Standards and safety regulations for thermal runaway sensors in energy storage

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Sensor Technology Background and Objectives

Thermal runaway in energy storage systems represents one of the most critical safety challenges facing the industry today. This phenomenon, characterized by an uncontrolled, self-accelerating exothermic reaction within battery cells, has been documented since the early development of lithium-ion technology in the 1990s. The evolution of thermal runaway sensor technology has progressed from basic temperature monitoring to sophisticated multi-parameter detection systems that can identify precursor events before catastrophic failure occurs.

The global energy transition has dramatically accelerated the deployment of battery energy storage systems (BESS) across utility, commercial, residential, and transportation sectors. This rapid expansion has been accompanied by high-profile thermal incidents that have highlighted the urgent need for advanced safety technologies. Between 2018 and 2023, documented BESS fires increased by approximately 800%, creating significant market pressure for enhanced safety solutions.

Thermal runaway sensor technology aims to address this critical safety gap by providing early detection capabilities that can prevent cascading failures within battery systems. The primary technical objectives include: reducing detection latency to sub-second timeframes, minimizing false positives while maintaining sensitivity, developing sensors capable of withstanding harsh operating environments, and creating cost-effective solutions that can be widely deployed across various energy storage applications.

Current sensor technologies primarily focus on temperature, gas, and voltage monitoring, with emerging solutions incorporating acoustic, optical, and electrochemical detection methods. The integration of these diverse sensing modalities represents a significant technical challenge, particularly in achieving the necessary balance between sensitivity and specificity required for reliable early warning systems.

Regulatory frameworks governing thermal runaway detection are evolving rapidly, with standards bodies such as UL, IEC, and NFPA establishing increasingly stringent requirements. UL 9540A and IEC 62619 have become particularly influential in defining testing protocols and safety requirements for energy storage systems, creating clear technical benchmarks for sensor performance.

The technological trajectory points toward multi-modal sensor fusion approaches that combine various detection methods with advanced analytics and machine learning algorithms. This integration enables more sophisticated pattern recognition capabilities that can distinguish between normal operational variations and genuine thermal runaway precursors, significantly reducing false alarms while improving detection reliability.

Research initiatives are increasingly focused on developing predictive capabilities that can identify potential failure modes hours or even days before thermal runaway occurs, representing a paradigm shift from reactive to preventative safety systems. This evolution requires advances in both hardware sensing technologies and software analytics to process complex, multi-dimensional data streams in real-time.

The global energy transition has dramatically accelerated the deployment of battery energy storage systems (BESS) across utility, commercial, residential, and transportation sectors. This rapid expansion has been accompanied by high-profile thermal incidents that have highlighted the urgent need for advanced safety technologies. Between 2018 and 2023, documented BESS fires increased by approximately 800%, creating significant market pressure for enhanced safety solutions.

Thermal runaway sensor technology aims to address this critical safety gap by providing early detection capabilities that can prevent cascading failures within battery systems. The primary technical objectives include: reducing detection latency to sub-second timeframes, minimizing false positives while maintaining sensitivity, developing sensors capable of withstanding harsh operating environments, and creating cost-effective solutions that can be widely deployed across various energy storage applications.

Current sensor technologies primarily focus on temperature, gas, and voltage monitoring, with emerging solutions incorporating acoustic, optical, and electrochemical detection methods. The integration of these diverse sensing modalities represents a significant technical challenge, particularly in achieving the necessary balance between sensitivity and specificity required for reliable early warning systems.

Regulatory frameworks governing thermal runaway detection are evolving rapidly, with standards bodies such as UL, IEC, and NFPA establishing increasingly stringent requirements. UL 9540A and IEC 62619 have become particularly influential in defining testing protocols and safety requirements for energy storage systems, creating clear technical benchmarks for sensor performance.

The technological trajectory points toward multi-modal sensor fusion approaches that combine various detection methods with advanced analytics and machine learning algorithms. This integration enables more sophisticated pattern recognition capabilities that can distinguish between normal operational variations and genuine thermal runaway precursors, significantly reducing false alarms while improving detection reliability.

Research initiatives are increasingly focused on developing predictive capabilities that can identify potential failure modes hours or even days before thermal runaway occurs, representing a paradigm shift from reactive to preventative safety systems. This evolution requires advances in both hardware sensing technologies and software analytics to process complex, multi-dimensional data streams in real-time.

