Surface Energy Tuning Of Nanocellulose For Polymer Compatibilization

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Surface Modification Background and Objectives

Nanocellulose has emerged as a revolutionary biomaterial over the past two decades, evolving from a laboratory curiosity to a commercially viable sustainable material. Derived from cellulose, the most abundant biopolymer on Earth, nanocellulose combines remarkable mechanical properties with biodegradability and renewability. The historical trajectory of nanocellulose research began in the 1980s but gained significant momentum in the early 2000s with advancements in production technologies and characterization methods.

The fundamental challenge in nanocellulose utilization lies in its inherent hydrophilicity, which creates compatibility issues when incorporated into hydrophobic polymer matrices. This incompatibility results in poor interfacial adhesion, phase separation, and ultimately compromised mechanical properties in composite materials. The surface energy mismatch between nanocellulose and polymers represents a critical barrier to the widespread adoption of nanocellulose in high-performance composite applications.

Surface energy tuning of nanocellulose has evolved through several technological generations. Initial approaches relied on simple esterification and silylation reactions, while contemporary methods employ sophisticated grafting techniques, plasma treatments, and supramolecular functionalization strategies. The technological evolution reflects a shift from merely reducing hydrophilicity to precisely engineering surface properties for targeted polymer interactions.

The global push toward sustainable materials has accelerated research in nanocellulose surface modification, with significant contributions from research centers in Scandinavia, North America, Japan, and increasingly China. This geographical distribution of research efforts highlights the international recognition of nanocellulose's potential as a sustainable alternative to conventional reinforcement materials.

The primary objective of surface energy tuning research is to develop scalable, environmentally friendly modification protocols that enhance nanocellulose-polymer compatibility without compromising the inherent sustainability advantages of nanocellulose. Secondary objectives include improving dispersion stability in non-polar media, enhancing interfacial adhesion with various polymer matrices, and maintaining the mechanical integrity of the nanocellulose structure during modification.

Recent technological trends indicate a growing interest in "green" modification approaches that avoid toxic reagents and minimize environmental impact. Additionally, there is increasing focus on developing multifunctional surface modifications that simultaneously address compatibility issues while imparting additional properties such as flame retardancy, antimicrobial activity, or stimuli-responsiveness to the resulting composites.

The ultimate goal is to position modified nanocellulose as a viable, sustainable alternative to conventional fillers and reinforcement materials in high-performance polymer composites across multiple industries, from packaging to automotive and construction sectors.

The fundamental challenge in nanocellulose utilization lies in its inherent hydrophilicity, which creates compatibility issues when incorporated into hydrophobic polymer matrices. This incompatibility results in poor interfacial adhesion, phase separation, and ultimately compromised mechanical properties in composite materials. The surface energy mismatch between nanocellulose and polymers represents a critical barrier to the widespread adoption of nanocellulose in high-performance composite applications.

Surface energy tuning of nanocellulose has evolved through several technological generations. Initial approaches relied on simple esterification and silylation reactions, while contemporary methods employ sophisticated grafting techniques, plasma treatments, and supramolecular functionalization strategies. The technological evolution reflects a shift from merely reducing hydrophilicity to precisely engineering surface properties for targeted polymer interactions.

The global push toward sustainable materials has accelerated research in nanocellulose surface modification, with significant contributions from research centers in Scandinavia, North America, Japan, and increasingly China. This geographical distribution of research efforts highlights the international recognition of nanocellulose's potential as a sustainable alternative to conventional reinforcement materials.

The primary objective of surface energy tuning research is to develop scalable, environmentally friendly modification protocols that enhance nanocellulose-polymer compatibility without compromising the inherent sustainability advantages of nanocellulose. Secondary objectives include improving dispersion stability in non-polar media, enhancing interfacial adhesion with various polymer matrices, and maintaining the mechanical integrity of the nanocellulose structure during modification.

Recent technological trends indicate a growing interest in "green" modification approaches that avoid toxic reagents and minimize environmental impact. Additionally, there is increasing focus on developing multifunctional surface modifications that simultaneously address compatibility issues while imparting additional properties such as flame retardancy, antimicrobial activity, or stimuli-responsiveness to the resulting composites.

