodium silicate in wastewater treatment does not introduce new environmental challenges. This includes research into the recovery and recycling of spent adsorbents and the development of bio-inspired silica materials that are more environmentally friendly.

As we look towards the future, the integration of sodium silicate-based technologies with other advanced treatment methods, such as photocatalysis and membrane filtration, presents exciting possibilities. The ultimate aim is to develop a comprehensive, efficient, and sustainable solution for organic dye removal from wastewater, addressing one of the most pressing environmental challenges of our time.

The use of sodium silicate in wastewater treatment dates back to the early 20th century, but its application in organic dye removal has gained prominence in recent decades. This surge in interest is primarily due to the growing textile industry and the consequent increase in dye-contaminated wastewater. The textile sector alone accounts for approximately 20% of global industrial water pollution, making it a critical area for technological intervention.

The evolution of sodium silicate-based treatment methods has been marked by significant milestones. Initially, it was used as a simple coagulant aid. However, advancements in material science and nanotechnology have led to the development of more sophisticated applications, such as the creation of mesoporous silica adsorbents and silica-based nanocomposites.

The primary objective of utilizing sodium silicate in organic dye removal is to achieve high removal efficiency while maintaining cost-effectiveness and environmental sustainability. Researchers aim to develop methods that can handle a wide range of dye molecules, operate under various pH conditions, and be easily integrated into existing wastewater treatment systems.

Current technological goals in this field include enhancing the adsorption capacity of silica-based materials, improving their selectivity towards specific dye molecules, and developing regeneration techniques to extend the lifespan of these adsorbents. There is also a growing emphasis on creating multifunctional materials that can simultaneously remove dyes and other pollutants, such as heavy metals.

The environmental impact of the treatment process itself is another crucial consideration. Efforts are being made to ensure that the use of sodium silicate in wastewater treatment does not introduce new environmental challenges. This includes research into the recovery and recycling of spent adsorbents and the development of bio-inspired silica materials that are more environmentally friendly.

As we look towards the future, the integration of sodium silicate-based technologies with other advanced treatment methods, such as photocatalysis and membrane filtration, presents exciting possibilities. The ultimate aim is to develop a comprehensive, efficient, and sustainable solution for organic dye removal from wastewater, addressing one of the most pressing environmental challenges of our time.

Market Demand for Organic Dye Removal Solutions

The global market for organic dye removal solutions in wastewater treatment has been experiencing significant growth due to increasing environmental regulations and growing awareness of water pollution issues. Industries such as textiles, paper and pulp, leather, and printing are major contributors to organic dye pollution in water bodies, driving the demand for effective treatment solutions.

The textile industry, in particular, represents a substantial portion of the market demand for organic dye removal technologies. With the rapid expansion of fast fashion and increasing textile production in developing countries, the need for efficient and cost-effective dye removal solutions has become more pressing. Environmental regulations in many countries now require industries to treat their wastewater before discharge, further boosting the market for dye removal technologies.

In recent years, there has been a shift towards more sustainable and eco-friendly dye removal methods. This trend has led to increased interest in technologies that not only remove dyes effectively but also allow for water reuse and resource recovery. Sodium silicate-based solutions have gained attention in this context due to their potential for both dye removal and water treatment.

The market demand for organic dye removal solutions is also influenced by the type and complexity of dyes used in various industries. As new, more complex dyes are developed to meet consumer demands for vibrant and long-lasting colors, the need for advanced removal technologies grows. This has created opportunities for innovative solutions that can handle a wide range of dye types and concentrations.

Geographically, the Asia-Pacific region dominates the market demand for organic dye removal solutions, primarily due to the high concentration of textile and other dye-intensive industries in countries like China, India, and Bangladesh. However, stringent environmental regulations in North America and Europe are also driving significant market growth in these regions.

The increasing focus on circular economy principles and zero liquid discharge (ZLD) systems in industrial processes is another factor shaping market demand. Industries are seeking solutions that not only remove dyes but also allow for the recovery and reuse of water and valuable chemicals, aligning with sustainability goals and potentially reducing operational costs.