Market Demand Analysis for Energy Storage Safety Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the electrification of transportation. This expansion has created a substantial demand for advanced safety solutions, particularly those addressing thermal runaway events in battery systems. Market research indicates that the energy storage safety solutions sector is projected to grow at a compound annual growth rate of 20% through 2030, significantly outpacing the overall energy storage market growth.

Insurance companies and regulatory bodies have become key demand drivers, as they increasingly require sophisticated safety monitoring systems before underwriting large-scale energy storage projects. This shift has transformed thermal runaway detection from a premium feature to an essential component, particularly in grid-scale installations where the financial and safety implications of failures are magnified.

Regional analysis reveals varying demand patterns, with Asia-Pacific leading in volume due to its dominant manufacturing position, while North American and European markets demonstrate higher willingness to pay for premium safety solutions. The commercial and utility segments represent the largest market share, accounting for approximately 65% of total demand, followed by residential applications at 20% and transportation at 15%.

End-user surveys indicate that facility managers and system integrators prioritize early detection capabilities, with 78% ranking this as their primary concern when selecting safety systems. Reliability under extreme conditions and integration capabilities with existing battery management systems follow as secondary priorities, highlighting the need for robust, interoperable solutions.

The market demonstrates strong price sensitivity in consumer applications but significantly less so in industrial and utility-scale implementations, where the cost of safety failures far outweighs the investment in prevention technologies. This has created a two-tiered market structure with different value propositions and pricing strategies across segments.

Recent high-profile thermal runaway incidents have accelerated demand growth, with a notable 35% increase in safety solution inquiries following widely publicized energy storage system failures. This trend is further reinforced by evolving insurance requirements, with many providers now mandating continuous thermal monitoring as a prerequisite for coverage of large-scale energy storage assets.

The aftermarket retrofit segment is emerging as a significant opportunity, as operators of existing installations seek to upgrade their safety systems to meet new standards without replacing entire energy storage systems. This segment is expected to represent a substantial portion of market value in the near term as the installed base of legacy systems continues to grow.

Insurance companies and regulatory bodies have become key demand drivers, as they increasingly require sophisticated safety monitoring systems before underwriting large-scale energy storage projects. This shift has transformed thermal runaway detection from a premium feature to an essential component, particularly in grid-scale installations where the financial and safety implications of failures are magnified.

Regional analysis reveals varying demand patterns, with Asia-Pacific leading in volume due to its dominant manufacturing position, while North American and European markets demonstrate higher willingness to pay for premium safety solutions. The commercial and utility segments represent the largest market share, accounting for approximately 65% of total demand, followed by residential applications at 20% and transportation at 15%.

End-user surveys indicate that facility managers and system integrators prioritize early detection capabilities, with 78% ranking this as their primary concern when selecting safety systems. Reliability under extreme conditions and integration capabilities with existing battery management systems follow as secondary priorities, highlighting the need for robust, interoperable solutions.

The market demonstrates strong price sensitivity in consumer applications but significantly less so in industrial and utility-scale implementations, where the cost of safety failures far outweighs the investment in prevention technologies. This has created a two-tiered market structure with different value propositions and pricing strategies across segments.

Recent high-profile thermal runaway incidents have accelerated demand growth, with a notable 35% increase in safety solution inquiries following widely publicized energy storage system failures. This trend is further reinforced by evolving insurance requirements, with many providers now mandating continuous thermal monitoring as a prerequisite for coverage of large-scale energy storage assets.

The aftermarket retrofit segment is emerging as a significant opportunity, as operators of existing installations seek to upgrade their safety systems to meet new standards without replacing entire energy storage systems. This segment is expected to represent a substantial portion of market value in the near term as the installed base of legacy systems continues to grow.

Current State and Challenges in Thermal Runaway Detection

The global landscape of thermal runaway detection in energy storage systems reveals significant disparities in technological maturity and regulatory frameworks. Currently, the most advanced detection systems employ multiple sensor types including temperature, gas, voltage, and current monitoring to provide early warning of potential thermal events. Leading markets such as the European Union, United States, and China have established varying degrees of regulatory oversight, though a unified international standard remains elusive.

Temperature monitoring represents the most widely implemented detection method, with systems typically utilizing thermocouples, thermistors, or infrared sensors strategically placed throughout battery modules. However, these systems often suffer from delayed response times, as significant temperature increases may only be detectable after thermal runaway has initiated. This critical limitation underscores the need for more sophisticated early detection mechanisms.