The ultimate goal is to position modified nanocellulose as a viable, sustainable alternative to conventional fillers and reinforcement materials in high-performance polymer composites across multiple industries, from packaging to automotive and construction sectors.

Market Analysis for Nanocellulose-Polymer Composites

The global market for nanocellulose-polymer composites has been experiencing significant growth, driven by increasing demand for sustainable and high-performance materials across various industries. The market size for these composites was valued at approximately $300 million in 2022 and is projected to reach $980 million by 2028, representing a compound annual growth rate (CAGR) of 21.8% during the forecast period.

The automotive sector represents one of the largest application areas for nanocellulose-polymer composites, accounting for roughly 28% of the total market share. Manufacturers are increasingly adopting these materials to reduce vehicle weight while maintaining structural integrity, directly contributing to improved fuel efficiency and reduced emissions. The packaging industry follows closely at 24% market share, where these composites offer superior barrier properties and biodegradability compared to conventional materials.

Construction and building materials constitute another significant market segment at 19%, with applications in insulation, structural reinforcement, and decorative elements. The electronics industry has also begun incorporating nanocellulose-polymer composites in flexible displays and circuit boards, currently representing 12% of the market but showing the fastest growth rate among all segments.

Regionally, North America leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, increasing environmental regulations, and growing awareness about sustainable materials.

Key market drivers include stringent environmental regulations promoting the use of biodegradable materials, increasing consumer preference for eco-friendly products, and technological advancements in nanocellulose production and surface modification techniques. The ability to tune surface energy of nanocellulose for better polymer compatibilization has opened new application possibilities, expanding the potential market size.

Major challenges hindering market growth include high production costs compared to conventional materials, scalability issues in nanocellulose production, and technical difficulties in achieving consistent quality in large-scale manufacturing. Additionally, the market faces competition from other bio-based and synthetic composites that may offer similar performance characteristics at lower costs.

The market is characterized by a fragmentation of suppliers and end-users, with increasing vertical integration as companies seek to secure their supply chains. Strategic partnerships between nanocellulose producers, polymer manufacturers, and end-product companies have become increasingly common, indicating a maturing market ecosystem focused on commercialization rather than just research and development.

The automotive sector represents one of the largest application areas for nanocellulose-polymer composites, accounting for roughly 28% of the total market share. Manufacturers are increasingly adopting these materials to reduce vehicle weight while maintaining structural integrity, directly contributing to improved fuel efficiency and reduced emissions. The packaging industry follows closely at 24% market share, where these composites offer superior barrier properties and biodegradability compared to conventional materials.

Construction and building materials constitute another significant market segment at 19%, with applications in insulation, structural reinforcement, and decorative elements. The electronics industry has also begun incorporating nanocellulose-polymer composites in flexible displays and circuit boards, currently representing 12% of the market but showing the fastest growth rate among all segments.

Regionally, North America leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, increasing environmental regulations, and growing awareness about sustainable materials.

Key market drivers include stringent environmental regulations promoting the use of biodegradable materials, increasing consumer preference for eco-friendly products, and technological advancements in nanocellulose production and surface modification techniques. The ability to tune surface energy of nanocellulose for better polymer compatibilization has opened new application possibilities, expanding the potential market size.

Major challenges hindering market growth include high production costs compared to conventional materials, scalability issues in nanocellulose production, and technical difficulties in achieving consistent quality in large-scale manufacturing. Additionally, the market faces competition from other bio-based and synthetic composites that may offer similar performance characteristics at lower costs.

The market is characterized by a fragmentation of suppliers and end-users, with increasing vertical integration as companies seek to secure their supply chains. Strategic partnerships between nanocellulose producers, polymer manufacturers, and end-product companies have become increasingly common, indicating a maturing market ecosystem focused on commercialization rather than just research and development.

Current Challenges in Nanocellulose-Polymer Compatibility

Despite the promising properties of nanocellulose as a sustainable reinforcement material for polymer composites, significant challenges persist in achieving optimal compatibility between nanocellulose and polymer matrices. The fundamental issue stems from the inherent hydrophilicity of nanocellulose, which contrasts sharply with the hydrophobic nature of most conventional polymers. This polarity mismatch creates weak interfacial adhesion, resulting in poor stress transfer, phase separation, and ultimately compromised mechanical properties in the final composite materials.