As water scarcity becomes a growing concern globally, the demand for technologies that enable water reuse in industrial processes is expected to rise. This trend is likely to favor solutions that offer both effective dye removal and water purification capabilities, potentially positioning sodium silicate-based technologies as attractive options in the market.

The textile industry, in particular, represents a substantial portion of the market demand for organic dye removal technologies. With the rapid expansion of fast fashion and increasing textile production in developing countries, the need for efficient and cost-effective dye removal solutions has become more pressing. Environmental regulations in many countries now require industries to treat their wastewater before discharge, further boosting the market for dye removal technologies.

In recent years, there has been a shift towards more sustainable and eco-friendly dye removal methods. This trend has led to increased interest in technologies that not only remove dyes effectively but also allow for water reuse and resource recovery. Sodium silicate-based solutions have gained attention in this context due to their potential for both dye removal and water treatment.

The market demand for organic dye removal solutions is also influenced by the type and complexity of dyes used in various industries. As new, more complex dyes are developed to meet consumer demands for vibrant and long-lasting colors, the need for advanced removal technologies grows. This has created opportunities for innovative solutions that can handle a wide range of dye types and concentrations.

Geographically, the Asia-Pacific region dominates the market demand for organic dye removal solutions, primarily due to the high concentration of textile and other dye-intensive industries in countries like China, India, and Bangladesh. However, stringent environmental regulations in North America and Europe are also driving significant market growth in these regions.

The increasing focus on circular economy principles and zero liquid discharge (ZLD) systems in industrial processes is another factor shaping market demand. Industries are seeking solutions that not only remove dyes but also allow for the recovery and reuse of water and valuable chemicals, aligning with sustainability goals and potentially reducing operational costs.

As water scarcity becomes a growing concern globally, the demand for technologies that enable water reuse in industrial processes is expected to rise. This trend is likely to favor solutions that offer both effective dye removal and water purification capabilities, potentially positioning sodium silicate-based technologies as attractive options in the market.

Current Challenges in Organic Dye Removal Technologies

The removal of organic dyes from wastewater presents several significant challenges in current treatment technologies. One of the primary obstacles is the complex and diverse nature of organic dyes, which vary widely in chemical structure, molecular weight, and reactivity. This diversity makes it difficult to develop a single, universally effective treatment method.

Adsorption, a commonly used technique, faces limitations in terms of adsorbent capacity and selectivity. Many adsorbents struggle to effectively remove a broad spectrum of dyes, particularly those with high molecular weights or complex structures. Additionally, the regeneration of spent adsorbents often proves costly and energy-intensive, raising concerns about the long-term sustainability of this approach.

Advanced oxidation processes (AOPs), while promising, encounter challenges related to high energy consumption and the potential formation of toxic by-products. The efficiency of AOPs can be significantly affected by the presence of other organic compounds or ions in the wastewater, leading to inconsistent treatment results. Moreover, the high operational costs associated with these processes often limit their large-scale implementation.

Membrane filtration technologies, such as nanofiltration and reverse osmosis, face issues with membrane fouling and high energy requirements. The accumulation of dye molecules on membrane surfaces can drastically reduce filtration efficiency over time, necessitating frequent cleaning or replacement of membranes. This not only increases operational costs but also generates additional waste streams that require further treatment.

Biological treatment methods, while environmentally friendly, often struggle with the recalcitrant nature of many synthetic dyes. The complex molecular structures of these dyes can resist biodegradation, leading to incomplete removal or extended treatment times. Furthermore, some dyes and their breakdown products may be toxic to the microorganisms used in biological treatment systems, further complicating the process.

The presence of sodium silicate in wastewater introduces additional challenges to organic dye removal. Sodium silicate can interfere with various treatment processes by altering the pH of the solution, forming complexes with dye molecules, or competing for adsorption sites on treatment materials. This interference can significantly reduce the efficiency of conventional treatment methods and necessitate the development of specialized approaches to address both dye removal and silicate management simultaneously.

In conclusion, the current challenges in organic dye removal technologies stem from the diverse nature of dyes, limitations of existing treatment methods, and the presence of interfering substances like sodium silicate. Overcoming these challenges requires innovative approaches that can address multiple aspects of wastewater treatment simultaneously, balancing efficiency, cost-effectiveness, and environmental sustainability.