Gas detection technologies have emerged as a promising complementary approach, capable of identifying volatile organic compounds released during the early stages of battery degradation. Despite their potential for earlier detection, these systems face challenges related to sensor drift, cross-sensitivity to environmental contaminants, and higher implementation costs compared to temperature-based solutions.

Voltage and current monitoring systems provide another layer of detection capability by identifying abnormal electrical behaviors that may precede thermal events. While these systems benefit from integration with existing battery management infrastructure, they struggle with distinguishing between normal operational fluctuations and genuine precursors to thermal runaway, resulting in potential false positives or missed detection events.

A significant technical challenge across all detection methodologies is achieving the delicate balance between sensitivity and specificity. Systems must be capable of detecting genuine thermal runaway precursors while minimizing false alarms that could lead to unnecessary system shutdowns and operational disruptions. This challenge is particularly acute in large-scale energy storage installations where the economic impact of false alarms is substantial.

The geographic distribution of thermal runaway detection technology development shows concentration in regions with advanced battery manufacturing capabilities. Japan, South Korea, and Germany lead in patent filings related to detection technologies, while China dominates in terms of implementation scale due to its expansive energy storage deployment. Emerging markets face additional challenges related to technology transfer, local regulatory development, and adaptation of detection systems to diverse environmental conditions.

Standardization efforts remain fragmented, with organizations such as UL, IEC, and ISO developing competing frameworks. This regulatory inconsistency creates compliance challenges for global manufacturers and potentially compromises safety through gaps in requirements across different markets. The absence of harmonized testing protocols further complicates the validation of detection system performance across different battery chemistries and form factors.

Temperature monitoring represents the most widely implemented detection method, with systems typically utilizing thermocouples, thermistors, or infrared sensors strategically placed throughout battery modules. However, these systems often suffer from delayed response times, as significant temperature increases may only be detectable after thermal runaway has initiated. This critical limitation underscores the need for more sophisticated early detection mechanisms.

Gas detection technologies have emerged as a promising complementary approach, capable of identifying volatile organic compounds released during the early stages of battery degradation. Despite their potential for earlier detection, these systems face challenges related to sensor drift, cross-sensitivity to environmental contaminants, and higher implementation costs compared to temperature-based solutions.

Voltage and current monitoring systems provide another layer of detection capability by identifying abnormal electrical behaviors that may precede thermal events. While these systems benefit from integration with existing battery management infrastructure, they struggle with distinguishing between normal operational fluctuations and genuine precursors to thermal runaway, resulting in potential false positives or missed detection events.

A significant technical challenge across all detection methodologies is achieving the delicate balance between sensitivity and specificity. Systems must be capable of detecting genuine thermal runaway precursors while minimizing false alarms that could lead to unnecessary system shutdowns and operational disruptions. This challenge is particularly acute in large-scale energy storage installations where the economic impact of false alarms is substantial.

The geographic distribution of thermal runaway detection technology development shows concentration in regions with advanced battery manufacturing capabilities. Japan, South Korea, and Germany lead in patent filings related to detection technologies, while China dominates in terms of implementation scale due to its expansive energy storage deployment. Emerging markets face additional challenges related to technology transfer, local regulatory development, and adaptation of detection systems to diverse environmental conditions.

Standardization efforts remain fragmented, with organizations such as UL, IEC, and ISO developing competing frameworks. This regulatory inconsistency creates compliance challenges for global manufacturers and potentially compromises safety through gaps in requirements across different markets. The absence of harmonized testing protocols further complicates the validation of detection system performance across different battery chemistries and form factors.

Current Technical Solutions for Thermal Runaway Prevention

01 Temperature monitoring systems for battery safety

Advanced temperature monitoring systems are essential for detecting early signs of thermal runaway in batteries. These systems utilize various sensors to continuously monitor battery temperature and trigger safety protocols when abnormal heat patterns are detected. The monitoring systems can be integrated with battery management systems (BMS) to provide real-time data and enable preventive actions before thermal runaway occurs, significantly enhancing battery safety in electric vehicles and energy storage systems.- Temperature monitoring systems for battery safety: Advanced temperature monitoring systems are essential for detecting early signs of thermal runaway in batteries. These systems utilize various sensors to continuously monitor battery temperature and trigger safety mechanisms when abnormal heat patterns are detected. The monitoring systems can be integrated with battery management systems to provide real-time data and enable preventive actions before thermal runaway occurs, significantly enhancing battery safety in various applications.