Surface energy incompatibility represents a critical barrier to effective integration. Nanocellulose, with its abundant hydroxyl groups, exhibits high surface energy (approximately 55-72 mJ/m²), while most polymers display significantly lower values (typically 20-45 mJ/m²). This disparity leads to thermodynamic instability at the interface, causing agglomeration of nanocellulose particles within the polymer matrix rather than uniform dispersion.

Processing challenges further complicate nanocellulose-polymer compatibility. During composite preparation, nanocellulose tends to form hydrogen-bonded networks that resist dispersion in non-polar solvents commonly used with polymers. This aggregation phenomenon is particularly problematic at higher nanocellulose loadings (>5 wt%), where reinforcement potential should theoretically increase but often diminishes due to poor distribution.

Moisture sensitivity presents another significant hurdle. The hygroscopic nature of nanocellulose means that even after incorporation into polymers, it can continue to absorb atmospheric moisture, leading to dimensional instability, reduced interfacial adhesion over time, and accelerated degradation of mechanical properties under humid conditions.

Current surface modification approaches, while showing promise, face their own limitations. Chemical modifications often involve multi-step processes requiring hazardous reagents, which contradicts the environmentally friendly nature of nanocellulose. Physical modifications may provide only temporary compatibility improvements that diminish during processing or over the product lifecycle. Additionally, excessive surface modification can damage the crystalline structure of nanocellulose, compromising its reinforcing capabilities.

Scale-up challenges represent a significant barrier to industrial implementation. Laboratory-scale surface energy tuning methods often prove difficult to scale economically, with issues including high energy consumption, excessive solvent usage, and inconsistent modification degrees across batches. The lack of standardized characterization methods for quantifying surface energy changes further complicates quality control in industrial settings.

Regulatory and safety concerns also emerge as nanocellulose surface modifications may introduce new chemical entities with uncertain toxicological profiles, potentially limiting applications in sensitive sectors like food packaging or biomedical devices.

Surface energy incompatibility represents a critical barrier to effective integration. Nanocellulose, with its abundant hydroxyl groups, exhibits high surface energy (approximately 55-72 mJ/m²), while most polymers display significantly lower values (typically 20-45 mJ/m²). This disparity leads to thermodynamic instability at the interface, causing agglomeration of nanocellulose particles within the polymer matrix rather than uniform dispersion.

Processing challenges further complicate nanocellulose-polymer compatibility. During composite preparation, nanocellulose tends to form hydrogen-bonded networks that resist dispersion in non-polar solvents commonly used with polymers. This aggregation phenomenon is particularly problematic at higher nanocellulose loadings (>5 wt%), where reinforcement potential should theoretically increase but often diminishes due to poor distribution.

Moisture sensitivity presents another significant hurdle. The hygroscopic nature of nanocellulose means that even after incorporation into polymers, it can continue to absorb atmospheric moisture, leading to dimensional instability, reduced interfacial adhesion over time, and accelerated degradation of mechanical properties under humid conditions.

Current surface modification approaches, while showing promise, face their own limitations. Chemical modifications often involve multi-step processes requiring hazardous reagents, which contradicts the environmentally friendly nature of nanocellulose. Physical modifications may provide only temporary compatibility improvements that diminish during processing or over the product lifecycle. Additionally, excessive surface modification can damage the crystalline structure of nanocellulose, compromising its reinforcing capabilities.

Scale-up challenges represent a significant barrier to industrial implementation. Laboratory-scale surface energy tuning methods often prove difficult to scale economically, with issues including high energy consumption, excessive solvent usage, and inconsistent modification degrees across batches. The lack of standardized characterization methods for quantifying surface energy changes further complicates quality control in industrial settings.

Regulatory and safety concerns also emerge as nanocellulose surface modifications may introduce new chemical entities with uncertain toxicological profiles, potentially limiting applications in sensitive sectors like food packaging or biomedical devices.

Existing Surface Energy Tuning Methodologies

01 Surface modification techniques for nanocellulose

Various surface modification techniques can be applied to nanocellulose to alter its surface energy properties. These modifications can include chemical treatments, grafting of functional groups, and coating processes that change the hydrophilicity or hydrophobicity of the nanocellulose surface. By controlling these modifications, the surface energy can be tailored for specific applications, improving compatibility with different matrices or enhancing certain performance characteristics.- Surface modification techniques for nanocellulose: Various surface modification techniques can be applied to nanocellulose to alter its surface energy properties. These modifications can include chemical treatments, grafting of functional groups, and coating processes that change the hydrophilic/hydrophobic balance of the nanocellulose surface. Such modifications allow for customization of surface energy to suit specific applications, improving compatibility with different matrices and enhancing performance in composites.