Adsorption, a commonly used technique, faces limitations in terms of adsorbent capacity and selectivity. Many adsorbents struggle to effectively remove a broad spectrum of dyes, particularly those with high molecular weights or complex structures. Additionally, the regeneration of spent adsorbents often proves costly and energy-intensive, raising concerns about the long-term sustainability of this approach.

Advanced oxidation processes (AOPs), while promising, encounter challenges related to high energy consumption and the potential formation of toxic by-products. The efficiency of AOPs can be significantly affected by the presence of other organic compounds or ions in the wastewater, leading to inconsistent treatment results. Moreover, the high operational costs associated with these processes often limit their large-scale implementation.

Membrane filtration technologies, such as nanofiltration and reverse osmosis, face issues with membrane fouling and high energy requirements. The accumulation of dye molecules on membrane surfaces can drastically reduce filtration efficiency over time, necessitating frequent cleaning or replacement of membranes. This not only increases operational costs but also generates additional waste streams that require further treatment.

Biological treatment methods, while environmentally friendly, often struggle with the recalcitrant nature of many synthetic dyes. The complex molecular structures of these dyes can resist biodegradation, leading to incomplete removal or extended treatment times. Furthermore, some dyes and their breakdown products may be toxic to the microorganisms used in biological treatment systems, further complicating the process.

The presence of sodium silicate in wastewater introduces additional challenges to organic dye removal. Sodium silicate can interfere with various treatment processes by altering the pH of the solution, forming complexes with dye molecules, or competing for adsorption sites on treatment materials. This interference can significantly reduce the efficiency of conventional treatment methods and necessitate the development of specialized approaches to address both dye removal and silicate management simultaneously.

In conclusion, the current challenges in organic dye removal technologies stem from the diverse nature of dyes, limitations of existing treatment methods, and the presence of interfering substances like sodium silicate. Overcoming these challenges requires innovative approaches that can address multiple aspects of wastewater treatment simultaneously, balancing efficiency, cost-effectiveness, and environmental sustainability.

Existing Sodium Silicate-based Treatment Solutions

01 Use of sodium silicate for organic dye removal

Sodium silicate is utilized as an effective agent for removing organic dyes from various substrates. Its alkaline nature and adsorption properties make it suitable for breaking down and extracting dye molecules from materials such as textiles, wastewater, and industrial effluents.- Use of sodium silicate for organic dye removal: Sodium silicate is utilized as an effective agent for removing organic dyes from various substrates. Its alkaline properties and ability to form insoluble complexes with dyes make it suitable for this application. The process often involves mixing sodium silicate with other compounds to enhance its dye removal efficiency.

- Combination of sodium silicate with oxidizing agents: The combination of sodium silicate with oxidizing agents, such as hydrogen peroxide or sodium hypochlorite, enhances the organic dye removal process. This synergistic effect leads to more efficient degradation and removal of dyes from wastewater or textile materials.

- Sodium silicate in adsorption-based dye removal systems: Sodium silicate is used in the preparation of adsorbent materials for organic dye removal. It can be incorporated into composite materials or used to modify existing adsorbents, improving their capacity and selectivity for dye molecules.

- pH adjustment using sodium silicate for dye removal: Sodium silicate is employed to adjust the pH of dye-containing solutions, creating optimal conditions for dye removal. The alkaline environment promoted by sodium silicate can facilitate dye precipitation or enhance the effectiveness of other treatment methods.

- Sodium silicate in membrane-based dye removal processes: Sodium silicate is utilized in the development and modification of membranes for organic dye removal. It can be incorporated into membrane materials or used in pretreatment processes to improve membrane performance and longevity in dye removal applications.