- Regulatory compliance for thermal runaway prevention: Safety regulations mandate specific requirements for thermal runaway prevention in battery systems. These regulations typically include standards for sensor placement, sensitivity thresholds, and response times. Compliance with international safety standards such as UL, IEC, and UN regulations is essential for manufacturers. The regulations also specify testing protocols to validate the effectiveness of thermal runaway detection systems and establish minimum safety performance criteria for batteries used in various applications.

- Innovative sensor technologies for early detection: Novel sensor technologies have been developed specifically for early detection of thermal runaway conditions. These include fiber optic sensors, gas detection sensors, and impedance measurement systems that can detect subtle changes preceding thermal events. Some advanced sensors can detect chemical changes or gas emissions that occur before significant temperature increases, providing earlier warnings than traditional temperature sensors alone. These innovative technologies enable more precise and timely detection of potential thermal runaway conditions.

- Integration of thermal runaway protection in battery management systems: Modern battery management systems incorporate comprehensive thermal runaway protection features. These systems integrate multiple sensor inputs with sophisticated algorithms to analyze thermal patterns and predict potential failures. The protection mechanisms include automatic disconnection of affected cells, cooling system activation, and emergency shutdown procedures. Advanced systems also feature redundant safety measures and fail-safe designs to ensure protection even if primary systems fail, creating multiple layers of safety for battery installations.

- Industry-specific thermal runaway safety solutions: Different industries have developed specialized thermal runaway safety solutions tailored to their specific applications and risk profiles. The automotive sector focuses on passenger safety with rapid detection and containment systems, while aerospace applications emphasize lightweight yet highly reliable solutions. Energy storage facilities implement large-scale monitoring networks with remote management capabilities, and consumer electronics employ miniaturized sensor systems with space-efficient designs. These industry-specific approaches address the unique challenges and regulatory requirements of each sector.

02 Regulatory compliance for thermal runaway prevention

Safety regulations mandate specific requirements for thermal runaway prevention in battery systems. These regulations typically include standards for sensor placement, sensitivity thresholds, response times, and integration with emergency shutdown systems. Manufacturers must comply with international standards such as IEC 62619, UL 1642, and UN 38.3 for transportation safety. Regulatory frameworks also specify testing protocols to validate the effectiveness of thermal runaway detection systems under various operating conditions and failure scenarios.Expand Specific Solutions03 Multi-parameter detection systems

Advanced thermal runaway prevention relies on multi-parameter detection systems that monitor not only temperature but also voltage, current, pressure, and gas emissions. These comprehensive systems provide more accurate early warning by analyzing multiple indicators simultaneously. The integration of different sensor types creates redundancy and improves reliability in detecting potential thermal runaway conditions. Machine learning algorithms can be employed to analyze sensor data patterns and predict thermal events before they reach critical stages.Expand Specific Solutions04 Thermal runaway mitigation technologies

Beyond detection, modern battery systems incorporate active and passive mitigation technologies to prevent thermal runaway propagation. These include phase change materials for heat absorption, fire-resistant barriers between cells, and emergency venting systems. Advanced cooling systems can be automatically activated when sensors detect temperature anomalies. Some designs incorporate physical separation and thermal isolation between battery modules to contain thermal events and prevent system-wide failures.Expand Specific Solutions05 Industry-specific safety implementations

Different industries have developed specialized thermal runaway safety implementations based on their unique risk profiles. Automotive applications focus on crash-resistant sensor systems and rapid emergency response mechanisms. Aerospace implementations emphasize lightweight, highly reliable sensors with redundant monitoring paths. Grid-scale energy storage systems utilize distributed sensor networks with centralized monitoring. Medical device batteries employ miniaturized sensors with extremely high sensitivity to ensure patient safety. Each industry adapts thermal runaway protection to its specific operational constraints and safety requirements.Expand Specific Solutions