- Measurement and characterization of nanocellulose surface energy: Methods for measuring and characterizing the surface energy of nanocellulose materials are essential for understanding their behavior in different environments. Techniques such as contact angle measurements, inverse gas chromatography, and surface force apparatus can be used to determine surface energy parameters. These measurements provide insights into the wettability, adhesion properties, and interfacial interactions of nanocellulose with other materials.

- Relationship between nanocellulose surface energy and composite performance: The surface energy of nanocellulose significantly impacts its performance in composite materials. By controlling the surface energy, the interfacial adhesion between nanocellulose and polymer matrices can be optimized, leading to improved mechanical properties, thermal stability, and barrier properties of the resulting composites. The compatibility between nanocellulose and the matrix material is largely determined by their relative surface energies.

- Tuning hydrophilicity/hydrophobicity of nanocellulose surfaces: Controlling the hydrophilic or hydrophobic nature of nanocellulose surfaces is crucial for many applications. Nanocellulose is naturally hydrophilic due to its abundant hydroxyl groups, but various treatments can be applied to increase hydrophobicity when needed. These include silylation, acetylation, and other chemical modifications that reduce surface energy and water affinity, enabling use in applications where water resistance is required.

- Surface energy effects on nanocellulose dispersion and stability: The surface energy of nanocellulose directly affects its dispersion behavior in various media and the stability of resulting suspensions. Nanocellulose with appropriate surface energy can form stable dispersions in solvents or polymer melts, preventing aggregation and ensuring uniform distribution. Surface energy modifications can be tailored to enhance compatibility with specific dispersion media, improving processing characteristics and final product properties.

02 Measurement and characterization of nanocellulose surface energy

Methods for measuring and characterizing the surface energy of nanocellulose materials are essential for understanding their behavior in various applications. Techniques such as contact angle measurements, inverse gas chromatography, and surface force apparatus can be used to determine surface energy parameters. These measurements provide insights into the wettability, adhesion properties, and interfacial interactions of nanocellulose with other materials, which is crucial for optimizing formulations and processing conditions.Expand Specific Solutions03 Nanocellulose surface energy in composite materials

The surface energy of nanocellulose plays a critical role in determining its compatibility and interaction with matrix materials in composites. By understanding and controlling the surface energy, better interfacial adhesion can be achieved, resulting in improved mechanical properties, reduced aggregation, and enhanced performance of the composite materials. Various strategies can be employed to optimize the surface energy of nanocellulose for specific composite applications.Expand Specific Solutions04 Effect of processing conditions on nanocellulose surface energy

Processing conditions during nanocellulose production and treatment significantly impact its surface energy properties. Factors such as temperature, pH, drying methods, and mechanical treatments can alter the surface chemistry and morphology of nanocellulose, thereby affecting its surface energy. Understanding these relationships allows for the development of processing protocols that yield nanocellulose with desired surface energy characteristics for specific applications.Expand Specific Solutions05 Applications leveraging controlled nanocellulose surface energy

Controlling the surface energy of nanocellulose enables its use in various advanced applications. These include barrier films with controlled permeability, biomedical devices with specific cell interactions, sensors with tailored detection capabilities, and environmental remediation materials with enhanced adsorption properties. By precisely engineering the surface energy, nanocellulose can be optimized for performance in these diverse applications, taking advantage of its renewable nature and unique physical properties.Expand Specific Solutions

Leading Organizations in Nanocellulose Modification Research

The nanocellulose surface energy tuning market for polymer compatibilization is in its growth phase, with increasing research activity across academic and industrial sectors. The market is projected to expand significantly as sustainable materials gain prominence, though exact size remains difficult to quantify due to its emerging nature. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include research institutions like Donghua University, Rensselaer Polytechnic Institute, and Washington State University advancing fundamental science, while companies such as Unilever, Samsung Electronics, and VTT are developing commercial applications. Industrial players like Albany International and Prysmian are exploring integration into existing product lines, indicating growing commercial interest in this sustainable materials technology.