02 Combination of sodium silicate with other chemicals for enhanced dye removal

The efficiency of organic dye removal can be improved by combining sodium silicate with other chemicals such as hydrogen peroxide, activated carbon, or specific enzymes. These combinations create synergistic effects that enhance the overall dye removal process.Expand Specific Solutions03 Development of novel sodium silicate-based adsorbents

Researchers have developed novel adsorbents based on modified sodium silicate structures, such as nanoparticles or composite materials. These advanced adsorbents exhibit improved surface area and selectivity for organic dye removal compared to conventional sodium silicate.Expand Specific Solutions04 Optimization of process parameters for sodium silicate-based dye removal

Studies have focused on optimizing various process parameters such as pH, temperature, contact time, and sodium silicate concentration to maximize the efficiency of organic dye removal. These optimized conditions enhance the overall performance of sodium silicate in dye removal applications.Expand Specific Solutions05 Integration of sodium silicate in wastewater treatment systems

Sodium silicate has been incorporated into various wastewater treatment systems and processes for large-scale organic dye removal. This integration involves the design of specialized reactors, filtration units, and recovery systems to effectively utilize sodium silicate in industrial-scale applications.Expand Specific Solutions

Key Players in Wastewater Treatment Industry

The competitive landscape for sodium silicate's impact on organic dye removal from wastewater is characterized by a diverse mix of academic institutions, government research bodies, and private companies. The industry is in a growth phase, with increasing market size driven by stringent environmental regulations and growing industrial wastewater treatment needs. Technological maturity varies, with established players like Clariant, Johns Manville, and Wanhua Chemical Group leading in commercial applications. Academic institutions such as Nanjing University and Soochow University are contributing to fundamental research, while government entities like CSIR are bridging the gap between research and industrial implementation. The market is seeing a blend of traditional chemical approaches and emerging innovative solutions, indicating a dynamic and evolving competitive environment.

Nanjing University

Technical Solution: Nanjing University has developed an innovative approach for organic dye removal from wastewater using sodium silicate-based materials. Their research focuses on synthesizing mesoporous silica materials modified with sodium silicate, which exhibit enhanced adsorption capacity for various organic dyes. The team has successfully created a hierarchical porous structure that combines micro-, meso-, and macropores, significantly increasing the surface area and adsorption sites[1]. This material demonstrates rapid adsorption kinetics and high removal efficiency for both cationic and anionic dyes. Additionally, they have explored the synergistic effect of combining sodium silicate with other metal oxides to create composite adsorbents with improved selectivity and regeneration capabilities[3].

Strengths: High adsorption capacity, rapid kinetics, and versatility for different dye types. The hierarchical porous structure allows for efficient mass transfer and utilization of adsorption sites. Weaknesses: Potential challenges in large-scale production and cost-effectiveness compared to conventional adsorbents.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a novel sodium silicate-based composite material for organic dye removal from wastewater. Their approach involves the synthesis of a nanocomposite combining sodium silicate with graphene oxide and magnetic nanoparticles. This innovative material exhibits exceptional adsorption capacity for a wide range of organic dyes, including azo dyes, reactive dyes, and disperse dyes[2]. The magnetic properties of the composite allow for easy separation and recovery of the adsorbent after treatment. CSIR researchers have also investigated the mechanism of dye removal, which involves both electrostatic interactions and surface complexation. The material shows excellent reusability, maintaining over 90% of its adsorption capacity after multiple cycles[4].

Strengths: High adsorption capacity, magnetic separation capability, and good reusability. The composite nature allows for multifunctional properties. Weaknesses: Potential complexity in synthesis process and higher production costs compared to single-component adsorbents.

Innovative Approaches in Organic Dye Removal

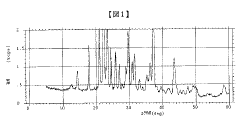

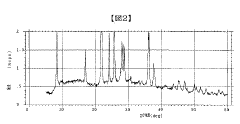

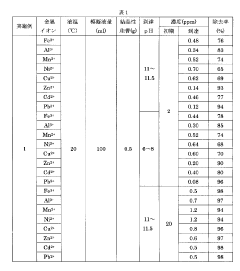

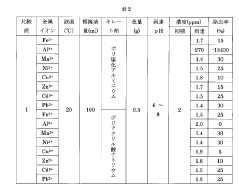

Method for purifying waste water using crystalline sodium silicate and agent therefor

PatentInactiveJP2007021485A

Innovation

- The use of crystalline sodium silicate (NaMSi xO2x+1yH2) for wastewater purification, which captures heavy metal ions by forming poorly soluble salts and stabilizing them within its layered structure, allowing for high removal rates and reduced environmental impact.