Key Industry Players in Energy Storage Safety Systems

The thermal runaway sensor market for energy storage is in a growth phase, driven by increasing safety concerns in the rapidly expanding energy storage sector. The market is characterized by a mix of established players and emerging specialists, with companies like BYD, CATL, LG Chem, and Fluence Energy leading technological innovation. These companies are developing advanced sensor systems that can detect early signs of thermal events in battery systems. The regulatory landscape is evolving, with organizations like the Korean Fire Protection Association helping establish safety standards. Technical maturity varies, with automotive-derived technologies from Bosch, Volvo, and GM being adapted for stationary storage applications, while specialized solutions from companies like EVE Energy and Webasto are emerging. Integration of AI and cloud analytics by Renesas Electronics and Huawei Digital Power represents the cutting edge of this safety-critical technology.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology with an integrated thermal runaway prevention system that focuses on early detection through a network of distributed temperature sensors and proprietary algorithms. Their approach includes a multi-layer safety architecture with thermal interface materials that can withstand temperatures up to 1000°C. BYD's thermal runaway sensors are designed to detect temperature gradients as small as 0.5°C across battery cells, triggering isolation protocols before cascading failures can occur. The company has developed gas sensors specifically calibrated to detect the early chemical signatures of electrolyte decomposition, providing warning signs before visible smoke appears. BYD's systems comply with UN38.3, IEC62133, and GB/T 31485 standards, with additional safety margins built in. Their Battery Management System (BMS) incorporates real-time impedance spectroscopy to monitor internal cell resistance changes that often precede thermal events, allowing for predictive rather than reactive safety measures.

Strengths: Exceptional thermal isolation capabilities, highly sensitive early detection of chemical precursors to thermal runaway, and proven safety record in real-world applications. Weaknesses: Proprietary technology creates potential vendor lock-in, higher initial cost compared to conventional lithium-ion batteries, and requires specialized training for maintenance personnel.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive thermal runaway detection system that integrates multiple sensor types including temperature, gas, and pressure sensors. Their Cell-to-Pack (CTP) technology incorporates thermal runaway prevention mechanisms with a rapid heat diffusion system that can detect temperature anomalies within milliseconds. The company's latest innovation is their "thermal runaway early warning" system that can predict potential failures 3-5 minutes before they occur, providing critical time for safety measures to activate. CATL complies with IEC 62619, UL 9540A, and GB/T 36276 standards for battery safety. Their sensors are designed with redundancy features, ensuring that if one sensor fails, others continue monitoring. The system includes AI algorithms that analyze sensor data to distinguish between normal temperature fluctuations and dangerous thermal events, reducing false alarms by approximately 60% compared to conventional threshold-based systems.

Strengths: Industry-leading early detection time (3-5 minutes before thermal runaway), high accuracy with AI-powered analytics, and comprehensive multi-sensor approach. Weaknesses: Higher implementation costs compared to simpler systems, requires sophisticated battery management systems, and potential complexity in retrofitting existing energy storage installations.

Critical Patents and Innovations in Thermal Sensing

Thermal sensor system

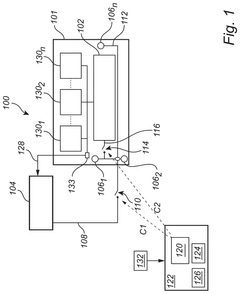

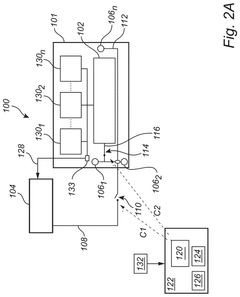

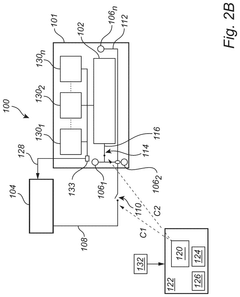

PatentPendingUS20250198852A1

Innovation

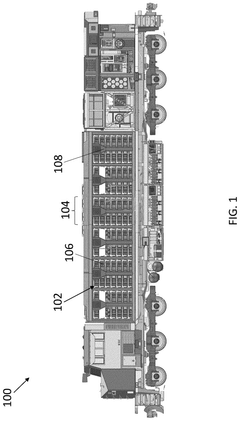

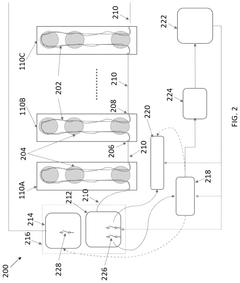

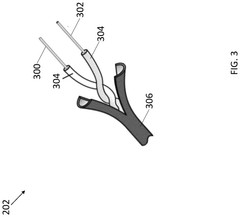

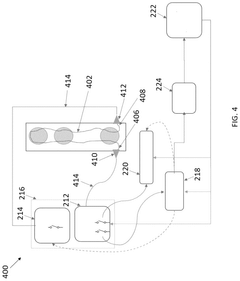

- A sensor system that employs elongated sensors, which can be threaded through various locations within a powered system, including energy storage device enclosures and exhaust chimneys. These sensors generate an electrical short or change light attenuation in response to temperature changes, allowing for early detection of thermal runaway events without the need for complex communication systems.