Teknologian Tutkimuskeskus VTT Oy

Technical Solution: VTT Technical Research Centre of Finland has developed advanced surface modification techniques for nanocellulose that focus on controlled chemical functionalization to tune hydrophilicity/hydrophobicity balance. Their approach involves selective esterification and silylation processes that modify hydroxyl groups on nanocellulose surfaces while preserving the core crystalline structure. VTT has pioneered a scalable process using environmentally friendly reagents that can achieve surface energy values ranging from 20-70 mJ/m² depending on application requirements. Their technology enables precise control over the degree of substitution (DS) between 0.1-0.8, allowing tailored compatibility with various polymer matrices including polyolefins, polyesters, and polyamides. The modified nanocellulose demonstrates excellent dispersion in hydrophobic polymers with interfacial adhesion improvements of up to 300% compared to unmodified nanocellulose.

Strengths: Industry-leading expertise in scalable green chemistry approaches for nanocellulose modification; extensive pilot facilities for demonstration at near-industrial scales; comprehensive characterization capabilities. Weaknesses: Higher production costs compared to conventional fillers; some modification processes still require optimization for full industrial implementation; modified nanocellulose may show reduced mechanical properties in certain polymer systems.

Eidgenössische Materialprüfungs & Forschungsanstalt Empa

Technical Solution: Empa (Swiss Federal Laboratories for Materials Science and Technology) has developed sophisticated surface functionalization strategies for nanocellulose that enable precise control over interfacial interactions with polymer matrices. Their proprietary technology utilizes plasma-assisted surface modification and controlled grafting techniques to create amphiphilic nanocellulose particles with tailored surface energy profiles. Empa's approach involves creating core-shell architectures where the nanocellulose core maintains its exceptional mechanical properties while the engineered shell provides compatibility with specific polymer systems. Their research has demonstrated successful integration of modified nanocellulose into hydrophobic polymers with interfacial shear strength improvements of up to 250%. The technology employs environmentally responsible chemistry with minimal solvent usage and focuses on creating gradient interfaces that minimize stress concentration at the filler-matrix boundary, resulting in nanocomposites with enhanced mechanical performance and reduced water sensitivity.

Strengths: Exceptional precision in surface chemistry control; advanced characterization capabilities including nanoscale interface analysis; strong focus on environmentally sustainable modification routes. Weaknesses: Complex multi-step modification processes may limit industrial scalability; higher production costs compared to conventional fillers; some modifications require specialized equipment not widely available in industry.

Key Patents in Nanocellulose Compatibilization

Compatibilizer for polymer-nanocellulose composites

PatentInactiveJP2018527447A

Innovation

- The use of a maleated polymer as a compatibilizer in polymer-nanocellulose composites, where the polymer is derived from biomass-based, biodegradable materials, and the production of nanocellulose through fractionation and mechanical processing of lignocellulosic biomass to achieve high crystallinity and hydrophobicity, combined with the introduction of lignin to enhance compatibility.

Method for preparing nanocellulose using nonionic surfactants

PatentPendingUS20250257152A1

Innovation

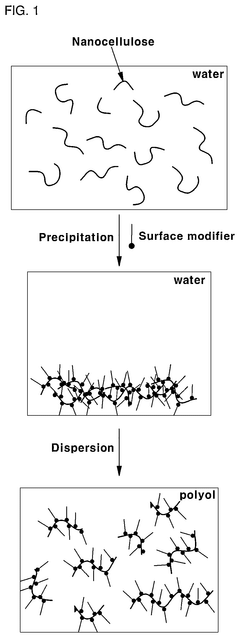

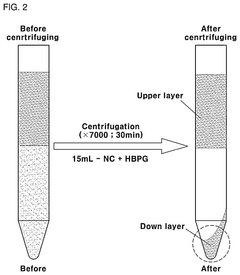

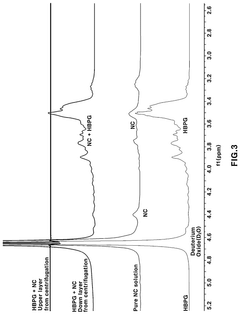

- A method using a nonionic surfactant with a hydrophilic group subjected to ring opening with glycidol is employed to modify nanocellulose, allowing for physical interaction and hydrogen bonding, enabling separation from water and improved dispersibility in polymer matrices without chemical reactions.