Method for preparing catalysts used in the oxidation reaction of organic substances by means of ozone

PatentWO1981002887A1

Innovation

- Development of a catalyst using pyrolysis silicate as the active surface component, which maintains catalytic activity and does not react with ozone, enhancing the ozonation process by increasing organic substance concentration in the water layer and accelerating reaction rates.

Environmental Impact Assessment

The use of sodium silicate in organic dye removal from wastewater has significant environmental implications that warrant careful consideration. This process, while effective in treating industrial effluents, can lead to both positive and negative environmental outcomes.

On the positive side, the application of sodium silicate in wastewater treatment contributes to the reduction of organic pollutants in aquatic ecosystems. By effectively removing dyes from industrial discharges, this method helps prevent the contamination of rivers, lakes, and groundwater resources. This, in turn, protects aquatic biodiversity and maintains the ecological balance of water bodies.

However, the environmental impact of sodium silicate usage is not without concerns. The introduction of silicate compounds into water systems can potentially alter the natural silica cycle. Elevated silica levels may lead to changes in phytoplankton communities, particularly favoring diatom growth. While this can increase primary productivity in some cases, it may also disrupt existing ecosystem dynamics.

Furthermore, the disposal of sludge generated from the treatment process presents another environmental challenge. This sludge, containing removed dyes and excess silicate, requires proper management to prevent secondary pollution. Improper disposal can lead to soil contamination and potential leaching of pollutants back into water sources.

The energy consumption associated with the production and application of sodium silicate in wastewater treatment also contributes to the overall environmental footprint. The manufacturing process of sodium silicate is energy-intensive, potentially leading to increased greenhouse gas emissions if not managed sustainably.

It is crucial to consider the long-term effects of continuous sodium silicate use on soil and water chemistry. Accumulation of silica in treated areas may alter soil properties, affecting plant growth and microbial communities. This could have cascading effects on local ecosystems and agricultural productivity.

To mitigate these environmental impacts, it is essential to implement comprehensive monitoring programs. These should assess the effects of sodium silicate treatment on water quality, aquatic life, and surrounding ecosystems. Additionally, research into optimizing the use of sodium silicate to minimize excess application and improve removal efficiency can help reduce its environmental footprint.

In conclusion, while sodium silicate offers an effective solution for organic dye removal from wastewater, its environmental impact is complex and multifaceted. Balancing the benefits of improved water quality with potential ecological alterations requires careful management and ongoing environmental assessment to ensure sustainable implementation of this treatment technology.

On the positive side, the application of sodium silicate in wastewater treatment contributes to the reduction of organic pollutants in aquatic ecosystems. By effectively removing dyes from industrial discharges, this method helps prevent the contamination of rivers, lakes, and groundwater resources. This, in turn, protects aquatic biodiversity and maintains the ecological balance of water bodies.

However, the environmental impact of sodium silicate usage is not without concerns. The introduction of silicate compounds into water systems can potentially alter the natural silica cycle. Elevated silica levels may lead to changes in phytoplankton communities, particularly favoring diatom growth. While this can increase primary productivity in some cases, it may also disrupt existing ecosystem dynamics.

Furthermore, the disposal of sludge generated from the treatment process presents another environmental challenge. This sludge, containing removed dyes and excess silicate, requires proper management to prevent secondary pollution. Improper disposal can lead to soil contamination and potential leaching of pollutants back into water sources.

The energy consumption associated with the production and application of sodium silicate in wastewater treatment also contributes to the overall environmental footprint. The manufacturing process of sodium silicate is energy-intensive, potentially leading to increased greenhouse gas emissions if not managed sustainably.

It is crucial to consider the long-term effects of continuous sodium silicate use on soil and water chemistry. Accumulation of silica in treated areas may alter soil properties, affecting plant growth and microbial communities. This could have cascading effects on local ecosystems and agricultural productivity.