System and method for thermal runaway detection in an electrical energy storage device

PatentPendingUS20250264538A1

Innovation

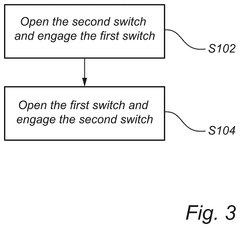

- A system utilizing a low voltage energy storage device to power thermal runaway detection sensors and processing circuitry, with switches to alternate power sources between high and low voltage systems based on vehicle conditions, ensuring continuous operation and reduced energy consumption.

Regulatory Framework and Compliance Requirements

The regulatory landscape for thermal runaway sensors in energy storage systems is governed by a complex framework of international, regional, and national standards. At the international level, the International Electrotechnical Commission (IEC) has established several key standards, including IEC 62619 for secondary lithium-ion cells and batteries for industrial applications, which mandates specific safety requirements and test methods for thermal management systems. Similarly, IEC 62660 addresses the performance and life testing of lithium-ion batteries specifically for electric vehicle applications, including thermal runaway prevention measures.

In the United States, UL 1973 provides comprehensive safety standards for batteries used in stationary applications, while NFPA 855 establishes installation requirements for energy storage systems, including specific provisions for thermal runaway detection and mitigation. The National Fire Protection Association (NFPA) has also developed NFPA 70, commonly known as the National Electrical Code, which includes provisions relevant to energy storage system safety.

The European Union has implemented EN 50604-1 for lithium batteries for light electric vehicles and EN 62619 for industrial applications, both addressing thermal safety concerns. Additionally, the UN Transportation Testing requirements (UN 38.3) mandate rigorous testing for lithium batteries during transportation, including thermal abuse tests that directly relate to runaway prevention.

Compliance with these regulations typically requires manufacturers to implement comprehensive testing protocols. These include thermal abuse tests, where batteries are subjected to elevated temperatures to assess their resistance to thermal runaway; overcharge and over-discharge tests to evaluate battery behavior under extreme operating conditions; and short circuit tests to verify protective measures against electrical faults that could trigger thermal events.

Certification processes generally involve third-party testing by accredited laboratories, documentation of test results and safety measures, and ongoing compliance monitoring. Many jurisdictions also require regular inspections and recertification, particularly for large-scale energy storage installations in critical infrastructure or public facilities.

Recent regulatory trends indicate a move toward more stringent requirements for early detection systems, with an increasing emphasis on real-time monitoring capabilities and automated response mechanisms. Regulations are also evolving to address specific application contexts, with different standards emerging for residential, commercial, grid-scale, and transportation energy storage systems, each with unique thermal safety considerations.

In the United States, UL 1973 provides comprehensive safety standards for batteries used in stationary applications, while NFPA 855 establishes installation requirements for energy storage systems, including specific provisions for thermal runaway detection and mitigation. The National Fire Protection Association (NFPA) has also developed NFPA 70, commonly known as the National Electrical Code, which includes provisions relevant to energy storage system safety.

The European Union has implemented EN 50604-1 for lithium batteries for light electric vehicles and EN 62619 for industrial applications, both addressing thermal safety concerns. Additionally, the UN Transportation Testing requirements (UN 38.3) mandate rigorous testing for lithium batteries during transportation, including thermal abuse tests that directly relate to runaway prevention.

Compliance with these regulations typically requires manufacturers to implement comprehensive testing protocols. These include thermal abuse tests, where batteries are subjected to elevated temperatures to assess their resistance to thermal runaway; overcharge and over-discharge tests to evaluate battery behavior under extreme operating conditions; and short circuit tests to verify protective measures against electrical faults that could trigger thermal events.

Certification processes generally involve third-party testing by accredited laboratories, documentation of test results and safety measures, and ongoing compliance monitoring. Many jurisdictions also require regular inspections and recertification, particularly for large-scale energy storage installations in critical infrastructure or public facilities.