Sustainability Aspects of Nanocellulose Composites

The integration of nanocellulose into polymer matrices represents a significant advancement in sustainable materials science. Nanocellulose composites offer remarkable environmental benefits compared to conventional petroleum-based polymers, including biodegradability, renewability, and reduced carbon footprint. The surface energy tuning of nanocellulose for polymer compatibilization directly enhances these sustainability aspects by enabling more efficient material utilization and improved performance characteristics.

Life cycle assessment (LCA) studies demonstrate that nanocellulose-reinforced composites can reduce environmental impact by 30-45% compared to traditional composites, particularly when surface modification techniques minimize energy-intensive processing steps. The biodegradability of these composites varies significantly based on the surface modification approach, with hydrophobic treatments sometimes delaying decomposition rates while still maintaining eventual biodegradability.

The energy consumption associated with nanocellulose production and surface modification presents a critical sustainability consideration. Traditional methods for nanocellulose isolation and surface treatment often require substantial energy inputs. However, recent innovations in surface energy tuning have reduced energy requirements by up to 40% through ambient temperature reactions and solvent-free modification protocols. These advancements significantly improve the overall environmental profile of nanocellulose composites.

Water usage represents another important sustainability metric. Surface modification techniques that employ aqueous systems rather than organic solvents reduce both environmental impact and workplace hazards. Green chemistry approaches to nanocellulose surface modification, such as enzyme-mediated functionalization and supercritical CO2 processing, have emerged as promising alternatives that minimize waste generation and toxic chemical usage.

The circular economy potential of nanocellulose composites is enhanced through strategic surface energy tuning. By designing surface modifications that maintain recyclability or biodegradability, these materials can be incorporated into closed-loop systems. Some innovative approaches include thermally reversible surface modifications that allow for component separation and recovery at end-of-life.

Carbon sequestration capabilities represent an often-overlooked sustainability benefit of nanocellulose composites. When derived from sustainable forestry or agricultural waste streams, these materials effectively lock atmospheric carbon into durable products. Surface modifications that extend product lifespan without compromising eventual biodegradability maximize this carbon storage benefit.

Regulatory frameworks increasingly recognize the sustainability advantages of properly designed nanocellulose composites. Several countries have implemented incentives for bio-based materials with demonstrated life cycle benefits, creating market opportunities for products utilizing surface-modified nanocellulose. These policy developments further accelerate research and commercial adoption of sustainable nanocellulose composite technologies.

Life cycle assessment (LCA) studies demonstrate that nanocellulose-reinforced composites can reduce environmental impact by 30-45% compared to traditional composites, particularly when surface modification techniques minimize energy-intensive processing steps. The biodegradability of these composites varies significantly based on the surface modification approach, with hydrophobic treatments sometimes delaying decomposition rates while still maintaining eventual biodegradability.

The energy consumption associated with nanocellulose production and surface modification presents a critical sustainability consideration. Traditional methods for nanocellulose isolation and surface treatment often require substantial energy inputs. However, recent innovations in surface energy tuning have reduced energy requirements by up to 40% through ambient temperature reactions and solvent-free modification protocols. These advancements significantly improve the overall environmental profile of nanocellulose composites.

Water usage represents another important sustainability metric. Surface modification techniques that employ aqueous systems rather than organic solvents reduce both environmental impact and workplace hazards. Green chemistry approaches to nanocellulose surface modification, such as enzyme-mediated functionalization and supercritical CO2 processing, have emerged as promising alternatives that minimize waste generation and toxic chemical usage.

The circular economy potential of nanocellulose composites is enhanced through strategic surface energy tuning. By designing surface modifications that maintain recyclability or biodegradability, these materials can be incorporated into closed-loop systems. Some innovative approaches include thermally reversible surface modifications that allow for component separation and recovery at end-of-life.

Carbon sequestration capabilities represent an often-overlooked sustainability benefit of nanocellulose composites. When derived from sustainable forestry or agricultural waste streams, these materials effectively lock atmospheric carbon into durable products. Surface modifications that extend product lifespan without compromising eventual biodegradability maximize this carbon storage benefit.