To mitigate these environmental impacts, it is essential to implement comprehensive monitoring programs. These should assess the effects of sodium silicate treatment on water quality, aquatic life, and surrounding ecosystems. Additionally, research into optimizing the use of sodium silicate to minimize excess application and improve removal efficiency can help reduce its environmental footprint.

In conclusion, while sodium silicate offers an effective solution for organic dye removal from wastewater, its environmental impact is complex and multifaceted. Balancing the benefits of improved water quality with potential ecological alterations requires careful management and ongoing environmental assessment to ensure sustainable implementation of this treatment technology.

Regulatory Framework for Wastewater Treatment

The regulatory framework for wastewater treatment plays a crucial role in governing the use of sodium silicate for organic dye removal from wastewater. This framework encompasses a complex network of laws, regulations, and standards at various levels of government, aimed at protecting public health and the environment.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for wastewater management. These guidelines often serve as a basis for national and regional regulations, emphasizing the importance of sustainable water use and pollution prevention.

In the United States, the Clean Water Act (CWA) serves as the primary federal law governing water pollution. The Environmental Protection Agency (EPA) is responsible for implementing and enforcing the CWA, setting effluent guidelines for various industries, including those that generate dye-containing wastewater. These guidelines often specify the allowable concentrations of pollutants in discharged water, which may impact the use of sodium silicate in dye removal processes.

The European Union has established the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive, which set standards for water quality and wastewater treatment across member states. These directives require the implementation of best available techniques (BAT) for industrial wastewater treatment, which may include the use of sodium silicate or alternative methods for dye removal.

Many countries have their own national regulations that complement or expand upon international guidelines. For instance, China's Water Pollution Prevention and Control Law and India's Water (Prevention and Control of Pollution) Act provide frameworks for managing industrial wastewater, including textile effluents containing dyes.

Local and regional authorities often have additional regulations that may impact the use of sodium silicate in wastewater treatment. These can include permitting requirements, monitoring and reporting obligations, and specific treatment standards tailored to local environmental conditions and water resources.

The regulatory landscape also includes industry-specific standards and voluntary initiatives. For example, the textile industry has developed various certification schemes and best practice guidelines that address wastewater treatment, such as the Zero Discharge of Hazardous Chemicals (ZDHC) programme.

As environmental concerns grow and scientific understanding advances, regulatory frameworks continue to evolve. There is an increasing focus on emerging contaminants, resource recovery, and circular economy principles in wastewater management. This may lead to new regulations that could affect the use of sodium silicate and other treatment technologies for organic dye removal.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for wastewater management. These guidelines often serve as a basis for national and regional regulations, emphasizing the importance of sustainable water use and pollution prevention.

In the United States, the Clean Water Act (CWA) serves as the primary federal law governing water pollution. The Environmental Protection Agency (EPA) is responsible for implementing and enforcing the CWA, setting effluent guidelines for various industries, including those that generate dye-containing wastewater. These guidelines often specify the allowable concentrations of pollutants in discharged water, which may impact the use of sodium silicate in dye removal processes.

The European Union has established the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive, which set standards for water quality and wastewater treatment across member states. These directives require the implementation of best available techniques (BAT) for industrial wastewater treatment, which may include the use of sodium silicate or alternative methods for dye removal.

Many countries have their own national regulations that complement or expand upon international guidelines. For instance, China's Water Pollution Prevention and Control Law and India's Water (Prevention and Control of Pollution) Act provide frameworks for managing industrial wastewater, including textile effluents containing dyes.

Local and regional authorities often have additional regulations that may impact the use of sodium silicate in wastewater treatment. These can include permitting requirements, monitoring and reporting obligations, and specific treatment standards tailored to local environmental conditions and water resources.

The regulatory landscape also includes industry-specific standards and voluntary initiatives. For example, the textile industry has developed various certification schemes and best practice guidelines that address wastewater treatment, such as the Zero Discharge of Hazardous Chemicals (ZDHC) programme.

As environmental concerns grow and scientific understanding advances, regulatory frameworks continue to evolve. There is an increasing focus on emerging contaminants, resource recovery, and circular economy principles in wastewater management. This may lead to new regulations that could affect the use of sodium silicate and other treatment technologies for organic dye removal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!