Recent regulatory trends indicate a move toward more stringent requirements for early detection systems, with an increasing emphasis on real-time monitoring capabilities and automated response mechanisms. Regulations are also evolving to address specific application contexts, with different standards emerging for residential, commercial, grid-scale, and transportation energy storage systems, each with unique thermal safety considerations.

Risk Assessment and Mitigation Strategies

Comprehensive risk assessment frameworks for thermal runaway in energy storage systems must address multiple dimensions of potential hazards. These frameworks typically evaluate the likelihood and severity of thermal events based on battery chemistry, system design, environmental conditions, and operational parameters. For lithium-ion batteries specifically, risk matrices commonly incorporate factors such as state of charge, ambient temperature, mechanical integrity, and electrical protection systems. Advanced assessment methodologies now employ probabilistic models that account for cascading failure mechanisms and incorporate real-time sensor data to dynamically update risk profiles.

Preventive measures represent the first line of defense against thermal runaway incidents. These include implementing robust battery management systems (BMS) with sophisticated algorithms capable of detecting early warning signs of abnormal behavior. Design-level mitigations such as physical cell separation, thermal barriers, and flame-retardant materials significantly reduce propagation risks. Additionally, operational controls like charging rate limitations, temperature-dependent power throttling, and regular maintenance protocols help maintain systems within safe operating parameters.

Detection strategies have evolved substantially, with multi-modal sensing approaches now considered best practice. These combine temperature monitoring, gas detection, voltage/current analysis, and impedance tracking to create comprehensive early warning systems. The integration of machine learning algorithms has enhanced detection capabilities by identifying subtle pattern changes that precede thermal events, potentially providing critical additional response time.

Containment and response protocols form the final layer of protection when preventive measures fail. These include automated shutdown sequences, emergency ventilation systems, and fire suppression technologies specifically designed for battery fires. Compartmentalization strategies limit damage propagation, while thermal management systems can actively cool affected areas. Industry standards increasingly require documented emergency response procedures with clear escalation paths and decision frameworks.

Testing and validation methodologies have become more rigorous, with accelerated aging tests, abuse testing, and failure mode simulations now standard practice. These protocols evaluate both the effectiveness of sensors and the integrated response systems. Certification bodies increasingly require demonstration of system resilience under various failure scenarios, with particular emphasis on sensor reliability during extreme conditions.

Implementation challenges remain significant, particularly regarding sensor integration in existing systems, cost-benefit considerations for different application contexts, and the need for standardized communication protocols between detection and response systems. The regulatory landscape continues to evolve, with emerging standards focusing on performance-based requirements rather than prescriptive approaches, allowing for technological innovation while maintaining safety objectives.

Preventive measures represent the first line of defense against thermal runaway incidents. These include implementing robust battery management systems (BMS) with sophisticated algorithms capable of detecting early warning signs of abnormal behavior. Design-level mitigations such as physical cell separation, thermal barriers, and flame-retardant materials significantly reduce propagation risks. Additionally, operational controls like charging rate limitations, temperature-dependent power throttling, and regular maintenance protocols help maintain systems within safe operating parameters.

Detection strategies have evolved substantially, with multi-modal sensing approaches now considered best practice. These combine temperature monitoring, gas detection, voltage/current analysis, and impedance tracking to create comprehensive early warning systems. The integration of machine learning algorithms has enhanced detection capabilities by identifying subtle pattern changes that precede thermal events, potentially providing critical additional response time.

Containment and response protocols form the final layer of protection when preventive measures fail. These include automated shutdown sequences, emergency ventilation systems, and fire suppression technologies specifically designed for battery fires. Compartmentalization strategies limit damage propagation, while thermal management systems can actively cool affected areas. Industry standards increasingly require documented emergency response procedures with clear escalation paths and decision frameworks.

Testing and validation methodologies have become more rigorous, with accelerated aging tests, abuse testing, and failure mode simulations now standard practice. These protocols evaluate both the effectiveness of sensors and the integrated response systems. Certification bodies increasingly require demonstration of system resilience under various failure scenarios, with particular emphasis on sensor reliability during extreme conditions.

Implementation challenges remain significant, particularly regarding sensor integration in existing systems, cost-benefit considerations for different application contexts, and the need for standardized communication protocols between detection and response systems. The regulatory landscape continues to evolve, with emerging standards focusing on performance-based requirements rather than prescriptive approaches, allowing for technological innovation while maintaining safety objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!