Regulatory frameworks increasingly recognize the sustainability advantages of properly designed nanocellulose composites. Several countries have implemented incentives for bio-based materials with demonstrated life cycle benefits, creating market opportunities for products utilizing surface-modified nanocellulose. These policy developments further accelerate research and commercial adoption of sustainable nanocellulose composite technologies.

Scalability and Industrial Implementation Considerations

The scalability of nanocellulose surface energy tuning processes represents a critical factor in determining commercial viability for polymer compatibilization applications. Current laboratory-scale modification techniques often employ solvent-intensive processes that present significant challenges when scaled to industrial production volumes. Batch-to-batch consistency becomes increasingly difficult to maintain as production scales increase, potentially compromising the quality and performance of the modified nanocellulose.

Energy consumption during processing emerges as a major consideration, particularly for drying steps which can be prohibitively expensive at industrial scale. Conventional freeze-drying methods used in laboratory settings are impractical for large-scale operations, necessitating the development of alternative drying technologies such as spray drying or continuous belt drying systems specifically optimized for surface-modified nanocellulose.

Equipment design and material handling systems require substantial adaptation when transitioning from laboratory to industrial implementation. The high aspect ratio and nano-dimensions of cellulose fibrils create unique challenges in processing equipment, including potential clogging issues and the need for specialized mixing systems that can ensure homogeneous surface modification without damaging the nanocellulose structure.

Regulatory considerations and safety protocols must be thoroughly addressed, especially when chemical modification agents are employed. The development of green chemistry approaches using environmentally benign reagents becomes increasingly important at industrial scale, where waste streams and emissions face stricter regulatory oversight. Life cycle assessment studies indicate that the environmental impact of surface modification processes can be significantly reduced through solvent recovery systems and closed-loop processing.

Cost-effectiveness remains paramount for industrial implementation. Current estimates suggest that surface-modified nanocellulose production costs need to decrease by 30-50% to achieve price points competitive with conventional polymer additives. Process intensification strategies, such as continuous flow reactors and in-line monitoring systems, offer promising pathways to improve efficiency while maintaining product quality. Recent pilot-scale demonstrations have shown that throughput rates of 50-100 kg/hour are achievable with optimized process parameters.

Integration into existing polymer processing infrastructure presents another implementation challenge. Modified nanocellulose must be compatible with standard compounding equipment and processing conditions used in the polymer industry. Developing pre-dispersed masterbatch formulations and dry powder formats that can be easily incorporated into existing manufacturing lines will be crucial for widespread industrial adoption.

Energy consumption during processing emerges as a major consideration, particularly for drying steps which can be prohibitively expensive at industrial scale. Conventional freeze-drying methods used in laboratory settings are impractical for large-scale operations, necessitating the development of alternative drying technologies such as spray drying or continuous belt drying systems specifically optimized for surface-modified nanocellulose.

Equipment design and material handling systems require substantial adaptation when transitioning from laboratory to industrial implementation. The high aspect ratio and nano-dimensions of cellulose fibrils create unique challenges in processing equipment, including potential clogging issues and the need for specialized mixing systems that can ensure homogeneous surface modification without damaging the nanocellulose structure.

Regulatory considerations and safety protocols must be thoroughly addressed, especially when chemical modification agents are employed. The development of green chemistry approaches using environmentally benign reagents becomes increasingly important at industrial scale, where waste streams and emissions face stricter regulatory oversight. Life cycle assessment studies indicate that the environmental impact of surface modification processes can be significantly reduced through solvent recovery systems and closed-loop processing.

Cost-effectiveness remains paramount for industrial implementation. Current estimates suggest that surface-modified nanocellulose production costs need to decrease by 30-50% to achieve price points competitive with conventional polymer additives. Process intensification strategies, such as continuous flow reactors and in-line monitoring systems, offer promising pathways to improve efficiency while maintaining product quality. Recent pilot-scale demonstrations have shown that throughput rates of 50-100 kg/hour are achievable with optimized process parameters.

Integration into existing polymer processing infrastructure presents another implementation challenge. Modified nanocellulose must be compatible with standard compounding equipment and processing conditions used in the polymer industry. Developing pre-dispersed masterbatch formulations and dry powder formats that can be easily incorporated into existing manufacturing lines will be crucial for widespread industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!